Scattering model for micro-defects on cavity mirrors in cavity ring-down spectroscopy instruments

-

摘要:

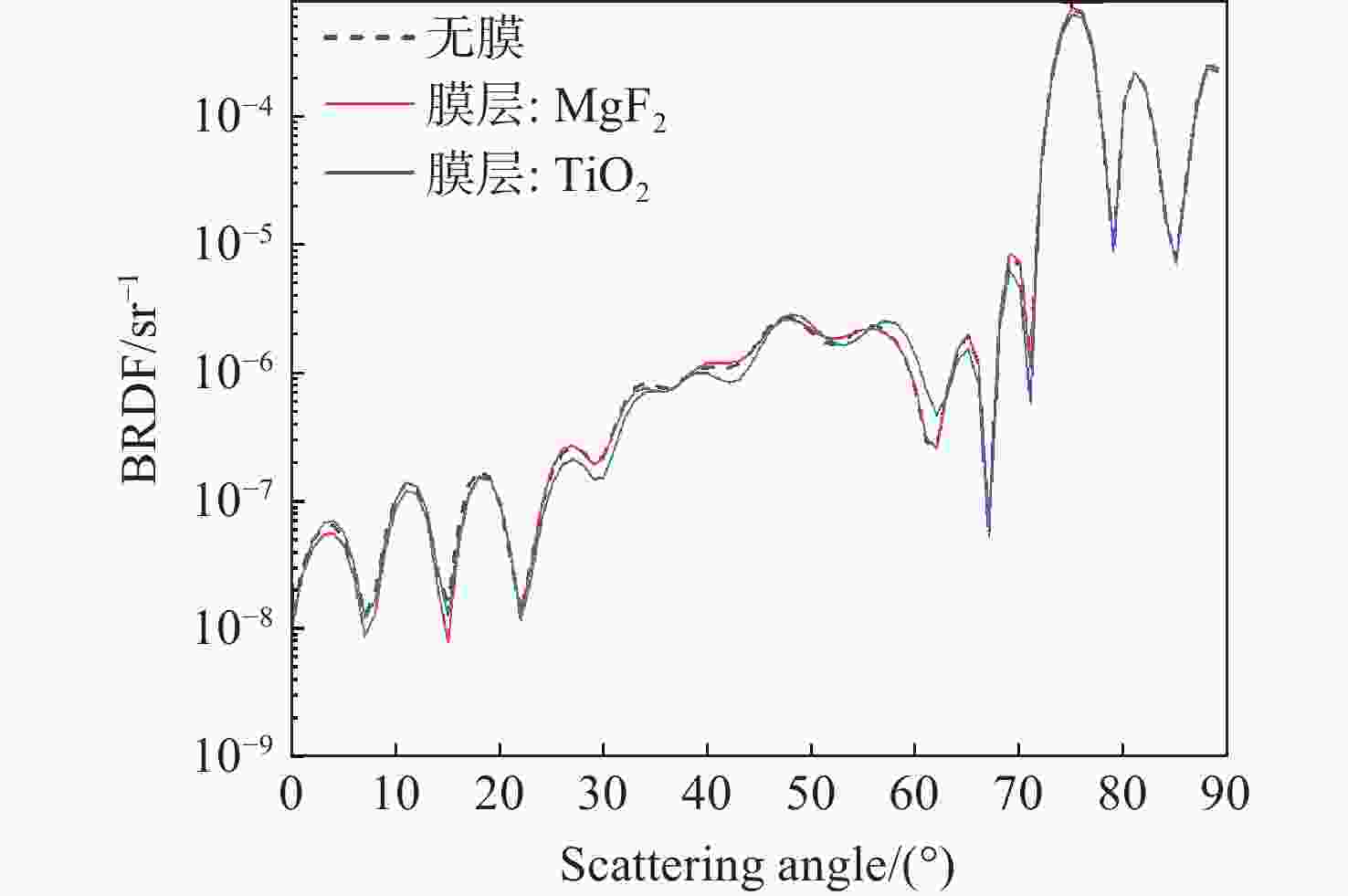

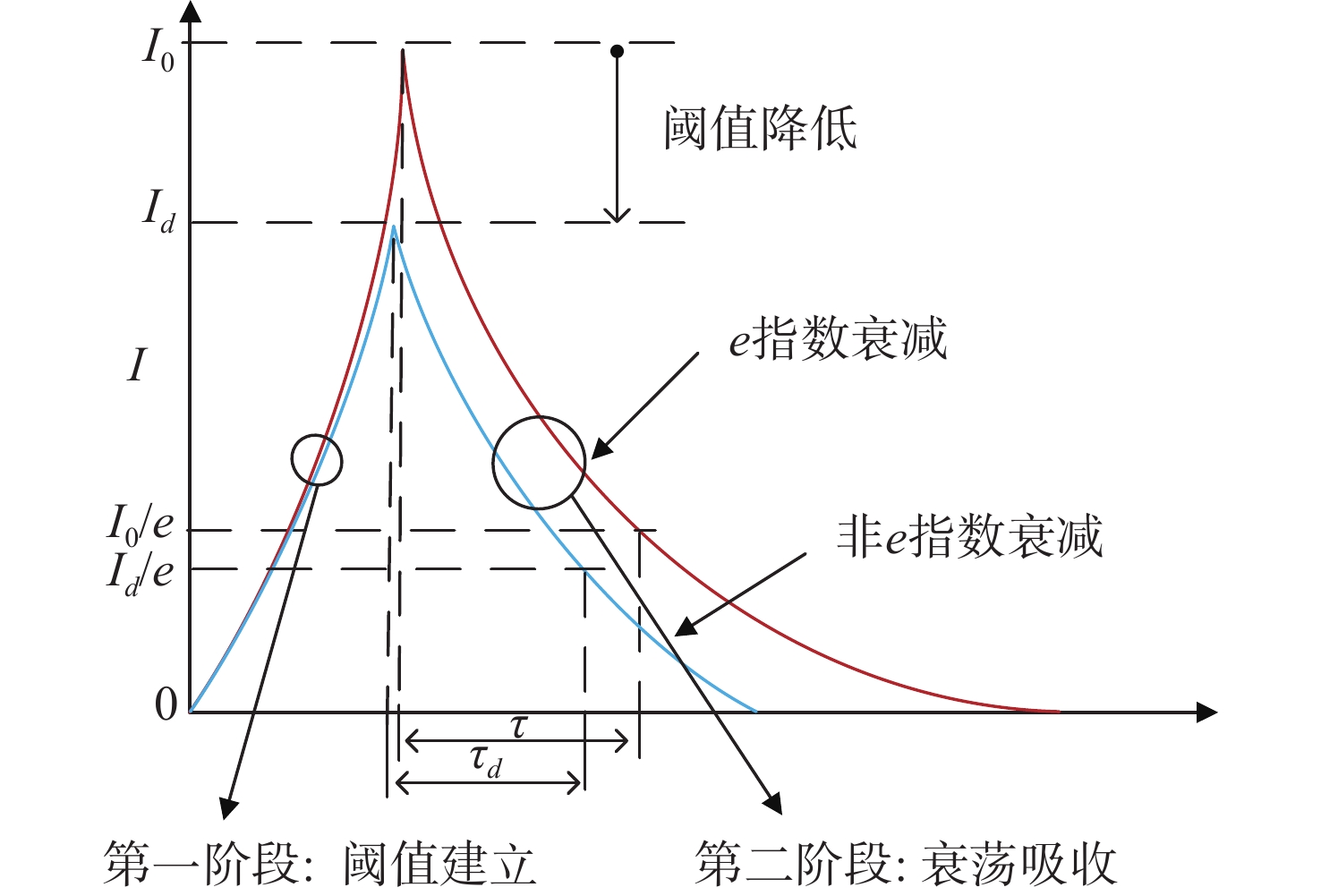

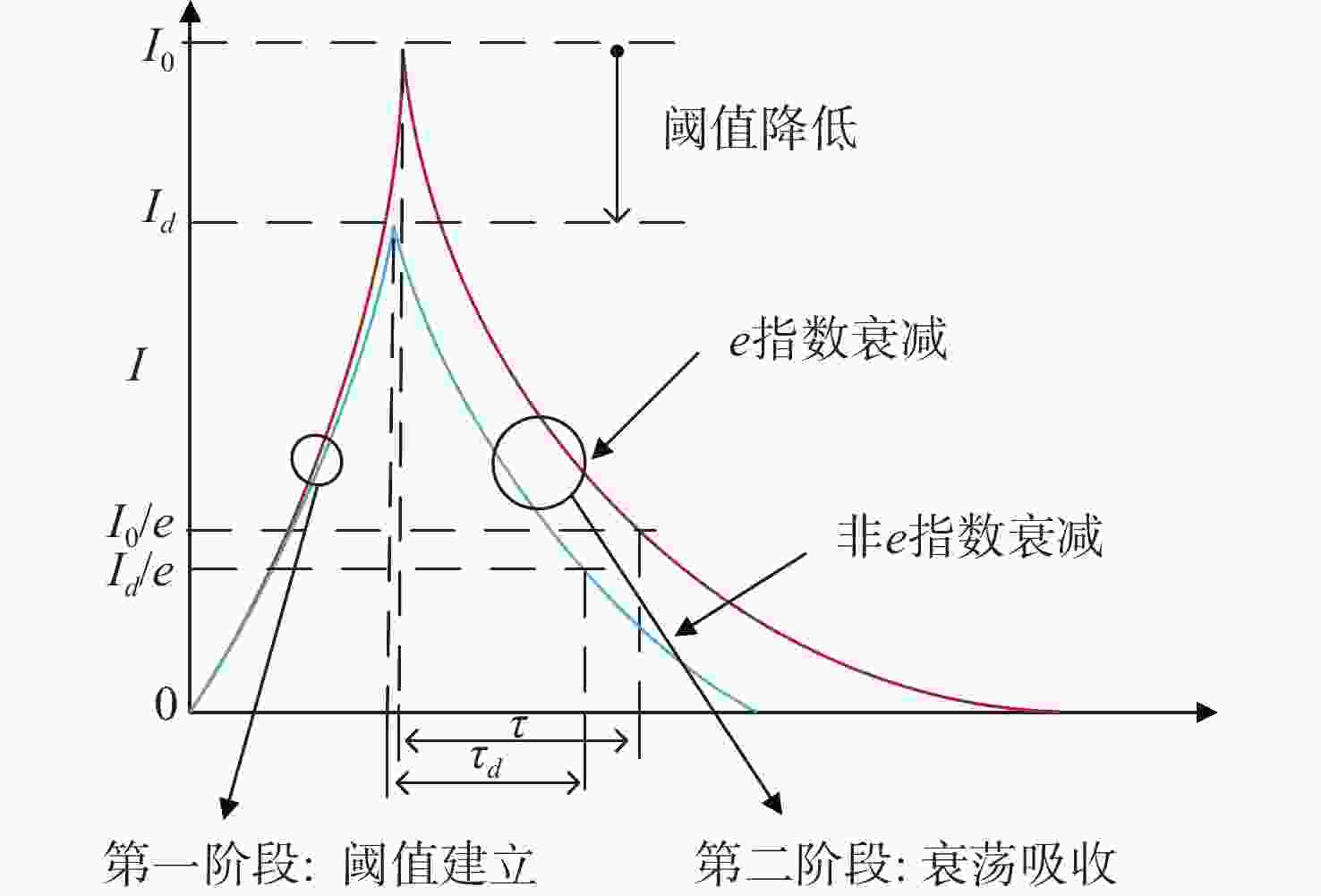

针对腔衰荡光谱仪器(CRDS)中的腔镜微缺陷会导致测量精度下降的问题,本文建立了基于Bobbert Vlieger BRDF 理论的腔镜微缺陷散射模型,分析了微缺陷在不同光源波长、入射角度、缺陷量级、缺陷类型、缺陷密度、基底膜层的散射光特性。腔镜微缺陷散射模型研究表明:微米至亚微米(100 μm~0.1 μm)量级缺陷会降低衰荡吸收精度。针对该量级微缺陷的检测,构建了腔镜微缺陷散射和微缺陷暗场检测的分析模型。CRDS腔镜微缺陷散射光模型的建立与分析,是实现腔镜微缺陷高精度检测和CRDS测量精度恢复的关键技术。

Abstract:Microdefects in cavity mirrors utilized in cavity ring-down spectroscopy (CRDS) instruments adversely affect measurement accuracy. Aiming at this problem, this paper establishes a scattering model for micro-defect on cavity mirrors based on the Bobbert and Vlieger Bidirectional Reflectance Distribution Function (BRDF) theory to analyze the characteristics of scattered light of microdefects under varying wavelengths, incident angles, defect sizes, defect types, defect densities, and substrate coatings. Studying on the cavity mirror microdefect scattering model shows that defects in the micrometer to submicron range (100 μm to 0.1 μm) affect the ring-down absorption accuracy. For the detection of micro-defects at this scale, analytical models for both cavity mirror micro-defect scattering and micro-defect dark-field detection is established. Establishing and analyzing the scattering light model for micro-defects in CRDS (Cavity Ring-Down Spectroscopy) cavity mirrors is critical to realizing the high-precision detection of microdefects on CRDS mirror and recovering CRDS measurement accuracy.

-

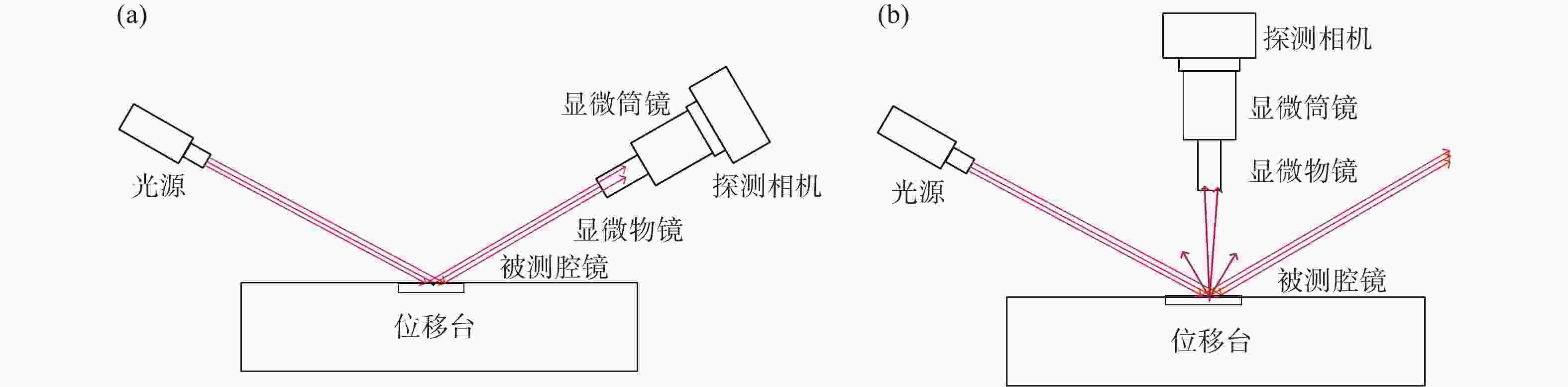

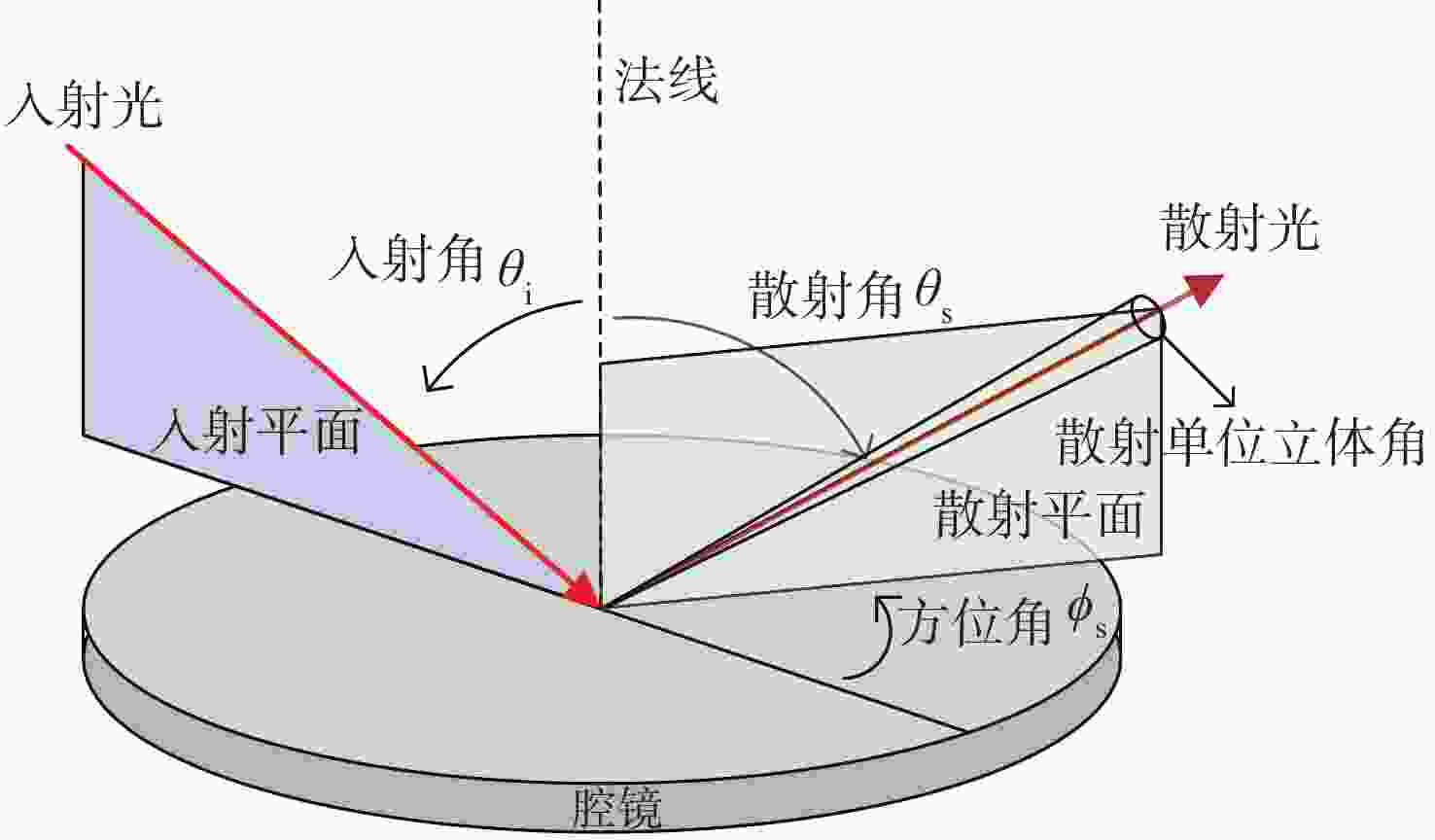

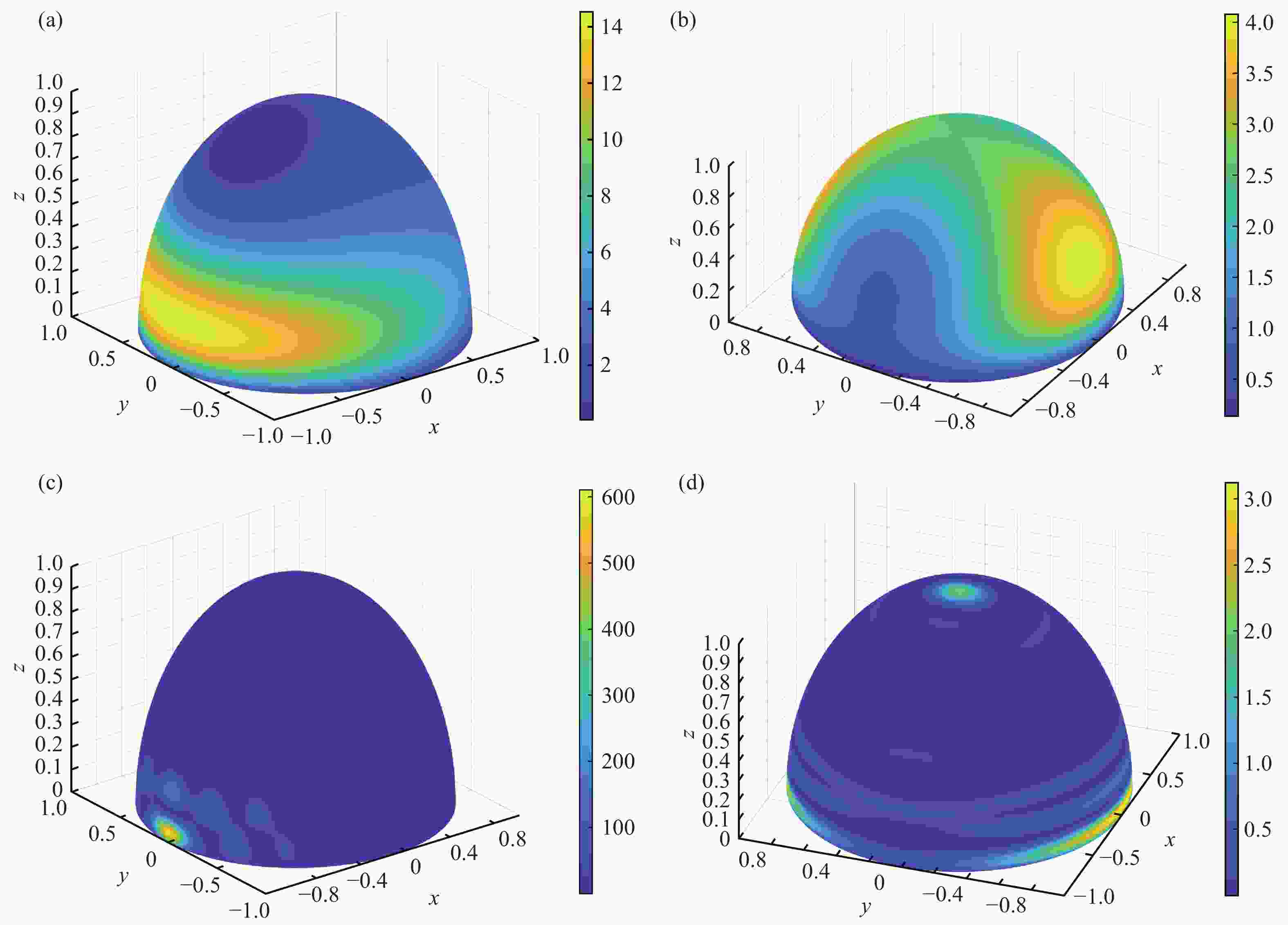

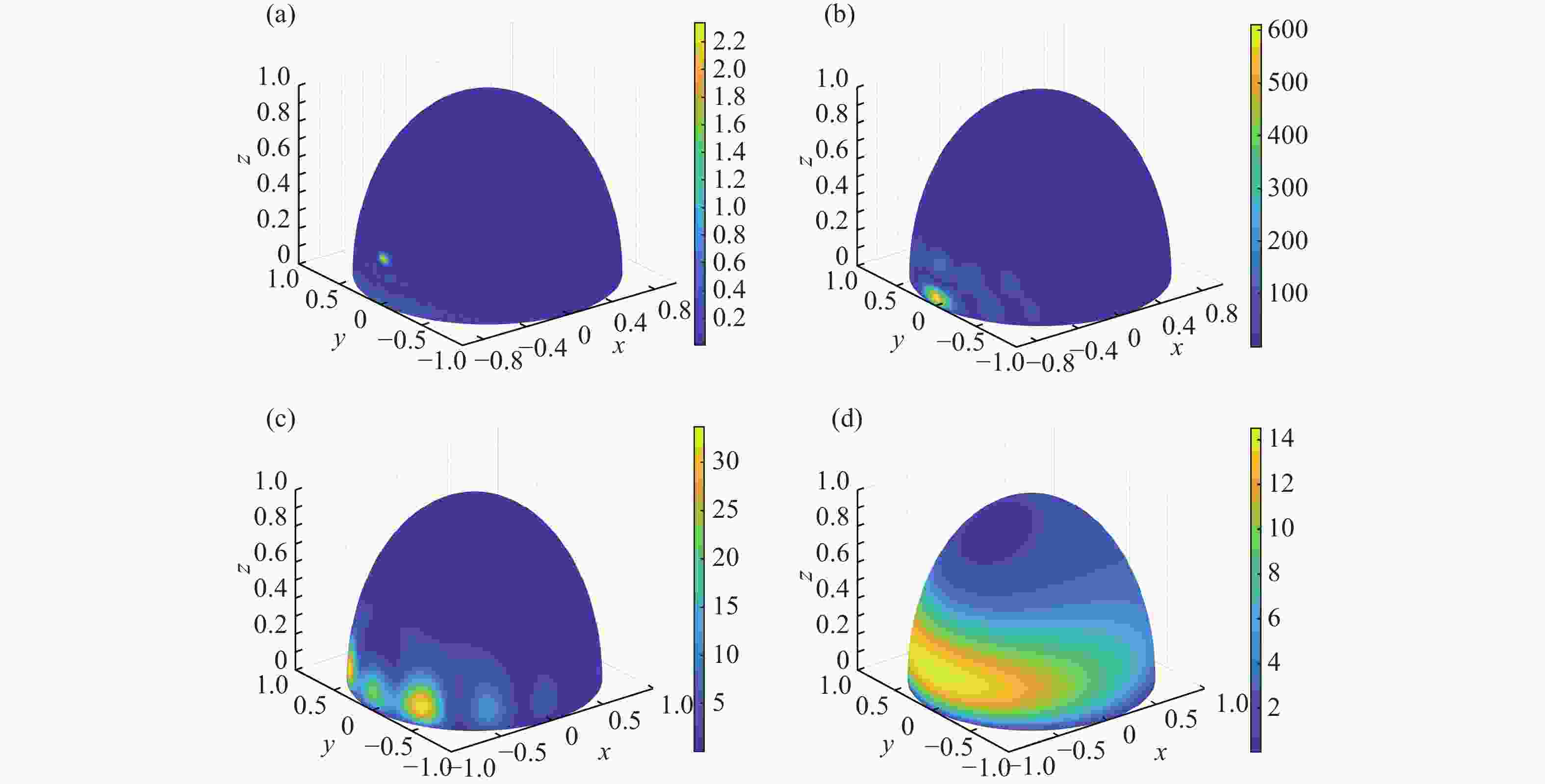

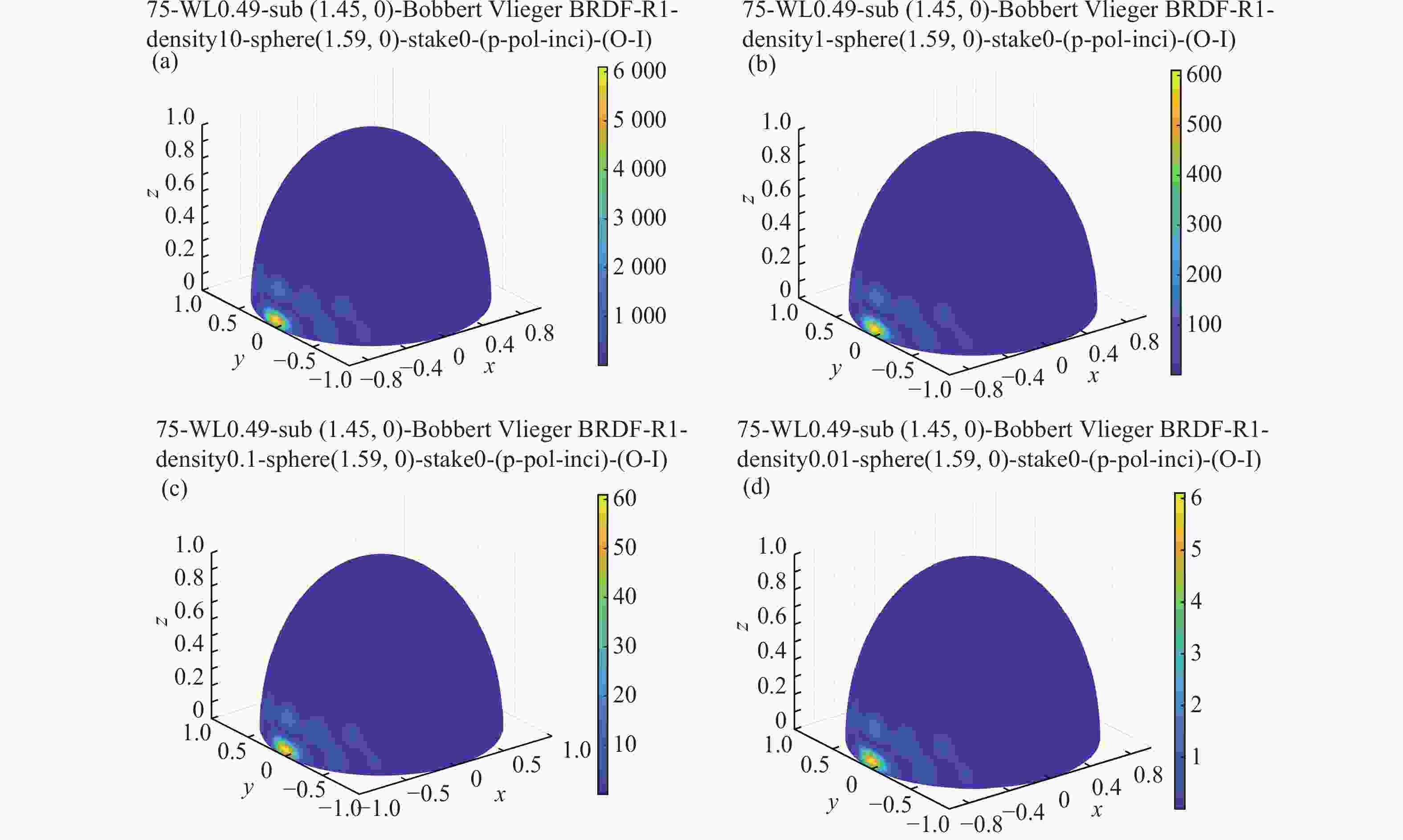

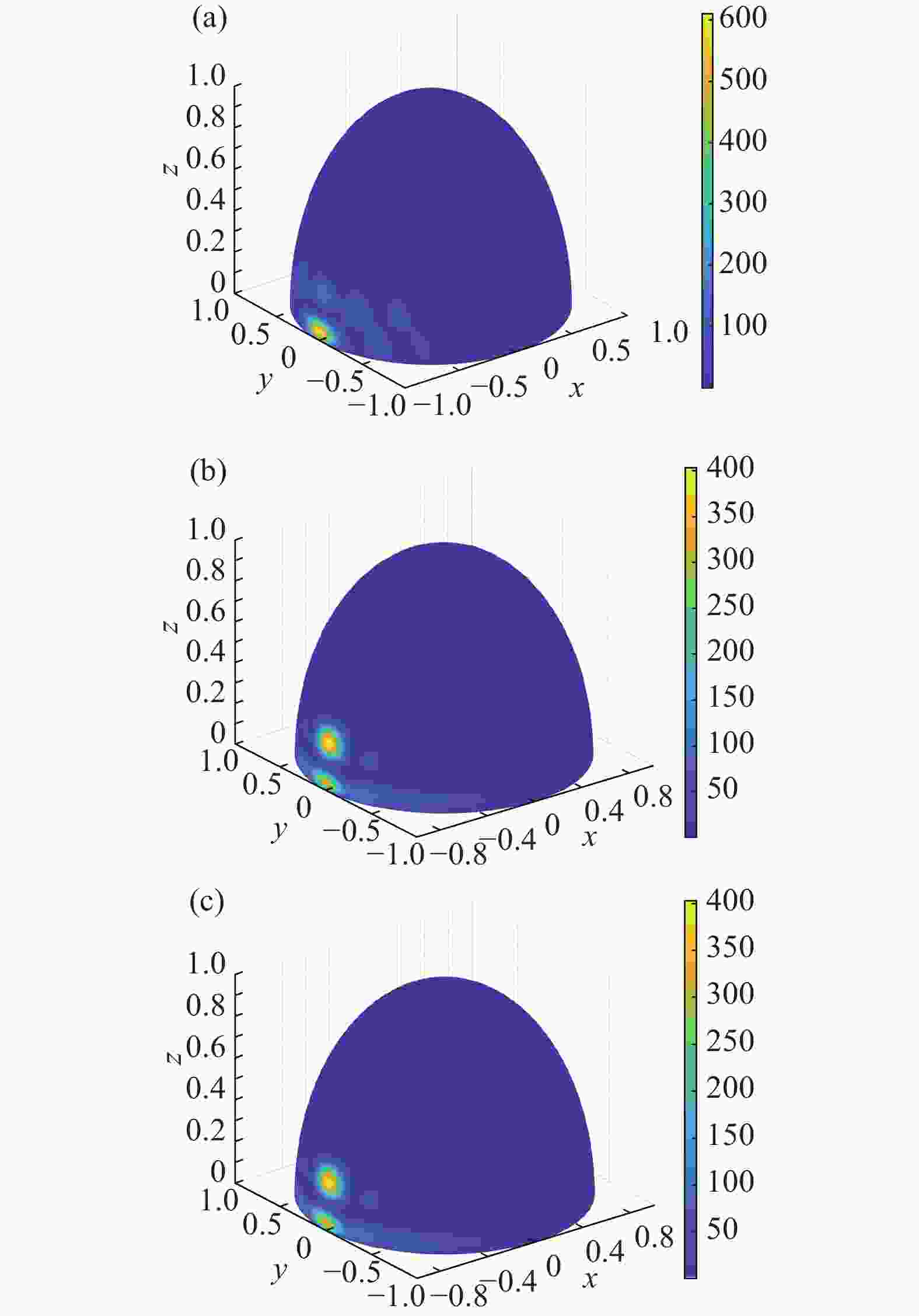

图 4 不同入射角度下的散射场空间分布。(a)和(b)为0.1 μm PSL颗粒在75°斜入射和正入射下的空间分布,(c)和(d)为1 μm PSL颗粒在75°斜入射和正入射下的空间分布

Figure 4. Spatial distribution of scattering field at different incidence angles. (a)-(b) Spatial distribution of 0.1 μm PSL particles under 75° oblique incidence and normal incidence; (c)-(d) spatial distribution of 1 μm PSL particles under 75° oblique incidence and normal incidence

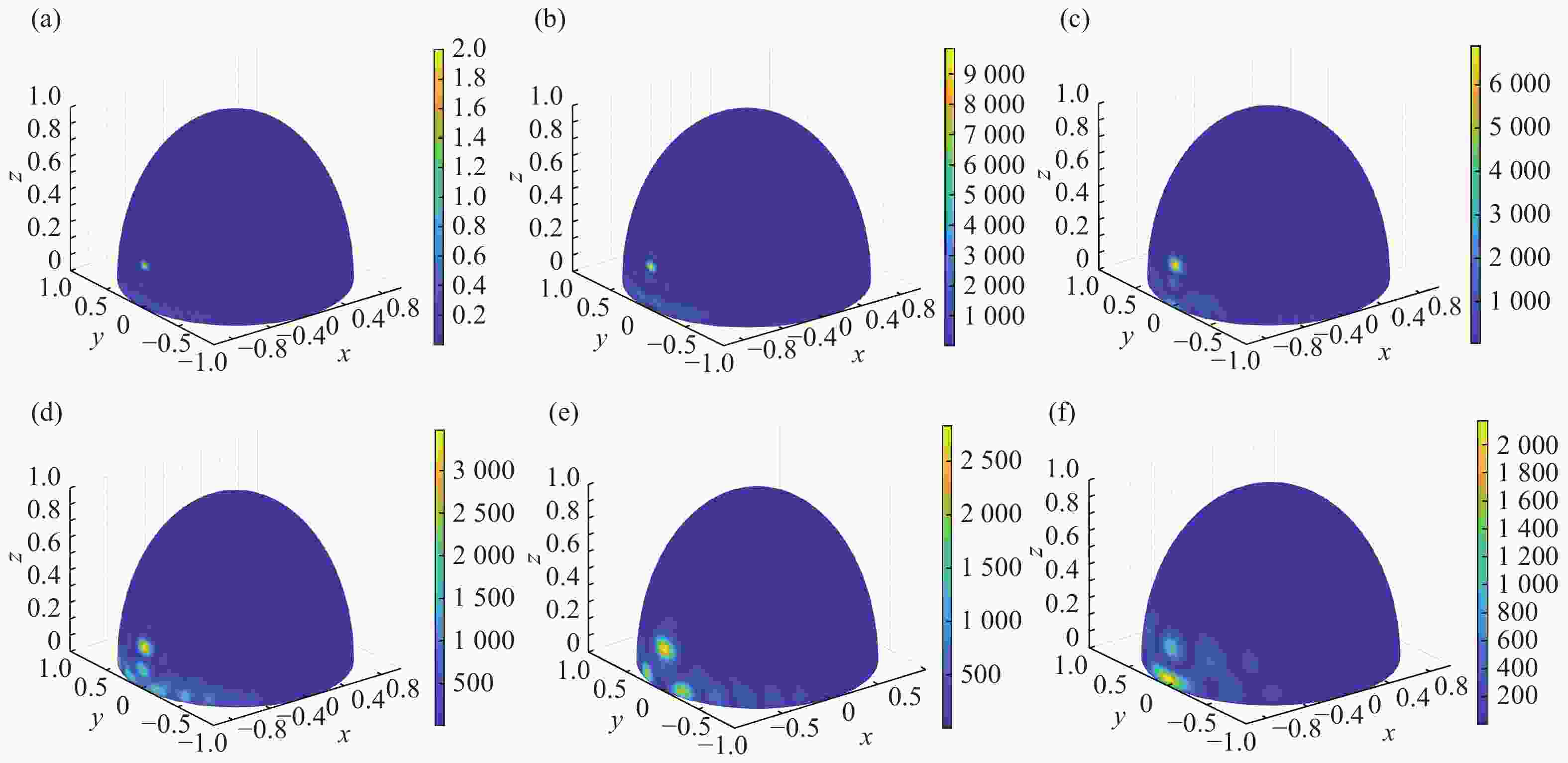

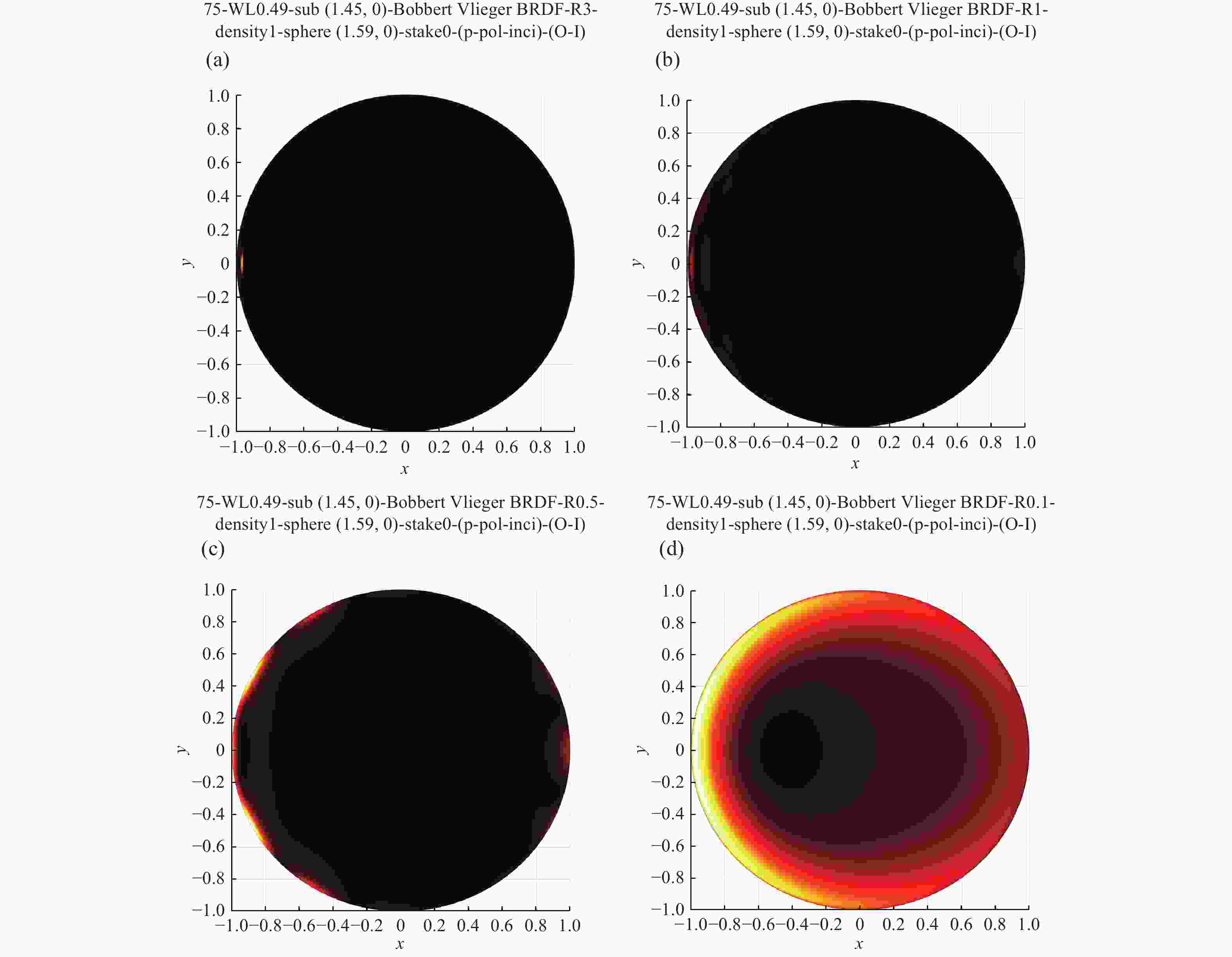

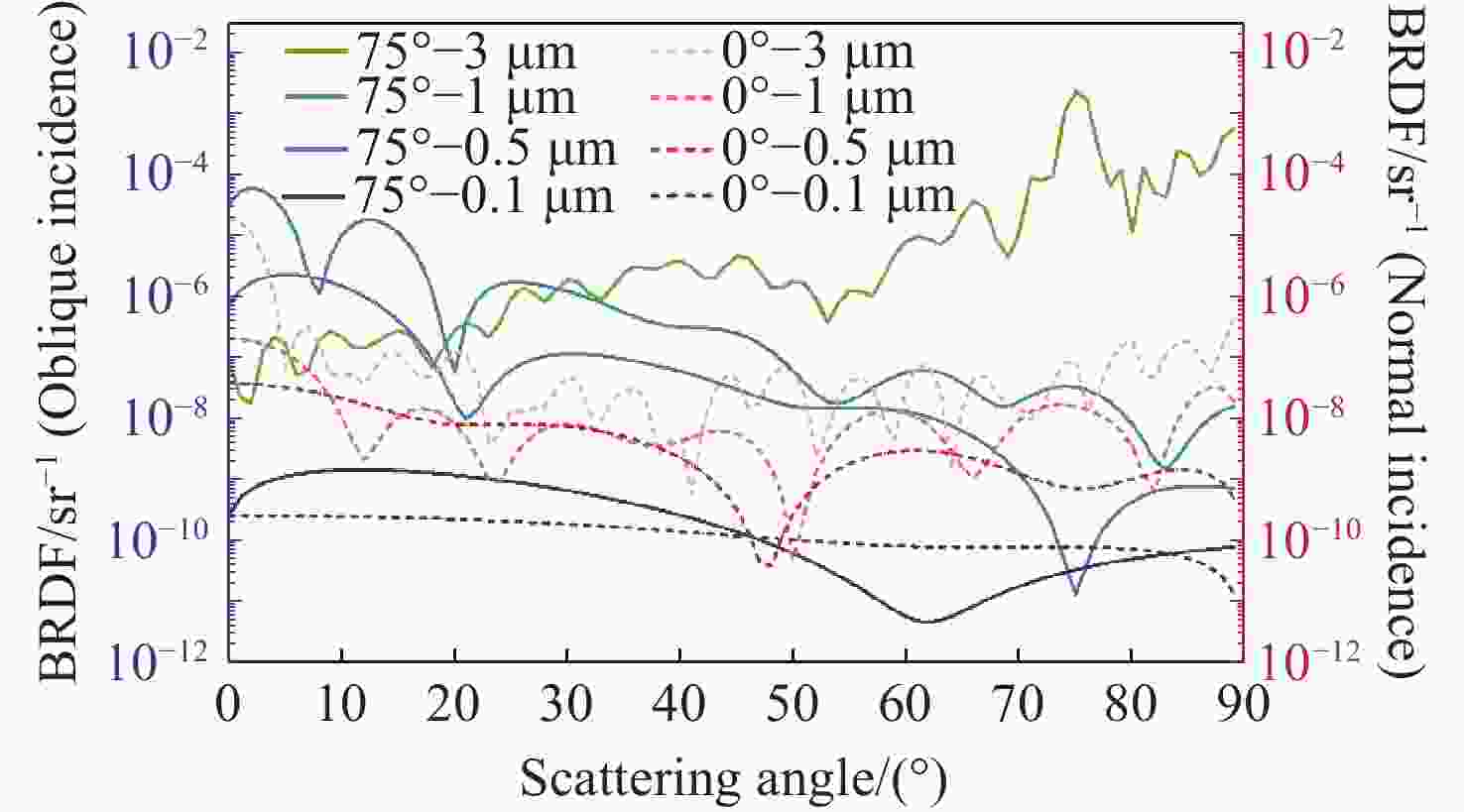

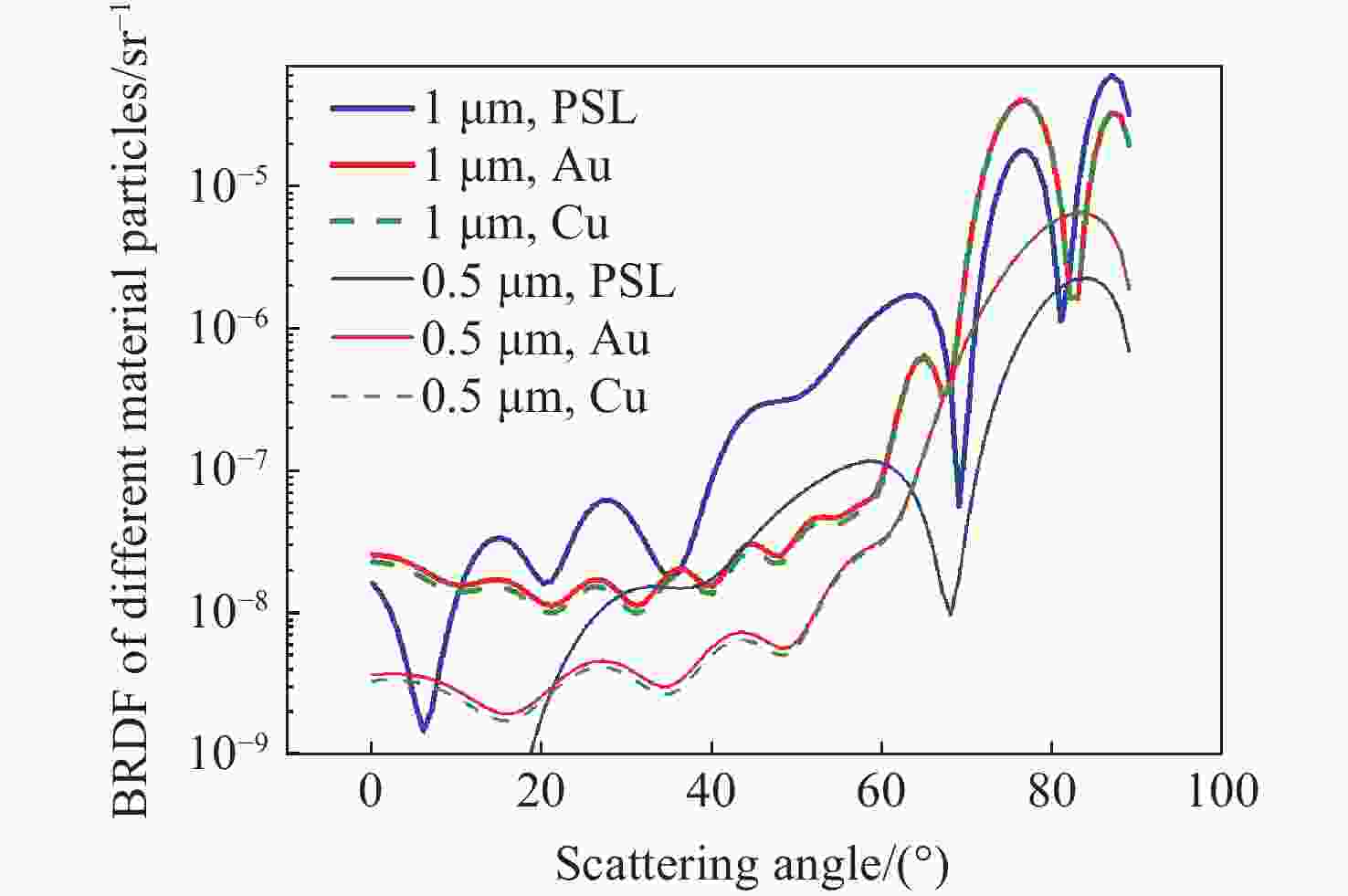

图 5 在正入射及斜入射时,微缺陷各散射角的能量分布。蓝色绿色实线和红色虚线分别为75°斜入射和正入射时反射面内不同散射角下半径分别为3 μm、1 μm、0.5 μm、0.1 μm PSL颗粒BRDF

Figure 5. The energy distributions of microdefects at each scattering angle under normal and oblique incidences. The lines show the BRDF of PSL particles with radii of 3 μm, 1 μm, 0.5 μm, and 0.1 μm at different scattering angles within the reflective surface. Blue and green solid lines are the BRDF under 75° oblique incidence, and red dashed lines are the BRDF under normal incidence

表 1 线偏振光(p光)正入射时,不同缺陷量级腔镜的散射光强度

Table 1. Scattered light intensity of cavity mirrors with different defect orders under normal incidence of linearly polarized light (p polarization)

Particle

radius/μmScattered light

intensity/ppms-polarization/

ppmp-polarization/

ppm0.01 7.939×10−11 2.3368 ×10−127.9242 ×10−110.05 1.2351 ×10−61.9405 ×10−81.2087 ×10−60.1 3.4466 ×10−51.9143 ×10−63.0221 ×10−50.5 2.9963 ×10−38.1627 ×10−42.3632 ×10−31 1.5833 ×10−22.6241 ×10−31.4189 ×10−2 -

[1] 任颐杰, 颜昌翔, 徐嘉蔚. 增强吸收光谱技术的研究进展及展望[J]. 中国光学, 2023, 16(6): 1273-1292. doi: 10.37188/CO.2022-0246REN Y J, YAN CH X, XU J W. Development and prospects of enhanced absorption spectroscopy[J]. Chinese Optics, 2023, 16(6): 1273-1292. (in Chinese). doi: 10.37188/CO.2022-0246 [2] ANDERSON D Z. Alignment of resonant optical cavities[J]. Applied Optics, 1984, 23(17): 2944-2949. doi: 10.1364/AO.23.002944 [3] REN Y J, YAN CH X, WU C J, et al. Resonant frequency separation characteristics of the same-order hermite-gaussian mode in the astigmatic triangular cavity of a cavity ring-down spectroscope[J]. IEEE Access, 2022, 10: 53703-53712. doi: 10.1109/ACCESS.2022.3176452 [4] SONG SH M, HU CH H, YAN CH X. Optical axis maladjustment sensitivity in a triangular ring resonator[J]. Applied Optics, 2019, 58(1): 29-36. doi: 10.1364/AO.58.000029 [5] LEHMANN K K, BERDEN G, ENGELN R. An Introduction to Cavity Ring-Down Spectroscopy[M]//BERDEN G, ENGELN R. Cavity Ring-Down Spectroscopy: Techniques and Applications. Chichester: Wiley, 2009: 1-26. [6] HUANG H, LEHMANN K K. Noise caused by a finite extinction ratio of the light modulator in CW cavity ring-down spectroscopy[J]. Applied Physics B, 2009, 94(2): 355-366. doi: 10.1007/s00340-008-3293-y [7] MO Z Q, YU J, WANG J D, et al. Differential measurement for cavity ring-down spectroscopy with dynamic allan variance[J]. Journal of Spectroscopy, 2020, 2020(1): 8398063. [8] WERLE P. Accuracy and precision of laser spectrometers for trace gas sensing in the presence of optical fringes and atmospheric turbulence[J]. Applied Physics B, 2011, 102(2): 313-329. doi: 10.1007/s00340-010-4165-9 [9] 王振, 杜艳君, 丁艳军, 等. 基于傅里叶变换的波长扫描腔衰荡光谱[J]. 物理学报, 2019, 68(20): 204204. doi: 10.7498/aps.68.20191062WANG ZH, DU Y J, DING Y J, et al. Wavelength-scanned cavity ring down spectroscopy based on Fourier transform[J]. Acta Physica Sinica, 2019, 68(20): 204204. (in Chinese). doi: 10.7498/aps.68.20191062 [10] 袁峰, 高晶, 姚路, 等. 球载CRDS高灵敏度甲烷测量系统的研制[J]. 光学 精密工程, 2020, 28(9): 1881-1892. doi: 10.37188/OPE.20202809.1881YUAN F, GAO J, YAO L, et al. Development of highly sensitive balloon-borne methane measurement system based on cavity ringdown spectroscopy[J]. Opties and Precision Engineering, 2020, 28(9): 1881-1892. (in Chinese). doi: 10.37188/OPE.20202809.1881 [11] 张锦龙, 王富美, 方圣欢, 等. 超低损耗激光薄膜的散射与机械损耗[J]. 光学 精密工程, 2022, 30(21): 2655-2677. doi: 10.37188/OPE.20223021.2655ZHANG J L, WANG F M, FANG SH H, et al. Scattering and mechanical loss of ultra-low loss laser coatings[J]. Optics and Precision Engineering, 2022, 30(21): 2655-2677. (in Chinese). doi: 10.37188/OPE.20223021.2655 [12] HUANG H F, KEVIN K K. Noise in cavity ring-down spectroscopy caused by transverse mode coupling[J]. Optics Express, 2007, 15(14): 8745-8759. doi: 10.1364/OE.15.008745 [13] 侯翔宇, 邱腾. 低维光电材料缺陷与界面增强拉曼散射[J]. 中国光学, 2021, 14(1): 170-181. doi: 10.37188/CO.2020-0145HOU X Y, QIU T. Defects- and interface-enhanced Raman scattering in low-dimensional optoelectronic materials[J]. Chinese Optics, 2021, 14(1): 170-181. (in Chinese). doi: 10.37188/CO.2020-0145 [14] REN Y J, LIU L H, YANG H B, et al. Light scattering defects and measurement accuracy in cavity ring-down spectroscopy[J]. Proceedings of SPIE, 2024, 12997: 129971R. [15] 杨甬英, 陆春华, 梁蛟, 等. 光学元件表面缺陷的显微散射暗场成像及数字化评价系统[J]. 光学学报, 2007, 27(6): 1031-1038. doi: 10.3321/j.issn:0253-2239.2007.06.015YANG Y Y, LU CH H, LIANG J, et al. Microscopic dark-field scattering imaging and digitalization evaluation system of defects on optical devices precision surface[J]. Acta Optica Sinica, 2007, 27(6): 1031-1038. (in Chinese). doi: 10.3321/j.issn:0253-2239.2007.06.015 [16] NICODEMUS F E. Directional reflectance and emissivity of an opaque surface[J]. Applied Optics, 1965, 4(7): 767-775. doi: 10.1364/AO.4.000767 [17] 高萍萍, 陆敏, 王治乐, 等. 表面纳米粒子缺陷的偏振散射特性区分[J]. 中国光学, 2020, 13(5): 975-987. doi: 10.37188/CO.2020-0083GAO P P, LU M, WANG ZH L, et al. Differentiation of polarization scattering characteristics of surface nanoparticle defects[J]. Chinese Optics, 2020, 13(5): 975-987. (in Chinese). doi: 10.37188/CO.2020-0083 [18] 葛春晖, 刘妍君, 年福东, 等. 基于半监督度量学习的激光诱导击穿光谱检测白芍中的重金属含量[J]. 分析化学, 2024, 53(4): 1254-1265.GE C H, LIU Y J, CHEN M S, et al. Prediction of Wind Turbine Lubricating Oil’s Acid Value by Ordinary Least Square Method Based on Attenuated Total Reflectance-Fourier Transform Infrared Spectroscopy Through Higher-Order Derivative Combined with Angular Metric[J]. Chinese Journal of Analytical Chemistry, 2024, 53(4): 1254-1265. (in Chinese). [19] 谷艳红, 李凡丁, 陈梦实, 等. 衰减全反射-傅里叶红外光谱高阶导数结合角度量的最小二乘预测风电机组润滑油酸值[J]. 分析化学, 2025, 52(9): 669-679.GU Y H, LI F D, NIAN F. Detection of Heavy Metal Content in White Peony by Laser-Induced Breakdown Spectroscopy Combined with Semi-Supervised Metric Learning[J]. Chinese Journal of Analytical Chemistry, 2025, 52(9): 669-679. (in Chinese). [20] 李仁, 孙满利, 焦立超, 等. 基于显微衰减全反射傅里叶变换红外光谱的沉船考古木材降解程度判别研究[J]. 分析化学, 2025, 53(6): 967-975.LI R, SUN M L, JIAO L C, et al. Research on Discrimination of Degradation Levels in Shipwreck Archaeological Wood Based on Microscale Attenuated Total Reflection Fourier Transform Infrared Spectroscopy[J]. Chinese Journal of Analytical Chemistry., 2025, 53(6): 967-975. (in Chinese). [21] 巩蕾, 吴振森. 基片表面微球体纳米级缺陷的光散射分析[J]. 中国激光, 2011, 38(1): 0110001. doi: 10.3788/CJL201138.0110001GONG L, WU ZH S. Analysis of light scattering about slightly non-spherical nanoparticles on wafers[J]. Chinese Journal of Lasers, 2011, 38(1): 0110001. (in Chinese). doi: 10.3788/CJL201138.0110001 [22] BOBBERT P A, VILEGER J. Light scattering by a sphere on a substrate[J]. Physica A: Statistical Mechanics and Its Applications, 1986, 137(1-2): 209-242. doi: 10.1016/0378-4371(86)90072-5 [23] BOBBERT P A, VILEGER J, GREEF R. Light reflection from a substrate sparsely seeded with spheres - comparison with an ellipsometric experiment[J]. Physica A: Statistical Mechanics and Its Applications, 1986, 137(1-2): 243-257. doi: 10.1016/0378-4371(86)90073-7 -

下载:

下载: