| [1] |

董家宁, 范杰, 王海珠, 等. 高反射光学薄膜激光损伤研究进展[J]. 中国光学,2018,11(6):931-948. doi: 10.3788/co.20181106.0931DONG J N, FAN J, WANG H ZH, et al. Research progress in laser damage of high reflective optical thin films[J]. Chinese Optics, 2018, 11(6): 931-948. (in Chinese) doi: 10.3788/co.20181106.0931

|

| [2] |

王超, 张一杨, 张雅静, 等. 掺Yb3+石英玻璃中非桥氧空穴缺陷特性的研究[J]. 发光学报,2018,39(10):1359-1364. doi: 10.3788/fgxb20183910.1359WANG CH, ZHANG Y Y, ZHANG Y J, et al. Characteristics of non-bridging oxygen hole centers defects in Yb3+-doped silica glass[J]. Chinese Journal of Luminescence, 2018, 39(10): 1359-1364. (in Chinese) doi: 10.3788/fgxb20183910.1359

|

| [3] |

BETTI R, HURRICANE O A. Inertial-confinement fusion with lasers[J]. Nature Physics, 2016, 12(5): 435-448. doi: 10.1038/nphys3736

|

| [4] |

ZHENG W G, WEI X F, ZHU Q H, et al. Laser performance of the SG-III laser facility[J]. High Power Laser Science and Engineering, 2016, 4: e21. doi: 10.1017/hpl.2016.20

|

| [5] |

王玺, 李志明, 谢运涛, 等. 紫外准分子激光损伤典型光学材料的特性分析[J]. 发光学报,2018,39(5):692-698. doi: 10.3788/fgxb20183905.0692WANG X, LI ZH M, XIE Y T, et al. Characteristics of typical optical materials damaged by ultraviolet excimer laser[J]. Chinese Journal of Luminescence, 2018, 39(5): 692-698. (in Chinese) doi: 10.3788/fgxb20183905.0692

|

| [6] |

田润妮, 邱荣, 蒋勇, 等. 熔石英亚表面球形杂质对入射光场的调制作用[J]. 光学学报,2015,35(4):0414003. doi: 10.3788/AOS201535.0414003TIAN R N, QIU R, JIANG Y, et al. Light field modulation induced by spherical inclusion in fused silica subsurface[J]. Acta Optica Sinica, 2015, 35(4): 0414003. (in Chinese) doi: 10.3788/AOS201535.0414003

|

| [7] |

CHENG X B, ZHANG J L, DING T, et al. The effect of an electric field on the thermomechanical damage of nodular defects in dielectric multilayer coatings irradiated by nanosecond laser pulses[J]. Light:Science &Applications, 2013, 2(6): e80.

|

| [8] |

ZHU ZH W, CHENG X G, HUANG L J, et al. Light field intensification induced by nanoinclusions in optical thin-films[J]. Applied Surface Science, 2012, 258(12): 5126-5130. doi: 10.1016/j.apsusc.2012.01.145

|

| [9] |

孙晓艳, 雷泽民, 卢兴强, 等. 表面颗粒污染物诱导薄光学元件初始损伤的机理[J]. 物理学报,2014,63(13):134201.SUN X Y, LEI Z M, LU X Q, et al. Mechanism of original damage of thin optical components induced by surface particle contamination[J]. Acta Physica Sinica, 2014, 63(13): 134201. (in Chinese)

|

| [10] |

CHENG J, CHEN M J, LIAO W, et al. Influence of surface cracks on laser-induced damage resistance of brittle KH2PO4 crystal[J]. Optics Express, 2014, 22(23): 28740-28755. doi: 10.1364/OE.22.028740

|

| [11] |

GÉNIN F Y, SALLEO A, PISTOR T V, et al. Role of light intensification by cracks in optical breakdown on surfaces[J]. Journal of the Optical Society of America A, 2001, 18(10): 2607-2616. doi: 10.1364/JOSAA.18.002607

|

| [12] |

FEIGENBAUM E, ELHADJ S, MATTHEWS J M. Light scattering from laser induced pit ensembles on high power laser optics[J]. Optics Express, 2015, 23(8): 10589-10597. doi: 10.1364/OE.23.010589

|

| [13] |

ZHENG Y, MA P, LI H B, et al. Studies on transmitted beam modulation effect from laser induced damage on fused silica optics[J]. Optics Express, 2013, 21(14): 16605-16614. doi: 10.1364/OE.21.016605

|

| [14] |

HARRIS C D, SHEN N, RUBENCHIK A M, et al. Characterization of laser-induced plasmas associated with energetic laser cleaning of metal particles on fused silica surfaces[J]. Optics Letter, 2015, 40(22): 5212-5215. doi: 10.1364/OL.40.005212

|

| [15] |

CORMONT P, COMBIS P, GALLAIS L, et al. Removal of scratches on fused silica optics by using a CO2 laser[J]. Optics Express, 2013, 21(23): 28272-28289. doi: 10.1364/OE.21.028272

|

| [16] |

LIU CH M, YAN ZH H, YANG L, et al. Mitigation scratch on fused silica optics using CO2 laser[J]. Optica Applicata, 2016, 46(3): 387-397.

|

| [17] |

CORMONT P, BOURGEADE A, CAVARO S, et al. Relevance of carbon dioxide laser to remove scratches on large fused silica polished optics[J]. Advanced Engineering Materials, 2015, 17(3): 253-259. doi: 10.1002/adem.201400383

|

| [18] |

JIANG Y, XIANG X, LIU CH M, et al. Two localized CO2 laser treatment methods for mitigation of UV damage growth in fused silica[J]. Chinese Physics B, 2012, 21(6): 064219. doi: 10.1088/1674-1056/21/6/064219

|

| [19] |

JIANG Y, LIU CH M, LUO CH S, et al. Mitigation of laser damage growth in fused silica by using a non-evaporative technique[J]. Chinese Physics B, 2012, 21(5): 054216. doi: 10.1088/1674-1056/21/5/054216

|

| [20] |

DOUALLE T, GALLAIS L, MONNERET S, et al. CO2 laser microprocessing for laser damage growth mitigation of fused silica optics[J]. Optical Engineering, 2016, 56(1): 011022.

|

| [21] |

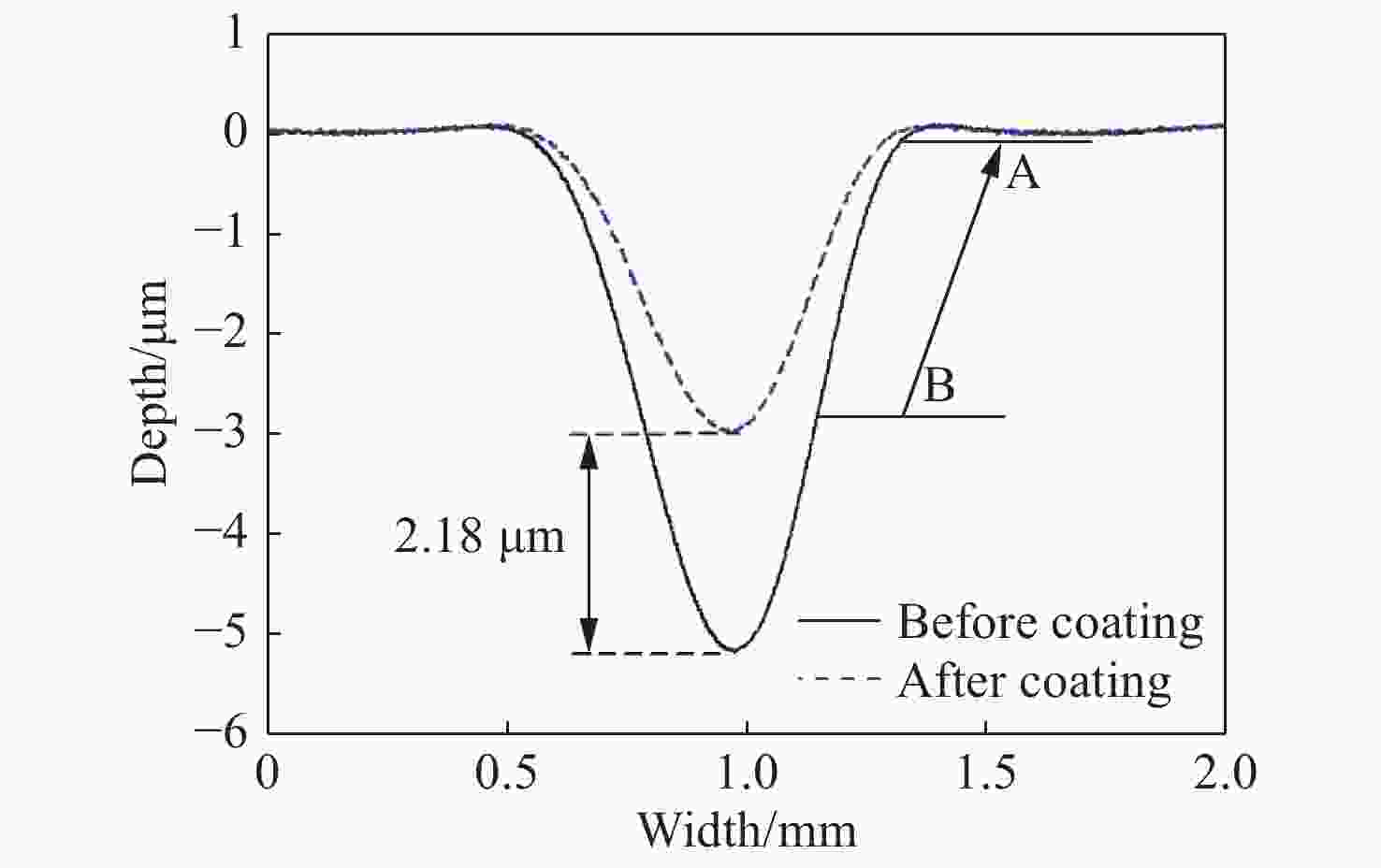

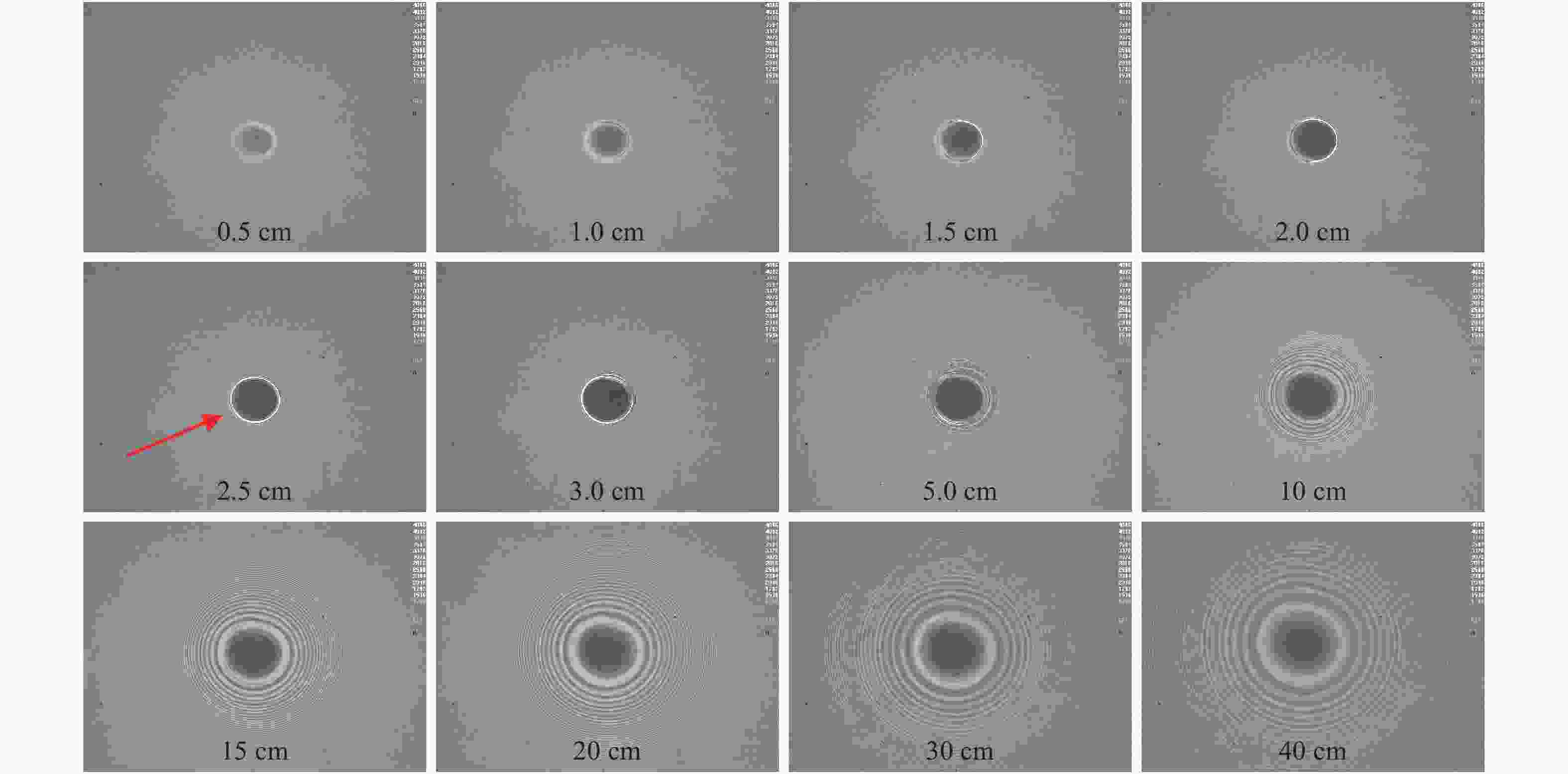

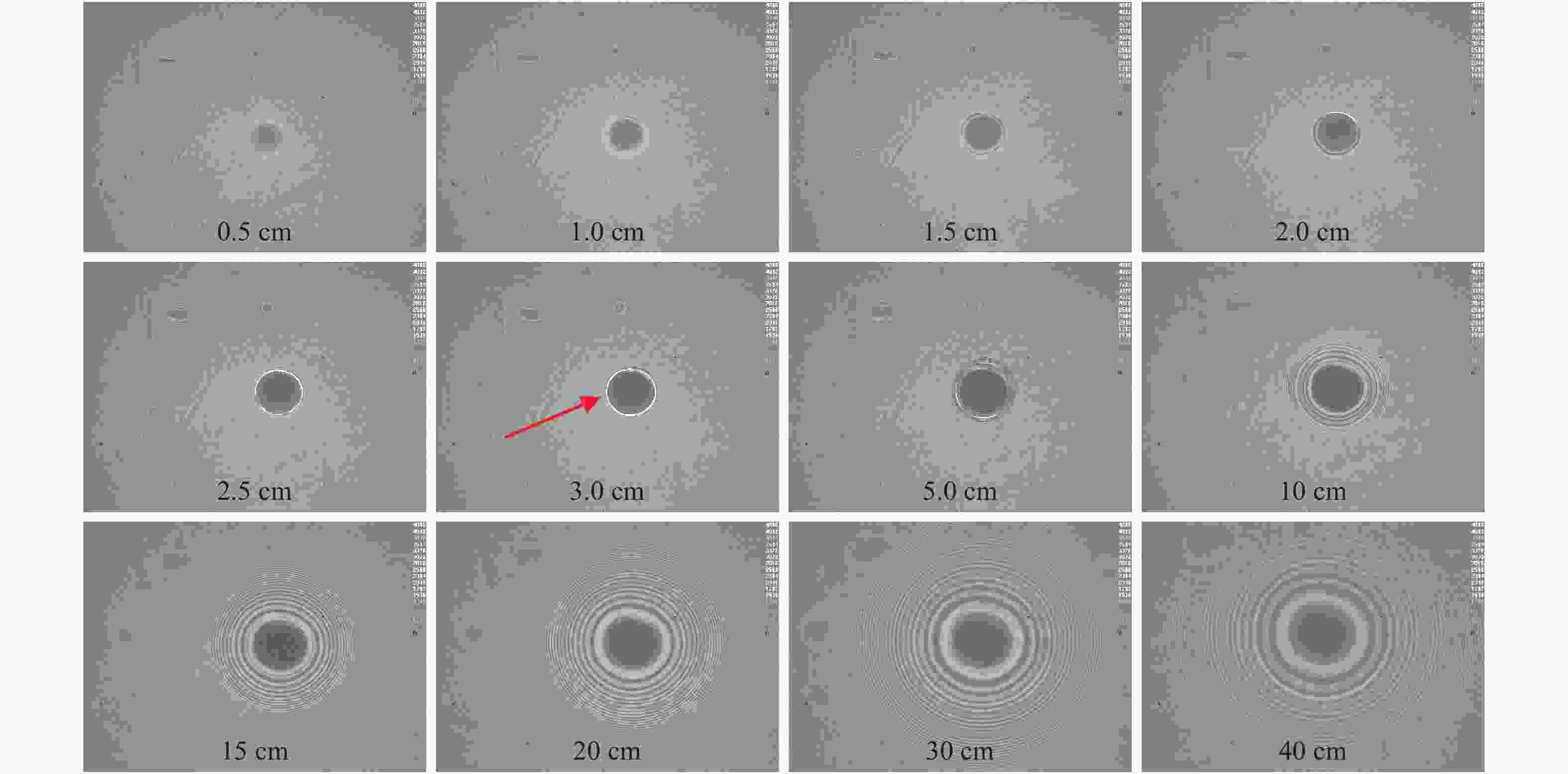

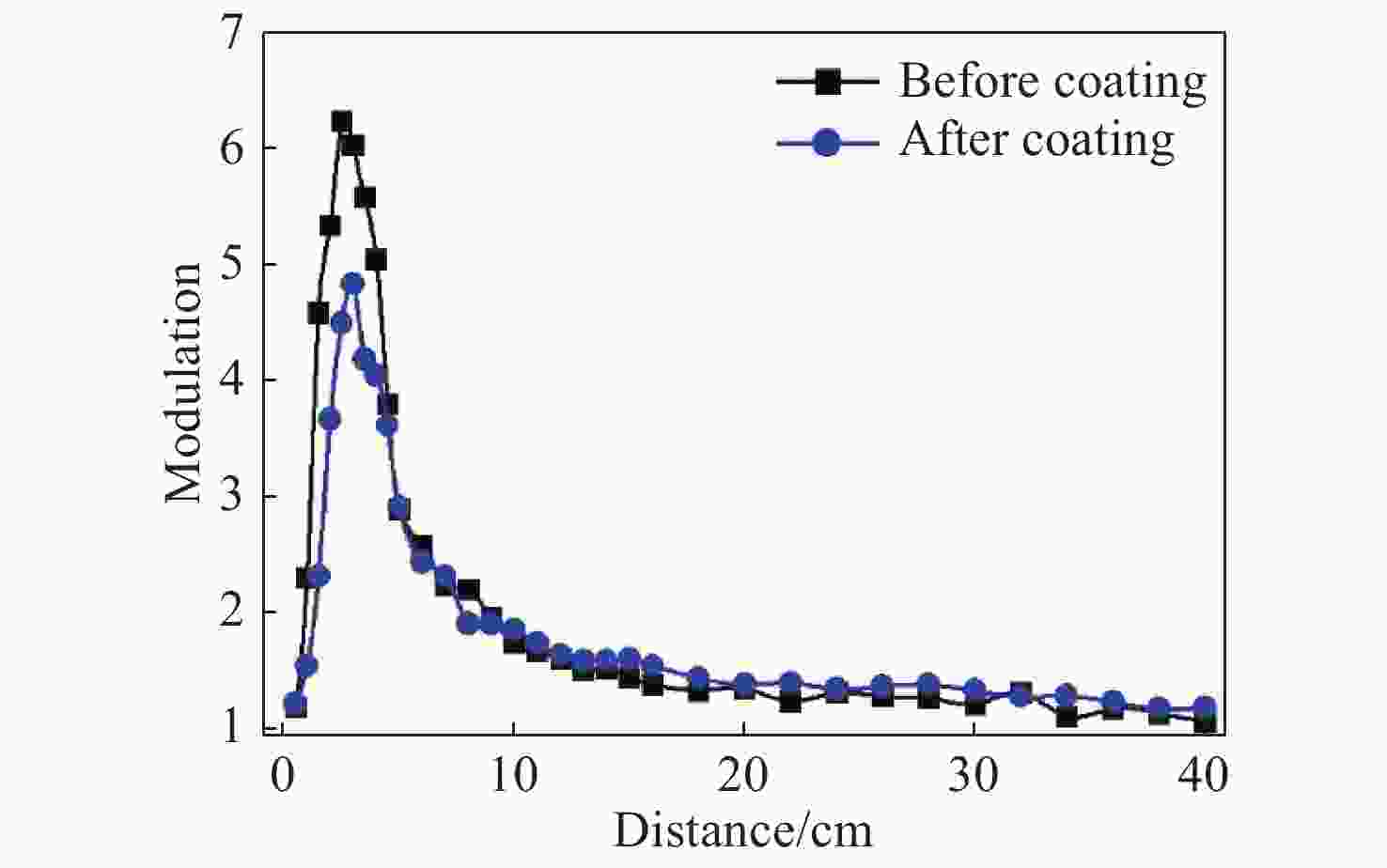

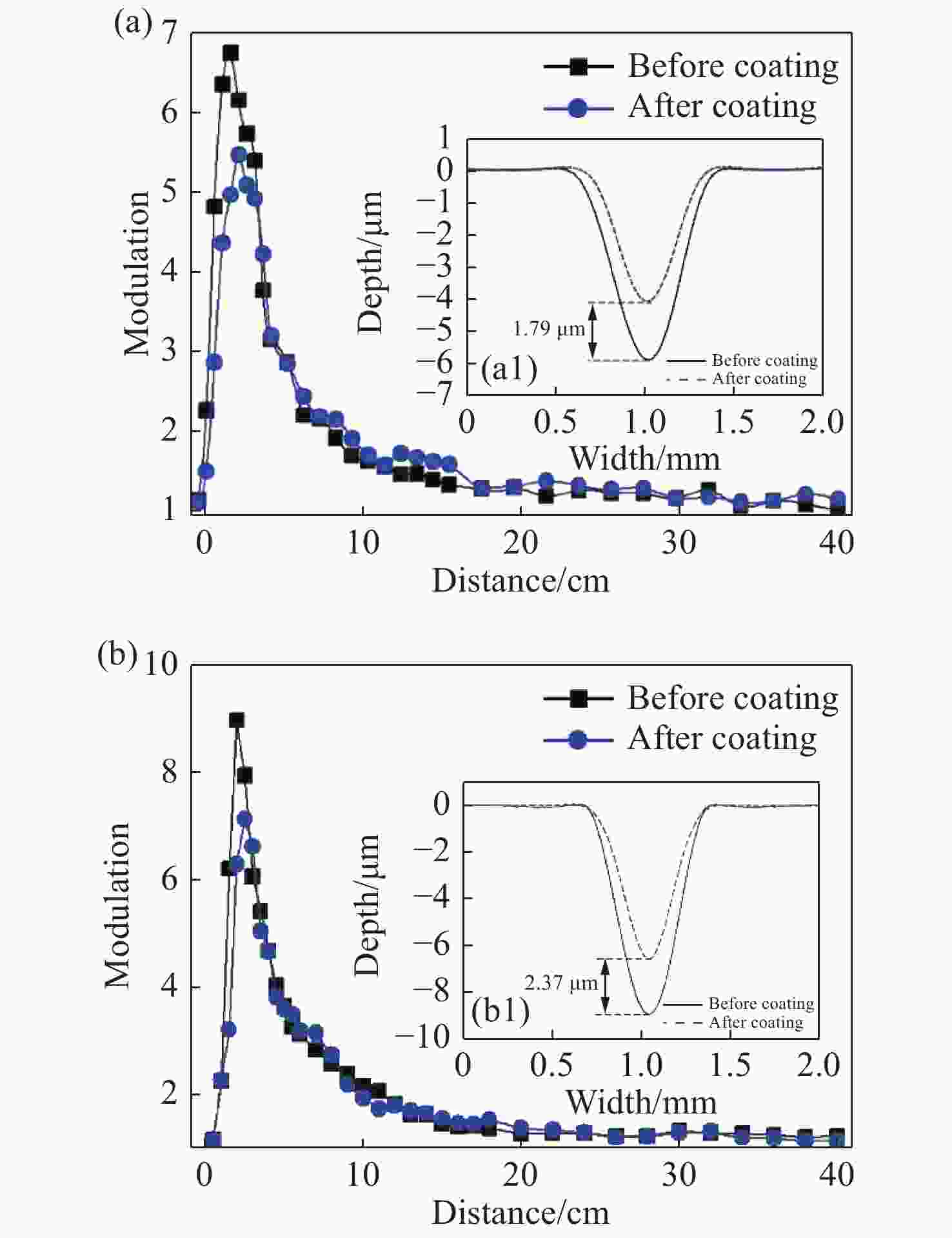

白阳, 张丽娟, 廖威, 等. 熔石英损伤修复坑下游光场调制的数值模拟与实验研究[J]. 物理学报,2016,65(2):024205. doi: 10.7498/aps.65.024205BAI Y, ZHANG L J, LIAO W, et al. Study of downstream light intensity modulation induced by mitigated damage pits of fused silica using numerical simulation and experimental measurements[J]. Acta Physica Sinica, 2016, 65(2): 024205. (in Chinese) doi: 10.7498/aps.65.024205

|

| [22] |

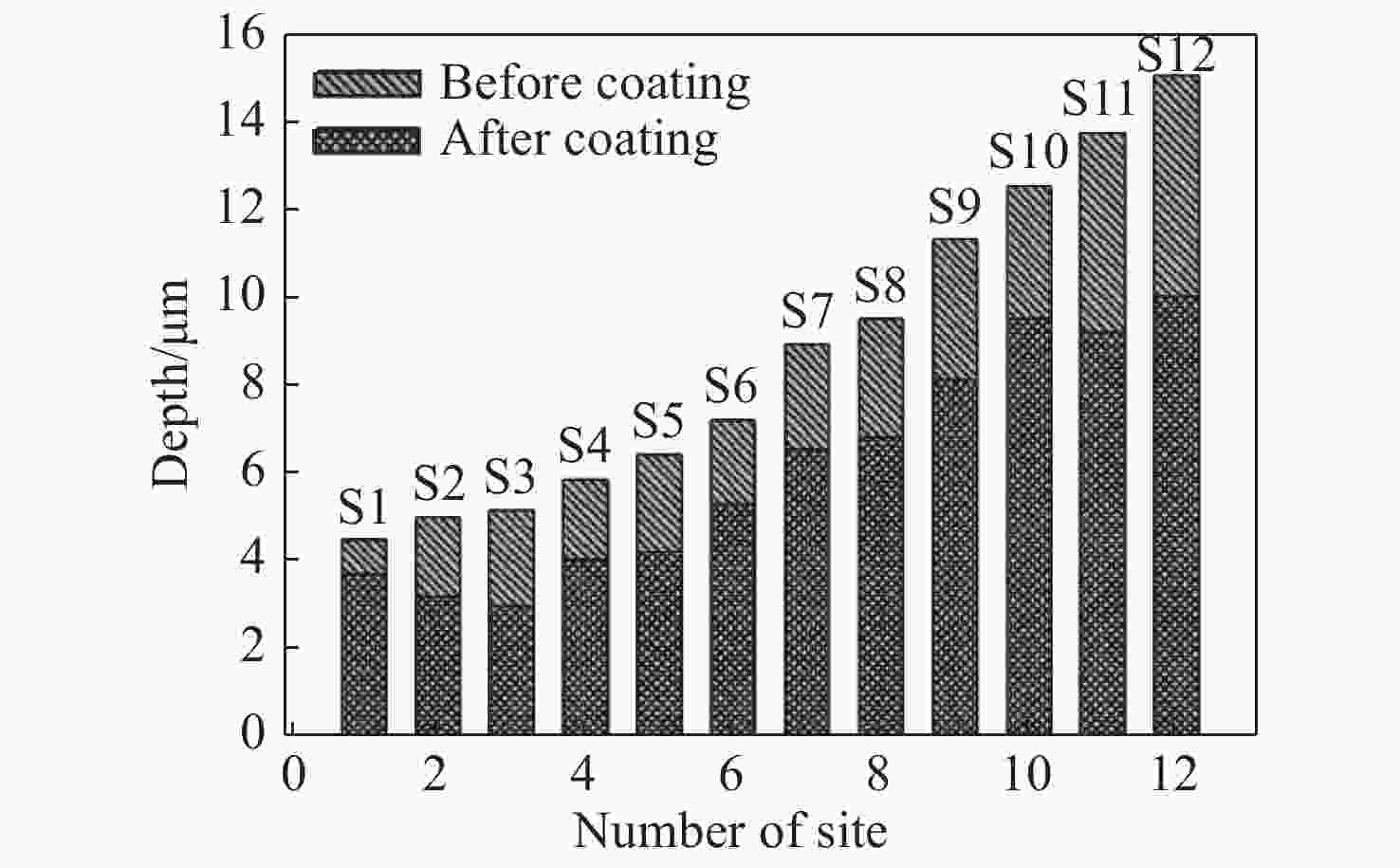

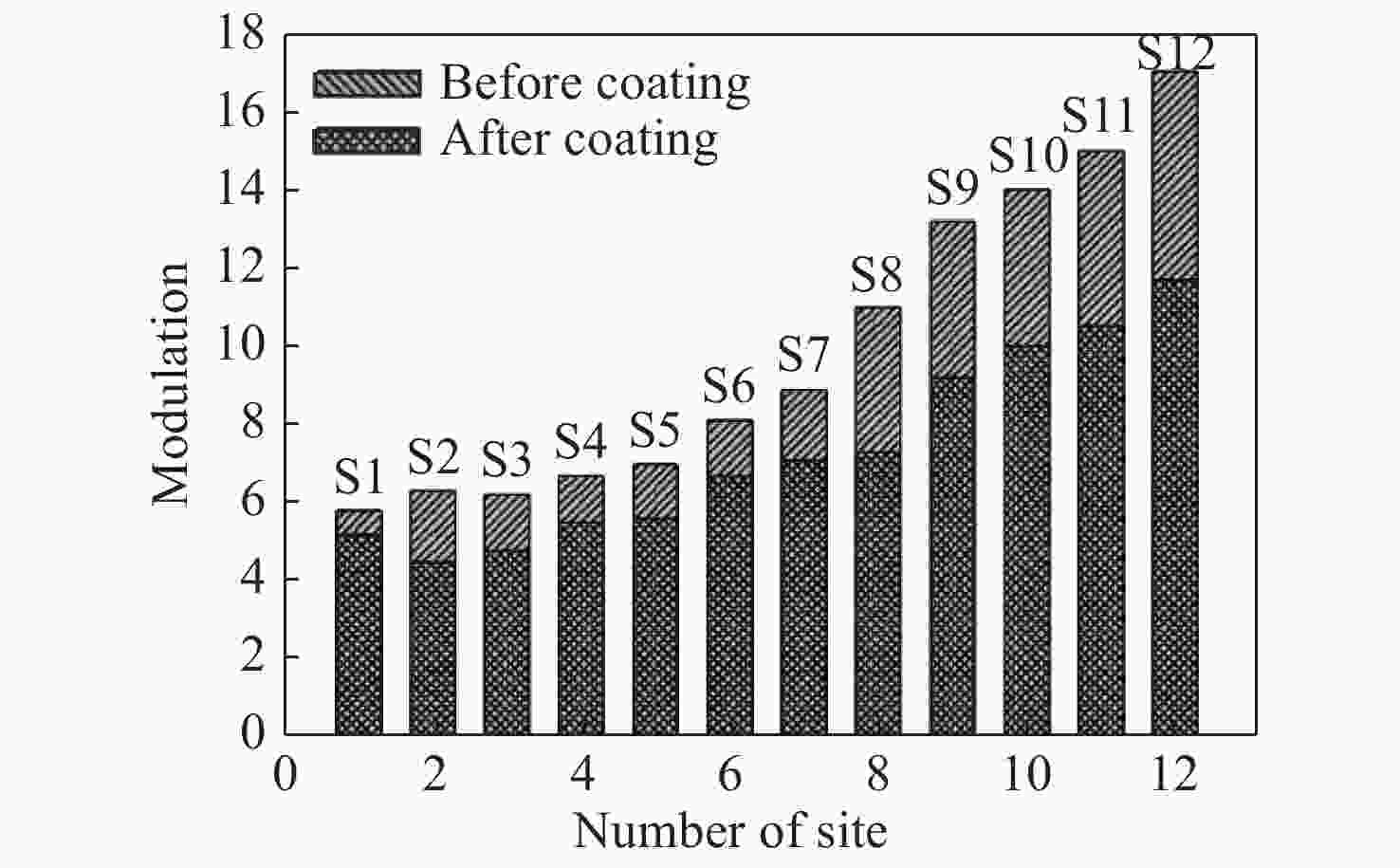

GAO X, JIANG Y, QIU R, et al. Effect of the repaired damage morphology of fused silica on the modulation of incident laser[J]. Optical Materials, 2017, 64: 295-301. doi: 10.1016/j.optmat.2016.12.032

|

| [23] |

LIAO W, LI B, ZHOU Q Y, et al. Optical modulation study of repaired damage morphologies of fused silica by scalar diffraction theory[J]. Optical Engineering, 2017, 56(1): 016113. doi: 10.1117/1.OE.56.1.016113

|

| [24] |

蒋勇, 向霞, 刘春明, 等. 熔石英表面损伤修复点上烧蚀碎片的分类与去除的研究[J]. 中国激光,2012,39(12):1203003. doi: 10.3788/CJL201239.1203003JIANG Y, XIANG X, LIU CH M, et al. Classification and elimination of ablation debris on the mitigated damage site in fused silica surface[J]. Chinese Journal of Lasers, 2012, 39(12): 1203003. (in Chinese) doi: 10.3788/CJL201239.1203003

|

| [25] |

蒋勇. 熔石英光学元件表面损伤修复的理论和实验研究[D]. 成都: 电子科技大学, 2012: 173-179.JIANG Y. Theoretical and experimental studies on surface damage repaire of fused silica optical components[D]. Chengdu: University of Electronic Science and Technology of China, 2012: 173-179. (in Chinese).

|

| [26] |

GUSS G, BASS I, DRAGGOO V, et al. Mitigation of growth of laser initiated surface damage in fused silica using a 4.6-micron wavelength laser[J]. Proceedings of SPIE, 2007, 6403: 64030M.

|

| [27] |

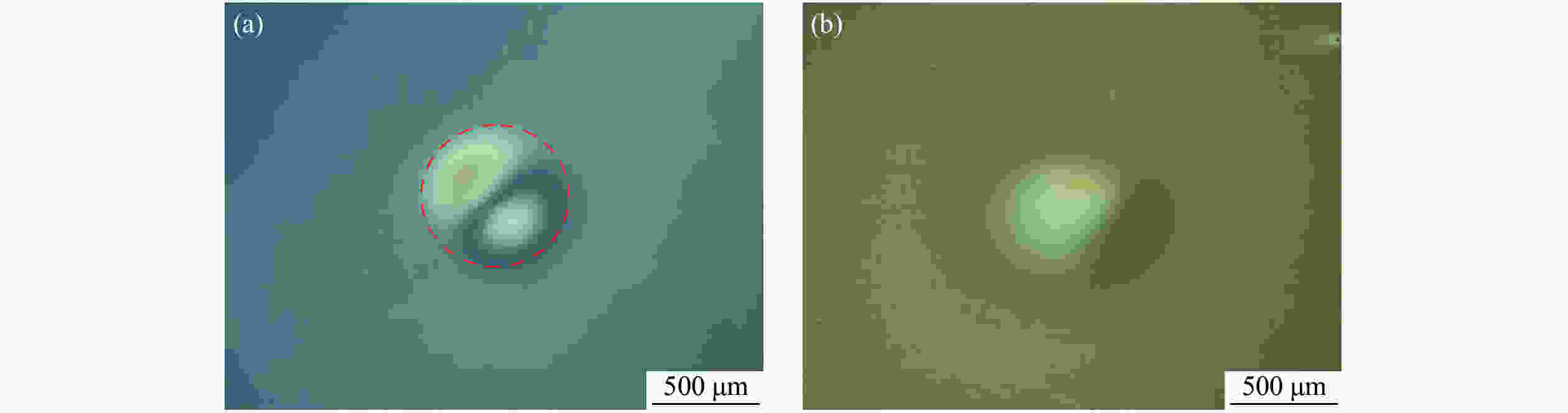

JIANG Y, MU X Y, QIU R, et al. Comparison of bare and sol-gel coated of mitigated site on fused silica[J]. Proceedings of SPIE, 2015, 9543: 95430M. doi: 10.1117/12.2177808

|

下载:

下载: