-

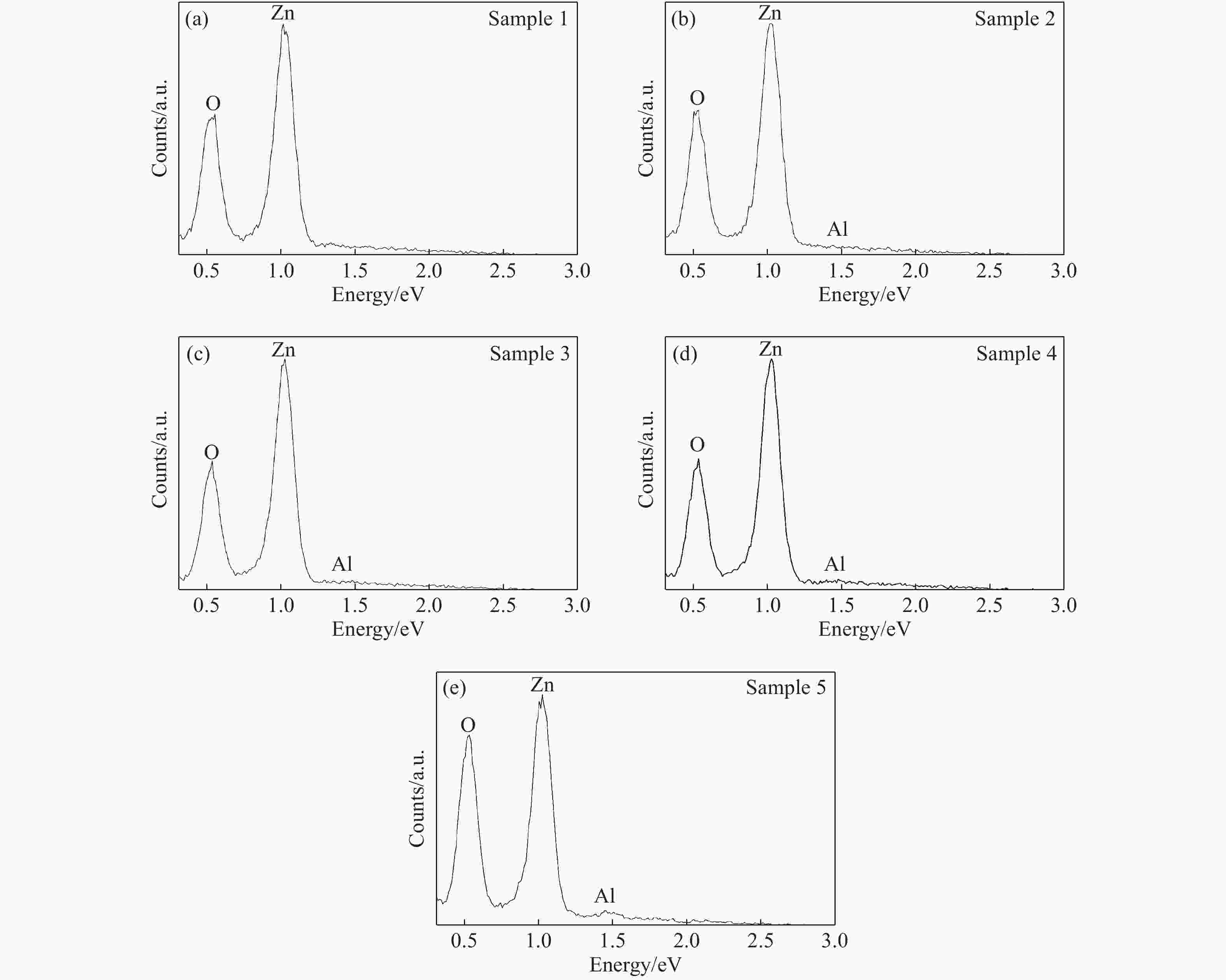

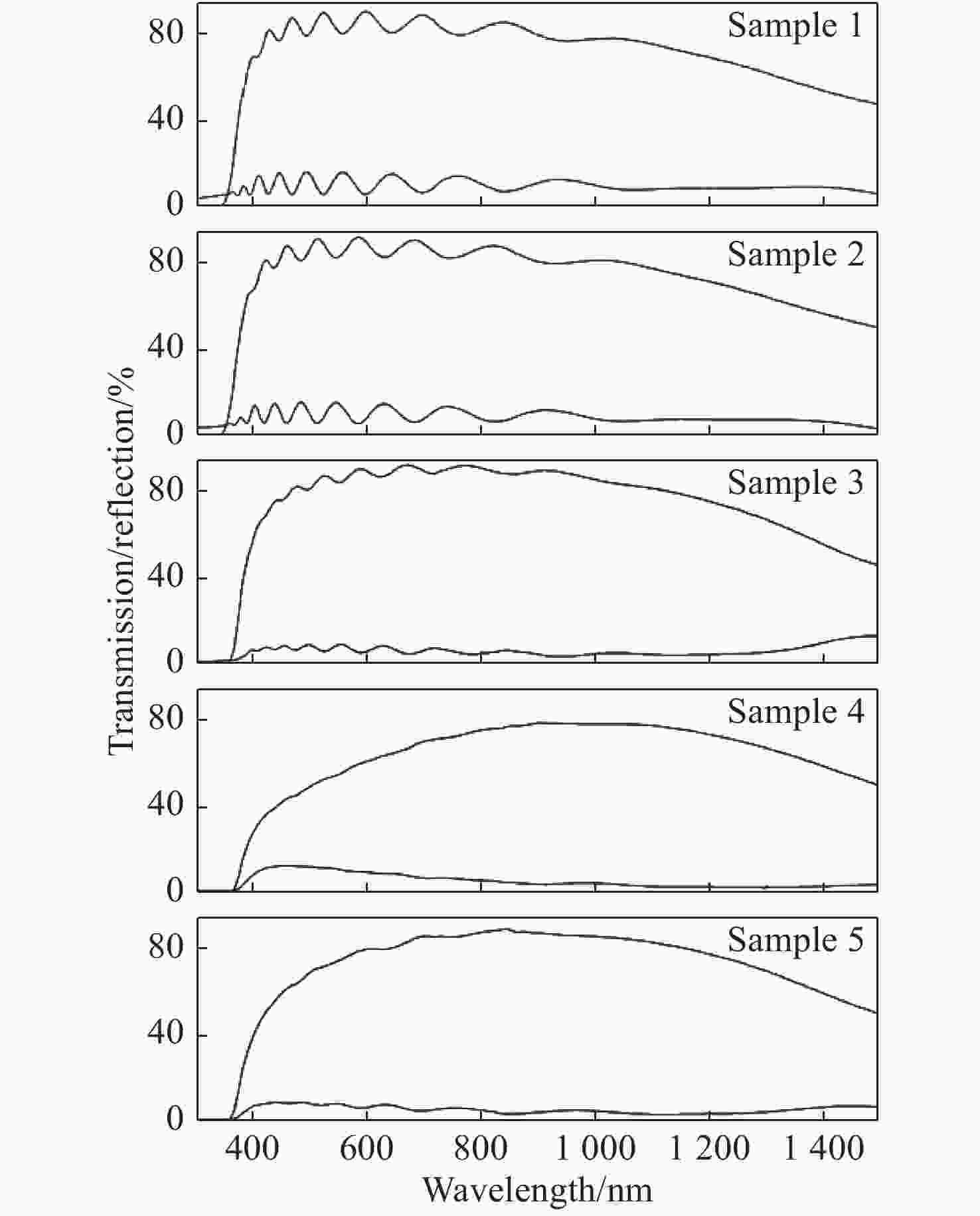

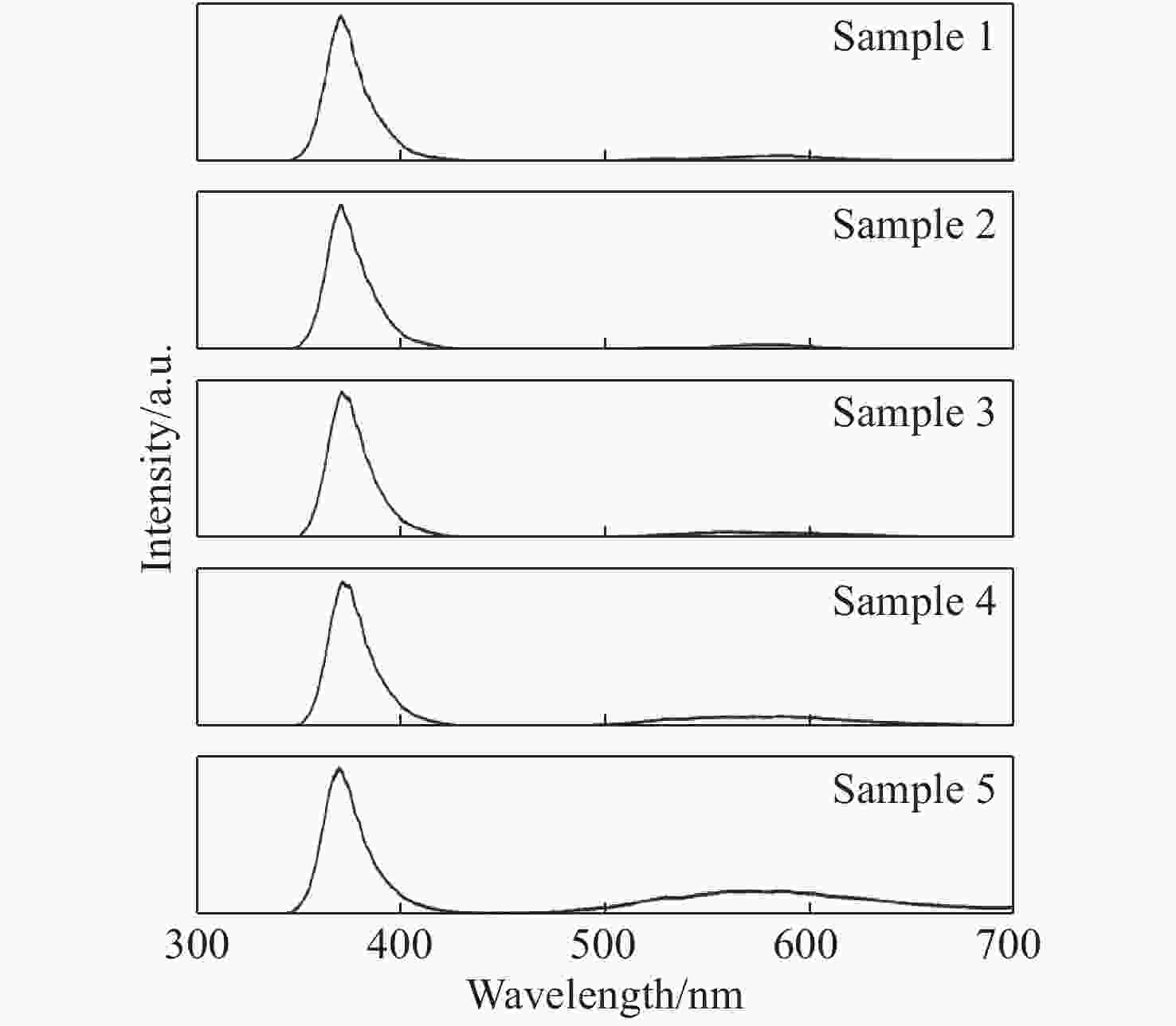

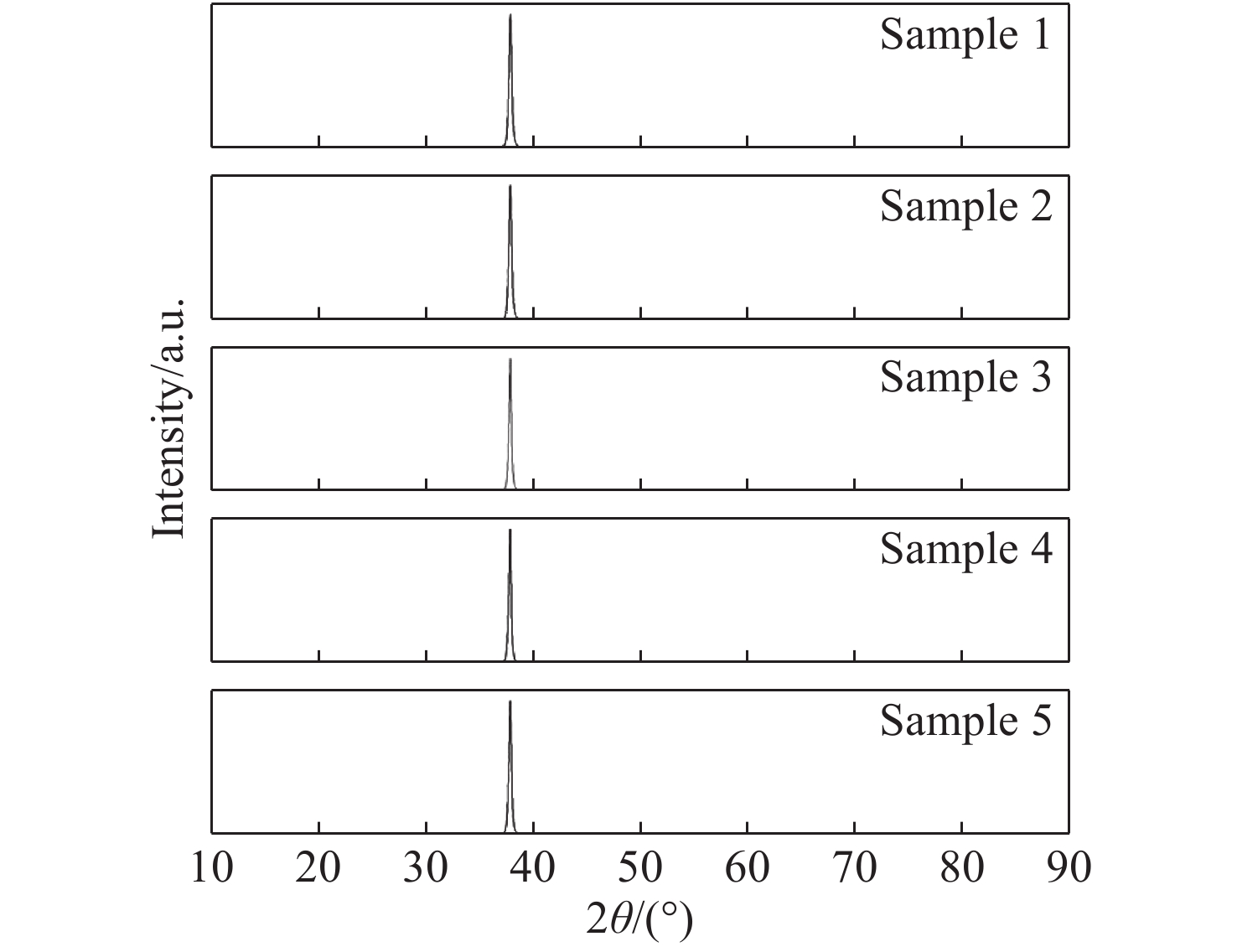

摘要: 为在新型纳米结构太阳能电池中应用ZnO纳米柱阵列材料,则要求能够对纳米柱的几何形貌与光电物理性质进行裁剪与操控。本文使用电沉积方法制备了ZnO纳米柱阵列,通过在电解液中使用Al(NO3)3 和NH4NO3,实现了对纳米柱晶体质量、直径、阵列密度、柱间距、Al掺杂浓度、光学带隙、近带边发射、斯托克斯位移等物理性质的调控。其可在28~102 nm范围内操控ZnO纳米柱的直径。NH4NO3的使用可将纳米柱的阵列密度降低至2.7×109 /cm2及将纳米柱间距增大至164 nm。电解液中NH4NO3的使用可将ZnO纳米柱中的Al/Zn重量比提升至2.92%,结果表明NH4NO3可以有效地促进ZnO纳米柱的Al掺杂。通过Al(NO3)3与NH4NO3可以对ZnO纳米柱的光学带隙在3.36~3.55 eV范围内进行裁剪,并对ZnO纳米柱的近带边发射性质进行操控。Al(NO3)3的引入使ZnO纳米柱的斯托克斯位移增大至200 meV。NH4NO3能够有效地将样品的斯托克斯位移降低至26 meV。通过使用Al(NO3)3 和NH4NO3实现了对ZnO纳米柱阵列几何形貌与光电物理性质的有效裁剪,获得了高质量的纳米柱阵列材料。Abstract: In order to achieve the implantation of the ZnO nanorod arrays in the nanostructured solar cells, it is necessary to tailor and control the nanorods’ morphology, optical and electrical properties. ZnO nanorods arrays were fabricated by electrodeposition. The physical properties such as the crystalline quality, diameter, density, distance, Al doping concentration, optical band gap energy, near band emission and stokes shift can be adjusted by using Al(NO3)3 and NH4NO3. The ZnO nanorods’ diameter can be adjusted from 28 nm to 102 nm. The nanorod arrays’ density can be reduced to 2.7×109 /cm2 by using NH4NO3, resulting in an increase in the distance between nanorods to 164 nm. The Al/Zn weight ratio was increased to 2.92% by using NH4NO3, indicating that NH4NO3 can boost Al doping in ZnO nanorods. The ZnO nanorods’ optical band gap energy can be tailored from 3.36 eV to 3.55 eV by using Al(NO3)3 and NH4NO3 and the near band edge emission can also be adjusted. The use of Al(NO3)3 led to the increase of the Stokes shift to 200 meV, but it can be greatly reduced to 26 meV as a result of the NH4NO3. The use of Al(NO3)3 and NH4NO3 resulted in the fabrication of high-quality ZnO nanorod arrays with effectively tailored morphology and optical properties.

-

Key words:

- ZnO /

- ammonium nitrate /

- aluminum nitrate /

- electrodeposition /

- optical band gap energy /

- stokes shift

-

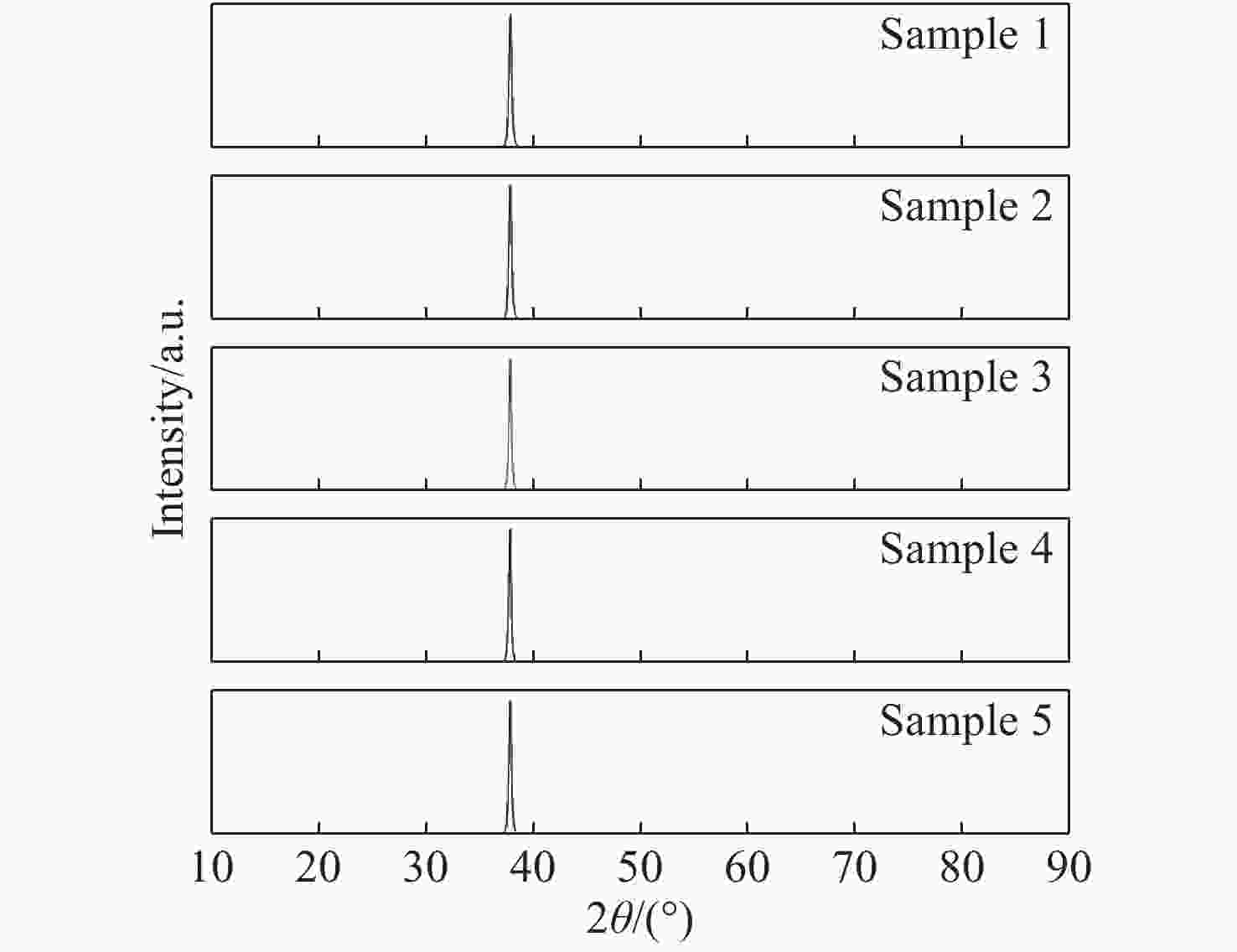

表 1 ZnO纳米柱的直径、密度、间距

Table 1. ZnO nanorods’ diameter, density and distance

Samples Diameter/nm Density/109 cm−2 Distance/nm 1 54±15 13.0 − 2 57±20 11.0 − 3 65±24 6.8 56 4 102±44 1.9 127 5 28±16 2.7 164 表 2 样品1~5中ZnO纳米柱的NBE 1、NBE 2峰位、斯托克斯位移。(样品1~5的近带边发射峰位为拟合峰)

Table 2. NBE 1, NBE 2 peak positions, and stokes shift of the ZnO nanorods in samples 1~5. The NBE peaks in samples 1~5 were from the fitting peaks.

Samples NBE 1(eV) NBE 2(eV) Stokes shift (meV) 1 3.347 3.252 183 2 3.350 3.263 200 3 3.336 3.227 94 4 3.334 3.221 26 5 3.353 3.236 67 -

[1] KIM D, YUN I, KIM H. Fabrication of rough Al doped ZnO films deposited by low pressure chemical vapor deposition for high efficiency thin film solar cells[J]. Current Applied Physics, 2010, 10(3): S459-S462. doi: 10.1016/j.cap.2010.02.030 [2] LUKA G, WITKOWSKI B S, WACHNICKI L. Electrical and mechanical stability of aluminum-doped ZnO films grown on flexible substrates by atomic layer deposition[J]. Materials Science and Engineering:B, 2014, 186: 15-20. doi: 10.1016/j.mseb.2014.03.002 [3] COMAN T, URSU E L, NICA V, et al. Improving the uncommon (110) growing orientation of Al-doped ZnO thin films through sequential pulsed laser deposition[J]. Thin Solid Films, 2014, 571: 198-205. doi: 10.1016/j.tsf.2014.10.037 [4] DUYGULU N E, KODOLBAS A O, EKERIM A. Effects of argon pressure and r. f. power on magnetron sputtered aluminum doped ZnO thin films[J]. Journal of Crystal Growth, 2014, 394: 116-125. doi: 10.1016/j.jcrysgro.2014.02.028 [5] CHEN J, YE H, AÉ L, et al. Tapered aluminum-doped vertical zinc oxide nanorod arrays as light coupling layer for solar energy applications[J]. Solar Energy Materials and Solar Cells, 2011, 95(6): 1437-1440. doi: 10.1016/j.solmat.2010.10.006 [6] RIEDEL W, TANG Y, OHM W, et al. Effect of initial galvanic nucleation on morphological and optical properties of ZnO nanorod arrays[J]. Thin Solid Films, 2015, 574: 177-183. doi: 10.1016/j.tsf.2014.12.006 [7] GUO L D, TANG Y, CHIANG F K, et al. Density-controlled growth and passivation of ZnO nanorod arrays by electrodeposition[J]. Thin Solid Films, 2017, 638: 426-432. doi: 10.1016/j.tsf.2017.08.015 [8] 汤洋, 郭逦达, 张增光, 等. 硝酸铵诱导电沉积氧化锌纳米柱的铝掺杂及光学性质操控[J]. 光学 精密工程,2015,23(5):1288-1296. doi: 10.3788/OPE.20152305.1288TANG Y, GUO L D, ZHANG Z G, et al. Aluminium doping and optical property control of electrodeposited zinc oxide nanorods induced by ammonium nitrate[J]. Optics and Precision Engineering, 2015, 23(5): 1288-1296. (in Chinese) doi: 10.3788/OPE.20152305.1288 [9] TANG Y, CHEN J, GREINER D, et al. Fast growth of high work function and high-quality ZnO nanorods from an aqueous solution[J]. The Journal of Physical Chemistry C, 2011, 115(13): 5239-5243. doi: 10.1021/jp109022k [10] KUMAR A, HUANG N, STAEDLER T, et al. Mechanical characterization of aluminum doped zinc oxide (Al: ZnO) nanorods prepared by sol–gel method[J]. Applied Surface Science, 2013, 265: 758-763. doi: 10.1016/j.apsusc.2012.11.101 [11] CHEN ZH W, ZHAN G H, WU Y P, et al. Sol–gel-hydrothermal synthesis and conductive properties of Al-doped ZnO nanopowders with controllable morphology[J]. Journal of Alloys and Compounds, 2014, 587: 692-697. doi: 10.1016/j.jallcom.2013.10.241 [12] 汤洋, 赵颖, 张增光, 等. 氧化锌纳米柱阵列的水热合成及其性能[J]. 材料研究学报,2015,29(7):529-534.TANG Y, ZHAO Y, ZHANG Z G, et al. Hydrothermal synthesis and properties of ZnO nanorod arrays[J]. Chinese Journal of Materials Research, 2015, 29(7): 529-534. (in Chinese) [13] 汤洋, 陈颉. 电沉积掺铝氧化锌纳米柱的光学带隙蓝移与斯托克斯位移[J]. 发光学报,2014,35(10):1165-1171. doi: 10.3788/fgxb20143510.1165TANG Y, CHEN J. Optical band gap blue shift and stokes shift in Al-doped ZnO nanorods by electrodeposition[J]. Chinese Journal of Luminescence, 2014, 35(10): 1165-1171. (in Chinese) doi: 10.3788/fgxb20143510.1165 [14] 胡明江, 晋兵营. 基于CuO/ZnO异质结纳米花的薄膜型丙酮传感器研究[J]. 分析化学,2019,47(3):363-370.HU M J, JIN B Y. Research on film type acetone sensor based on copper oxide/zinc oxide heterostructure nanoflower[J]. Chinese Journal of Analytical Chemistry, 2019, 47(3): 363-370. (in Chinese) [15] 梁彩云, 刘凤平, 张翠忠, 等. 基于铜纳米粒子/氧化锌/石墨烯修饰电极的电化学方法测定硫酸卡那霉素[J]. 分析化学,2019,47(5):739-747.LIANG C Y, LIU F P, ZHANG C ZH, et al. Electrochemical determination of kanamycin sulfate based on copper nanoparticle/zinc oxide/graphene modified electrode[J]. Chinese Journal of Analytical Chemistry, 2019, 47(5): 739-747. (in Chinese) [16] 刘书绘, 雷杰, 吴媛, 等. 基于四氧化三钴-多壁碳纳米管纳米复合材料修饰阳极的苯酚/氧气燃料电池的构建[J]. 分析化学,2019,47(8):1195-1204.LIU SH H, LEI J, WU Y, et al. Cobaltosic oxide-multi-walled carbon nanotubes nanocomposite-modified electrode as anode[J]. Chinese Journal of Analytical Chemistry, 2019, 47(8): 1195-1204. (in Chinese) [17] 唐小强, 陈裕雲, 罗燕妮, 等. 基于TiO2 NRs@ZnIn2S4 NSs复合材料的谷胱甘肽光电化学传感器的构建与应用[J]. 分析化学,2019,47(8):1188-1194.TANG X Q, CHEN Y Y, LUO Y N, et al. Photoelectrochemical sensor based on titanium dioxide nanorods@ZnIn2S4 nanosheets nanocomposites[J]. Chinese Journal of Analytical Chemistry, 2019, 47(8): 1188-1194. (in Chinese) [18] CHO S, JUNG S H, JANG J W, et al. Simultaneous synthesis of Al-doped ZnO nanoneedles and zinc aluminum hydroxides through use of a seed layer[J]. Crystal Growth and Design, 2008, 8(12): 4553-4558. doi: 10.1021/cg800593q [19] KIM C E, MOON P, KIM S, et al. Effect of carrier concentration on optical bandgap shift in ZnO: Ga thin films[J]. Thin Solid Films, 2010, 518(22): 6304-6307. doi: 10.1016/j.tsf.2010.03.042 [20] CHEN J, AÉ L, LUX-STEINER M C. High internal quantum efficiency ZnO nanorods prepared at low temperature[J]. Applied Physics Letters, 2008, 92(16): 161906. doi: 10.1063/1.2910769 -

下载:

下载: