Metal-sensitive diaphragm fiber optic Fabry-Perot pressure sensor with temperature compensation

doi: 10.37188/CO.EN-2025-0021

-

摘要:

本文针对油气井、发动机燃油系统和航空液压系统等高温密闭环境下压力监测的技术难题,研发了一种具有温度补偿的金属膜片式光纤压力传感器。该传感器采用金属敏感膜片与蓝宝石晶片构成温度-压力双法珀(Fabry-Perot, FP)干涉腔结构,并结合互相关信号解调算法与温度解耦方法,有效降低温度串扰对压力测试的影响。实验结果表明,该传感器在常温和300 °C的压力测量中最大非线性误差分别为0.75% FS和0.99% FS。经过温度解耦后,压力测量精度可达1.7% FS。该传感器具有良好的静态压力响应、稳定性和可靠性,为高温压力监测场景提供了一种有效的解决方案。

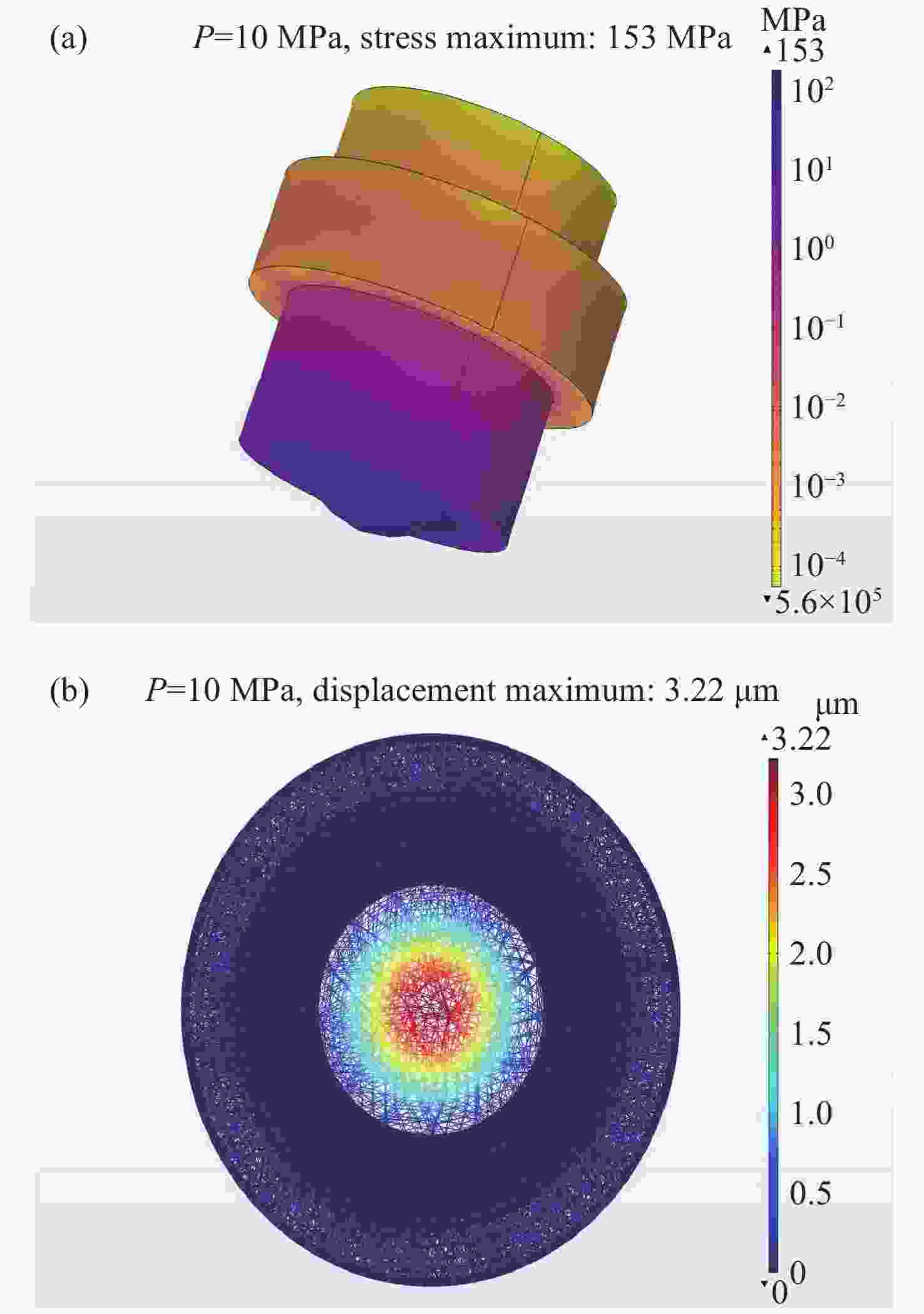

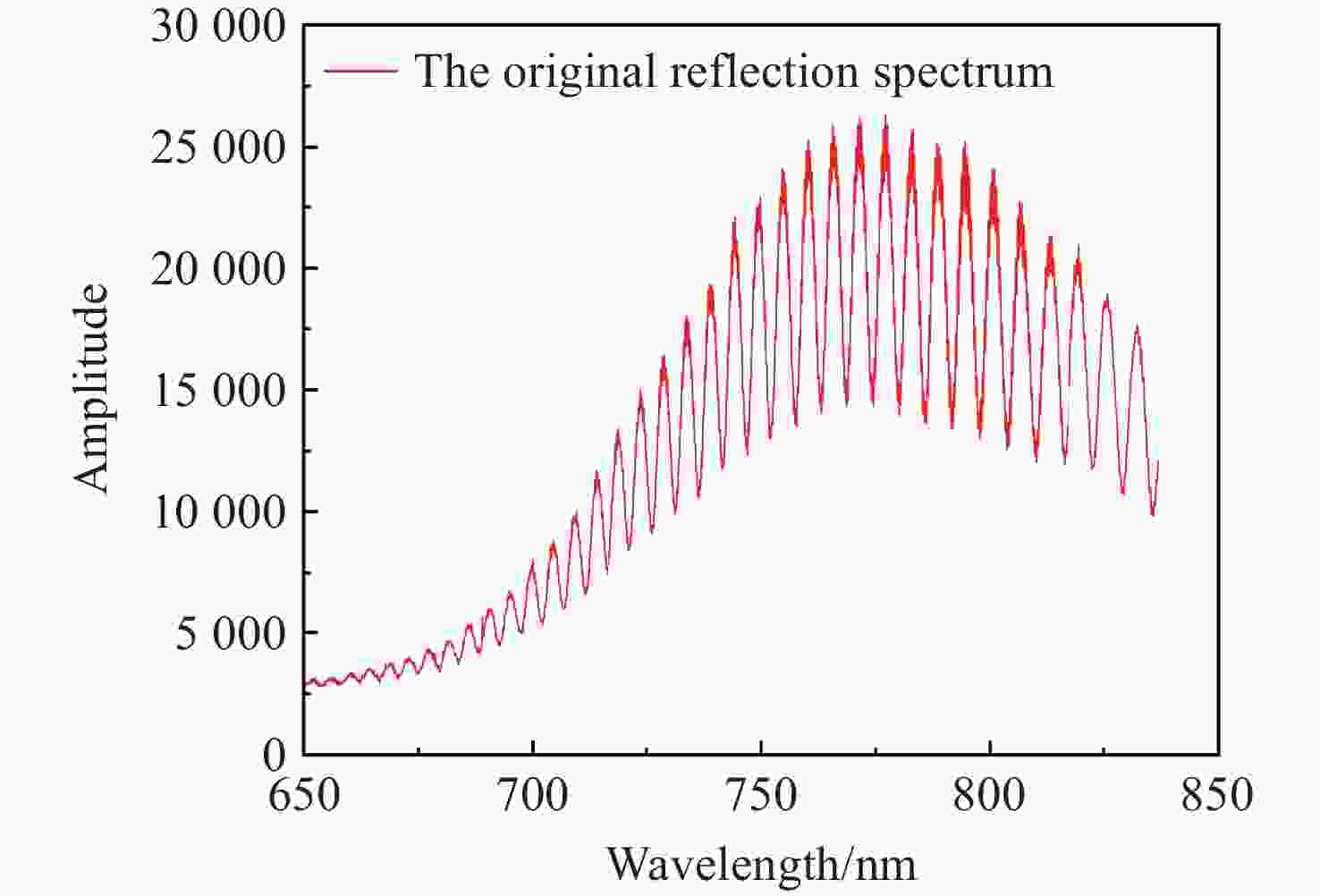

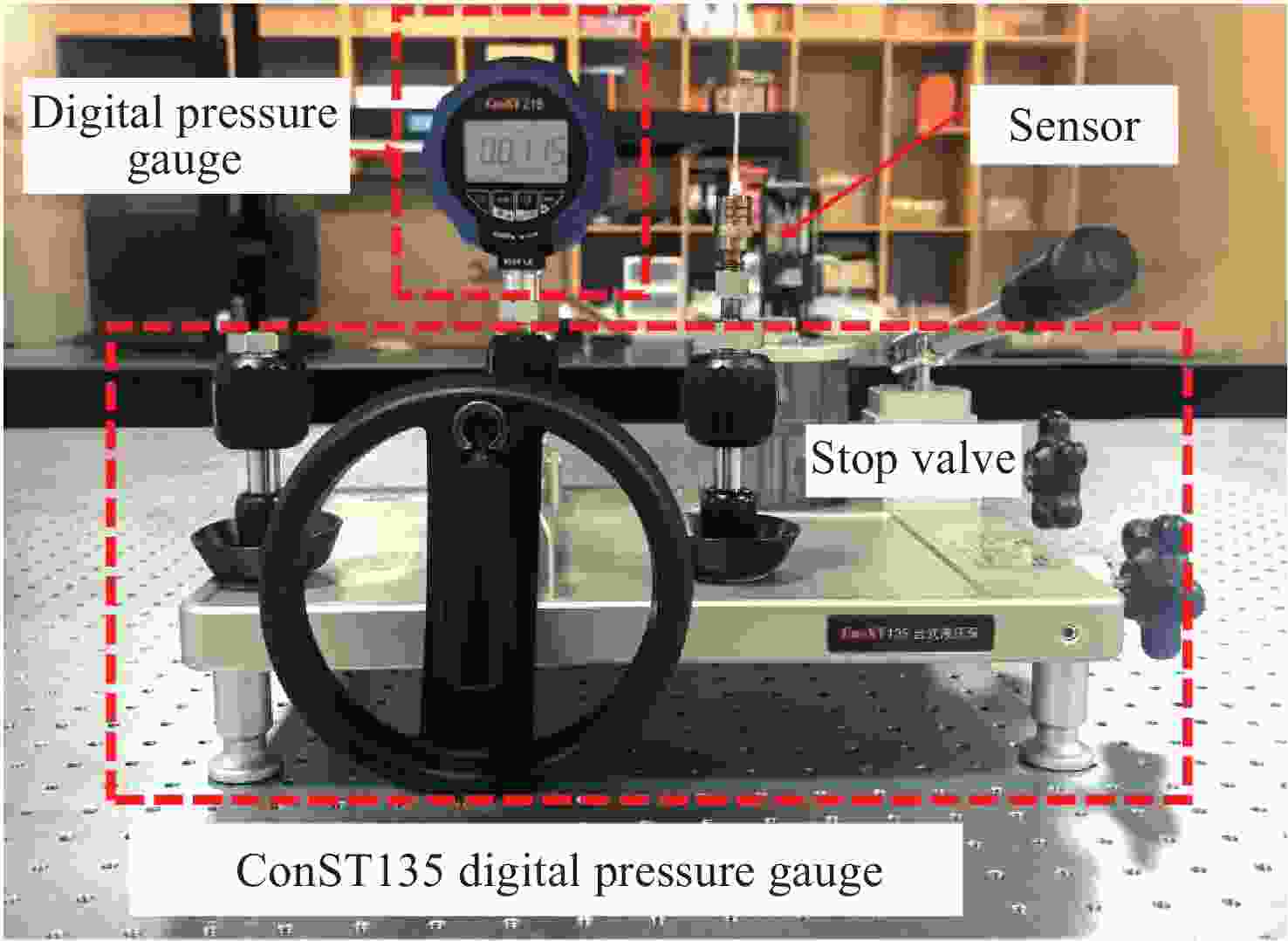

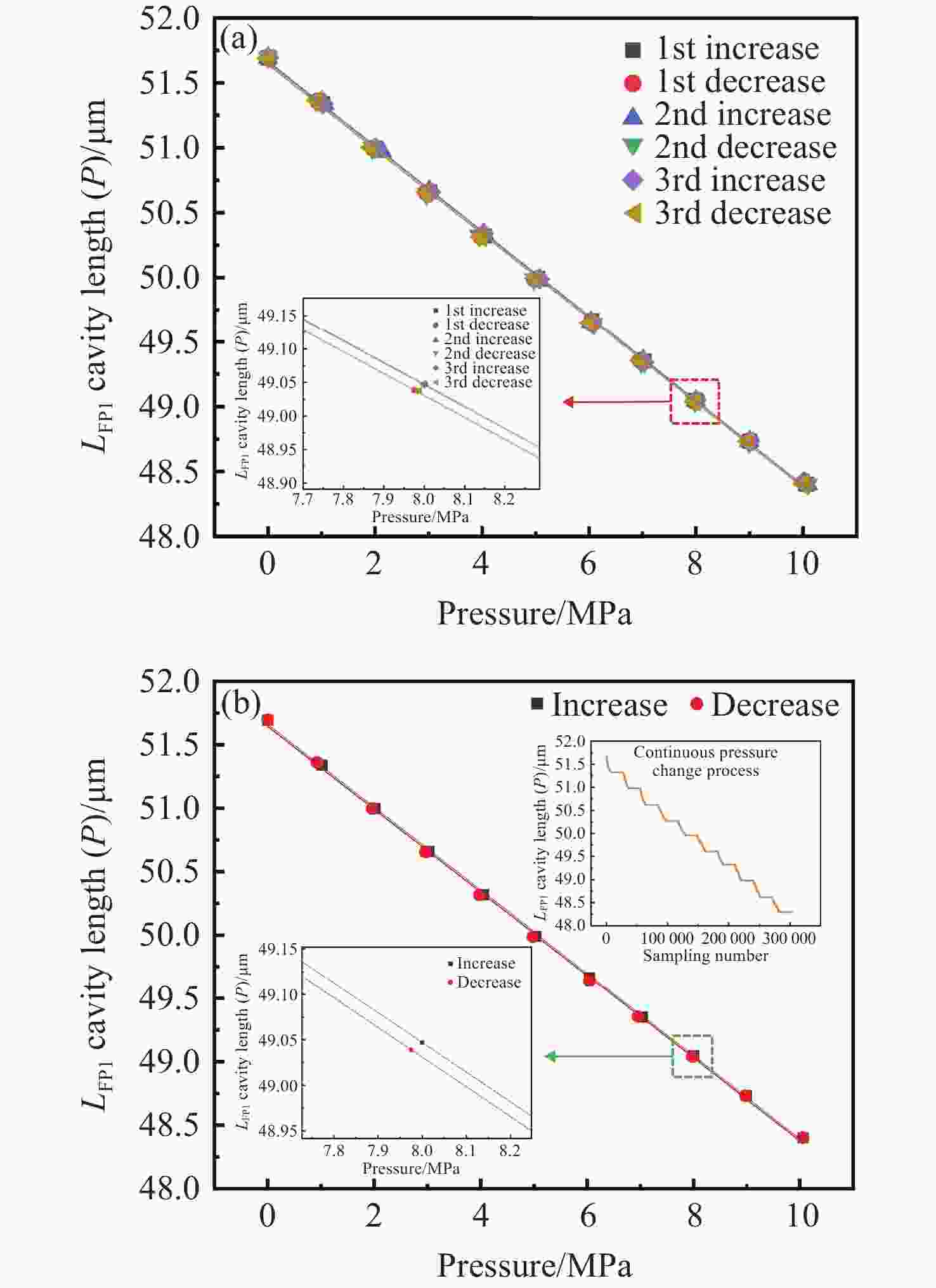

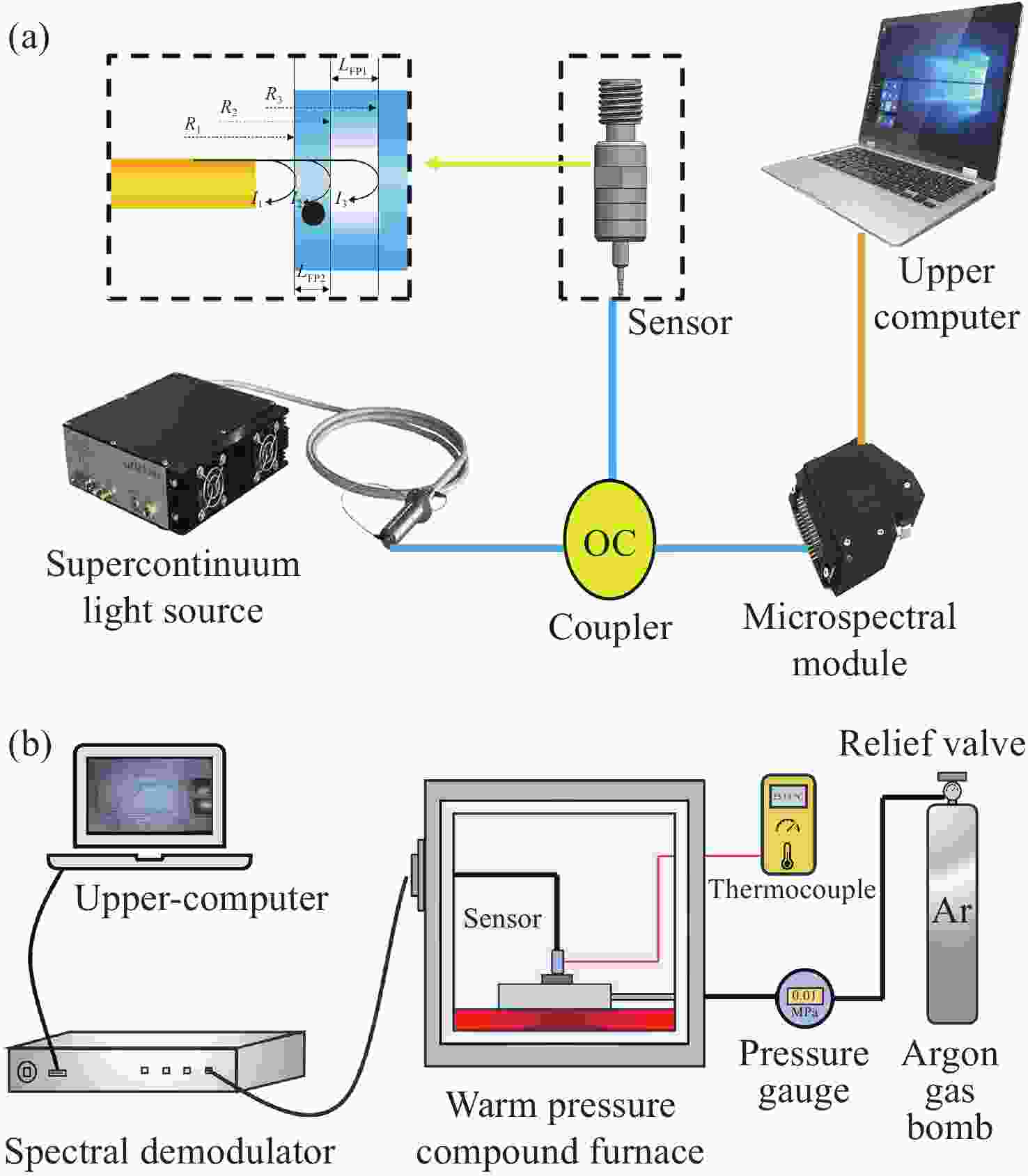

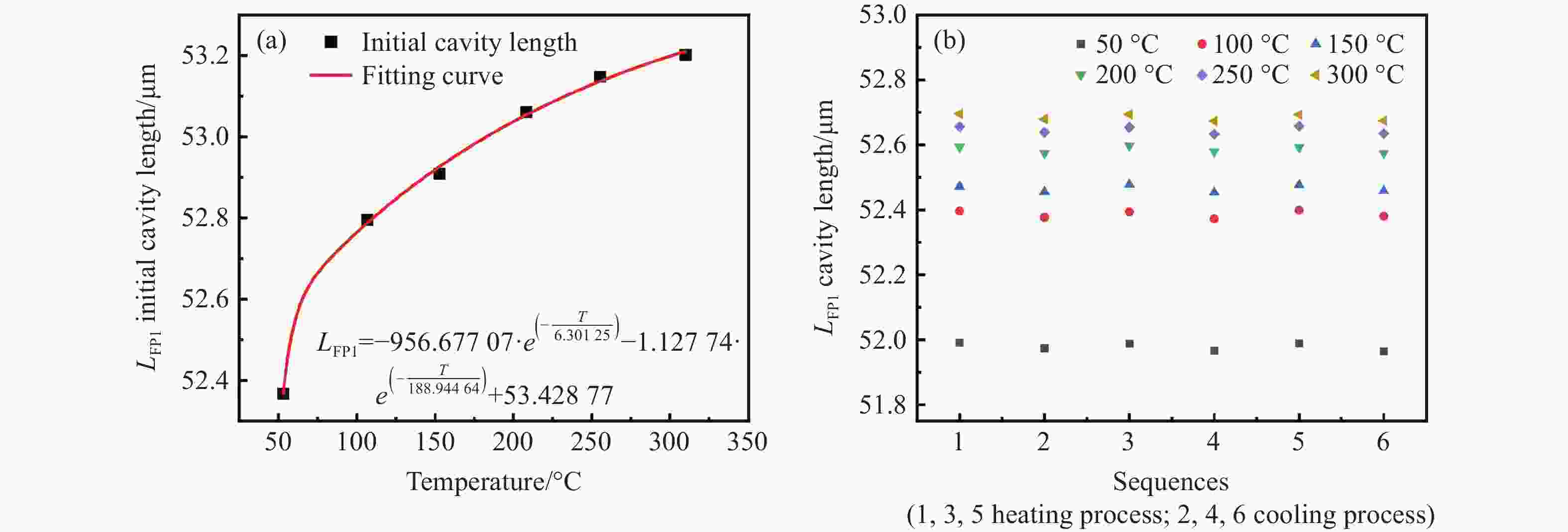

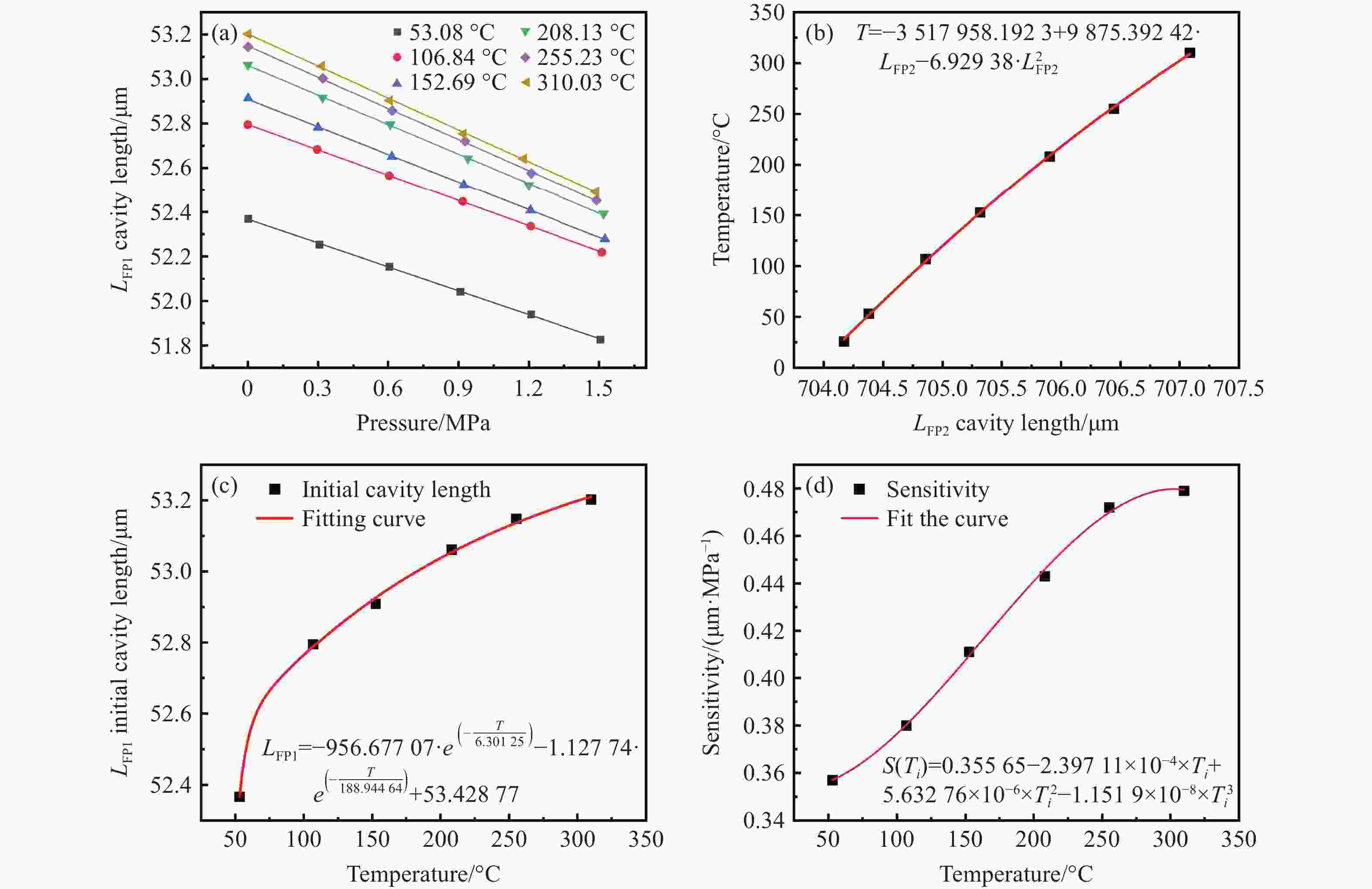

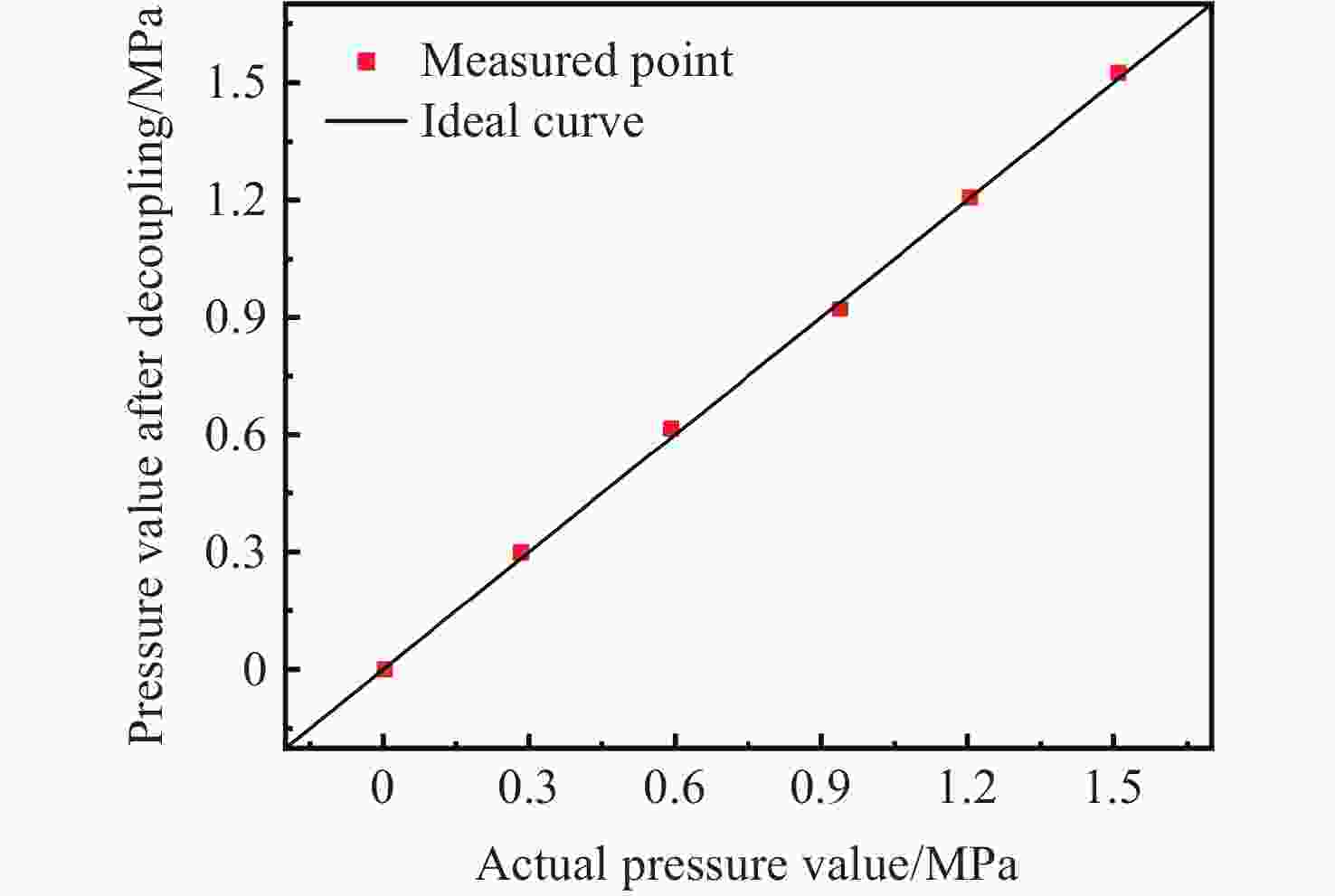

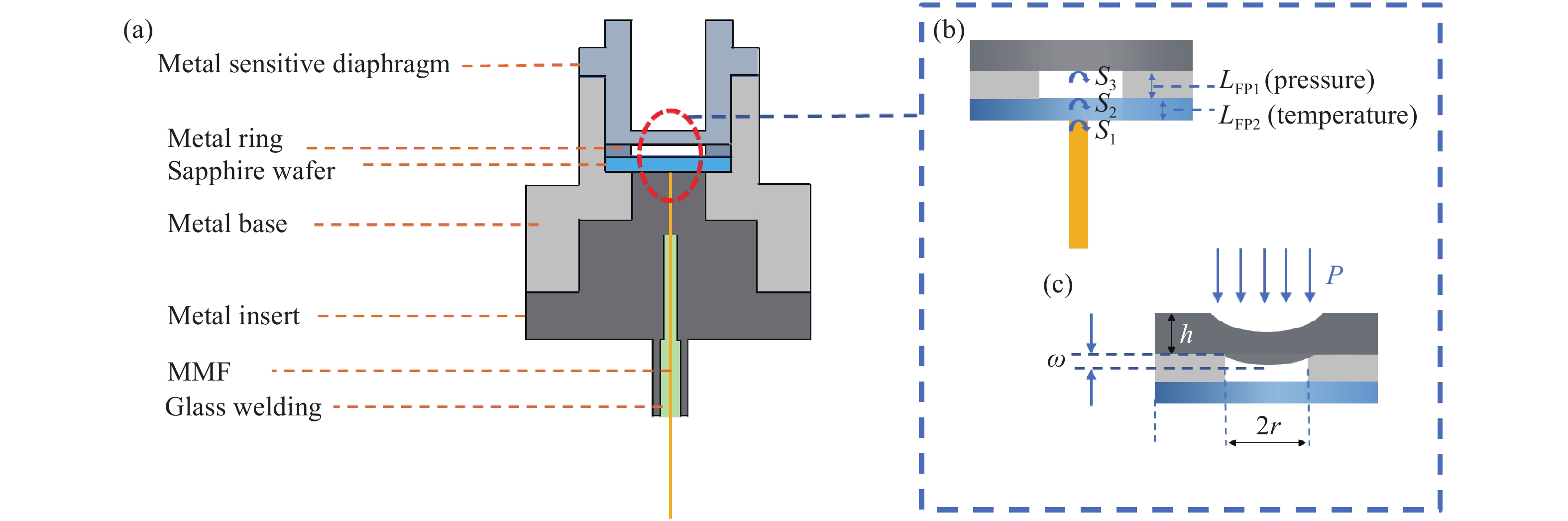

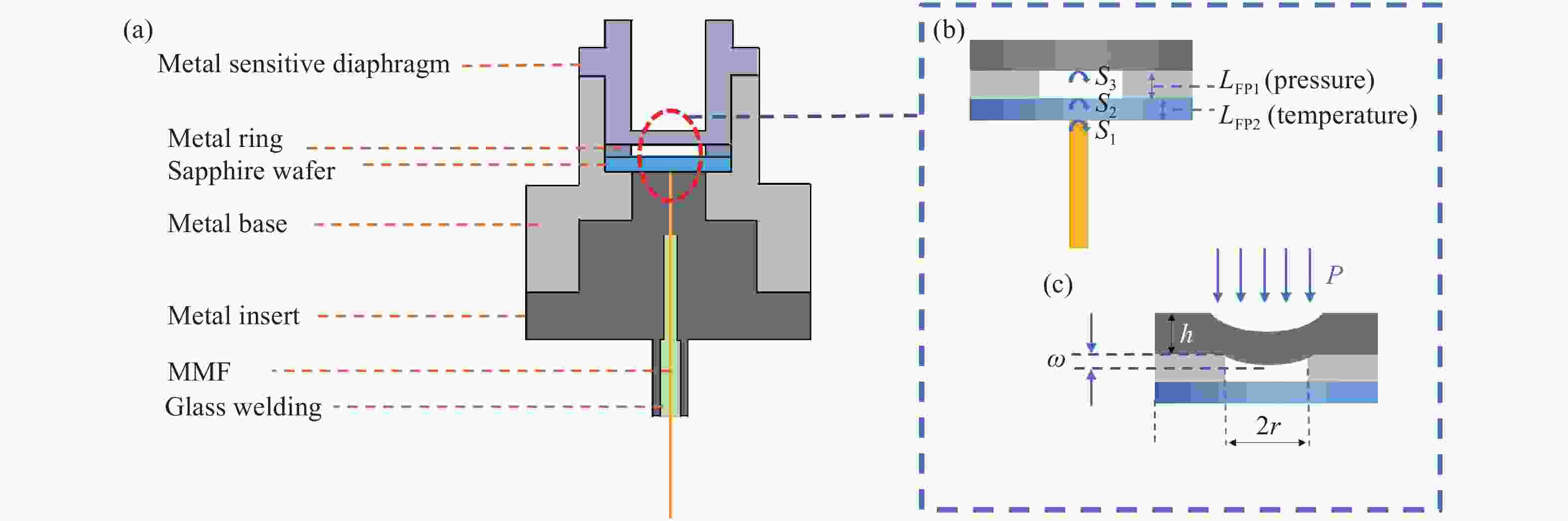

Abstract:A metal-sensitive diaphragm fiber optic pressure sensor with temperature compensation is developed for pressure monitoring in high-temperature environments, such as engine fuel systems, oil and gas wells, and aviation hydraulic systems. The sensor combines a metal-sensitive diaphragm and a sapphire wafer to form a temperature-pressure dual Fabry-Perot (FP) interference cavity. A cross-correlation signal demodulation algorithm and a temperature decoupling method are utilized to reduce the influence of temperature crosstalk on pressure measurement. Experimental results show that the maximum nonlinear error of the sensor pressure measurement is 0.75% full scale (FS) and 0.99% FS at room temperature and 300 °C, respectively, in a pressure range of 0−10 MPa and 0−1.5 MPa. The sensor’s pressure measurement accuracy is 1.7% FS when using the temperature decoupling method. The sensor exhibits good static pressure characteristics, stability, and reliability, providing an effective solution for high-temperature pressure monitoring applications.

-

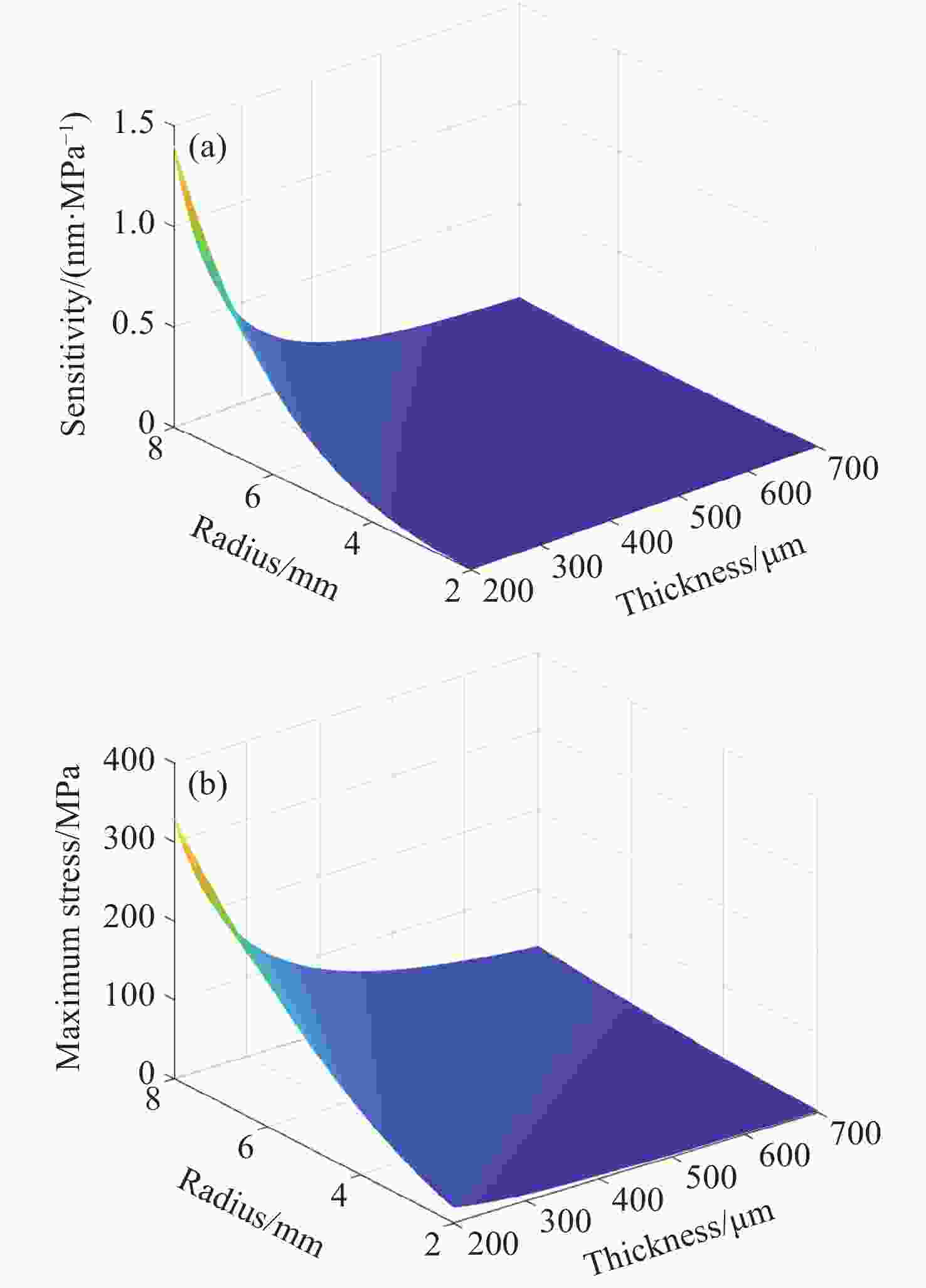

Table 1. Structural parameters of the metal-sensitive diaphragm

Parameters Symbol Value Diaphragm radius/mm r 4 Diaphragm thickness/mm h 0.5 Sensor pressure range/MPa P 0~10 Sensitivity/(μm·MPa−1) S 0.322 Diaphragm yield stress/MPa σ 170 -

[1] Wu D, Xu W H, Wang M G, et al. Biorecognition Elements and Signal Amplification Strategies in Electrochemical Biosensing[J]. Cinese journal of Analytical Chemistry, 2024, 52(11): 1629-1639. [2] REN J, WARD M, KINNELL P, et al. Plastic deformation of micromachined silicon diaphragms with a sealed cavity at high temperatures[J]. Sensors, 2016, 16(2): 204. doi: 10.3390/s16020204 [3] Ming-Yu LIU, Jing-Wei DAI. Hydrogels: Exploring Innovative Materials for the Future of Medicine[J]. Chinese Journal of Applied Chemistry, 2024, 41(10): 1511-1518. [4] MARQUES C A F, POSPORI A, SÁEZ-RODRÍGUEZ D, et al. Aviation fuel gauging sensor utilizing multiple diaphragm sensors incorporating polymer optical fiber Bragg gratings[J]. IEEE Sensors Journal, 2016, 16(15): 6122-6129. doi: 10.1109/JSEN.2016.2577782 [5] HAVRELAND A S, PETERSEN S D, ØSTERGAARD C, et al. Micro-fabricated all optical pressure sensors[J]. Microelectronic Engineering, 2017, 174: 11-15. doi: 10.1016/j.mee.2016.12.010 [6] JIANG X N, KIM K, ZHANG SH J, et al. High-temperature piezoelectric sensing[J]. Sensors, 2014, 14(1): 144-169. [7] MAILLAUD F F M, PECHSTEDT R D. High-accuracy optical pressure sensor for gas turbine monitoring[J]. Proceedings of SPIE, 2012, 8421: 8421AF. [8] YAO Z, LIANG T, JIA P G, et al. A high-temperature piezoresistive pressure sensor with an integrated signal-conditioning circuit[J]. Sensors, 2016, 16(6): 913. doi: 10.3390/s16060913 [9] WANG ZH F, CHEN J, WEI H M, et al. Sapphire Fabry–Perot interferometer for high-temperature pressure sensing[J]. Applied Optics, 2020, 59(17): 5189-5196. doi: 10.1364/AO.393353 [10] LIU J, JIA P G, FENG F, et al. MgO single crystals MEMS-based fiber-optic fabry–perot pressure sensor for harsh monitoring[J]. IEEE Sensors Journal, 2021, 21(4): 4272-4279. doi: 10.1109/JSEN.2020.3029152 [11] CAMPANELLA C E, CUCCOVILLO A, CAMPANELLA C, et al. Fibre bragg grating based strain sensors: review of technology and applications[J]. Sensors, 2018, 18(9): 3115. doi: 10.3390/s18093115 [12] SAHOTA J K, GUPTA N, DHAWAN D, et al. Fiber Bragg grating sensors for monitoring of physical parameters: a comprehensive review[J]. Optical Engineering, 2020, 59(6): 060901. [13] WANG Q, ZHANG L, SUN CH S, et al. Multiplexed fiber-optic pressure and temperature sensor system for down-hole measurement[J]. IEEE Sensors Journal, 2008, 8(11): 1879-1883. doi: 10.1109/JSEN.2008.2006253 [14] ZHAO Q CH, LIU X H, MA L, et al. Optical fiber pressure sensor based on F-P cavity in the oil and gas well[J]. IOP Conference Series: Earth and Environmental Science, 2017, 64: 012007. doi: 10.1088/1755-1315/64/1/012007 [15] CHENG L, TONG X L, WEI J CH, et al. Highly accurate differential pressure FBG gas flow sensor[J]. Optical Fiber Technology, 2023, 75: 103189. doi: 10.1016/j.yofte.2022.103189 [16] HU X S, SU D, QIAO X G, et al. Diaphragm-structured fiber-optic pressure sensors for oil downhole applications[J]. IEEE Sensors Journal, 2024, 24(9): 14270-14278. doi: 10.1109/JSEN.2024.3376085 [17] CHEN H B, CHEN Q Q, WANG W, et al. Fiber-optic, extrinsic Fabry-Perot interferometric dual-cavity sensor interrogated by a dual-segment, low-coherence Fizeau interferometer for simultaneous measurements of pressure and temperature[J]. Optics Express, 2019, 27(26): 38744-38758. doi: 10.1364/OE.382761 [18] SHAO ZH Q, WU Y L, SUN ZH Q, et al. Excellent repeatability, all-sapphire Fabry-Perot optical Pressure sensor based on wet etching and direct bonding for Harsh Environment Applications[J]. Optics Express, 2021, 29(13): 19831-19838. doi: 10.1364/OE.423753 [19] SHAO ZH Q, WU Y L, WANG SH, et al. All-sapphire-based fiber-optic pressure sensor for high-temperature applications based on wet etching[J]. Optics Express, 2021, 29(3): 4139-4146. doi: 10.1364/OE.417246 [20] ZHANG Y T, JIANG Y, YANG SH W, et al. Design of high-temperature vacuum fiber optic absolute pressure sensor for near-space vehicles[J]. Journal of Rocket Propulsion, 2024, 50(3): 118-123. (in Chinese). doi: 10.3969/j.issn.1672-9374.2024.03.013 [21] ZHANG Y T, JIANG Y, YANG SH W, et al. All-sapphire fiber-optic sensor for the simultaneous measurement of ultra-high temperature and high pressure. Optics Express, 2024, 32(8): 14826-14836. [22] LI J S, JIA P G, WANG J, et al. Silica-MEMS-based fiber-optic fabry-perot pressure sensor for high-temperature applications[J]. Acta Photonica Sinica, 2022, 51(6): 0606005. doi: 10.3788/gzxb20225106.0606005 [23] LIANG Y CH, CHEN H T. Design of diaphragm optical fiber pressure sensor based on F-P interference[J]. Journal of Hunan Post and Telecommunication College, 2021, 20(2): 1-3,35. (in Chinese). doi: 10.3969/j.issn.2095-7661.2021.02.001 [24] CHEN H B, LIU J, ZHANG X X, et al. High-order harmonic-frequency cross-correlation algorithm for absolute cavity length interrogation of white-light fiber-optic Fabry-Perot sensors[J]. Journal of Lightwave Technology, 2020, 38(4): 953-960. doi: 10.1109/JLT.2019.2948214 [25] ZHANG J Y, ZHANG X X, GUO Z L, et al. Fundamental and high-order cross-correlation combined demodulation method for absolute cavity length measurement of fiber-optic Fabry-Perot sensors[J]. Optical Engineering, 2022, 61(9): 096102. [26] KANG J W, CHEN H B, ZHANG X X, et al. Valley-positioning-assisted discrete cross-correlation algorithm for fast cavity length interrogation of fiber-optic Fabry-Perot sensors[J]. Measurement, 2022, 198: 11411. -

下载:

下载: