-

摘要:

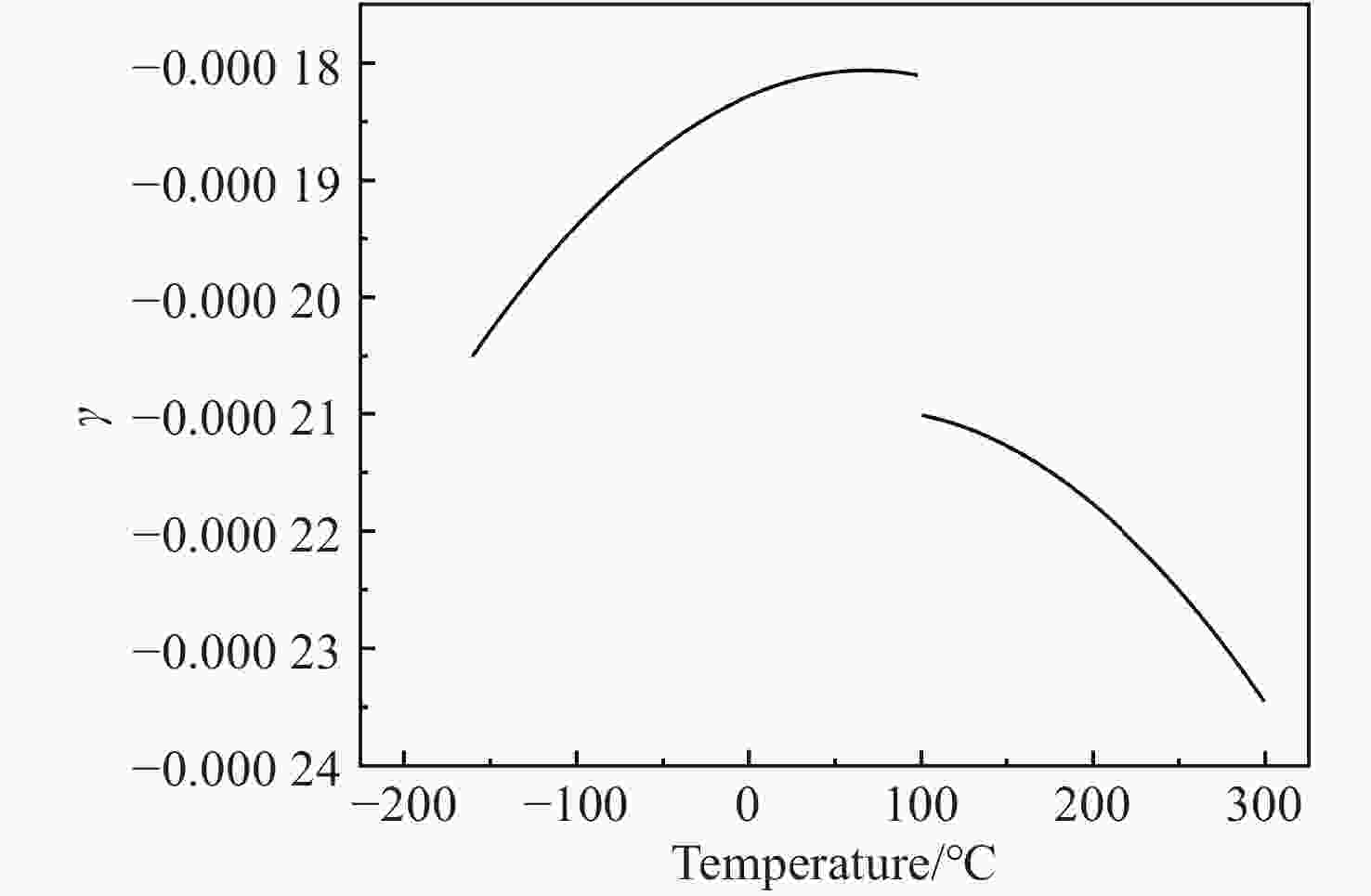

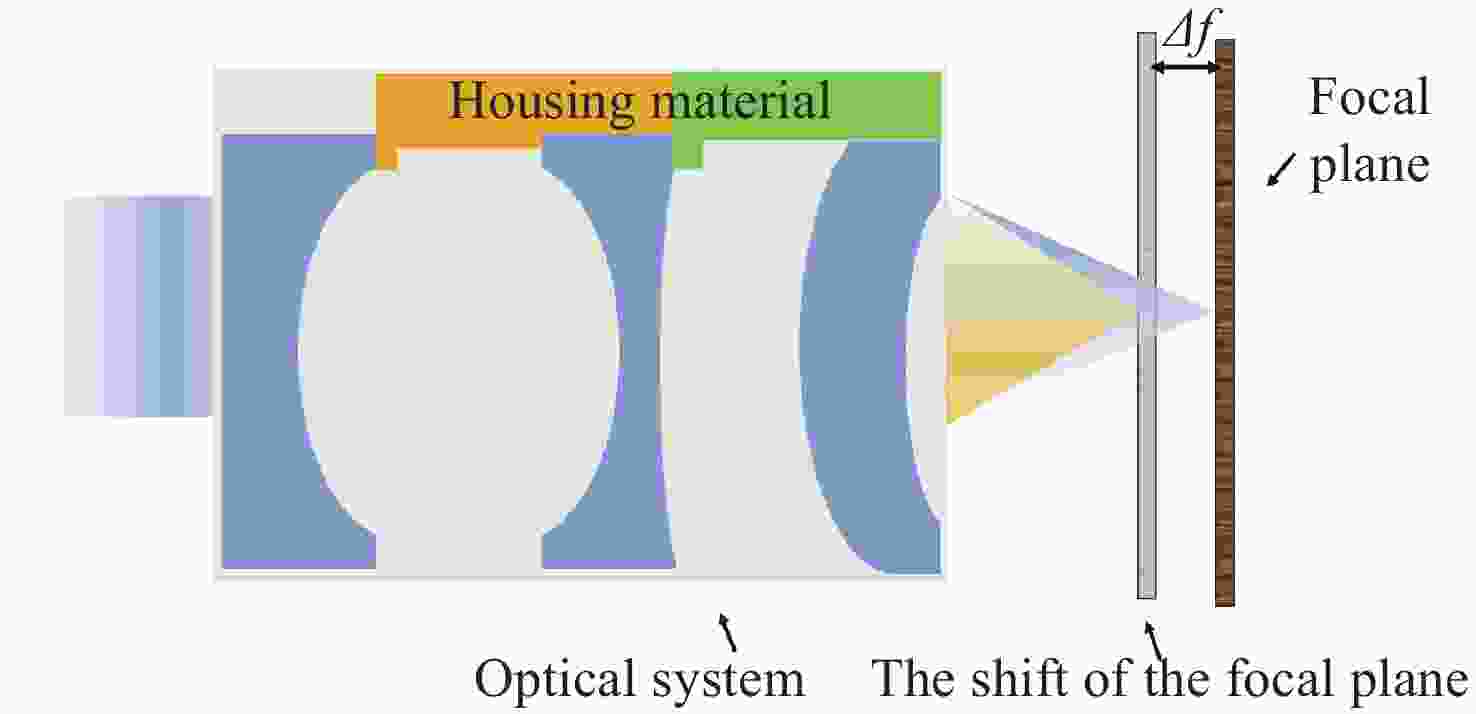

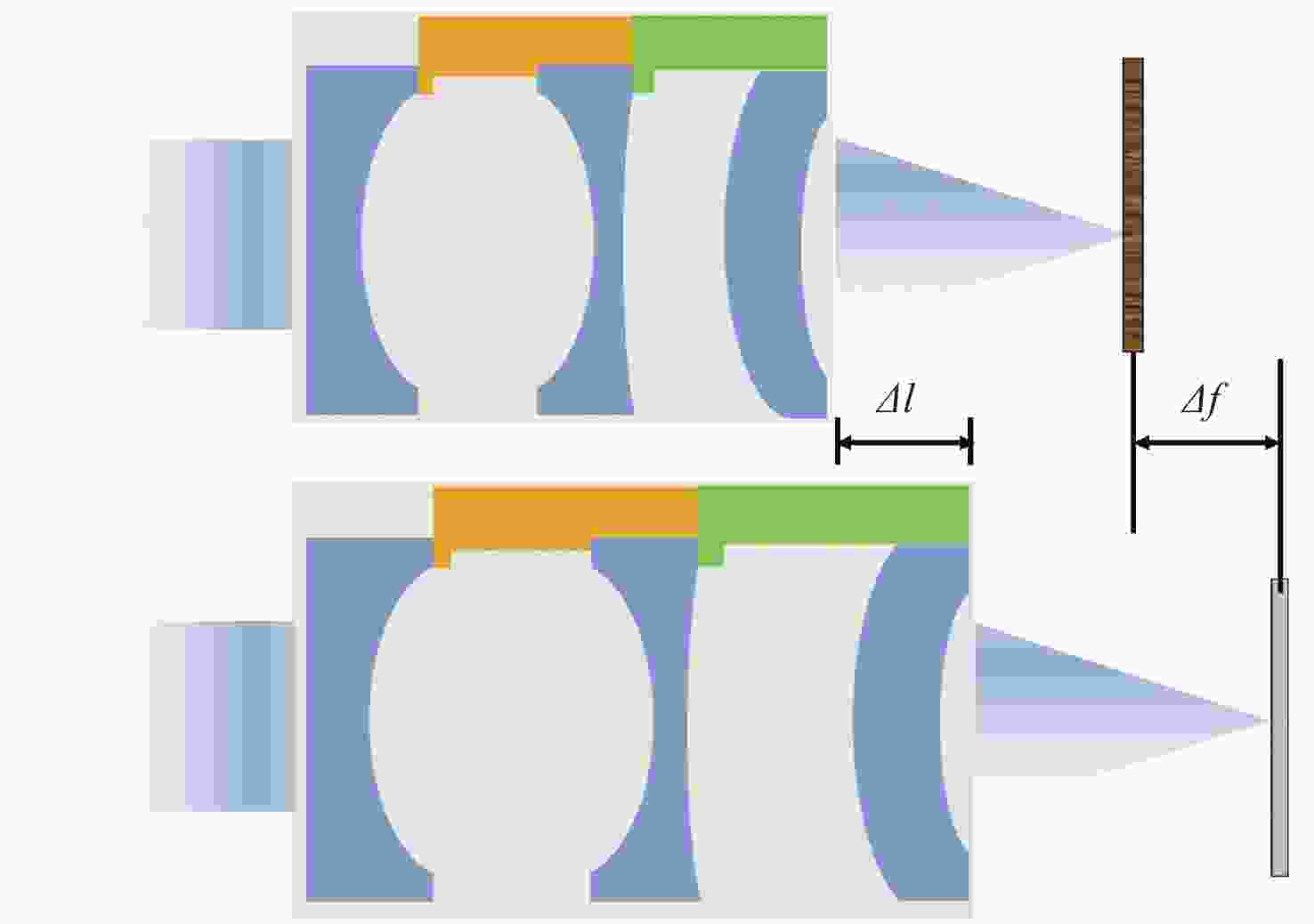

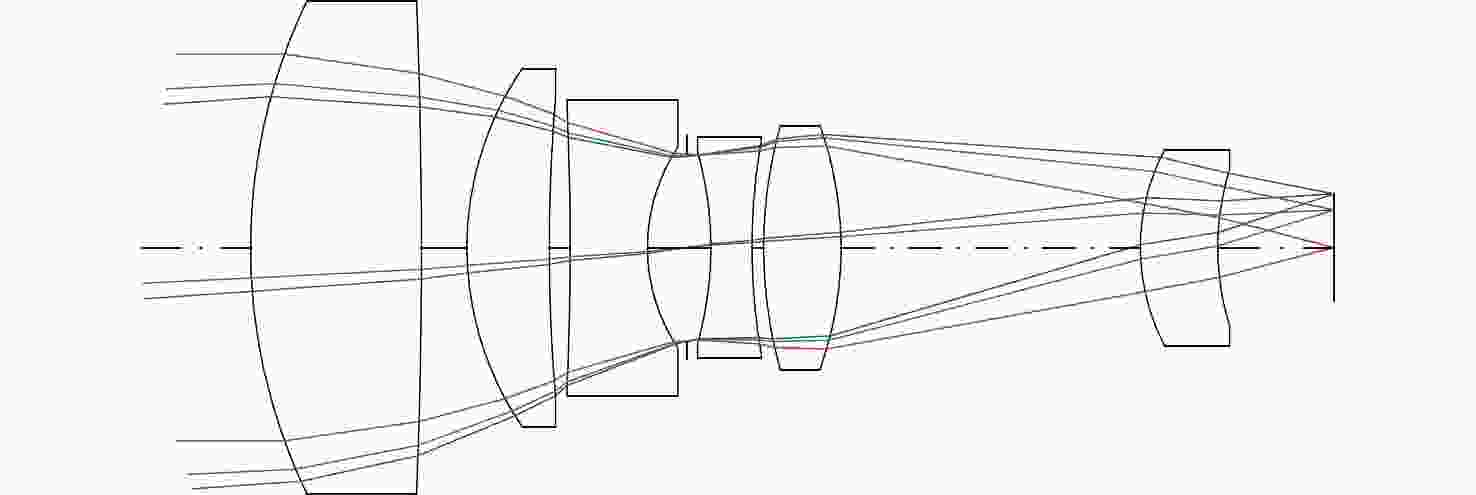

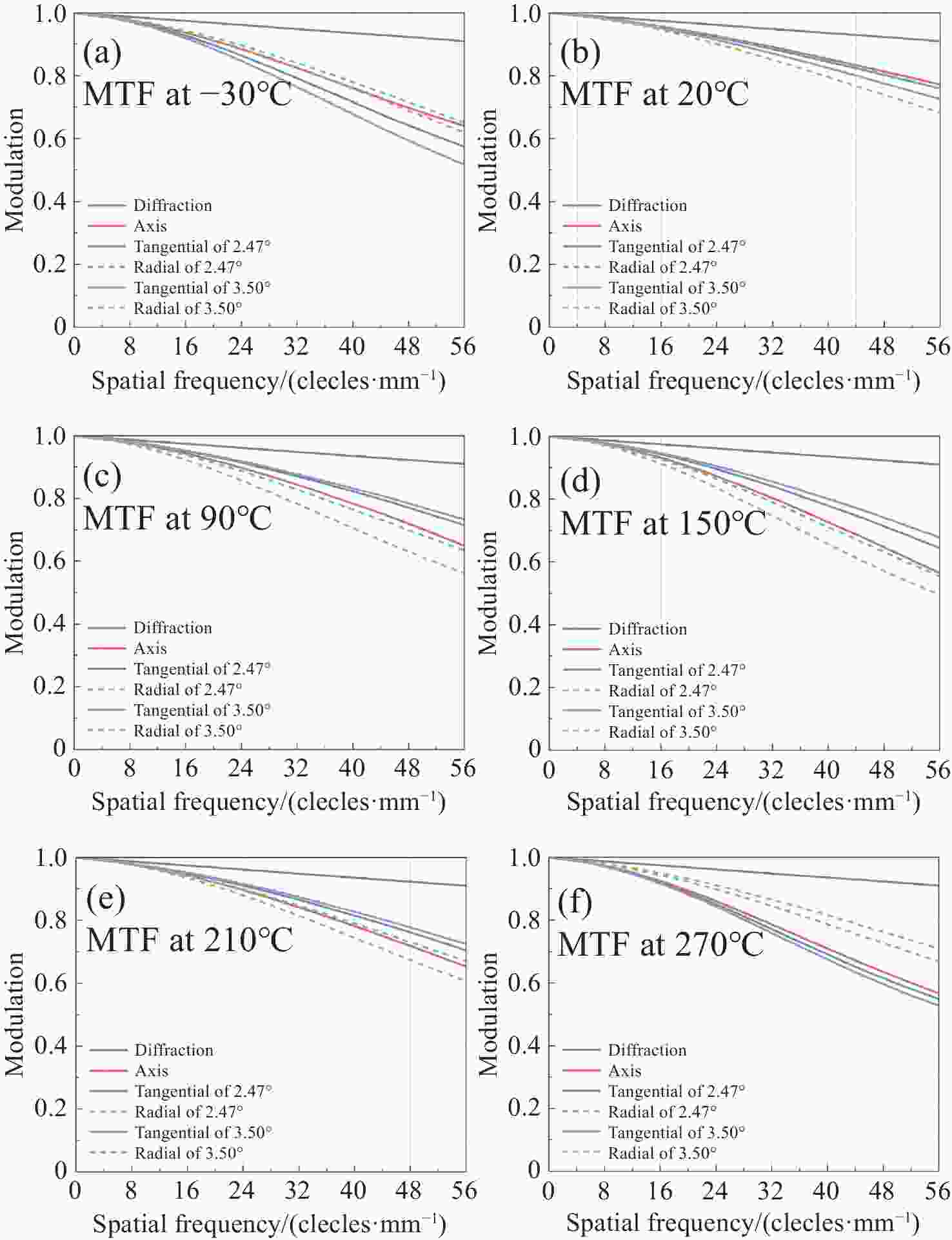

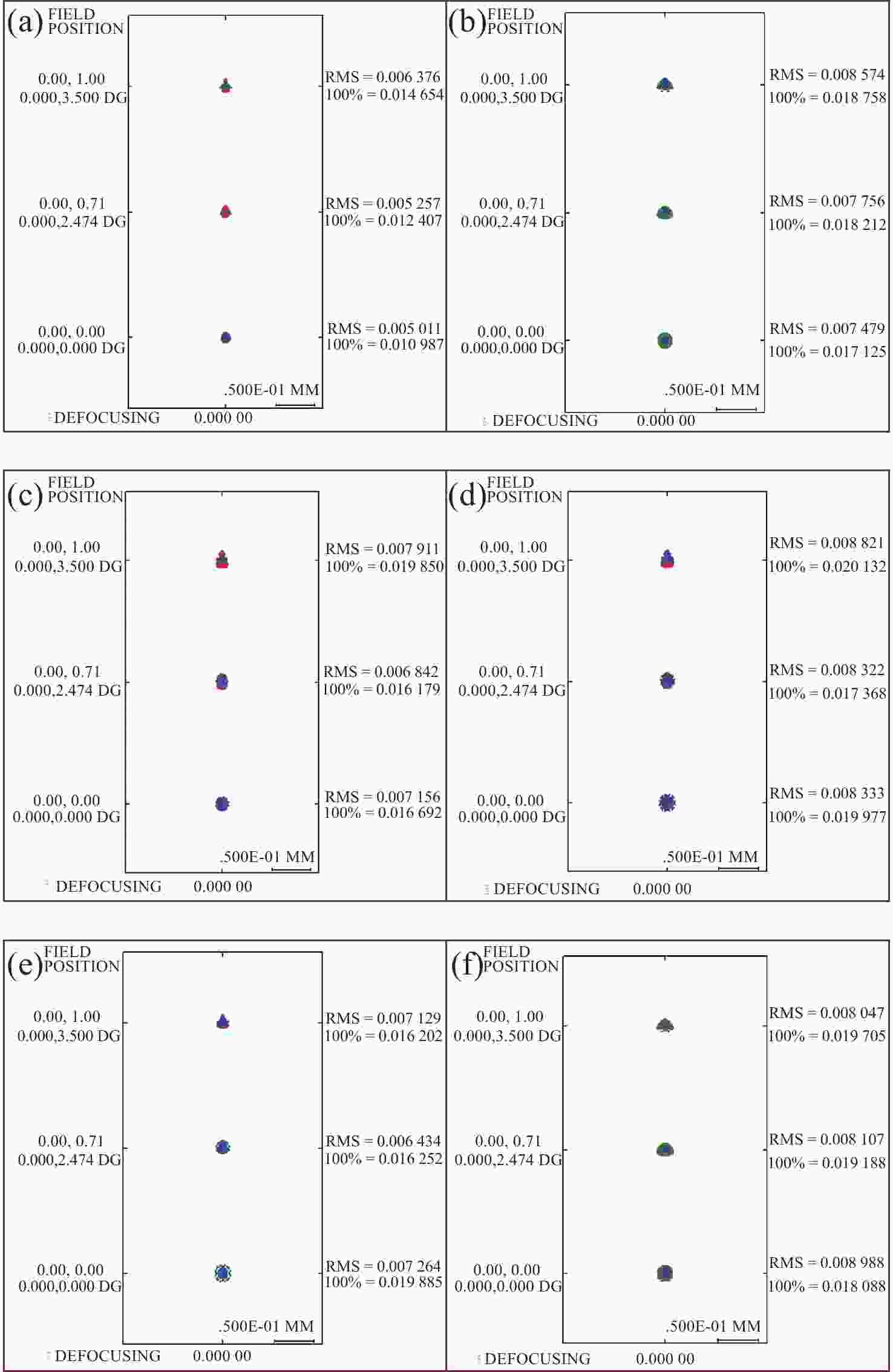

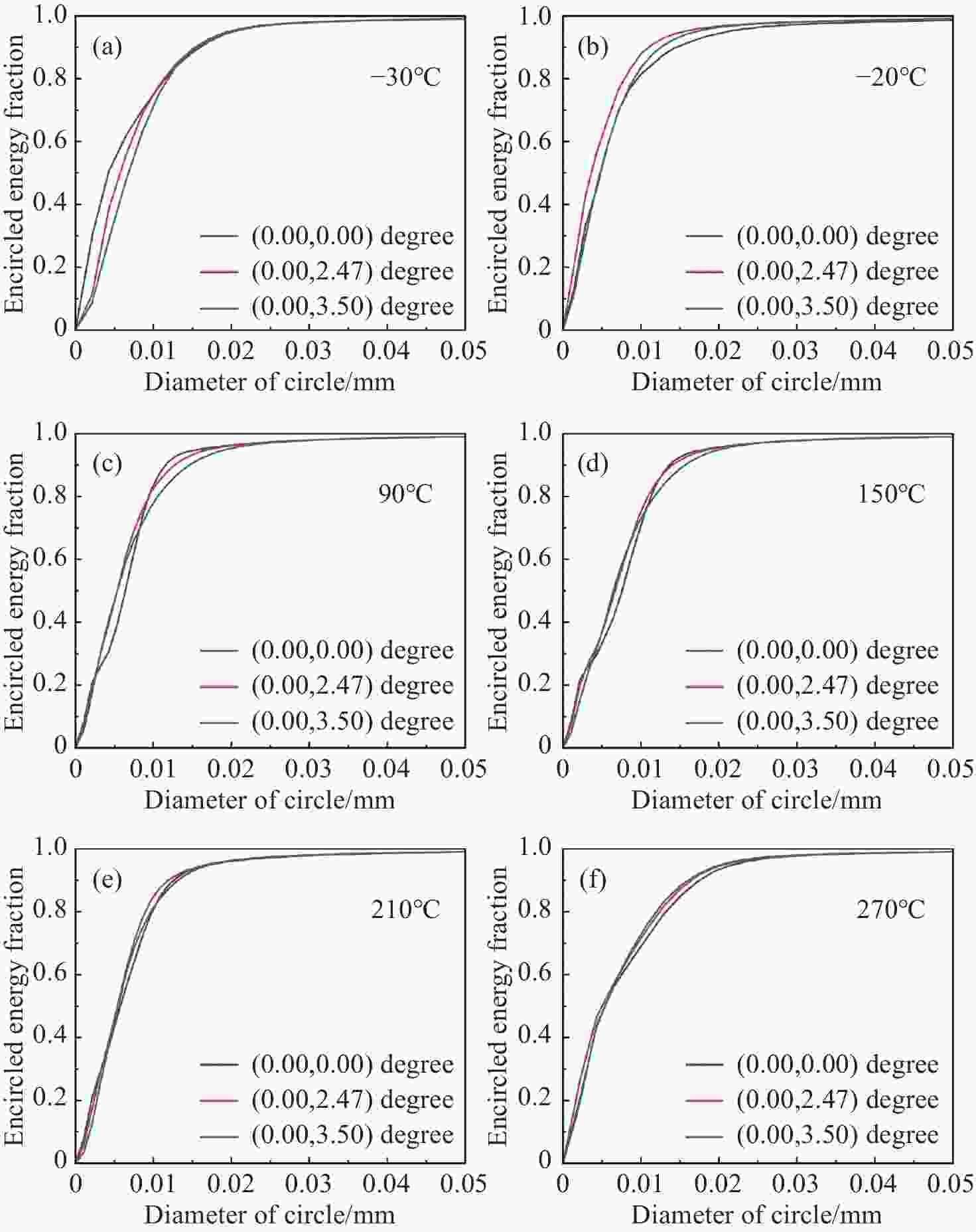

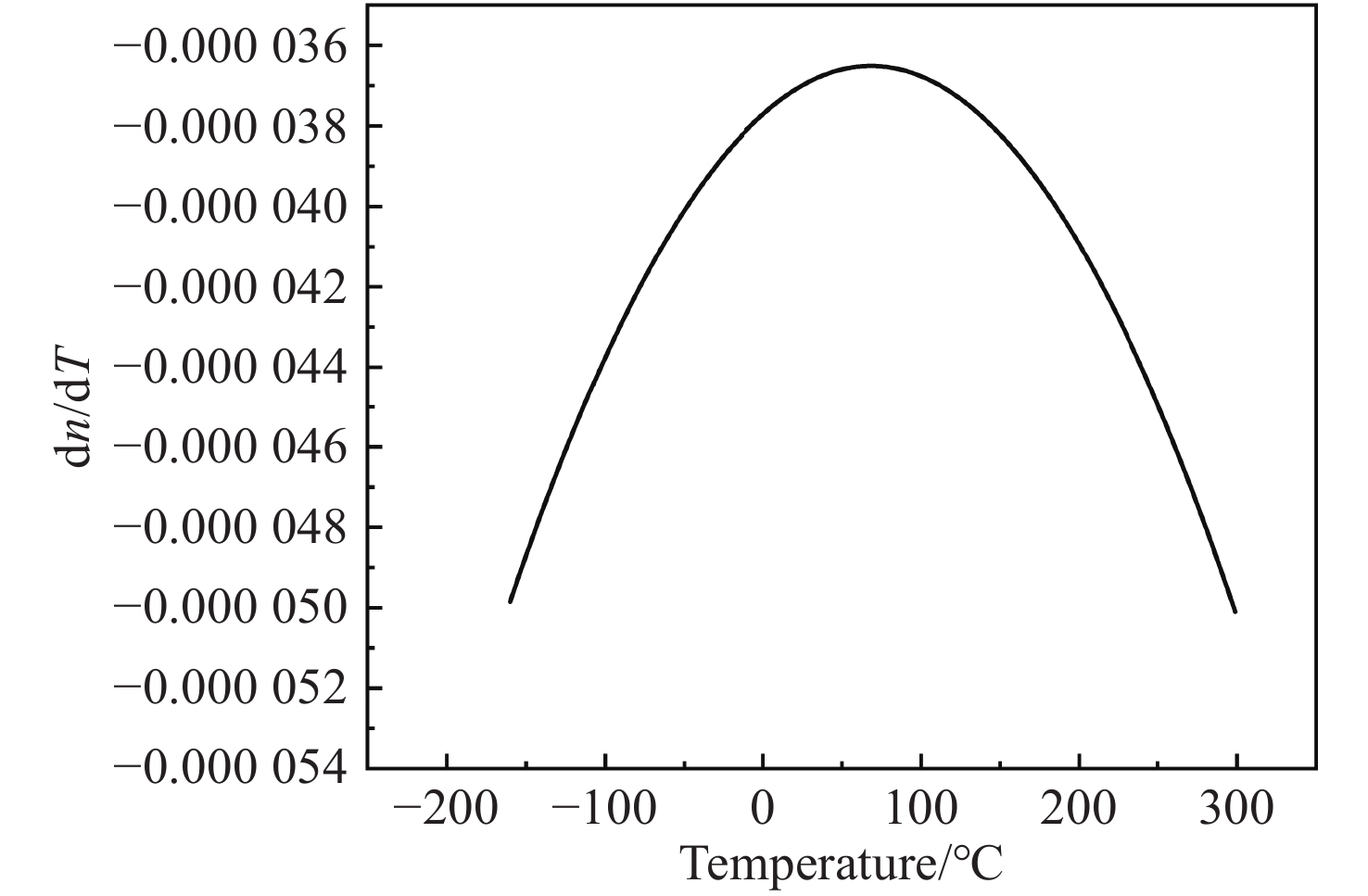

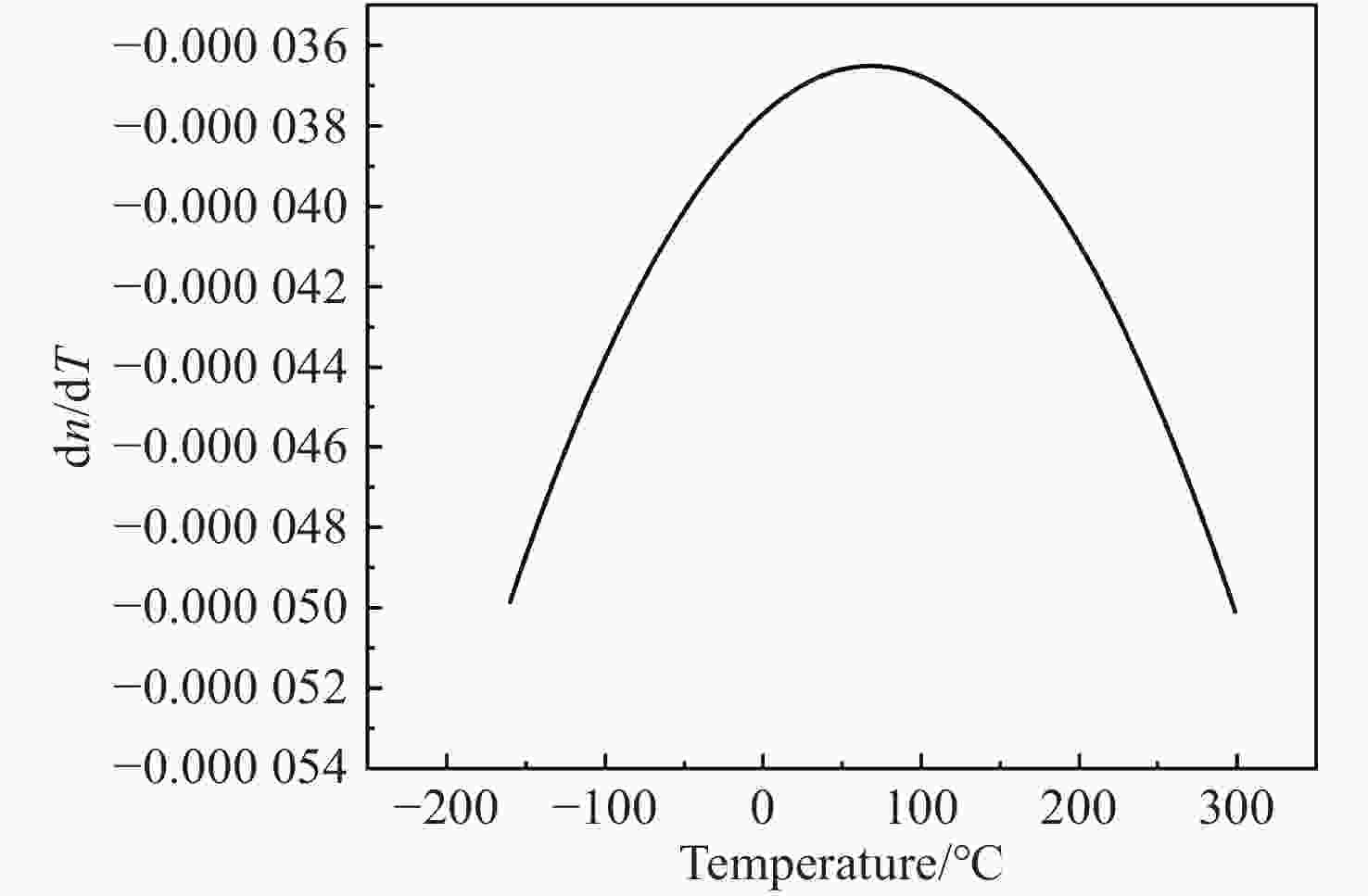

在宽温域应用场景中,传统光学系统往往难以维持稳定的成像质量,其主要原因在于常规无热化设计方法未能充分考虑玻璃材料在高温与低温下线胀系数与折射率温度系数的差异。针对这一问题,本文提出了一种面向宽温域的无热化设计方法,通过重建热像差建模过程,准确表征热像差随温度变化的非线性响应,进而筛选出在宽温域内综合热光焦度最小的玻璃材料组合,并结合镜筒材料热膨胀特性,有效抑制系统焦点漂移。设计验证中,构建了一套焦距为100 mm、F 数为2.2、视场角为 7°的光学系统。结果表明,在−30 °C至270 °C的温度范围内,该系统始终保持优异的成像性能:在全视场和全温度条件下,MTF(@56 lp/mm)均大于 0.5,弥散斑直径小于9 μm,且90%以上的能量聚焦在直径18 μm的包围圆内。上述结果充分验证了所提方法的有效性,为宽温域光学系统的无热化设计提供了有力支撑。同时,该方法具备良好的工程适应性,在复杂环境下的成像系统设计中展现出广阔的应用前景。

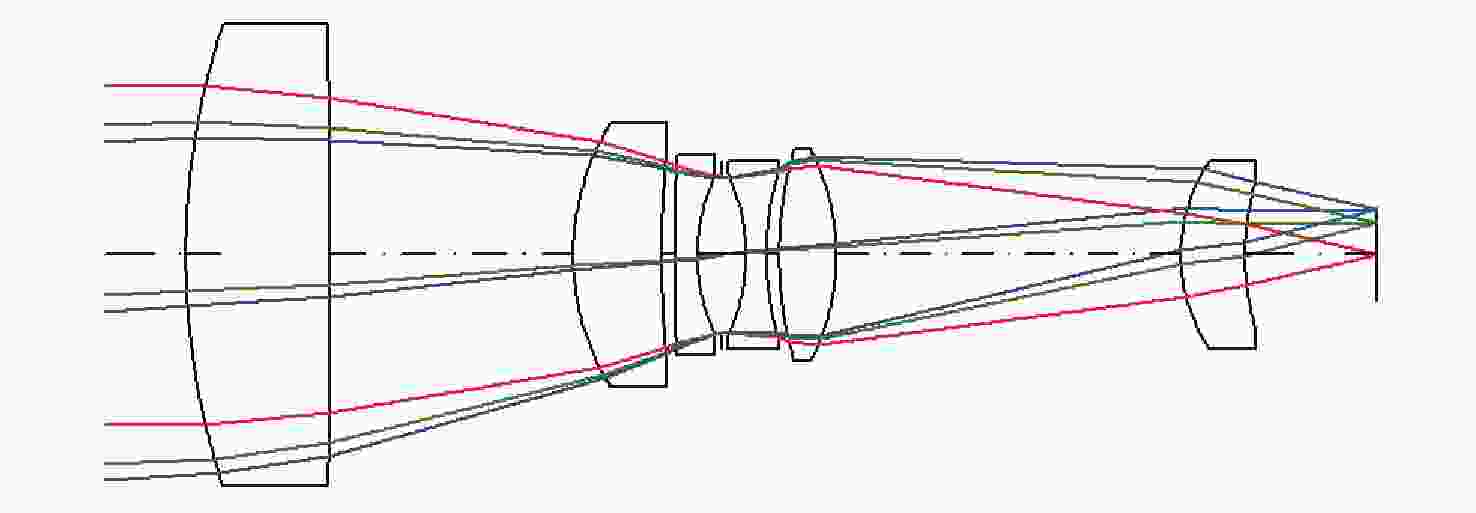

Abstract:In wide-temperature-range applications, traditional optical systems often struggle to maintain stable imaging quality, primarily because conventional athermal design methods fail to fully account for the differences in the linear expansion coefficients and refractive index temperature coefficient of glass materials at high and low temperatures. To address this issue, this paper proposes an athermal design method for wide temperature ranges. By reconstructing the thermal aberration modeling process, the method accurately characterizes the nonlinear response of thermal aberrations to temperature variation, thereby selecting glass material combinations that minimize the overall thermal optical power within the wide temperature range. In combination with the thermal expansion properties of the housing material, it effectively suppresses system focal shift. To validate the effectiveness of the proposed method, an optical system with a focal length of 100 mm, an F-number of 2.2, and a field of view of 7° was designed. Simulation results show that within the temperature range of −30°C to 270°C, the system consistently maintains high imaging performance. The modulation transfer function (MTF) remains above 0.5 at 56 lp/mm across all fields and temperatures. The spot diameter is less than 9 μm, and more than 90% of the energy is enclosed within an 18 μm circle. The above results fully verify the effectiveness of the proposed method and provide strong support for athermal design of optical systems under wide temperature ranges. Meanwhile, the method demonstrates good engineering adaptability and shows broad application prospects in the design of imaging systems for complex environments.

-

表 1 光学系统指标

Table 1. Optical system performance parameters

Parameter Performance indicators Spectral range 550~710 nm FOV 7° Focal 100 mm F number 2.22 Aperture 45 mm Temperature range −30~270 °C 表 2 光学系统初始结构折射率与阿贝数

Table 2. Initial structure refractive index and Abbe number of the optical system

Element Refractive index Abbe number 1 1.66934 52.37 2 1.65149 54.88 3 1.74934 27.82 4 1.65878 32.91 5 1.74397 44.85 6 1.74397 44.85 表 3 备选玻璃材料热光系数

Table 3. Thermo-optic coefficient of candidate glass materials

Lens1 H-LAK1 H-LAK11 H-ZBAF3 H-ZBAF50 H-LAK70 γ 1.49×10−5 1.99×10−5 1.84×10−5 1.96×10−5 2.37×10−5 Lens2 H-LAK1 H-LAK11 H-LAK10 H-ZBAF3 H-LAK67 γ 1.49×10−5 1.99×10−5 1.97×10−5 1.84×10−5 2.37×10−5 Lens3 ZF50 H-ZF6 ZF12 ZF51 H-ZF50 γ 2.38×10−5 2.47×10−5 4.29×10−5 3.92×10−5 2.51×10−5 Lens4 H-ZF1 H-ZF39 H-ZF2 H-F51 H-ZBAF4 γ 1.64×10−5 1.86×10−5 1.92×10−6 2.21×10−5 4.98×10−5 Lens5 H-LaF3B `H-LAF6LA H-ZF12 H-ZBAF20 H-LAF53 γ 1.92×10−5 2.71×10−5 2.49×10−5 3.13×10−5 3.18×10−5 Lens6 H-LaF3B `H-LAF6LA H-ZF12 H-ZBAF20 H-LAF53 γ 1.92×10−5 2.71×10−5 2.49×10−5 3.13×10−5 3.18×10−5 表 4 不同镜筒材料线胀系数

Table 4. CTE of different housing materials

Materials CTE (10−6/°C) Invar 2.4 TC4 8.9 AL 23.6 Mg 25 -

[1] 李文雄, 申军立, 张星祥, 等. 低温红外离轴三反准直系统设计[J]. 光学 精密工程, 2023, 31(9): 1285-1294. doi: 10.37188/OPE.20233109.1285LI W X, SHEN J L, ZHANG X X, et al. Design of low temperature infrared off-axis three-mirror collimation system[J]. Optics and Precision Engineering, 2023, 31(9): 1285-1294. (in Chinese). doi: 10.37188/OPE.20233109.1285 [2] 张运方, 朱飞虎, 郑岩, 等. 小行星地形探测激光雷达接收光学系统设计[J]. 光学 精密工程, 2025, 33(4): 521-531. doi: 10.37188/OPE.20253304.0521ZHANG Y F, ZHU F H, ZHENG Y, et al. Design of receiving optical system for asteroid terrain detection LiDAR[J]. Optics and Precision Engineering, 2025, 33(4): 521-531. (in Chinese). doi: 10.37188/OPE.20253304.0521 [3] LIU Y, LI J H, ZHANG P F, et al. Design method for a small F-number two-material uniform dispersion immersion grating imaging spectrometer[J]. Optics Express, 2023, 31(21): 35054-35067. doi: 10.1364/OE.502867 [4] ZHANG L, LI B, LI H SH, et al. Method for designing a grid-slit spectrometer with low spectral-line bending[J]. Optics and Lasers in Engineering, 2024, 183: 108514. doi: 10.1016/j.optlaseng.2024.108514 [5] LIN J, ZHAO L J, WANG J H. Numerical investigation on aero-thermodynamic characteristics of wedge shaped nose cone of near space supersonic flight[J]. Applied Mechanics and Materials, 2014, 541-542: 608-612. [6] MANGANO M, MARTINS J R R A. Multipoint aerodynamic shape optimization for subsonic and supersonic regimes[J]. Journal of Aircraft, 2021, 58(3): 650-662. doi: 10.2514/1.C036216 [7] LIU T, WANG CH, YU Y, et al. Passive athermal optical design method considering thermal-induced surface deformation[J]. Photonics, 2021, 8(9): 396. doi: 10.3390/photonics8090396 [8] SHEN B L, CHANG J, NIU Y J, et al. Deformable mirror-based optical design of dynamic local athermal longwave infrared optical systems[J]. Optics and Lasers in Engineering, 2018, 106: 1-9. [9] TAMAGAWA Y, TAJIME T. Expansion of an athermal chart into a multilens system with thick lenses spaced apart[J]. Optical Engineering, 1996, 35(10): 3001-3006. doi: 10.1117/1.600984 [10] MA Y J, YANG H T, CHEN W N, et al. Athermal and apochromatic design of equivalent two-component optical system in 3D glass diagram[J]. Photonics, 2024, 11(8): 719. doi: 10.3390/photonics11080719 [11] LIM T Y, KIM Y S, PARK S C. Achromatic and athermal design of an optical system with corrected petzval curvature on a three-dimensional glass chart[J]. Current Optics and Photonics, 2017, 1(4): 378-388. [12] AHN B I, KIM Y S, PARK S C. Athermal and achromatic design for a night vision camera using tolerable housing boundary on an expanded athermal glass map[J]. Current Optics and Photonics, 2017, 1(2): 125-131. doi: 10.3807/COPP.2017.1.2.125 [13] KUCUKCELEBI D, AYDEMIR S E. Passive athermalization of MWIR optical designs utilizing different infrared optical materials[J]. Proceedings of SPIE, 2022, 12217: 1221705. [14] LI J, DING Y L, LIU X J, et al. Achromatic and athermal design of aerial catadioptric optical systems by efficient optimization of materials[J]. Sensors, 2023, 23(4): 1754. doi: 10.3390/s23041754 [15] 马志远, 王鹏飞, 吴志强, 等. 基于1stOpt求解光学玻璃折射率温度系数经验公式常量的方法[J]. 光子学报, 2017, 46(6): 0616002. doi: 10.3788/gzxb20174606.0616002MA ZH Y, WANG P F, WU ZH Q, et al. A method for solving the refractive index temperature coefficient empirical formula constants of optical glasses based on 1stOpt[J]. Acta Photonica Sinica, 2017, 46(6): 0616002. (in Chinese). doi: 10.3788/gzxb20174606.0616002 [16] 唐晗, 夏丽昆, 刘炼, 等. 大变倍比制冷型长波红外变焦光学系统设计[J]. 中国光学(中英文), 2024, 17(1): 69-78. doi: 10.37188/CO.2023-0052TANG H, XIA L K, LIU L, et al. Design of cooled long-wave infrared optical system with large zooming range[J]. Chinese Optics, 2024, 17(1): 69-78. (in Chinese). doi: 10.37188/CO.2023-0052 [17] 张丽芝, 陆秋萍, 段帆琳, 等. 长焦镜头光学系统设计及无热化研究[J]. 光学学报, 2024, 44(8): 0822004. doi: 10.3788/AOS231926ZHANG L ZH, LU Q P, DUAN F L, et al. Optical system design and athermalization of telephoto lens[J]. Acta Optica Sinica, 2024, 44(8): 0822004. (in Chinese). doi: 10.3788/AOS231926 [18] MONROE J A, FEHLBERG O, ZAVISLAN J M. Athermalizing mounted doublets with ALLVAR alloys[J]. Proceedings of SPIE, 2024, 13131: 131310A. [19] JIANG CH, LIU M Q. Athermalization of a lens system by glass selection using simulated annealing with memory augmentation[J]. Optics Express, 2024, 32(8): 14860-14875. doi: 10.1364/OE.521560 [20] ZHANG L, LI J H, LI H SH, et al. A high resolution prism-grating panoramic imaging spectrometer based on occultation observations[J]. Optics Communications, 2024, 560: 130436. doi: 10.1016/j.optcom.2024.130436 -

下载:

下载: