Variable image distance bending using an elliptical bending mechanism with a constant cross-section mirror

-

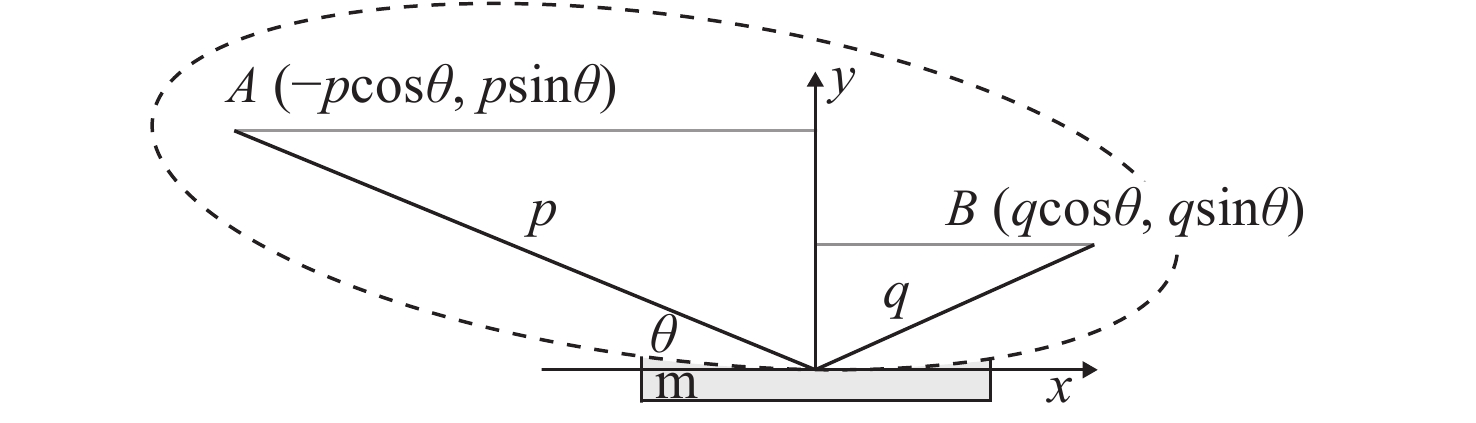

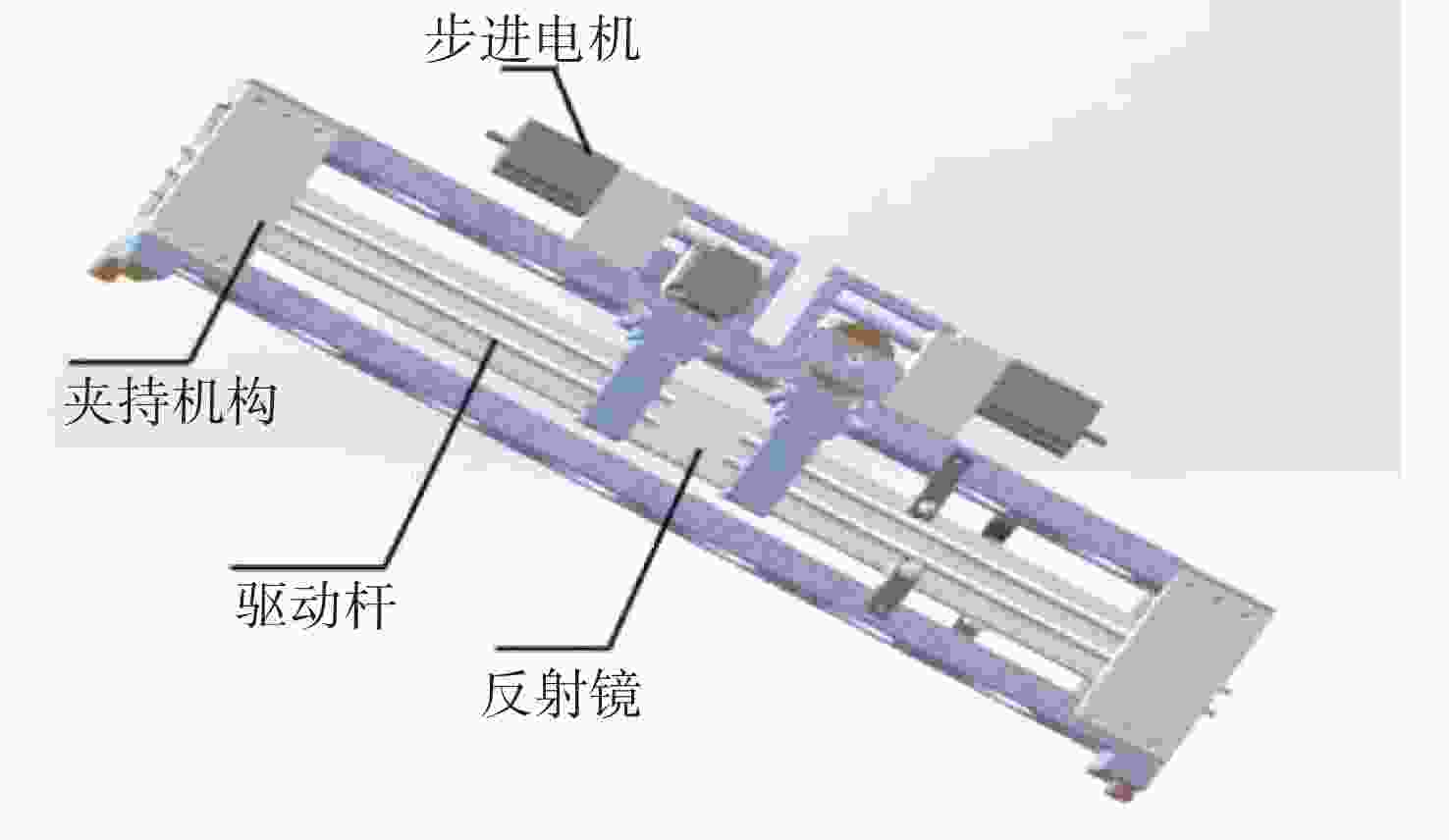

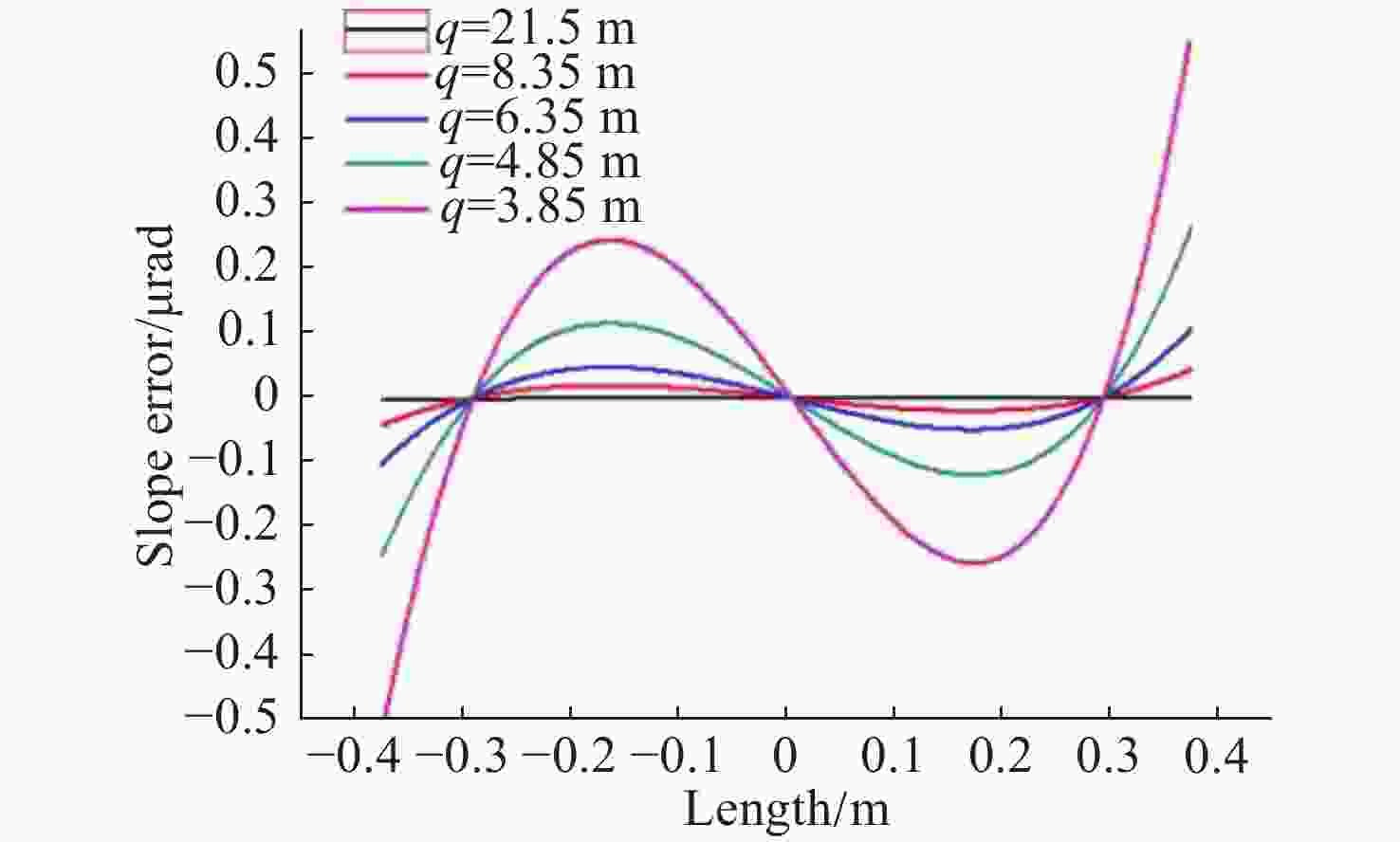

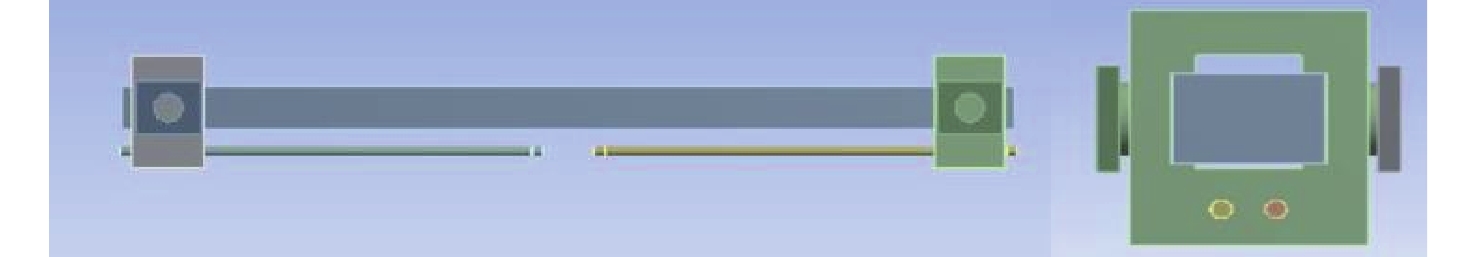

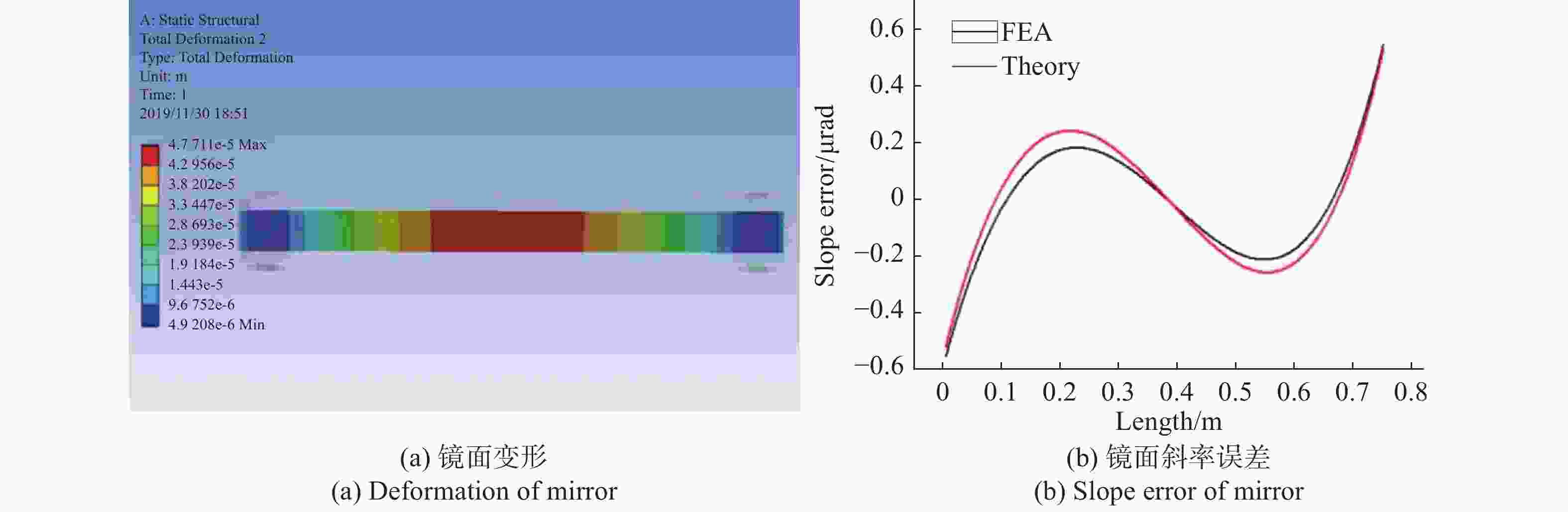

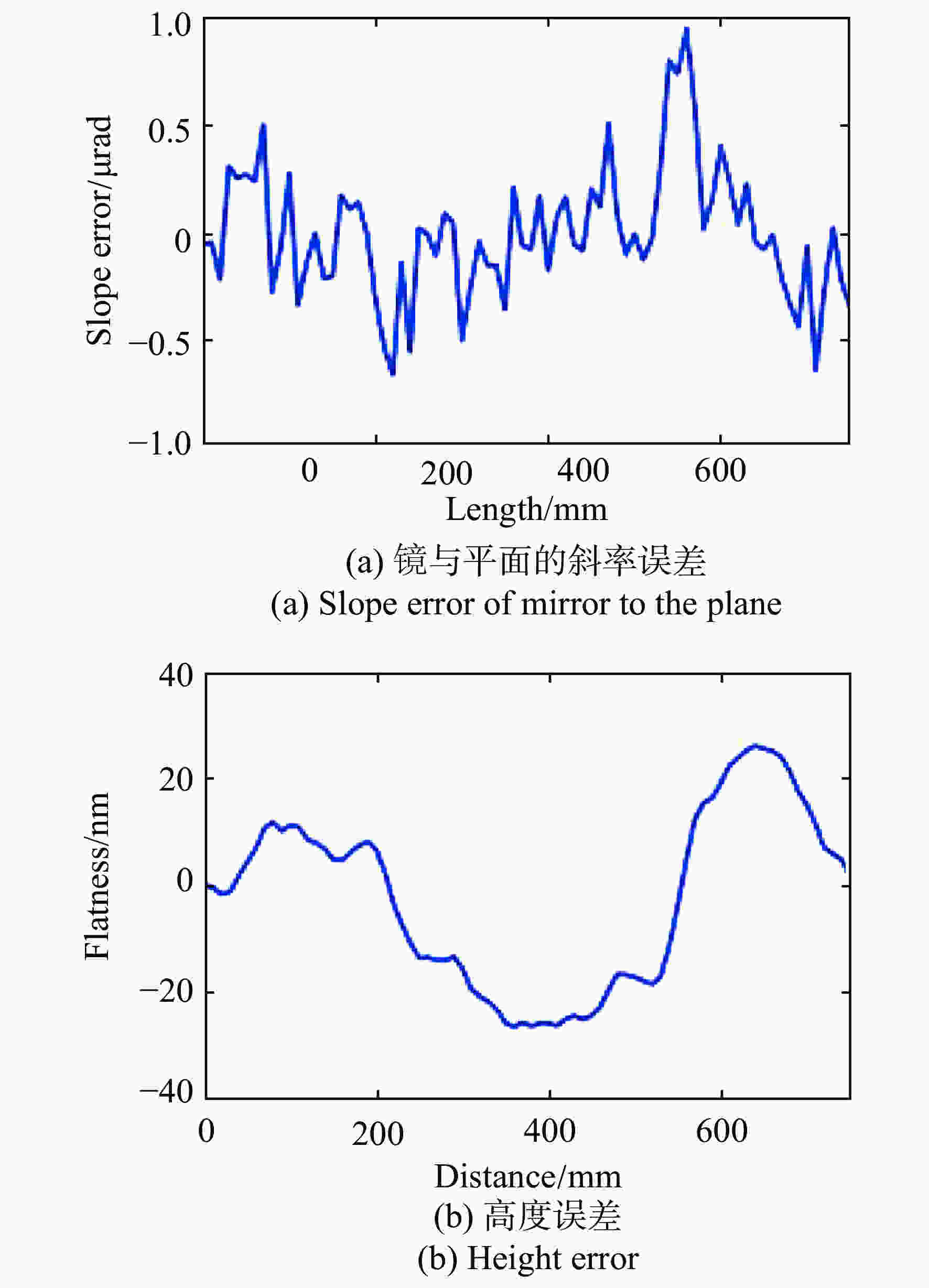

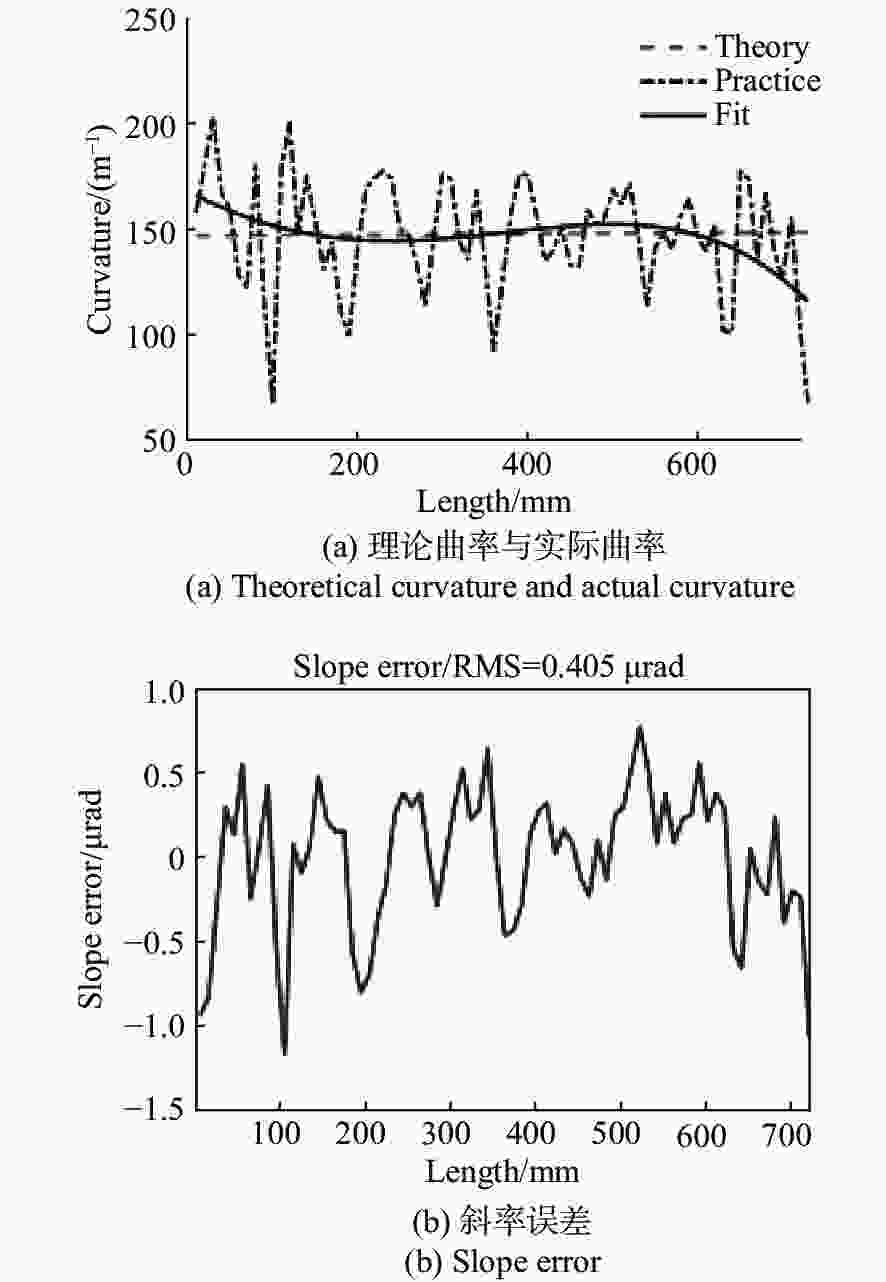

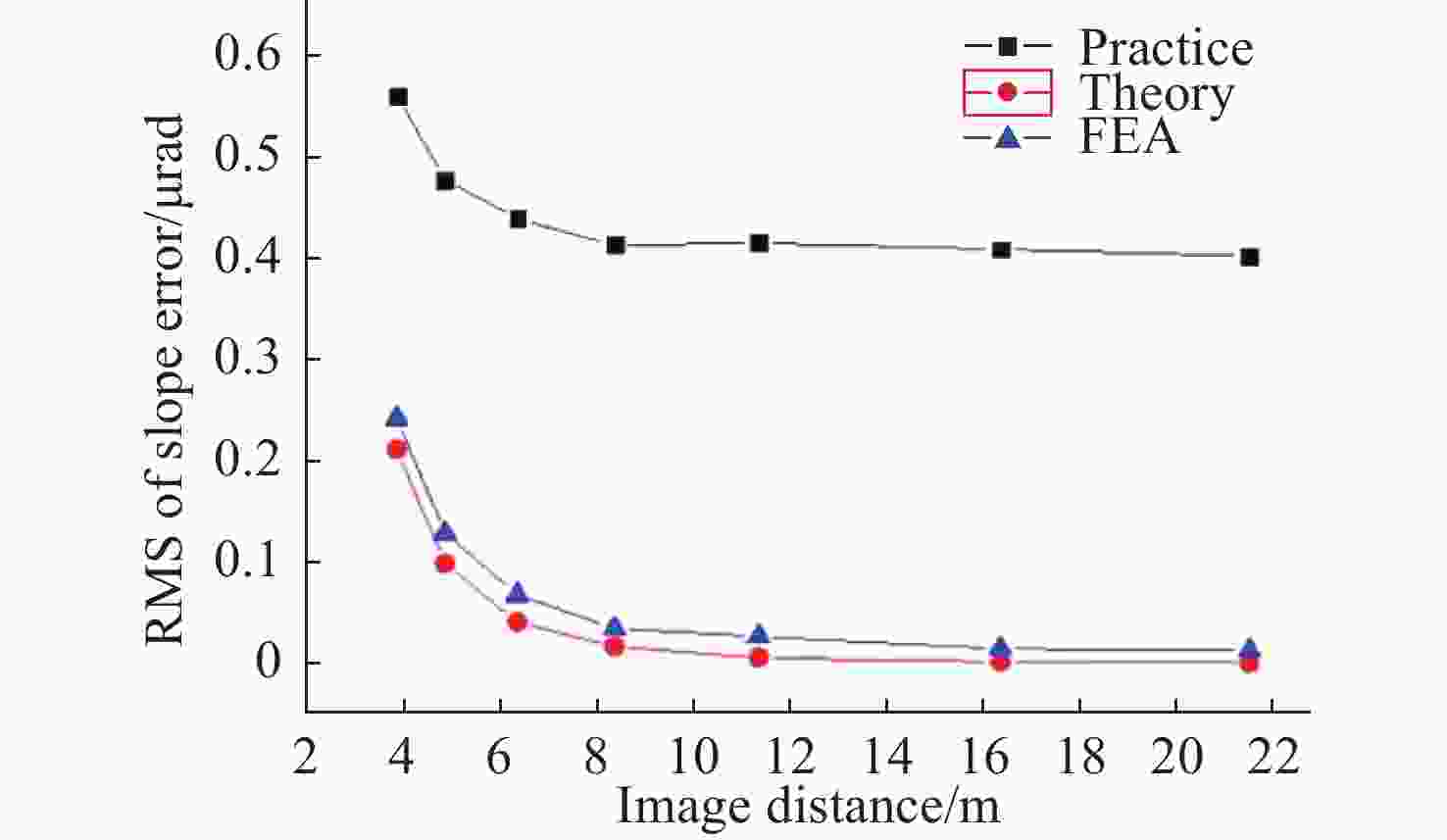

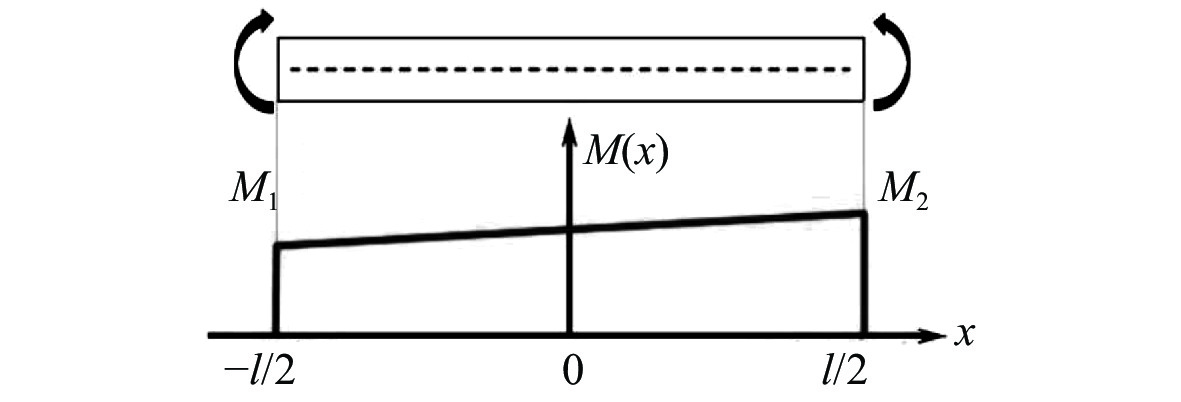

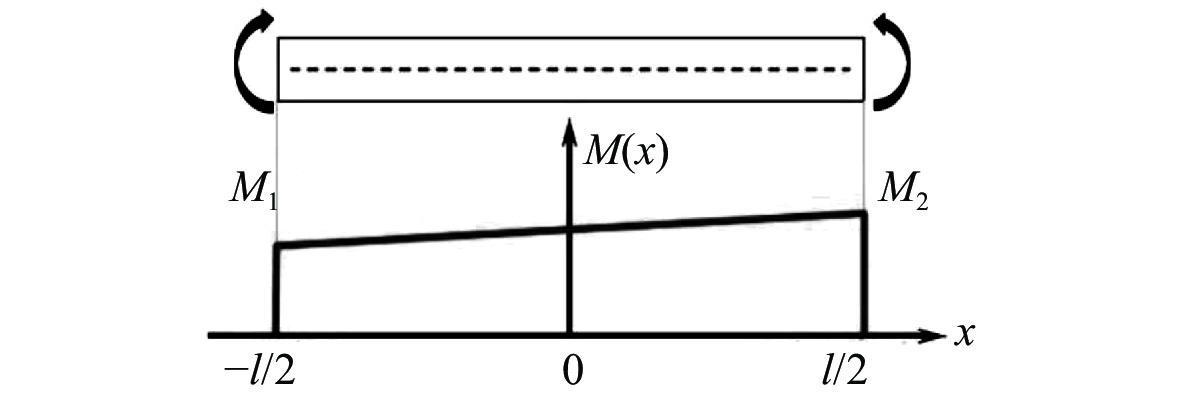

摘要: 针对新设计的等截面反射镜椭圆压弯机构在固定物距(即反射镜在光路中位置不变)的情况下,研究了实现大范围像距调整(即样品位置发生改变)时镜面面形误差等问题。通过理论分析并借助有限元分析软件计算等截面平面镜压弯至不同(反射点处像距不同)椭圆柱面时的理论斜率误差,最后对椭圆压弯机构样机进行了实际压弯测试。实验结果与计算分析均表明:保持物距、掠入射角不变,压弯镜面与理想椭圆柱面之间的斜率误差会随着像距的减小而增大,并且像距越小,镜面斜率误差的增加速度越大。实验测得在反射镜面初始斜率误差为0.397 μrad的情况下,全部像距范围(21.5~3.8 m)内压弯镜面的实际斜率误差在0.402~0.560 μrad之间,重复精度为0.051 μrad,均满足上海光源光束线的设计要求。本文研究证明了使用等截面反射镜压弯机构进行椭圆柱面压弯可以实现聚焦镜工作像距在大范围内的连续调节。Abstract: In this paper, the surface shape error of latest elliptical bending mechanism with a constant cross-section mirror is studied when the object distance is fixed (when the position of the mirror in the light path is invariable) and the image distance is adjusted drastically (when the position of the sample is changed). Based on theoretical analysis and the finite element analysis, theoretical slope error is calculated when it is caused by bending a mirror with a width equal to an elliptical cylinder with a different shape (different image distances at the reflection point). Then, a bending experiment of a prototype of the elliptical bending mechanism is conducted. Experimental results and analysis indicate that the slope error between the bending mirror and an ideal elliptic cylinder will increase with a decrease in image distance, and the slope error of the mirror will increase more quickly as the image distance is shortened. When the initial slope error of the reflecting mirror is 0.397 μrad, the slope error of the bent mirror in the whole range of image distance (21.5~3.8 m) is 0.402~0.560 μrad and the repeatable accuracy is 0.051 urad, which meets the design requirements of the beamline of the Shanghai Synchrotron Radiation Facility (SSRF). It is proven that in elliptically bending mirrors, continuous adjustment of the image distance from the focusing mirror can be achieved by using a bending mechanism with constant cross-section mirror.

-

Key words:

- synchrotron radiation /

- bending mechanism /

- elliptical cylindrical mirror /

- slope error

-

表 1 椭圆压弯反射镜的参数及设计指标

Table 1. Parameters and design indexes of elliptical bending mirror

材料 聚焦镜尺寸/mm 镜面有效尺寸/mm 自身斜率误差/μrad 单晶硅 1000×70×50 700×20 0.4 物距p/m 掠入射角θ/mrad 像距q/m 要求压完后

斜率误差/μrad26.5 3.5 21.5~3.8 <0.60 表 2 压弯部件材料属性

Table 2. Material properties of the bending mechanism,s parts

材料 泊松比 杨氏模量/GPa 密度/kg·m−3 Si 0.3 169 2330 结构钢 Structural steel (OCr18Ni9) 0.33 206 7800 轴承钢 Beering steel (Gcr15) 0.3 208 7800 表 3 不同像距下镜面斜率误差RMS值的有限元计算结果

Table 3. FEA results of RMS values of slope error at different image distances

理论像距/m 斜率误差RMS 左右驱动杆位移/mm 21.5 0.013 3.96 4.27 16.5 0.015 4.53 5.18 11.5 0.027 5.57 7.32 8.5 0.035 6.10 7.93 6.5 0.078 7.42 8.96 4.8 0.128 9.05 12.83 3.8 0.242 10.10 17.20 表 4 实际压弯测试结果

Table 4. Actual bending experiment results

理论像距/m 斜率误差RMS/μrad 重复精度/μrad 驱动杆位移/mm 21.5 0.402 0.011 4.13,4.30 16.5 0.409 0.021 4.65,5.05 11.5 0.415 0.013 5.67,6.30 8.5 0.413 0.021 6.35,7.80 6.5 0.439 0.026 7.70,9.55 4.8 0.478 0.023 9.70,13.10 3.8 0.560 0.051 10.55,17.60 -

[1] 马礼敦. 同步辐射装置——上海光源及其应用[J]. 理化检验-物理分册,2009,45(11):717-723.MA L D. Shanghai synchrotron radiation facility and its application[J]. Physical Testing and Chemical Analysis (Part A:Physical Testing) , 2009, 45(11): 717-723. (in Chinese) [2] 卢启鹏, 高飒飒, 彭忠琦. 同步辐射水平偏转压弯镜面形误差分析与补偿[J]. 光学精密工程,2011,19(11):2644-2650. doi: 10.3788/OPE.20111911.2644LU Q P, GAO S S, PENG ZH Q. Analysis and compensation of slope error for synchrotron radiation horizontal deflected mirror[J]. Optics and Precision Engineering, 2011, 19(11): 2644-2650. (in Chinese) doi: 10.3788/OPE.20111911.2644 [3] 秦超, 薛松, 王楠, 等. 压弯椭圆柱面镜的有限元分析[J]. 核技术,2018,41(1):010101. doi: 10.11889/j.0253-3219.2018.hjs.41.010101QIN CH, XUE S, WANG N, et al. The finite element analysis of the bent elliptical cylindrical mirror[J]. Nuclear Techniques, 2018, 41(1): 010101. (in Chinese) doi: 10.11889/j.0253-3219.2018.hjs.41.010101 [4] 金利民, 罗红心, 王劼, 等. 双压电片镜在同步辐射光源光学系统中的应用[J]. 中国光学,2017,10(6):699-707. doi: 10.3788/co.20171006.0699JIN L M, LUO H X, WANG J, et al. Application of bimorph mirror in the optical system of synchrotron radiation light source[J]. Chinese Optics, 2017, 10(6): 699-707. (in Chinese) doi: 10.3788/co.20171006.0699 [5] 程光宇, 黄智超, 王克逸, 等. 同步辐射聚焦镜压弯机构设计与面形误差分析[J]. 应用光学,2019,40(1):120-126.CHENG G Y, HUANG ZH CH, WANG K Y, et al. Design and surface shape error analysis of synchronous radiation focusing mirror bending mechanism[J]. Journal of Applied Optics, 2019, 40(1): 120-126. (in Chinese) [6] 吕清涛, 薛松, 彭忠琦, 等. 拉杆式压弯聚焦镜组件线性与接触非线性方法的比较[J]. 光学精密工程,2010,18(8):1842-1848.LÜ Q T, XUE S, PENG ZH Q, et al. Comparison on linear and contact nonlinear analysis methods of pull-rod bent focusing mirror assembly[J]. Optics and Precision Engineering, 2010, 18(8): 1842-1848. (in Chinese) [7] 黄智超, 程建高, 李飞, 等. 同步辐射压弯镜重力补偿方法[J]. 强激光与粒子束,2018,30(8):085102. doi: 10.11884/HPLPB201830.180066HUANG ZH CH, CHENG J G, LI F, et al. Gravity compensation for bent mirror of synchrotron radiation[J]. High Power Laser and Particle Beams, 2018, 30(8): 085102. (in Chinese) doi: 10.11884/HPLPB201830.180066 [8] 毛成文, 余笑寒, 肖体乔. 变宽度压弯椭圆柱面聚焦镜的光学参数可调性[J]. 核技术,2009,32(5):333-336. doi: 10.3321/j.issn:0253-3219.2009.05.003MAO CH W, YU X H, XIAO T Q. Tunability of optical parameters of width-variable bent elliptical microfocus mirror[J]. Nuclear Techniques, 2009, 32(5): 333-336. (in Chinese) doi: 10.3321/j.issn:0253-3219.2009.05.003 [9] PADMORE H A, HOWELLS M R, IRICK S C, et al. New schemes for producing high-accuracy elliptical x-ray mirrors by elastic bending[J]. Proceedings of SPIE, 1996, 2856: 145-156. doi: 10.1117/12.259867 [10] NISTEA I T, ALCOCK S G, KRISTIANSEN P, et al. Long, elliptically bent, active X-ray mirrors with slope errors <200 nrad[J]. Journal of Synchrotron Radiation, 2017, 24(3): 615-621. doi: 10.1107/S1600577517005422 [11] 徐乐, 张春雷, 代雷, 等. 高精度非回转对称非球面加工方法研究[J]. 中国光学,2016,9(3):364-370. doi: 10.3788/co.20160903.0364XU L, ZHANG CH L, DAI L, et al. Research on manufacturing method of non-rotationally symmetrical aspheric surface with high accuracy[J]. Chinese Optics, 2016, 9(3): 364-370. (in Chinese) doi: 10.3788/co.20160903.0364 [12] 闫力松, 杨甬英, 马冬林, 等. 长条形镜面面形拟合技术研究[J]. 中国光学,2018,11(6):1011-1016. doi: 10.3788/co.20181106.1011YAN L S, YANG Y Y, MA D L, et al. Surface fitting technology of rectangular mirror[J]. Chinese Optics, 2018, 11(6): 1011-1016. (in Chinese) doi: 10.3788/co.20181106.1011 [13] 秦超. 同步辐射椭圆柱面压弯镜机构的研究[D]. 上海: 中国科学院上海应用物理研究所, 2018.QIN CH. Research on synchrotron radiation elliptic cylinder mirror bender[D]. Shanghai: Shanghai Institute of Applied Physics, Chinese Academy of Sciences, 2018. (in Chinese) [14] HOWELLS M R, CAMBIE D, IRICK S C, et al. Theory and practice of elliptically bent x-ray mirrors[J]. Optical Engineering, 2000, 39(10): 2748-2762. doi: 10.1117/1.1289879 [15] 周泗忠, 杨晓许, 时惠霞. 压弯聚焦镜自重的平衡[J]. 核技术,2005,28(3):180-182. doi: 10.3321/j.issn:0253-3219.2005.03.004ZHOU S ZH, YANG X X, SHI H X. Study of gravity compensation of bent focusing mirror[J]. Nuclear Techniques, 2005, 28(3): 180-182. (in Chinese) doi: 10.3321/j.issn:0253-3219.2005.03.004 [16] 卢启鹏, 彭忠琦. 压弯机构在同步辐射光束线中的应用[J]. 光机电信息,2011,28(6):8-13. doi: 10.3788/OMEI20112806.0008LU Q P, PENG ZH Q. Application of bender in synchrotron radiation beamline[J]. OME Information, 2011, 28(6): 8-13. (in Chinese) doi: 10.3788/OMEI20112806.0008 [17] MAO CH W, JIANG H, HE Y, et al. Compensation for gravitational sag of bent mirror[J]. Nuclear Instruments and Methods in Physics Research Section A:Accelerators,Spectrometers,Detectors and Associated Equipment, 2017, 853: 20-26. [18] 孙福权, 傅远, 祝万钱, 等. 压弯镜系统自重平衡多点调节方法的研究[J]. 核技术,2011,34(4):246-250.SUN F Q, FU Y, ZHU W Q, et al. A study on multi-point gravity compensation of mirror bending system[J]. Nuclear Techniques, 2011, 34(4): 246-250. (in Chinese) -

下载:

下载: