Structural optimization for the design of an ultra-lightweight SiC mirror with a diameter of 500 mm

-

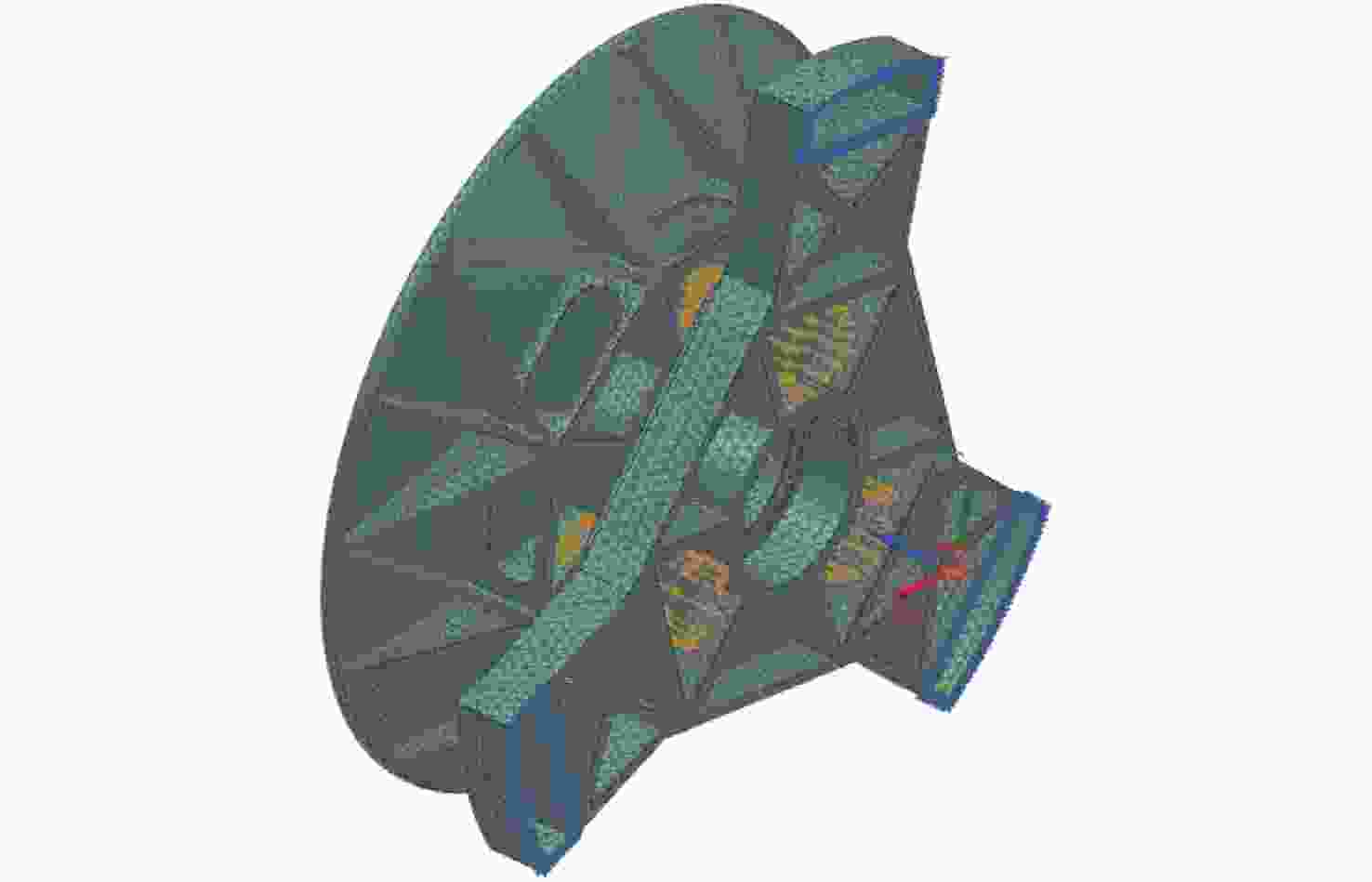

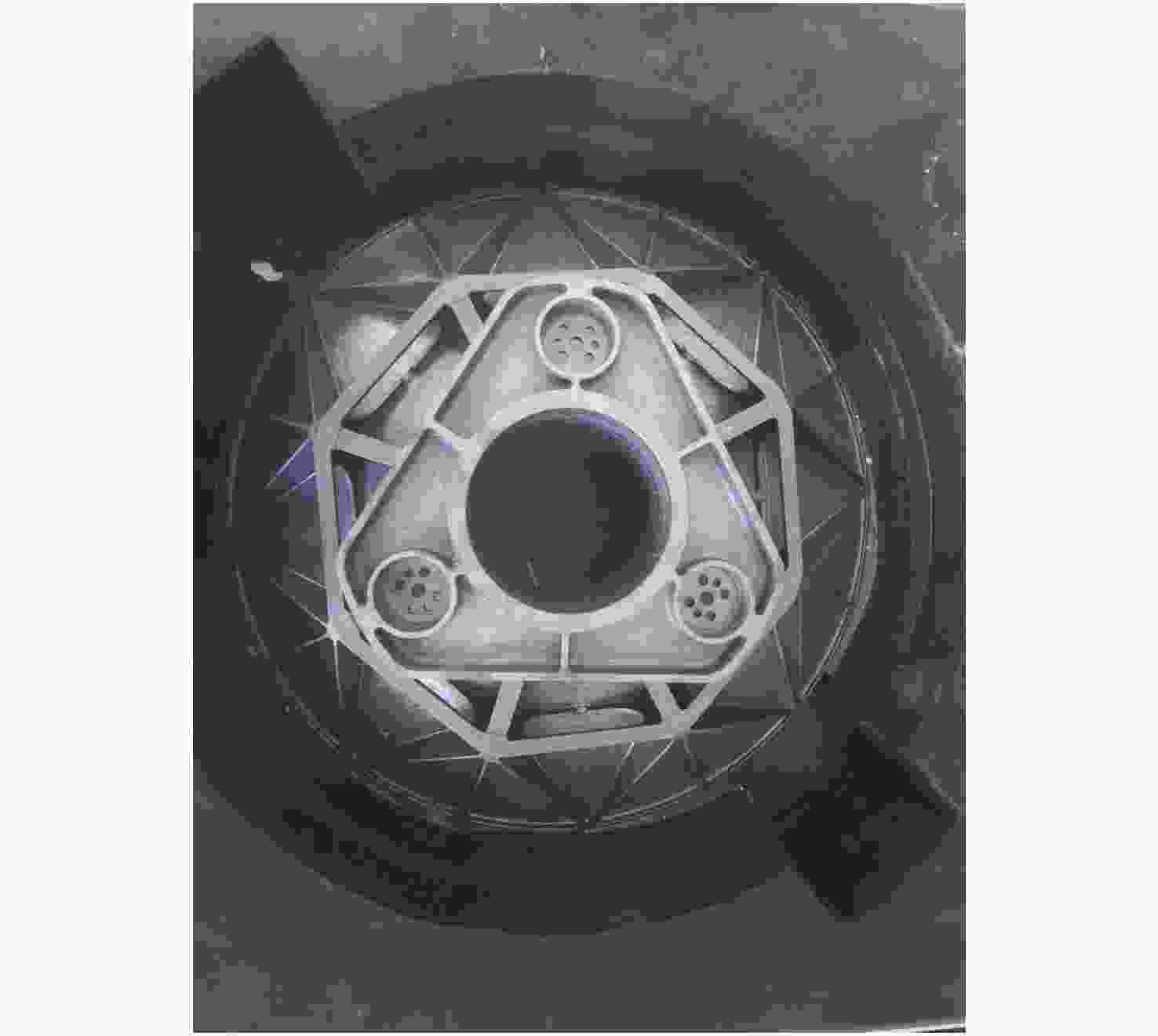

摘要: 为满足超轻量化光学系统近衍射极限的性能要求,利用先进的CAE仿真与现代高性能SiC制作工艺,研究Φ500 mm SiC反射镜的超轻量化反射镜结构。首先,通过对比现有反射镜常用材料和制作工艺,选取反射镜材料。针对圆形对称反射镜结构特性,采用全等刚度设计,结合集成优化方法,设计反射镜结构形式。同时,采用背部支撑结构,完成反射镜组件结构设计。仿真结果表明:主镜质量小于5 kg,面密度小于20 kg/m2。3个方向自重变形下及4 ℃温升工况下的面形误差(RMS值)均优于λ/50;主镜组件的一阶谐振频率不小于120 Hz,动态响应分析表明最薄弱处应力小于100 MPa。满足反射镜设计要求,轻量化效果显著,结构稳定可靠。Abstract: To meet the performance requirements of ultra-lightweight Φ500 mm-reflector optical system in near diffraction limit, the structure of the reflector is studied using advanced CAE simulation and modern high-performance SiC fabrication technology. Firstly, mirror materials were selected by comparing the common materials and manufacturing processes of existing mirrors. Then, with regards to the structural characteristics of circular symmetrical reflectors, the structure of proposed reflector was designed based on integrated optimization of the full stiffness method. Finally, the reflector assembly was designed with a back-support structure. The simulation results show that the mass of proposed primary mirror is less than 5 kg and the surface density is less than 20 kg/m2. The surface errors (RMS value) of the three directions of dead weight deformation at 4 ℃ temperature rise are less than λ/50. The first-order resonance frequency of the primary mirror assembly is no less than 120 Hz and the stress at the weakest point as measured by dynamic response analysis is less than 100 MPa. The structural optimization of the mirror meets its design requirements, with a remarkable lightweight effect and a structure that is both stable and reliable.

-

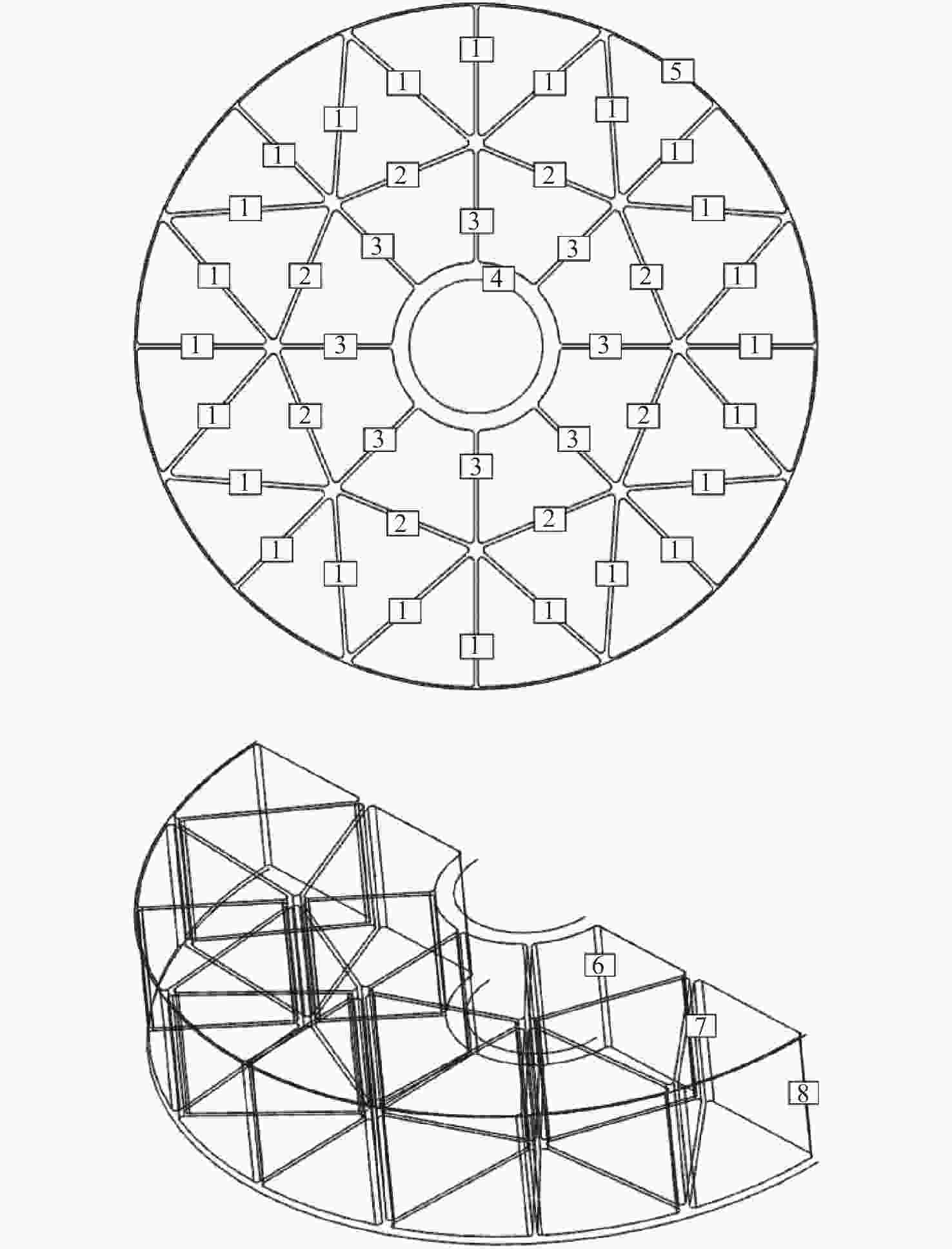

表 1 优化结果

Table 1. Optimized results

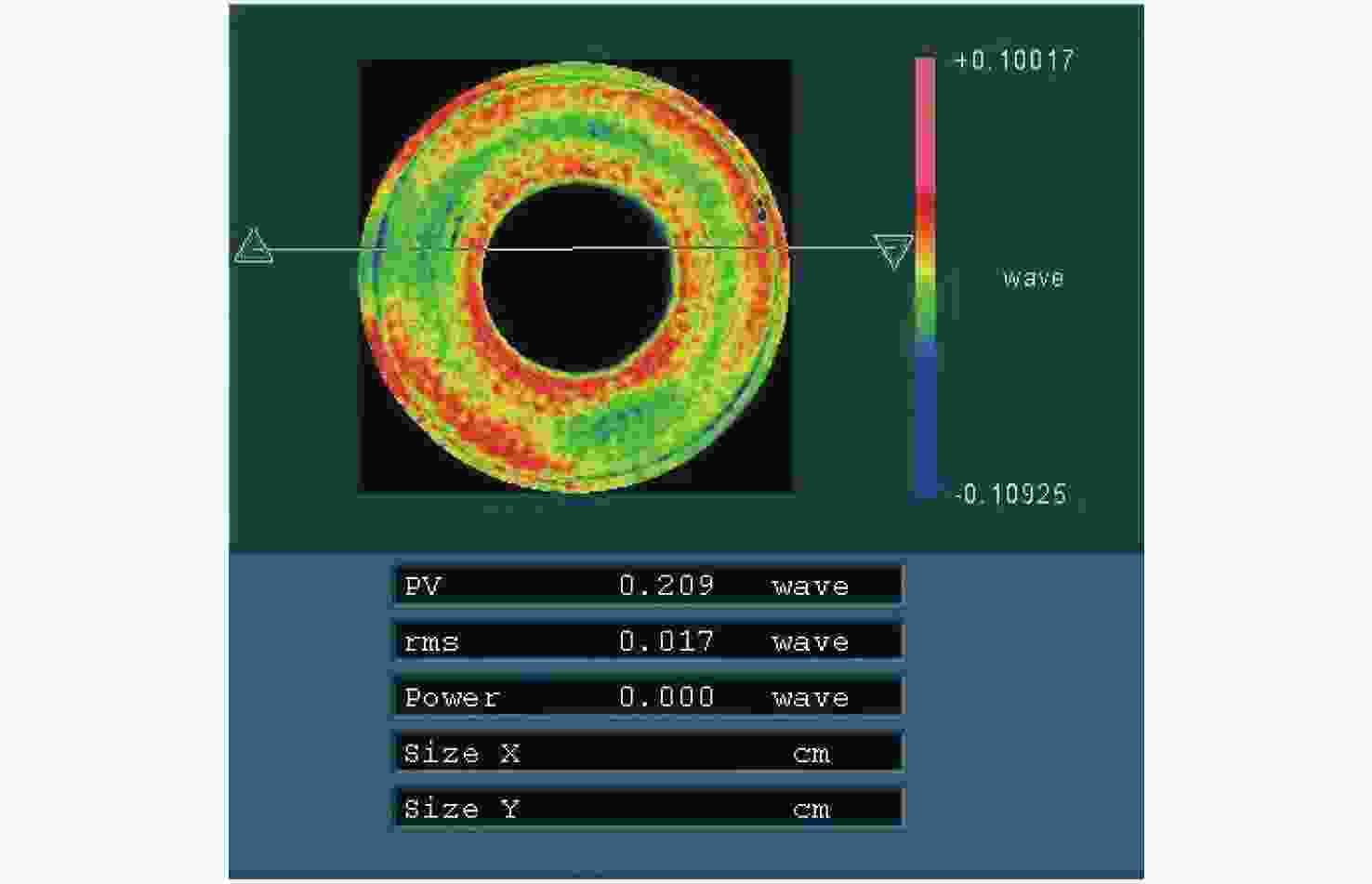

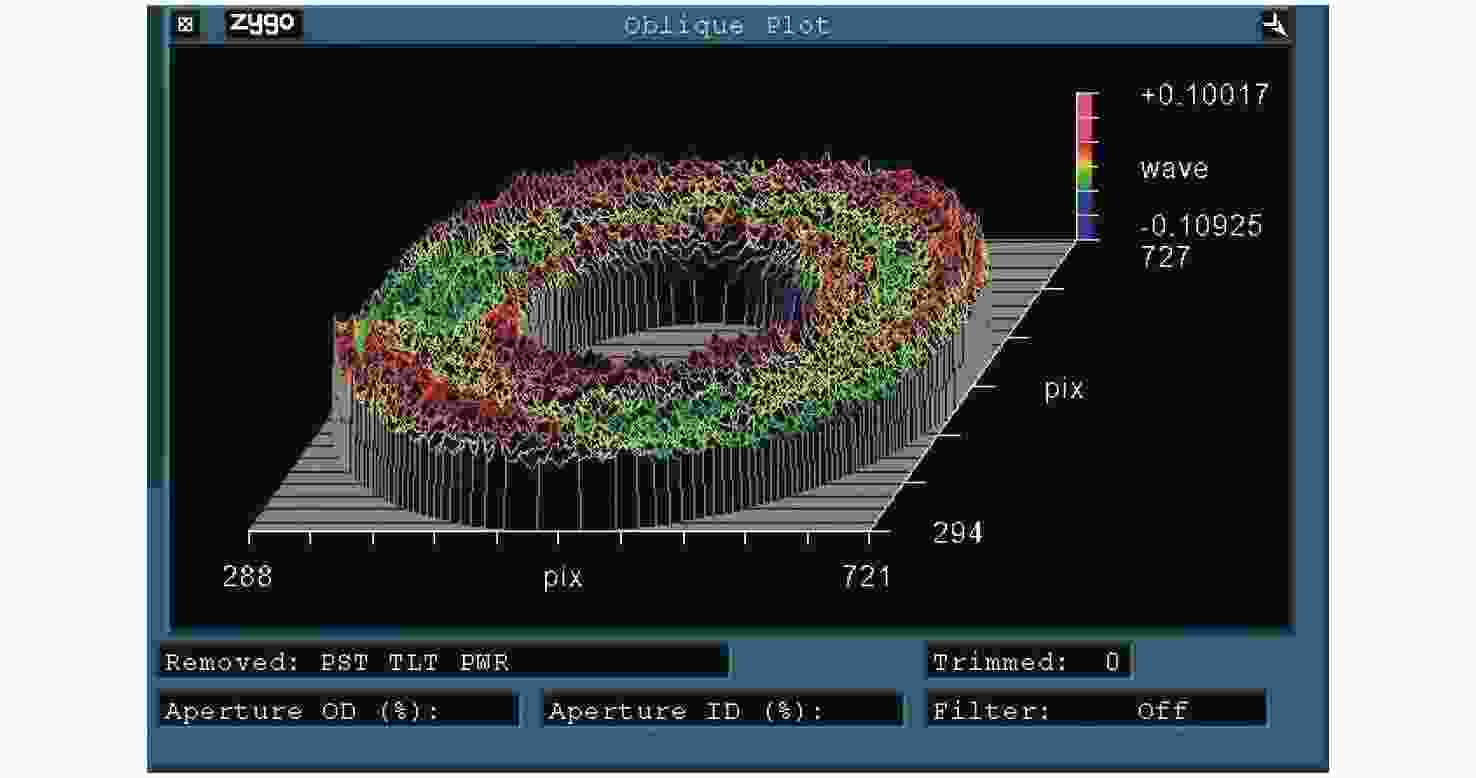

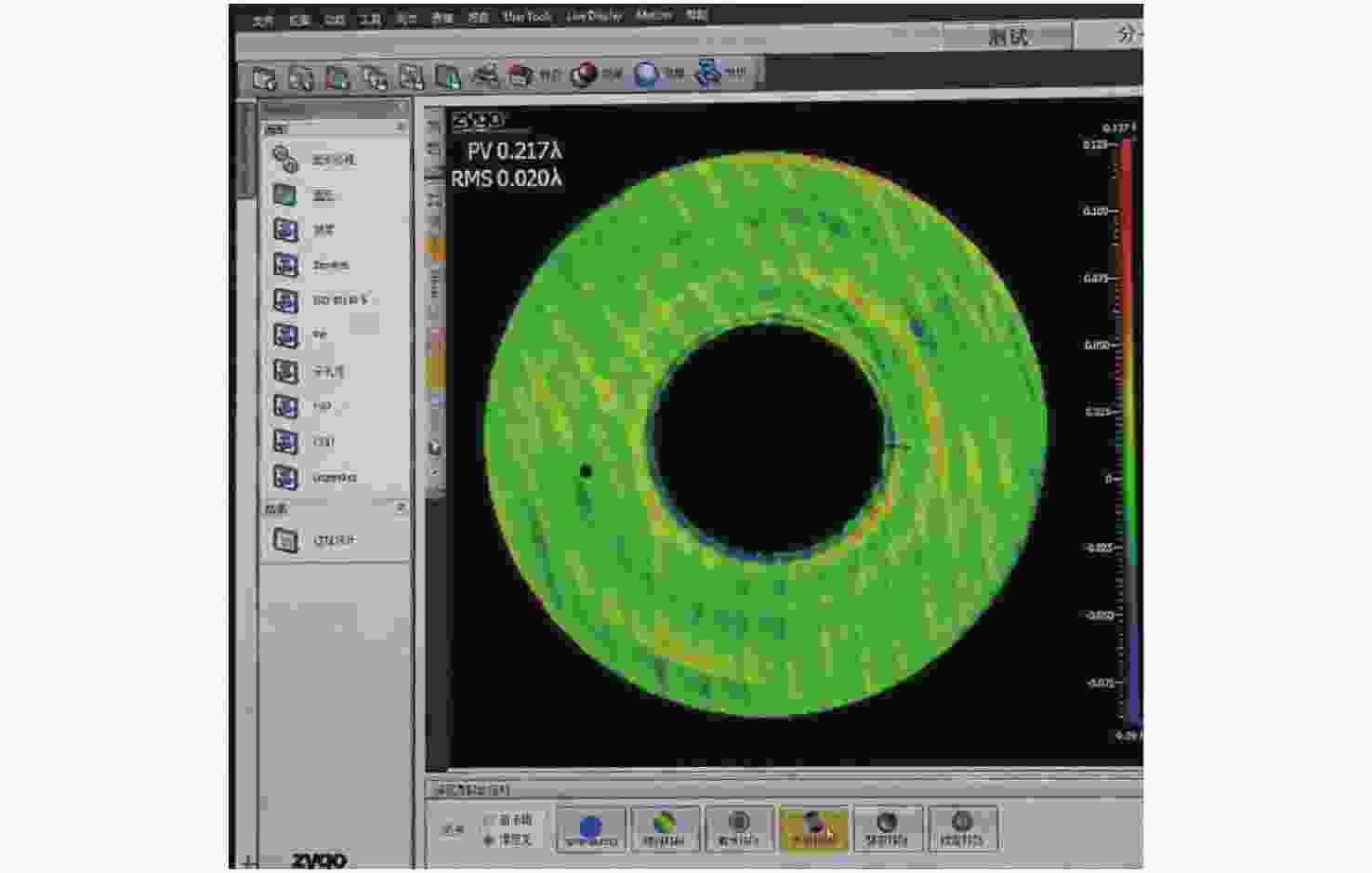

Variable Domain Original Optimized 1/mm 2≤(1)≤2.5 3 2 2/ mm 2≤(2)≤2.5 4 2 3/ mm 2≤(3)≤5 5 4 4/ mm 5≤(4)≤20 10 15 5/ mm 2≤(5)≤4 4 3 6/ mm −10≤(6)≤50 0 25 7/ mm −30≤(7)≤20 0 −6 8/ mm −50≤(8)≤20 0 −48 Mass/kg − 8.763 3.26 $ {\mathrm{R}\mathrm{M}\mathrm{S}}_{Y} $/nm − 5.436 6.368 $ {\mathrm{R}\mathrm{M}\mathrm{S}}_{Z} $/nm − 25.784 4.421 表 2 反射镜组件面形精度分析结果

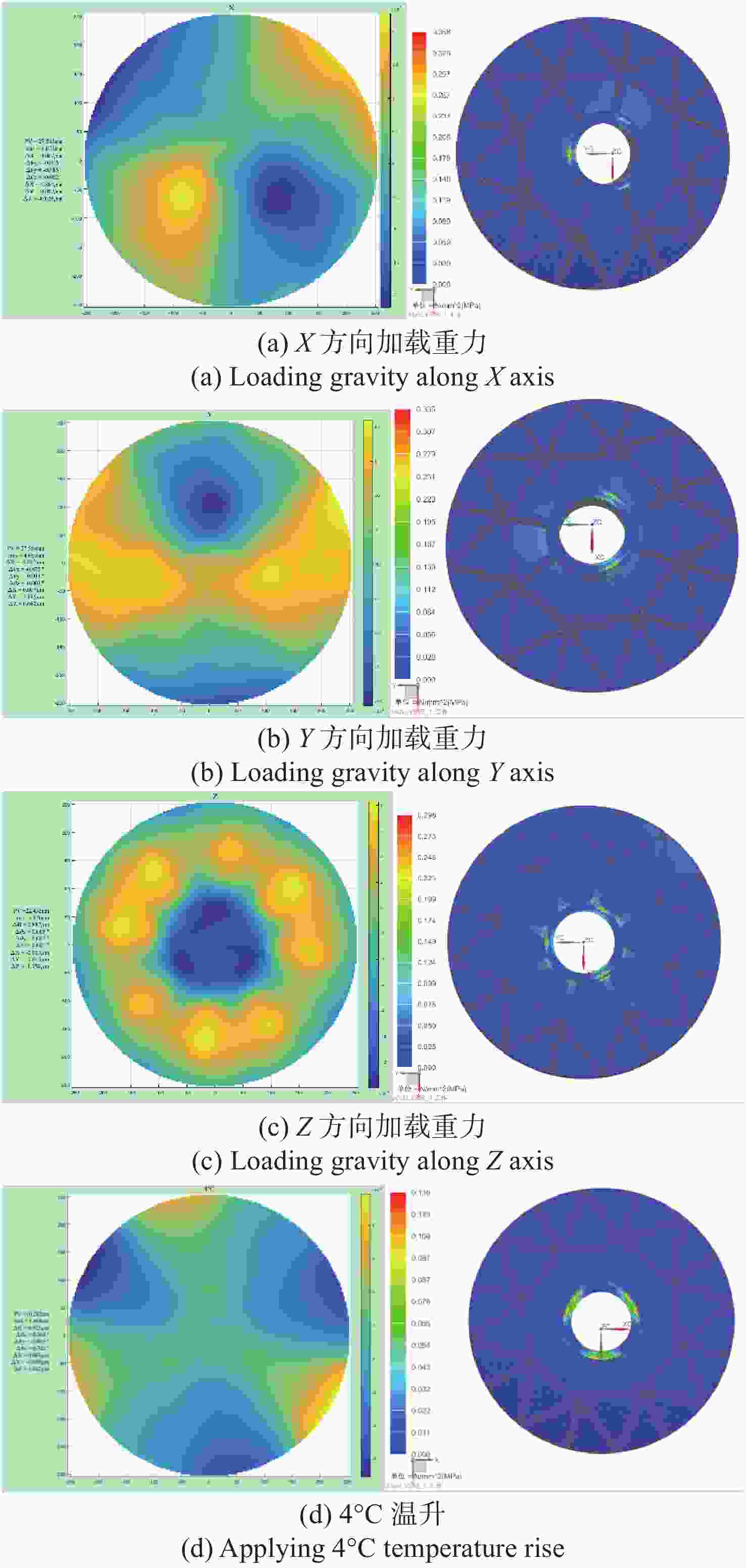

Table 2. Analysis results of mirror surface precision

载荷工况 PV/nm RMS/nm 转角/″ 线位移/μm 重力_X 27.565 4.672 0.886 4.864 重力_y 27.564 4.663 0.873 5.135 重力_Z 22.433 3.876 0.007 1.358 4 ℃温升 10.282 1.468 − − 表 3 主镜组件前6阶模态分析结果

Table 3. The first 6-order modal analysis results of primary mirror subassembly

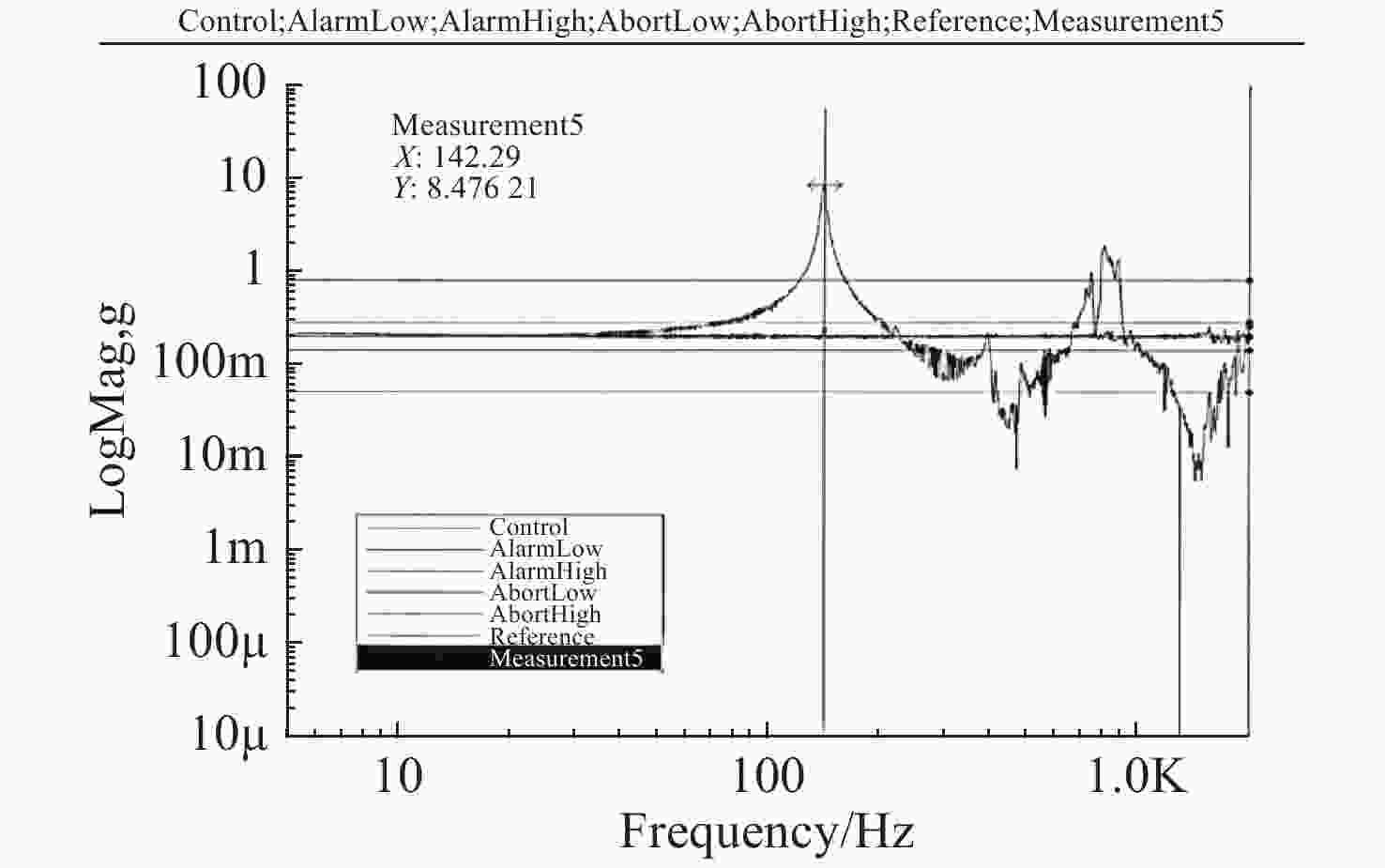

阶数 频率/Hz 振型 1 140.366 Rotate along Y-axis 2 145.386 Rotate along X-axis 3 218.985 Rotate along Z-axis 4 359.664 Move along Z-axis 5 478.532 Move along Y-axis 6 658.369 Move along X-axis 表 4 反射镜组件特性扫频结果

Table 4. Test results of characteristic frequency for mirror subassembly

Order Frequency/Hz Libration form 1 142.29 Y-axis 2 147.68 X-axis 3 320.10 Z-axis -

[1] 董斌超, 张舸. 超轻量化SiC反射镜的制备及性能[J]. 光学 精密工程,2015,23(8):2185-2191. doi: 10.3788/OPE.20152308.2185DONG B CH, ZHANG G. Fabrication and properties of ultra-lightweight SiC mirror[J]. Optics and Precision Engineering, 2015, 23(8): 2185-2191. (in Chinese) doi: 10.3788/OPE.20152308.2185 [2] 赵文兴, 张舸, 赵汝成, 等. 轻型碳化硅质反射镜坯体的制造工艺[J]. 光学 精密工程,2011,19(11):2609-2617. doi: 10.3788/OPE.20111911.2609ZHAO W X, ZHANG G, ZHANG R CH, et al. Fabrication of silicon carbide lightweight mirror blank[J]. Optics and Precision Engineering, 2011, 19(11): 2609-2617. (in Chinese) doi: 10.3788/OPE.20111911.2609 [3] 康健, 宣斌, 谢京江. 表面改性碳化硅基底反射镜加工技术现状[J]. 中国光学,2013,6(6):824-833.KANG J, XUAN B, XIE J J. Manufacture technology status of surface modified silicon carbide mirrors[J]. Chinese Optics, 2013, 6(6): 824-833. (in Chinese) [4] ROBICHAUD J L, SCHWARTZ J, LANDRY D, et al. Recent advances in reaction bonded silicon carbide optics and optical systems[J]. Proceedings of SPIE, 2005, 5868: 586802. doi: 10.1117/12.617406 [5] HADAWAY J B, ENG R, STAHL H P, et al. Cryogenic performance of lightweight SiC and C/SiC mirrors[J]. Proceedings of SPIE, 2004, 5487: 1018-1029. doi: 10.1117/12.552409 [6] 张德坷, 曹英斌, 刘荣军, 等. C/SiC复合材料空间光机结构的研究进展与展望[J]. 材料导报,2012,26(13):7-11. doi: 10.3969/j.issn.1005-023X.2012.13.002ZHANG D K, CAO Y B, LIU R J, et al. Progress and prospect of C/SiC composites used in space opto-mechanical structures[J]. Materials Review, 2012, 26(13): 7-11. (in Chinese) doi: 10.3969/j.issn.1005-023X.2012.13.002 [7] 徐宏, 关英俊. 大口径SiC轻量化反射镜组件的结构设计[J]. 红外与激光工程,2014,43(S1):83-88.XU H, GUAN Y J. Structural design of large aperture SiC mirror subassembly[J]. Infrared and Laser Engineering, 2014, 43(S1): 83-88. (in Chinese) [8] 陈洪达, 史婷婷, 刘晓华, 等. 空间反射镜的轻量化及支撑设计研究[J]. 红外与激光工程,2014,43(2):535-540. doi: 10.3969/j.issn.1007-2276.2014.02.037CHEN H D, SHI T T, LIU X H, et al. Lightweight and mounting design for primary mirror in space camera[J]. Infrared and Laser Engineering, 2014, 43(2): 535-540. (in Chinese) doi: 10.3969/j.issn.1007-2276.2014.02.037 [9] 袁健, 任建岳. 碳化硅反射镜轻量化结构的改进与优化[J]. 光子学报,2015,44(8):34-39.YUAN J, REN J Y. Improvement and optimization of lightweight structure for SiC reflective mirror[J]. Acta Photonica Sinica, 2015, 44(8): 34-39. (in Chinese) [10] 包奇红, 沙巍, 陈长征, 等. 中心支撑Φ610 mm圆形主镜的超轻量化设计[J]. 光子学报,2016,45(9):0912007. doi: 10.3788/gzxb20164509.0912007BAO Q H, SHA W, CHEN CH ZH, et al. Ultra-lightweight design of Φ610 mm circular primary mirror supported in centre[J]. Acta Photonica Sinica, 2016, 45(9): 0912007. (in Chinese) doi: 10.3788/gzxb20164509.0912007 [11] 袁健, 沙巍, 陈长征, 等. 长条形反射镜的集成优化设计[J]. 光电工程,2015,42(6):85-89, 94. doi: 10.3969/j.issn.1003-501X.2015.06.015YUAN J, SHA W, CHEN CH ZH, et al. Integrated optimization design of rectangular reflective mirror[J]. Opto-Electronic Engineering, 2015, 42(6): 85-89, 94. (in Chinese) doi: 10.3969/j.issn.1003-501X.2015.06.015 -

下载:

下载: