Quantitative prediction of laser-cut slag adhesion by integrating image and frequency-domain features

-

摘要:

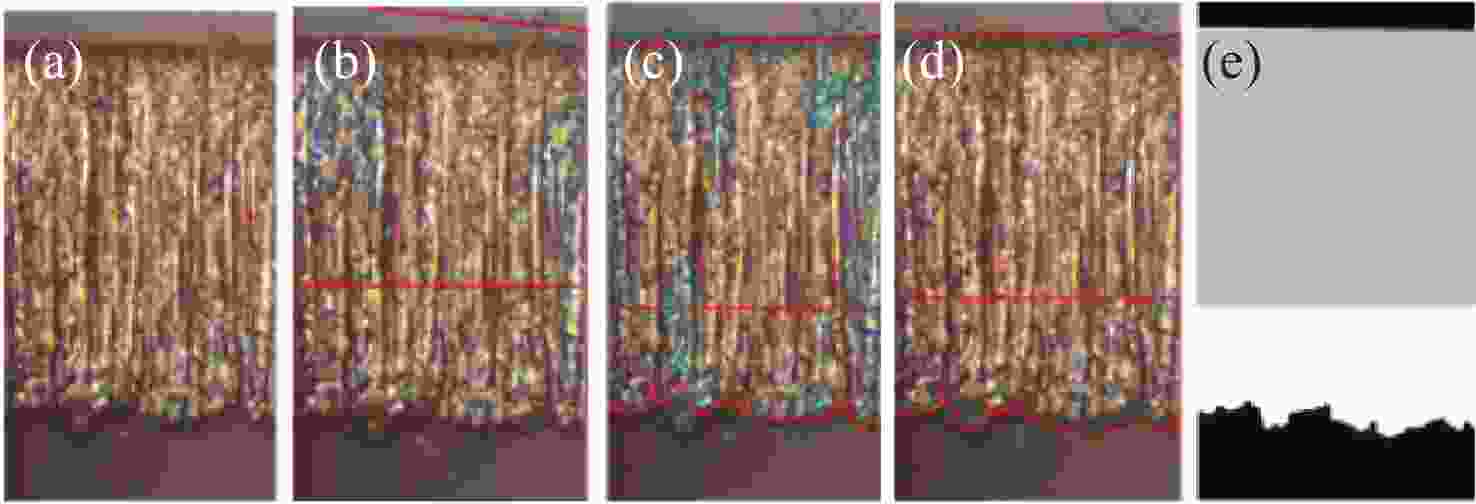

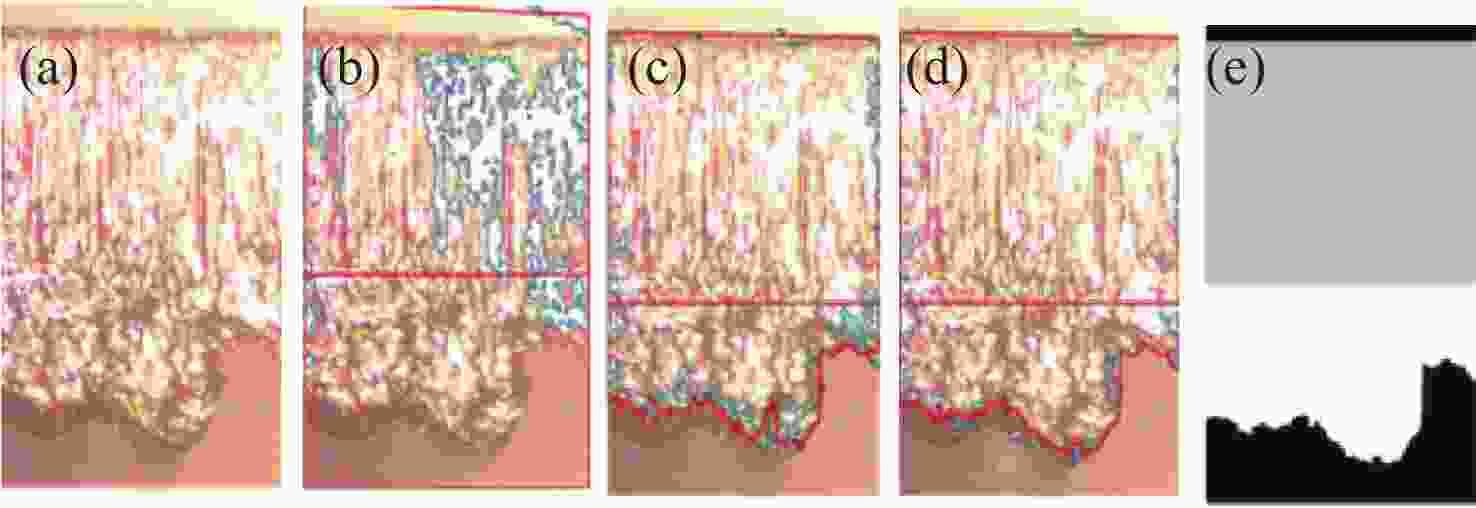

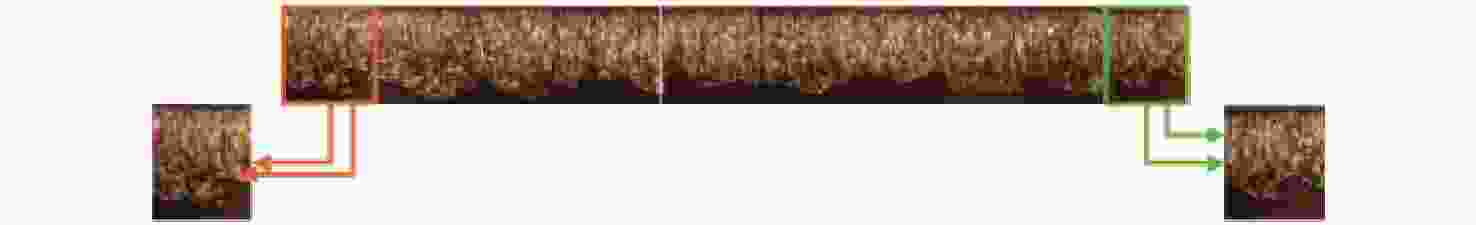

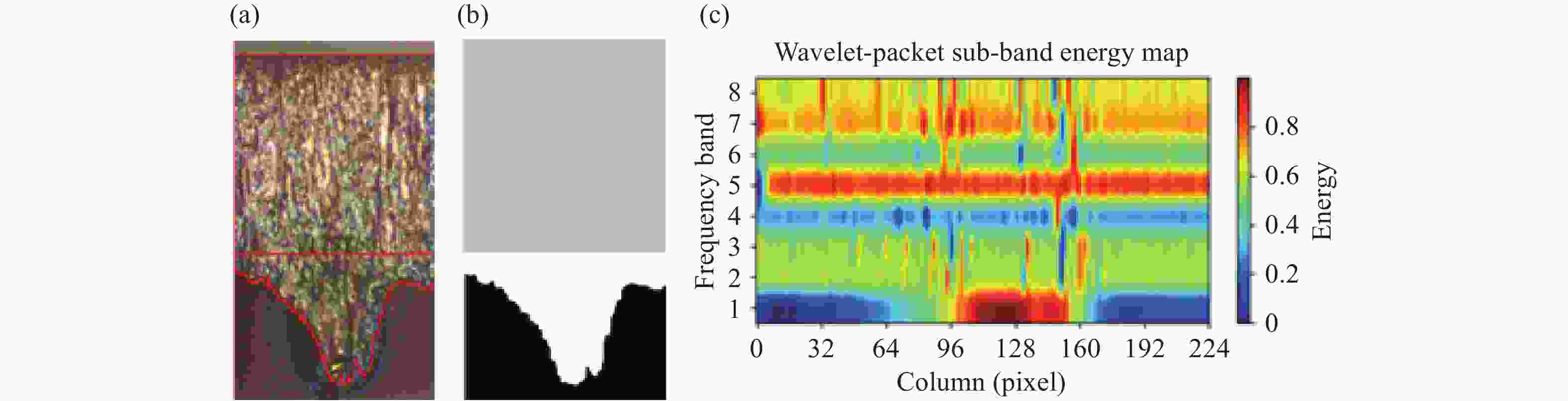

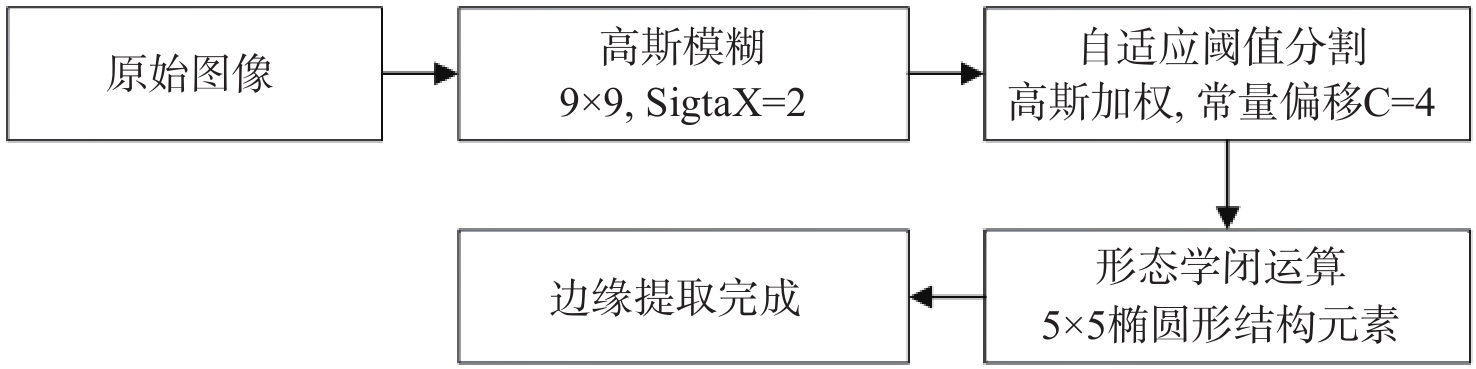

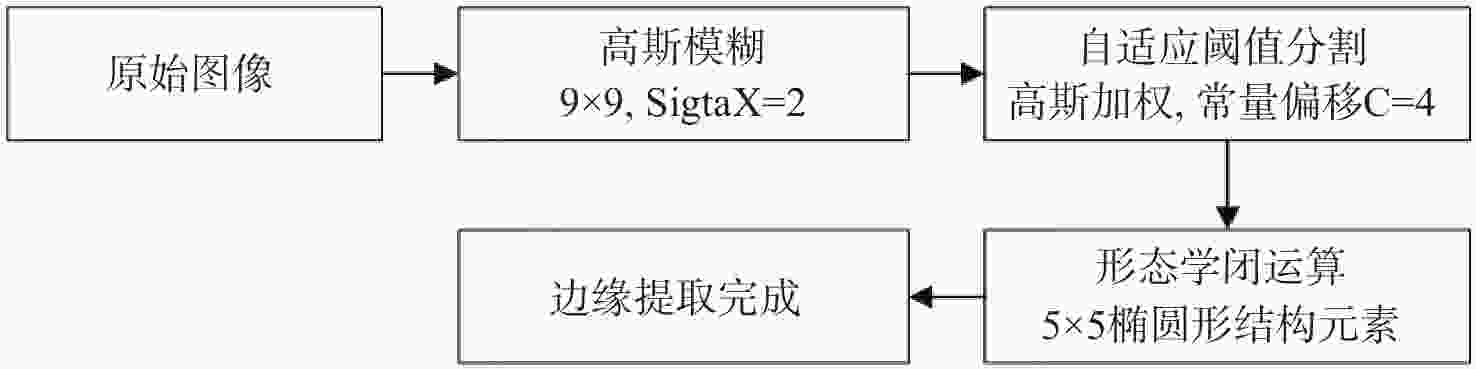

为实现激光切割熔渣附着精准量化与工艺优化,本研究探索一种基于图像与频域特征的卷积神经网络(CNN)预测方法。构建包含

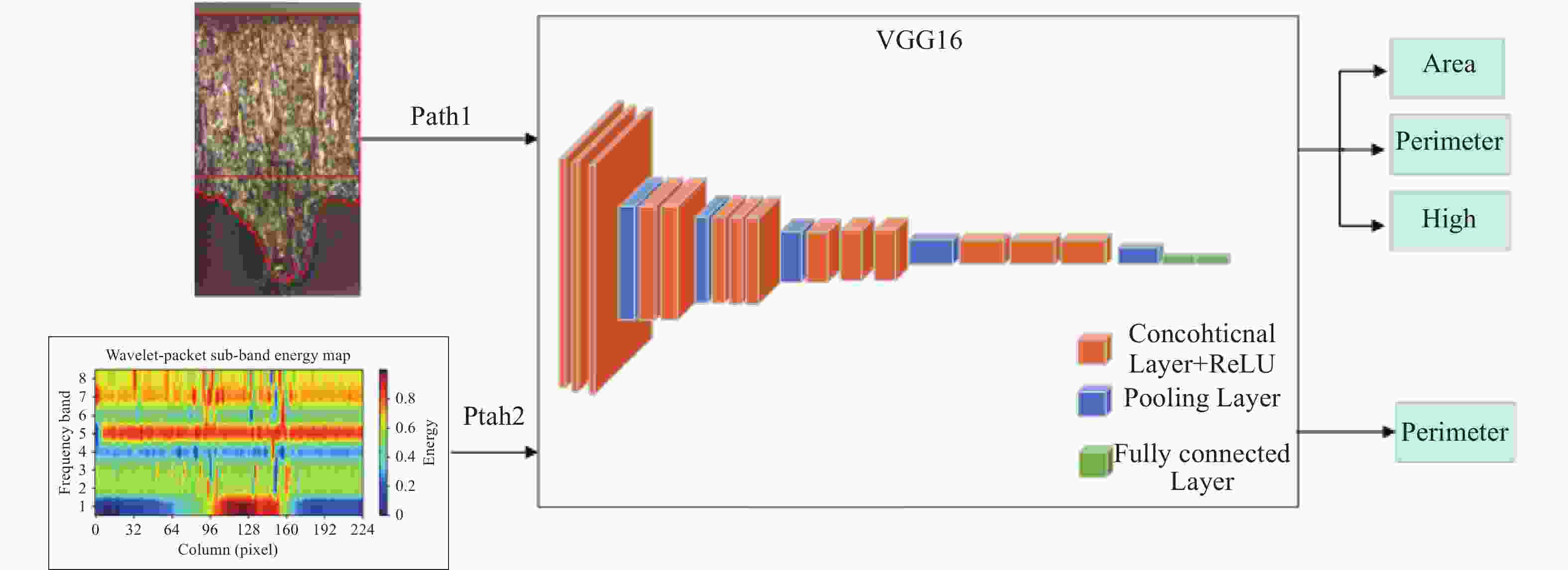

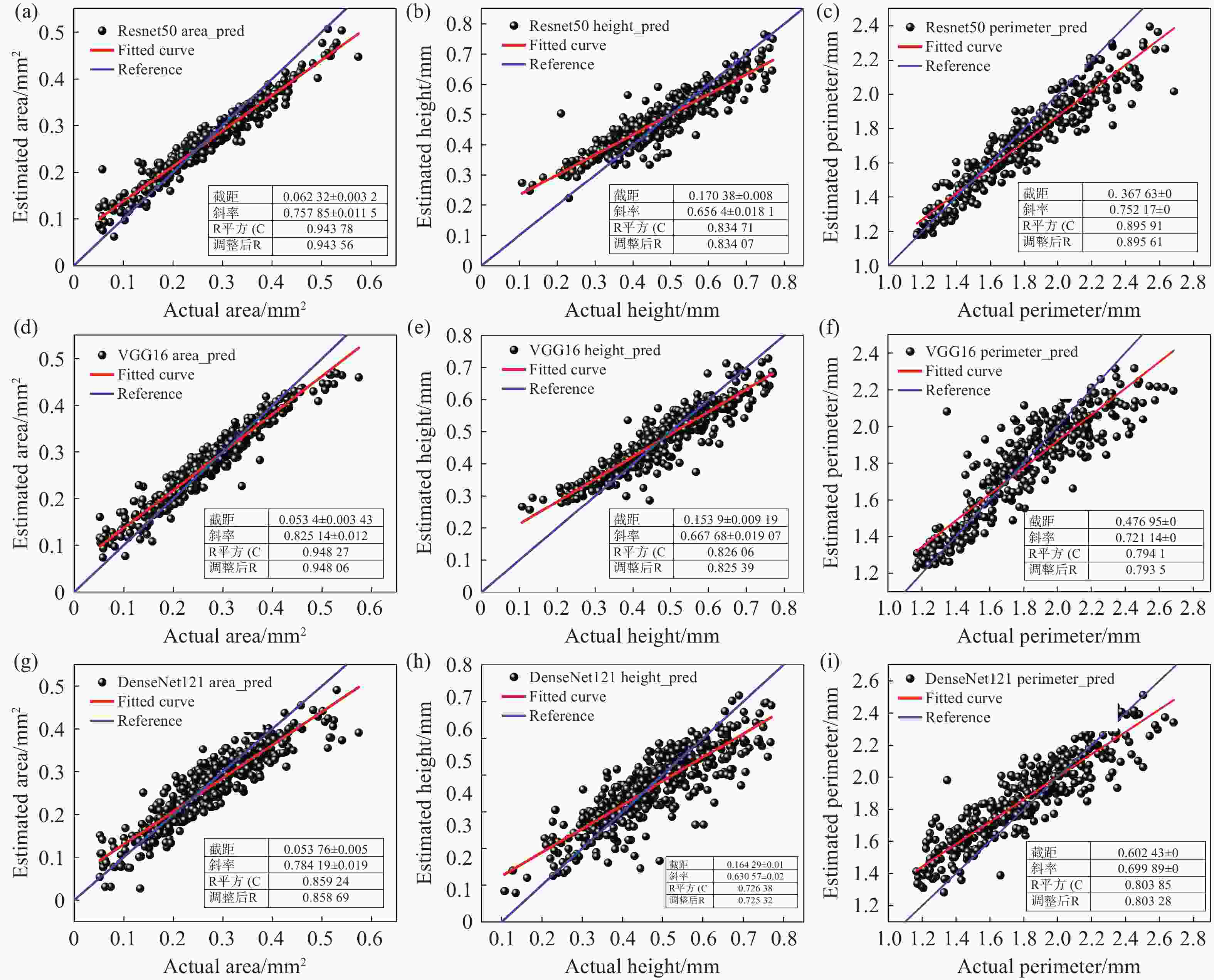

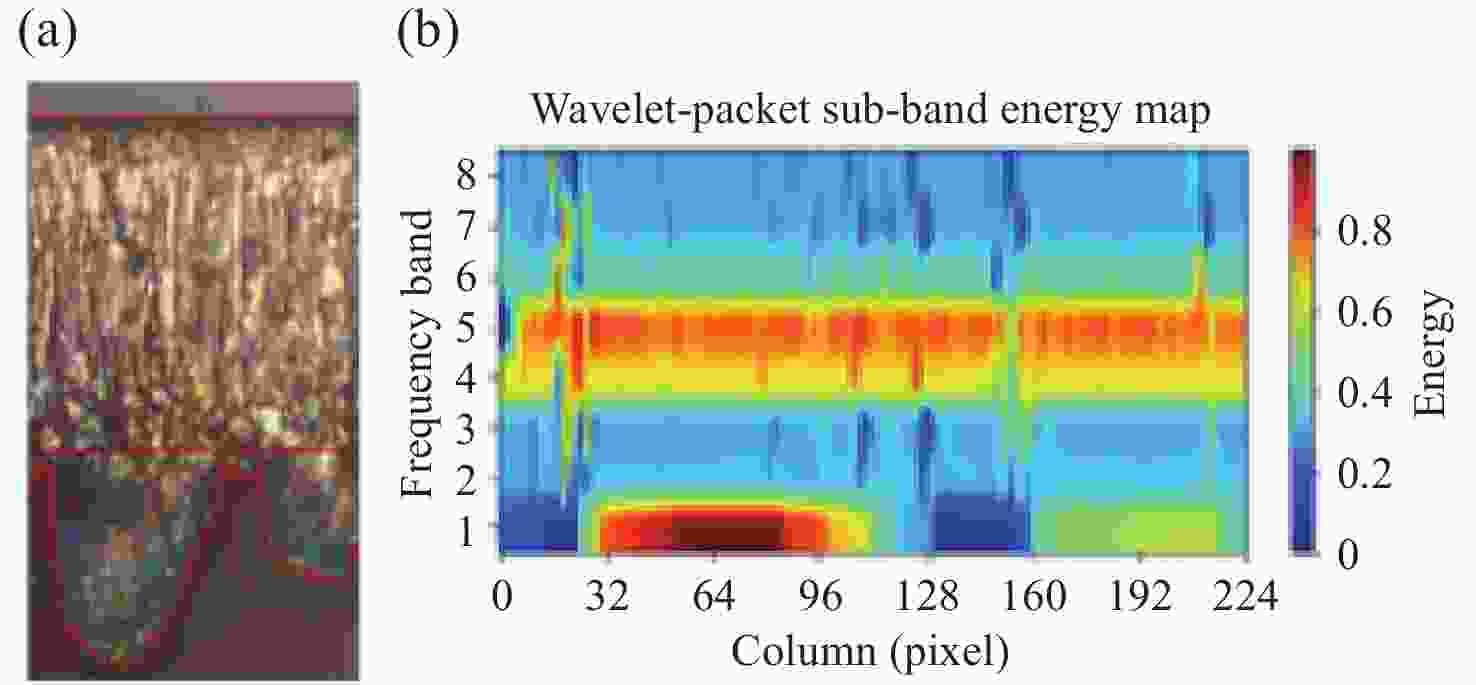

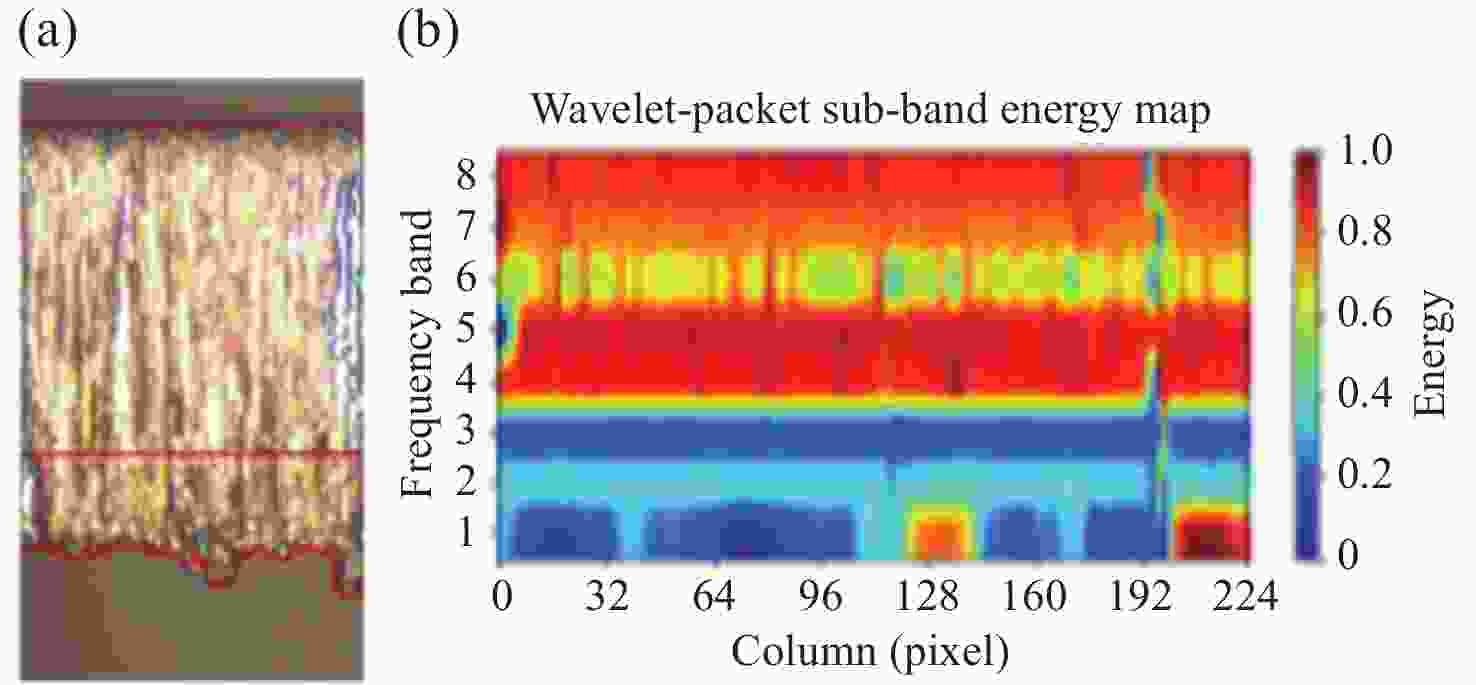

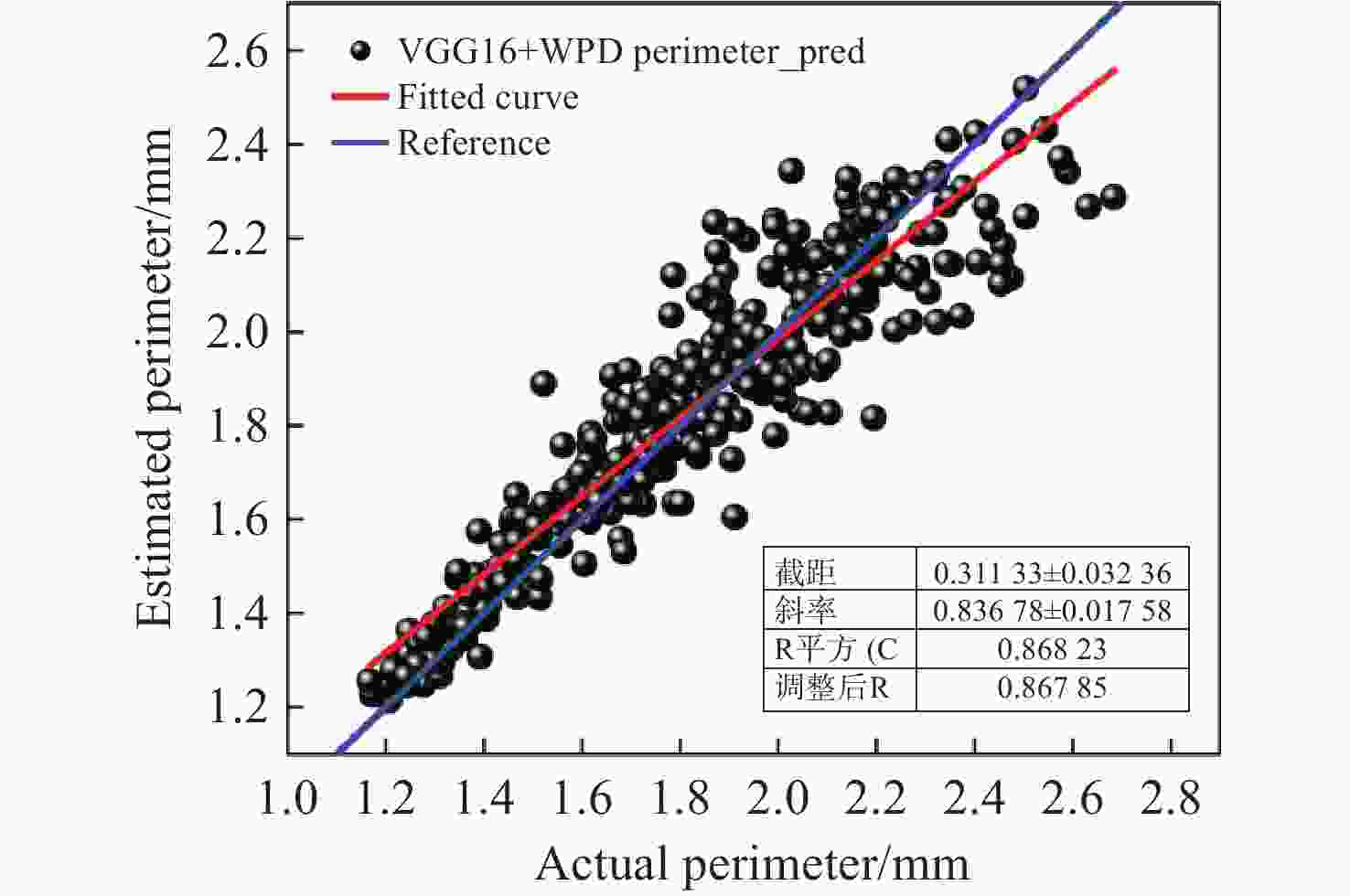

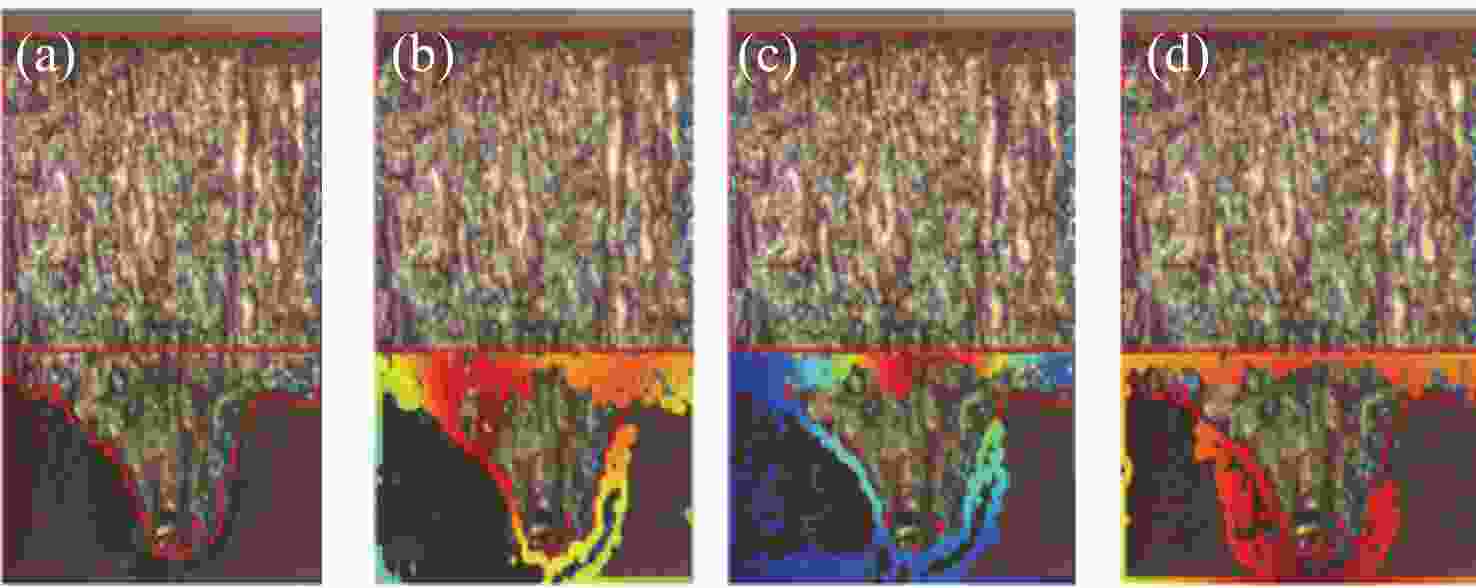

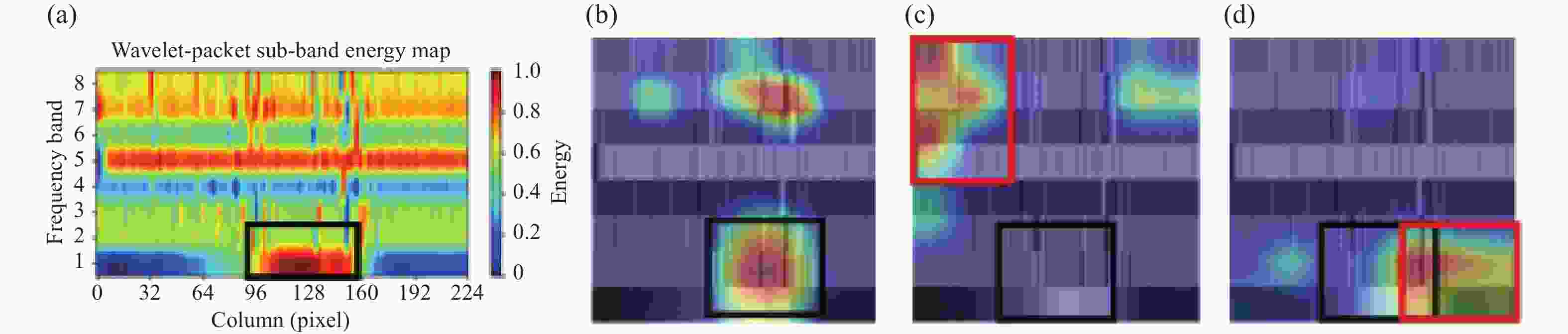

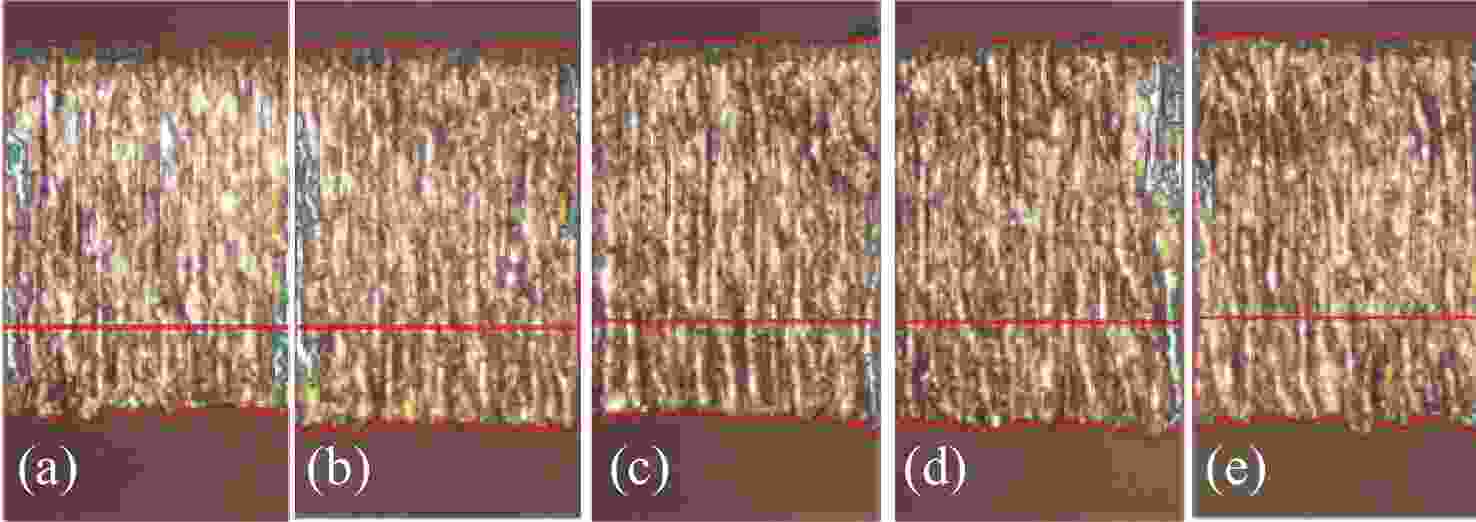

2160 张1 mm厚304不锈钢切割端面图像数据集。基于该数据集,采用高斯模糊、自适应阈值及形态学闭运算等图像处理算法,精确提取了挂渣的面积、高度及周长,将它们作为量化特征。为评估不同特征预测潜力,采用RGB图像及其经二值化处理小波包分解(WPD)频域图像作为输入,并系统对比了VGG16、ResNet50和DenseNet121三种CNN架构回归性能。结果表明,在RGB图像输入路径下,VGG16网络对挂渣面积和高度预测最为精准,其平均绝对误差(MAE)分别达到0.019 mm2和0.044 mm。而对于更能反映动态过程状态的轮廓周长特征,WPD频域输入路径的预测效果显著提升,MAE降至0.094 mm,归一化平均误差(nMAE)为5.25%,且其预测值与真实值间拟合斜率与决定系数R 2分别为0.83与0.86,呈现强线性关系。本研究证实,VGG16网络在熔渣特征预测中具备良好适用性,且WPD频域特征能更有效地捕捉激光切割过程瞬态信息,所提出方法可作为工艺智能评估与闭环优化的可靠量化工具。Abstract:To achieve precise quantification of laser cutting slag adhesion and process optimization, this study investigates a convolutional neural network (CNN)-based prediction method that integrates both image and frequency-domain features. A dataset of

2160 cross-sectional images of 1 mm thick 304 stainless steel was constructed. From these images, key dross characteristics-area, height, and perimeter were accurately extracted using a combination of image processing techniques including Gaussian blur, adaptive thresholding, and morphological closing operations. To evaluate the predictive potential of different input representations, both RGB images and binarized images transformed via wavelet packet decomposition (WPD) were used as model inputs. The regression performance of three CNN architectures-VGG16, ResNet50, and DenseNet121 was systematically compared. Experimental results demonstrate that VGG16 achieved the highest prediction accuracy for dross area and height using RGB images, with mean absolute errors (MAE) of 0.019 mm2 and 0.044 mm, respectively. For predicting the perimeter, which better reflects dynamic process behavior, the WPD frequency-domain input path yielded a significantly improved MAE of 0.094 mm and a normalized MAE (nMAE) of 5.25%. The regression fit between predicted and actual values showed a slope of 0.83 and a coefficient of determination (R2) of 0.86, indicating a strong linear correlation. This study confirms the effectiveness of VGG16 in predicting dross-related features and demonstrates the capability of WPD-derived frequency-domain features in capturing transient process information during laser cutting. The proposed methodology offers a reliable quantitative tool for intelligent process evaluation and closed-loop optimization. -

图 7 三种网络架构RGB模型预测-真实散点对比。(a)、(b)、(c)分别为面积、高度、周长ResNet50预测结果;(d)、(e)、(f)分别为面积、高度、周长VGG16预测结果;(g)、(h)、(i)分别为面积、高度、周长DenseNet121预测结果

Figure 7. Comparison of predicted vs. actual scatter plots for three CNN architectures with RGB image input. (a), (b), (c) Scatter plots of predicted vs. actual values for area, height, and perimeter using ResNet50; (d), (e), (f) scatter plots of predicted vs. actual values for area, height, and perimeter using VGG16;(g), (h), (i) scatter plots of predicted vs. actual values for area, height, and perimeter using DenseNet12

表 1 三种CNN模型基于RGB图像挂渣特征预测MAE与nMAE结果对比

Table 1. Comparison of MAE and nMAE for slag feature prediction using three CNN models on RGB images

网络架构 挂渣面积MAE

(mm2)挂渣高度MAE

(mm)挂渣周长MAE

(mm)挂渣面积nMAE

(%)挂渣高度nMAE

(%)挂渣周长nMAE

(%)ResNet50 0.023 0.046 0.106 8.48 9.72 5.91 VGG16 0.019 0.044 0.117 7 9.38 6.49 DenseNet121 0.029 0.054 0.106 10.6 11.4 5.91 表 2 WPD频域训练下挂渣周长预测MAE与nMAE

Table 2. MAE and nMAE for slag perimeter in frequency-domain training

模型 WPD频域MAE(mm) WPD频域nMAE(%) ResNet50 0.145 8.11 VGG16 0.094 5.25 DenseNet121 0.131 7.31 表 3 三种模型RGB与WPD支路熵对比

Table 3. Comparison of entropy between RGB and WPD branches in three models

模型 RGB 支路熵 WPD 支路熵 VGG16 2.62 2.41 ResNet50 3.12 3.68 DenseNet121 2.80 2.96 表 4 随机森林模型三种挂渣特征预测性能

Table 4. Prediction performance of three slag adhension features in the random forest model

挂渣特征 RMSE MAE R2 面积 0.029 0.022 0.901 高度 0.055 0.040 0.810 周长 0.215 0.157 0.629 表 5 激光切割工艺参数优化结果

Table 5. Optimization results for laser cutting process parameters

离焦量 (mm) 速度(m/s) 预测挂渣面积平均值( mm2) 超标率(%) −0.8 10 0.18 0 −1 10 0.18 0 −0.6 10 0.19 20 −0.8 12 0.19 20 −1 12 0.20 30 -

[1] GABZDY J T. Effects of gases on laser cutting of stainless steels[C]. Proceedings of the Laser Materials Processing Conference, Laser Institute of America, 1996: 39-44. [2] SHARIFF S M, SUNDARARAJAN G, JOSHI S V. Parametric influence on cut quality attributes and generation of processing maps for laser cutting[J]. Journal of Laser Applications, 1999, 11(2): 54-63. doi: 10.2351/1.521886 [3] 陈宇翔, 高亮. 正交法分析激光切割高温合金钢工艺参数[J]. 激光与光电子学进展, 2016, 53(11): 111403. doi: 10.3788/LOP53.111403CHEN Y X, GAO L. Analysis of processing parameters for laser cutting high-temperature alloy steel by orthogonal method[J]. Laser & Optoelectronics Progress, 2016, 53(11): 111403. (in Chinese). doi: 10.3788/LOP53.111403 [4] PARTHIBAN A, DHANASEKARAN C, SIVAGANESAN S, et al. Modeling on surface cut quality of CO2 laser cutting for Austenitic Stainless steel sheet[J]. Materials Today: Proceedings, 2020, 21: 823-827. doi: 10.1016/j.matpr.2019.07.428 [5] 王勇, 陈娇娇, 张鹏, 等. 基于响应面-遗传算法的不锈钢激光切割工艺参数优化与试验研究[J]. 应用激光, 2023, 43(11): 85-94. doi: 10.14128/j.cnki.al.20234311.085WANG Y, CHEN J J, ZHANG P, et al. Process parameter optimization and experimental research on stainless steel laser cutting based on response surface-genetic method[J]. Applied Laser, 2023, 43(11): 85-94. (in Chinese). doi: 10.14128/j.cnki.al.20234311.085 [6] SHIN J S, OH S Y, PARK H, et al. High-speed fiber laser cutting of thick stainless steel for dismantling tasks[J]. Optics & Laser Technology, 2017, 94: 244-247. doi: 10.1016/j.optlastec.2017.03.040 [7] OH S Y, SHIN J S, KIM T S, et al. Effect of nozzle types on the laser cutting performance for 60-mm-thick stainless steel[J]. Optics & Laser Technology, 2019, 119: 105607. doi: 10.1016/j.optlastec.2019.105607 [8] SHIN J S, SONG K H, OH S Y, et al. Laser cutting studies on 10-60 mm thick stainless steels with a short focus head for nuclear decommissioning[J]. Optics & Laser Technology, 2024, 169: 110121. doi: 10.1016/j.optlastec.2023.110121 [9] SHIN J S. Laser cutting study on 30 mm thick stainless steel for application in decommissioning of calandria shells in heavy-water reactors[J]. Nuclear Engineering and Technology, 2025, 57(3): 103242. doi: 10.1016/j.net.2024.10.004 [10] 陈达, 章轩, 赵圣斌, 等. 基于深度学习的激光熔覆层表面缺陷识别研究[J]. 光学学报, 2025, 45(9): 0915001. doi: 10.3788/AOS250462CHEN D, ZHANG X, ZHAO SH B, et al. Surface defect recognition of laser cladding layer based on deep learning[J]. Acta Optica Sinica, 2025, 45(9): 0915001. (in Chinese). doi: 10.3788/AOS250462 [11] 王颖, 高胜, 戴哲. 基于CNN-Transformer混合网络的焊缝激光条纹分割[J]. 中国激光, 2024, 51(24): 2402110. doi: 10.3788/CJL240710WANG Y, GAO SH, DAI ZH. Laser stripe segmentation of weld seam based on CNN-Transformer hybrid networks[J]. Chinese Journal of Lasers, 2024, 51(24): 2402110. (in Chinese). doi: 10.3788/CJL240710 [12] 张臣, 胡佩佩, 朱新旺, 等. 基于高密度点云的激光焊接缺陷智能在线检测(特邀)[J]. 中国激光, 2024, 51(4): 0402105. doi: 10.3788/CJL231293ZHANG CH, HU P P, ZHU X W, et al. Intelligent online detection of laser welding defects based on high density point clouds (invited)[J]. Chinese Journal of Lasers, 2024, 51(4): 0402105. (in Chinese). doi: 10.3788/CJL231293 [13] 马炜鑫, 谢冠明, 林杰凯, 等. 基于机器视觉的激光焊接气孔缺陷智能检测方法[J]. 激光与光电子学进展, 2026, 63(1): 0114012.MA W X, XIE G M, LIN J K, et al. Laser welding porosity defect detection method based on machine vision[J]. Laser & Optoelectronics Progress, 2026, 63(1): 0114012. (in Chinese). [14] 姚宇超, 周锐, 严星, 等. 基于卷积神经网络判定方法的激光微透镜阵列微米级加工工艺[J]. 光学精密工程, 2024, 32(1): 43-52. doi: 10.37188/OPE.20243201.0043YAO Y C, ZHOU R, YAN X, et al. Micron-level processing technology of microlens array (MLA) photolithography based on convolutional neural network[J]. Optics and Precision Engineering, 2024, 32(1): 43-52. (in Chinese). doi: 10.37188/OPE.20243201.0043 [15] REN X F, FAN J W, PAN R, et al. Modeling and process parameter optimization of laser cutting based on artificial neural network and intelligent optimization algorithm[J]. The International Journal of Advanced Manufacturing Technology, 2023, 127(3): 1177-1188. doi: 10.1007/s00170-023-11543-6 [16] CHAKI S, BOSE D, BATHE R N. Multi-objective optimization of pulsed Nd: YAG laser cutting process using entropy-based ANN-PSO model[J]. Lasers in Manufacturing and Materials Processing, 2020, 7(1): 88-110. doi: 10.1007/s40516-019-00109-8 [17] 何鹏, 孙帆, 胡小方, 等. 小样本激光切割工艺参数预测模型优化[J]. 激光杂志, 2021, 42(12): 170-175. doi: 10.14016/j.cnki.jgzz.2022.12.170HE P, SUN F, HU X F, et al. Optimization of prediction system for small sample laser cutting process parameters[J]. Laser Journal, 2021, 42(12): 170-175. (in Chinese). doi: 10.14016/j.cnki.jgzz.2022.12.170 [18] 钟毅, 栾显晔, 李晓宇, 等. 碳钢板激光切割工艺分析及优化[J]. 制造技术与机床, 2024(2): 38-45. doi: 10.19287/j.mtmt.1005-2402.2024.02.005ZHONG Y, LUAN X Y, LI X Y, et al. Analysis and optimization of laser cutting process of carbon steel plate[J]. Manufacturing Technology & Machine Tool, 2024(2): 38-45. (in Chinese). doi: 10.19287/j.mtmt.1005-2402.2024.02.005 [19] FRANCESCHETTI L, PACHER M, TANELLI M, et al. Dross attachment estimation in the laser-cutting process via Convolutional Neural Networks (CNN)[C]. Proceedings of the 28th Mediterranean Conference on Control and Automation, IEEE, 2020: 850-855. [20] ADELMANN B, SCHLEIER M, HELLMANN R. Laser cut interruption detection from small images by using convolutional neural network[J]. Sensors, 2021, 21(2): 655. doi: 10.3390/s21020655 [21] TATZEL L, LEÓN F P. Image-based roughness estimation of laser cut edges with a convolutional neural network[J]. Procedia CIRP, 2020, 94: 469-473. doi: 10.1016/j.procir.2020.09.166 [22] TATZEL L, TAMIMI O A, HAUEISE T, et al. Image-based modelling and visualisation of the relationship between laser-cut edge and process parameters[J]. Optics & Laser Technology, 2021, 141: 107028. doi: 10.1016/j.optlastec.2021.107028 [23] HE K M, ZHANG X Y, REN S Q, et al. Deep residual learning for image recognition[C]. Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition, IEEE, 2016: 770-778. [24] HE K M, ZHANG X Y, REN S Q, et al. Identity mappings in deep residual networks[C]. Proceedings of the 14th European Conference on Computer Vision, Springer, 2016: 630-645. [25] AL-HAIJA Q A, ADEBANJO A. Breast cancer diagnosis in histopathological images using ResNet-50 convolutional neural network[C]. Proceedings of the IEEE International IOT, Electronics and Mechatronics Conference, IEEE, 2020: 1-7. [26] MUKTI I Z, BISWAS D. Transfer learning based plant diseases detection using ResNet50[C]. Proceedings of the 4th International Conference on Electrical Information and Communication Technology, IEEE, 2019: 1-6. [27] LIU Y, ZHANG Z L, LIU X, et al. Deep learning-based image classification for online multi-coal and multi-class sorting[J]. Computers & Geosciences, 2021, 157: 104922. doi: 10.1016/j.cageo.2021.104922 [28] MASCARENHAS S, AGARWAL M. A comparison between VGG16, VGG19 and ResNet50 architecture frameworks for Image Classification[C]. Proceedings of 2021 International Conference on Disruptive Technologies for Multi-Disciplinary Research and Applications, IEEE, 2021, 1: 96-99. -

下载:

下载: