Writing nanopores on a ZnS crystal with ultrafast Bessel beams

doi: 10.37188/CO.2020-0101

-

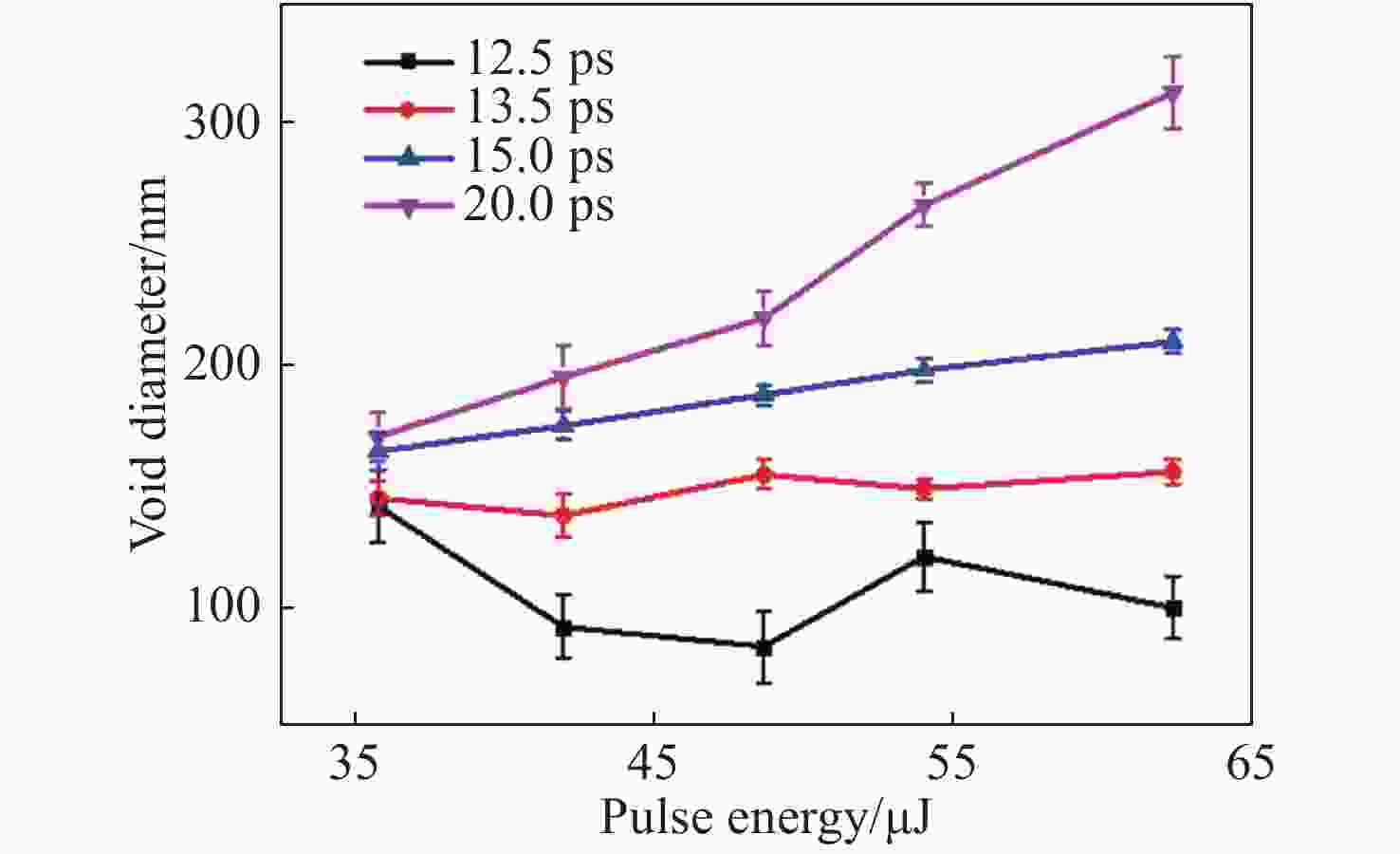

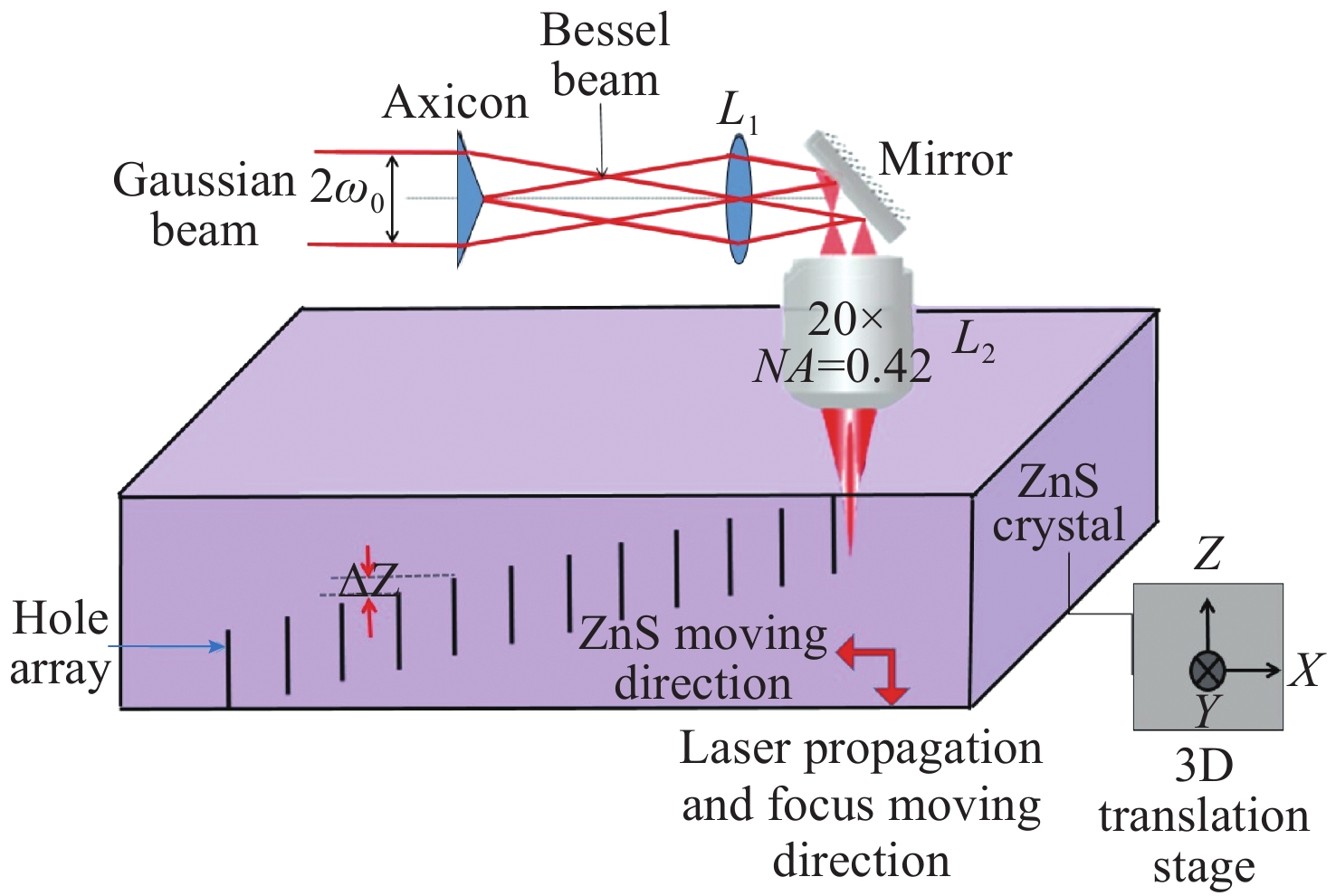

摘要: 硫化锌(ZnS)晶体是重要的宽光谱红外窗口材料,高深径比纳米孔的超快激光制造技术为中红外波导傅立叶变换光谱仪等光子器件的实现提供了重要的技术途径。本文采用中心波长为1030 nm、重复频率为100 kHz、脉冲宽度为223 fs~20 ps可调的Yb: KGW激光光源,用石英锥镜产生高斯-贝塞尔光束,并用4f系统构建了40倍缩束的超快激光直写系统。在能量为36~63 μJ,脉宽为12.5~20 ps的情况下,在ZnS晶体上成功刻写了直径为80~320 nm的纳米孔结构。通过聚焦离子束(FIB)剥蚀和扫描电子显微镜(SEM)成像确定了纳米孔隙表面形貌、直径及深度信息。研究了激光脉冲能量、脉冲宽度对纳米孔隙的影响。结果表明,在20 ps脉冲宽度、48 µJ脉冲能量的激光参数下,纳米孔隙的深度约为270 μm。Abstract: Zinc sulfide (ZnS) crystal is one of the important materials used to make the wide-spectrum infrared window. The ultrafast laser technology for manufacturing the nanopores with high aspect ratio provides an important approach to fabricate the photonic devices such as mid-infrared waveguide Fourier transform spectrometer etc. In this paper, a 40-times-demagnification ultrafast laser direct-writing system was built with a 4f system and a Gaussian-Bessel beam generated by a quartz axicon and a Yb:KGW laser source that operated at a wavelength of 1030 nm, a repetition rate of 100 kHz and a pulse width tunable from 223 fs to 20 ps. When the pulse energy was changed from 36 μJ to 63 μJ and the pulse duration was changed from 12.5 ps to 20 ps, the nanopore structure with a diameter of 80~320 nm was successfully written on the ZnS crystal. The surface morphology, diameter and depth of the nanopores were determined by FIB (Focused Ion Beams) ablation and SEM (Scanning Electron Microscopy) imaging. The influence of laser pulse energy and pulse width on the nanopores was studied. The results show that when the pulse width is 20 ps and the pulse energy is 48 µJ, the depth of a nanopore is about 270 µm.

-

Key words:

- ZnS crystal /

- high aspect ratio nanopores /

- photonic devices /

- Gaussian-Bessel beam

-

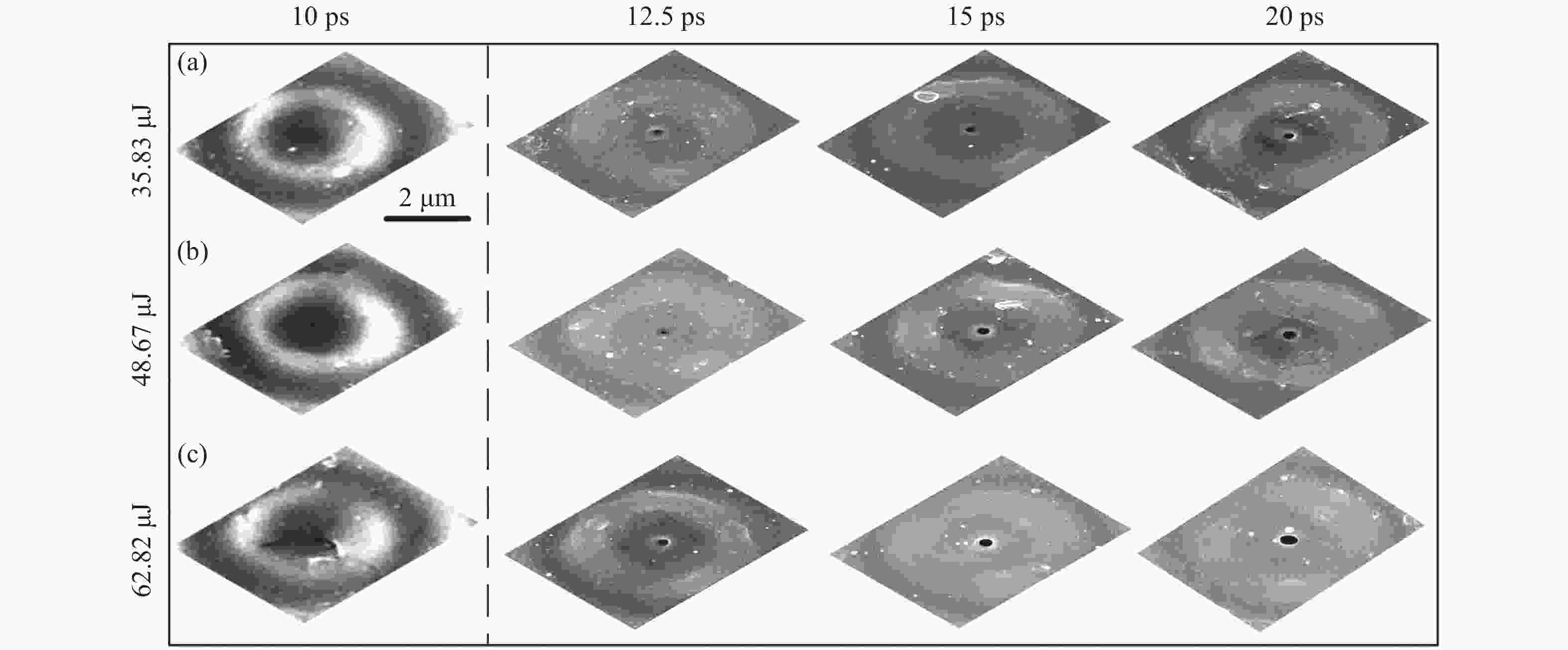

图 2 不同激光参数下ZnS表面纳米孔隙结构的SEM形貌。 (a) 35.83 μJ;(b) 48.67 μJ;(c) 62.82 μJ。第1到4列的激光脉冲宽度分别是10ps, 12.5 ps, 15 ps和20 ps

Figure 2. SEM images of nanopores on ZnS surface at various pulse energies. (a) 35.83 μJ; (b) 48.67 μJ; (c) 62.82 μJ. The laser pulse widths in columns 1 to 4 are 10 ps, 12.5 ps, 15 ps and 20 ps respectively

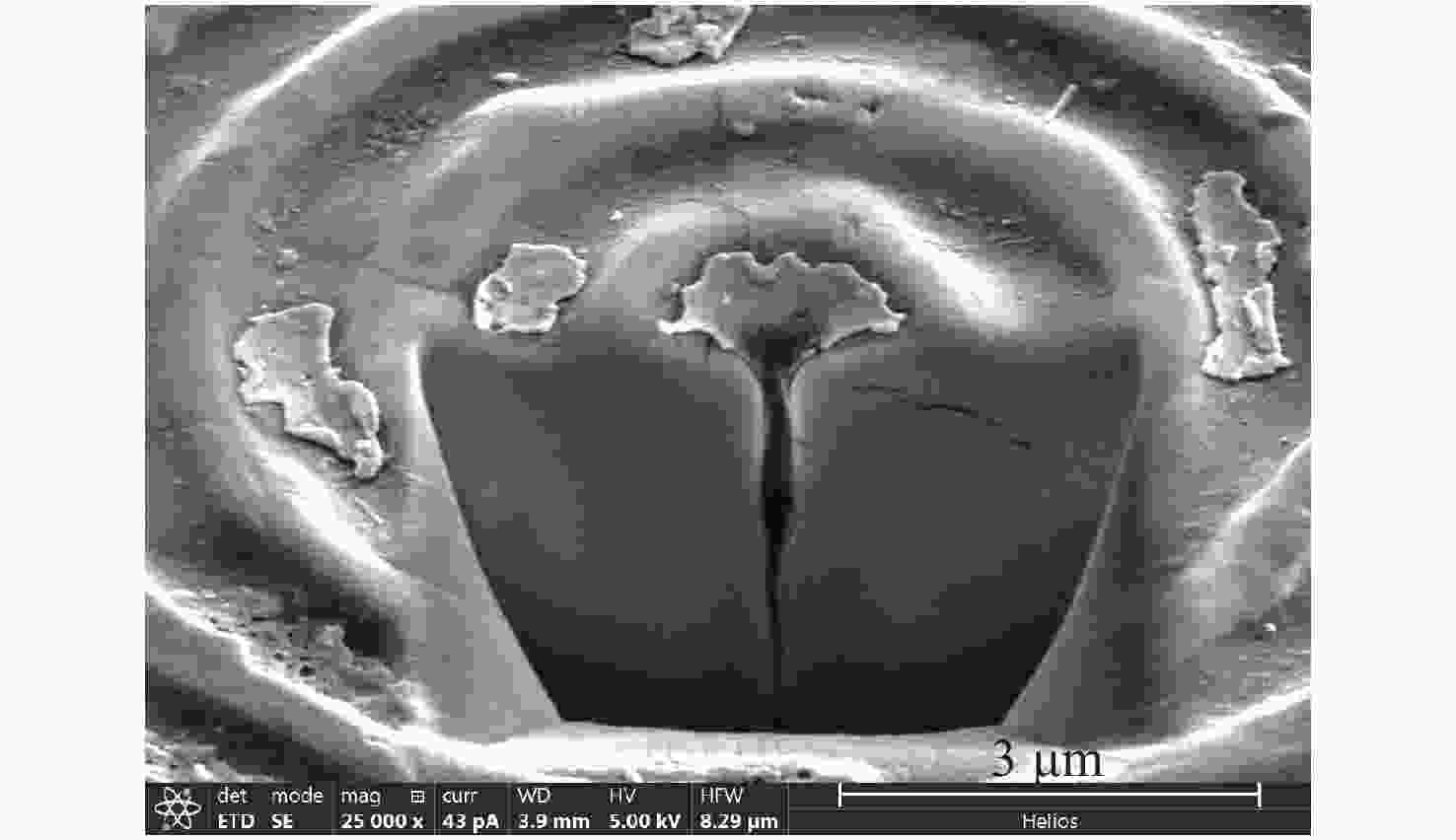

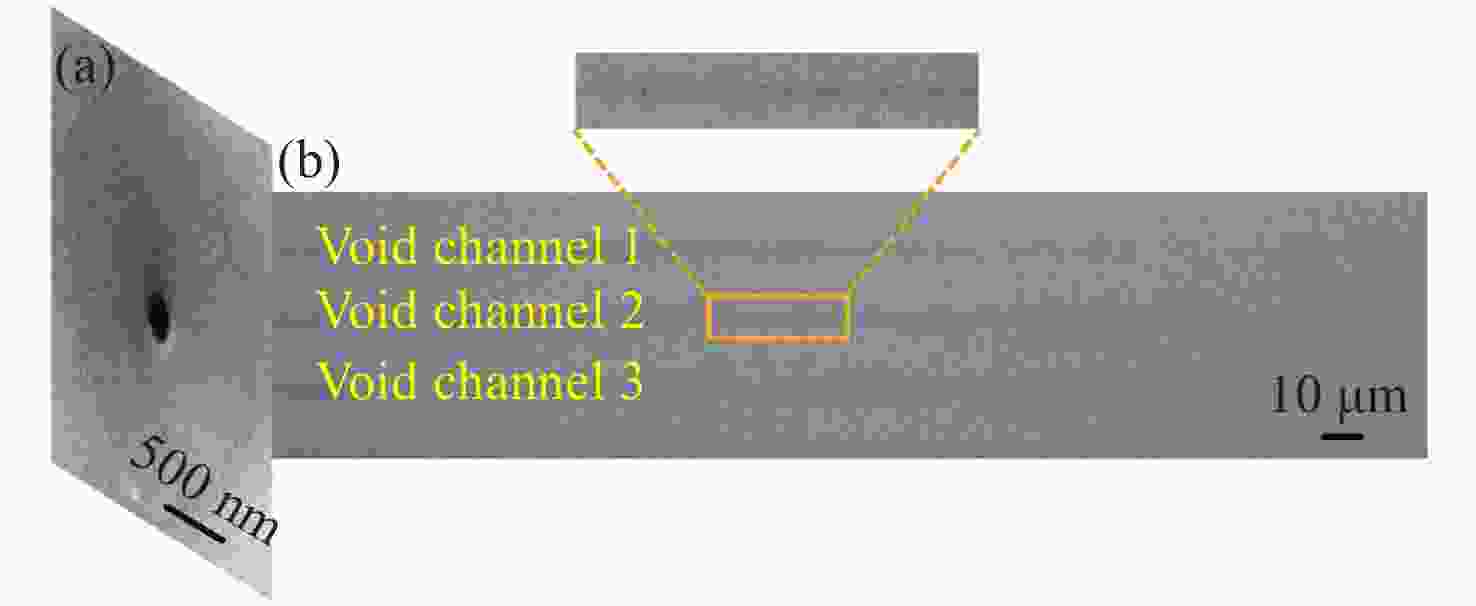

图 5 ZnS晶体内部纳米孔隙的结构特征。 (a)抛光后纳米孔隙横截面的SEM图;(b) 20×相衬显微镜下的纳米孔隙结构的侧面图(透射式显微模式),上方插图是微通道的放大图,图中的微结构均是在20 ps, 48.67 μJ的激光参数下刻写的

Figure 5. Characteristics of nanopore inside ZnS crystal. (a) SEM image of cross-section of polished nanopore; (b) side view of the nanopore under a 20 × phase contrast microscope (transmission microscopy type). The upper inset is an enlarged view of a microchannel. Note that all the microstructures in the picture are written under the laser parameters of 20 ps and 48.67 μJ

-

[1] LIN H T, LUO ZH Q, GU T, et al. Mid-infrared integrated photonics on silicon: a perspective[J]. Nanophotonics, 2018, 7(2): 393-420. [2] AN Q, REN Y Y, JIA Y CH, et al. Mid-infrared waveguides in zinc sulfide crystal[J]. Optical Materials Express, 2013, 3(4): 466-471. doi: 10.1364/OME.3.000466 [3] HU J J, MEYER J, RICHARDSON K, et al. Feature issue introduction: mid-IR photonic materials[J]. Optical Materials Express, 2013, 3(9): 1571-1575. doi: 10.1364/OME.3.001571 [4] PILE D, HORIUCHI N, WON R, et al. Extending opportunities[J]. Nature Photonics, 2012, 6(7): 407. doi: 10.1038/nphoton.2012.164 [5] FU L G, LÜ F X, WANG X W, et al. Defects in CVDZnS[J]. Rare Metals, 2011, 30(4): 387-391. doi: 10.1007/s12598-011-0401-7 [6] BHUYAN M K, VELPULA P K, COLOMBIER J P, et al. Single-shot high aspect ratio bulk nanostructuring of fused silica using chirp-controlled ultrafast laser Bessel beams[J]. Applied Physics Letters, 2014, 104(2): 021107. doi: 10.1063/1.4861899 [7] ROSEN J, YARIV A. Synthesis of an arbitrary axial field profile by computer-generated holograms[J]. Optics Letters, 1994, 19(11): 843-845. doi: 10.1364/OL.19.000843 [8] STOIAN R, BHUYAN M K, ZHANG G D, et al. Ultrafast Bessel beams: advanced tools for laser materials processing[J]. Advanced Optical Technologies, 2018, 7(3): 165-174. doi: 10.1515/aot-2018-0009 [9] BHUYAN M K, COURVOISIER F, LACOURT P A, et al. High aspect ratio nanochannel machining using single shot femtosecond Bessel beams[J]. Applied Physics Letters, 2010, 97(8): 081102. doi: 10.1063/1.3479419 [10] BHUYAN M K, COURVOISIER F, PHING H S, et al. Laser micro- and nanostructuring using femtosecond Bessel beams[J]. The European Physical Journal Special Topics, 2011, 199(1): 101-110. doi: 10.1140/epjst/e2011-01506-0 [11] MITRA S, CHANAL M, CLADY R, et al. Millijoule femtosecond micro-Bessel beams for ultra-high aspect ratio machining[J]. Applied Optics, 2015, 54(24): 7358-7365. doi: 10.1364/AO.54.007358 [12] ZHANG G D, STOIAN R, CHENG G H, et al. Femtosecond laser Bessel beam welding of transparent to non-transparent materials with large focal-position tolerant zone[J]. Optics Express, 2018, 26(2): 917-926. [13] MEYER R, FROEHLY L, GIUST R, et al. Extremely high-aspect-ratio ultrafast Bessel beam generation and stealth dicing of multi-millimeter thick glass[J]. Applied Physics Letters, 2019, 114(20): 201105. doi: 10.1063/1.5096868 [14] RAPP L, MEYER R, GIUST R, et al. High aspect ratio micro-explosions in the bulk of sapphire generated by femtosecond Bessel beams[J]. Scientific Reports, 2016, 6: 34286. doi: 10.1038/srep34286 [15] ZHANG F, DUAN J A, ZHOU X F, et al. Broadband and wide-angle antireflective subwavelength microstructures on zinc sulfide fabricated by femtosecond laser parallel multi-beam[J]. Optics Express, 2018, 26(26): 34016-34030. doi: 10.1364/OE.26.034016 [16] LI Y P, ZHANG T H, FAN S L, et al. Fabrication of micro hole array on the surface of CVD ZnS by scanning ultrafast pulse laser for antireflection[J]. Optical Materials, 2017, 66: 356-360. doi: 10.1016/j.optmat.2017.02.019 [17] RUDENKO A, COLOMBIER J P, ITINA T E. Nanopore-mediated ultrashort laser-induced formation and erasure of volume nanogratings in glass[J]. Physical Chemistry Chemical Physics, 2018, 20(8): 5887-5899. doi: 10.1039/C7CP07603G [18] WANG X L, ZHANG N, ZHAO Y B, et al. Determination of air ionization threshold with femtosecond laser pulses[J]. Acta Physica Sinica, 2008, 57(1): 354-357. (in Chinese) [19] STOIAN R, BHUYAN M K, RUDENKO A, et al. High-resolution material structuring using ultrafast laser non-diffractive beams[J]. Advances in Physics:X, 2019, 4(1): 1659180. doi: 10.1080/23746149.2019.1659180 [20] GLEZER E N, MAZUR E. Ultrafast-laser driven micro-explosions in transparent materials[J]. Applied Physics Letters, 1997, 71(7): 882-884. doi: 10.1063/1.119677 [21] JUODKAZIS S, NISHIMURA K, TANAKA S, et al. Laser-induced microexplosion confined in the bulk of a sapphire crystal: evidence of multimegabar pressures[J]. Physical Review Letters, 2006, 96(16): 166101. doi: 10.1103/PhysRevLett.96.166101 [22] GAMALY E G, JUODKAZIS S, NISHIMURA K, et al. Laser-matter interaction in the bulk of a transparent solid: confined microexplosion and void formation[J]. Physical Review B, 2006, 73(21): 214101. doi: 10.1103/PhysRevB.73.214101 [23] ZHANG G D, CHENG G H, BHUYAN M K, et al. Ultrashort Bessel beam photoinscription of Bragg grating waveguides and their application as temperature sensors[J]. Photonics Research, 2019, 7(7): 806-814. doi: 10.1364/PRJ.7.000806 [24] ZHANG G D, CHENG G H, BHUYAN M, et al. Efficient point-by-point Bragg gratings fabricated in embedded laser-written silica waveguides using ultrafast Bessel beams[J]. Optics Letters, 2018, 43(9): 2161-2164. doi: 10.1364/OL.43.002161 [25] POLESANA P, FRANCO M, COUAIRON A, et al. Filamentation in Kerr media from pulsed Bessel beams[J]. Physical Review A, 2008, 77(4): 043814. doi: 10.1103/PhysRevA.77.043814 [26] D'AMICO C, CHENG G H, MAUCLAIR C, et al. Large-mode-area infrared guiding in ultrafast laser written waveguides in Sulfur-based chalcogenide glasses[J]. Optics Express, 2014, 22(11): 13091-13101. doi: 10.1364/OE.22.013091 [27] DAM B, RECTOR J, CHANG M F, et al. Laser ablation threshold of YBa2Cu3O6+x[J]. Applied Physics Letters, 1994, 65(12): 1581-1583. doi: 10.1063/1.112921 [28] JOGLEKAR A P, LIU H H, MEYHÖFER G, et al. Optics at critical intensity: applications to nanomorphing[J]. Proceedings of the National Academy of Sciences of the United States of America, 2004, 101(16): 5856-5861. doi: 10.1073/pnas.0307470101 [29] GAMALY E G, VAILIONIS A, MIZEIKIS V, et al. Warm dense matter at the bench-top: Fs-laser-induced confined micro-explosion[J]. High Energy Density Physics, 2012, 8(1): 13-17. doi: 10.1016/j.hedp.2011.10.003 [30] CHENG G H, RUDENKO A, D'AMICO C, et al. Embedded nanogratings in bulk fused silica under non-diffractive Bessel ultrafast laser irradiation[J]. Applied Physics Letters, 2017, 110(26): 261901. doi: 10.1063/1.4987139 [31] MARTIN G, BHUYAN M, TROLES J, et al. Near infrared spectro-interferometer using femtosecond laser written GLS embedded waveguides and nano-scatterers[J]. Optics Express, 2017, 25(7): 8386-8397. doi: 10.1364/OE.25.008386 [32] DOUGLASS G, ARRIOLA A, HERAS I, et al. Novel concept for visible and near infrared spectro-interferometry: laser-written layered arrayed waveguide gratings[J]. Optics Express, 2018, 26(14): 18470-18479. doi: 10.1364/OE.26.018470 [33] SHANKAR R, LEIJSSEN R, BULU I, et al. Mid-infrared photonic crystal cavities in silicon[J]. Optics Express, 2011, 19(6): 5579-5586. doi: 10.1364/OE.19.005579 -

下载:

下载: