Composition analysis of the surface and depth distribution of metal and ceramic cultural relics by laser-induced breakdown spectroscopy

-

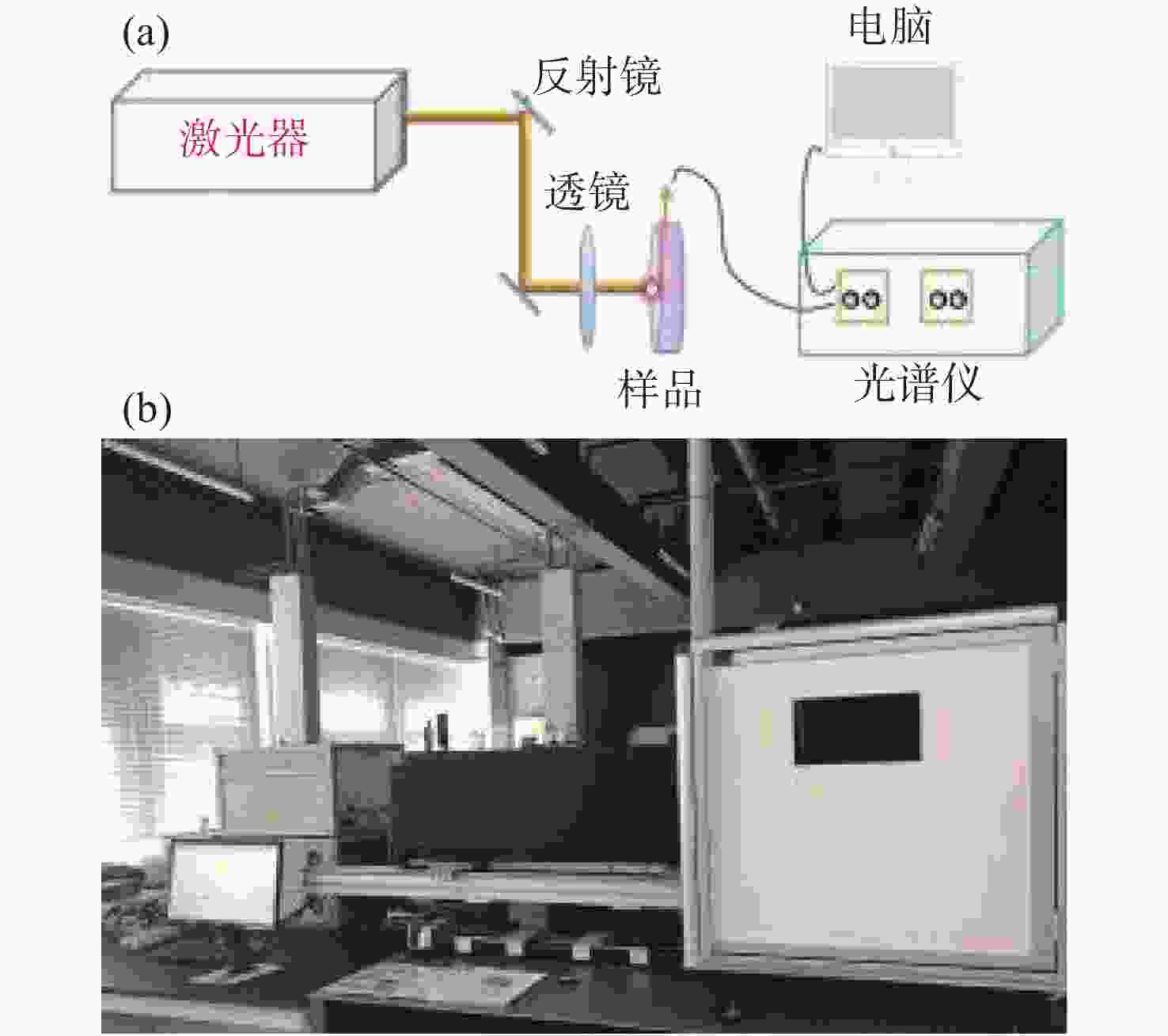

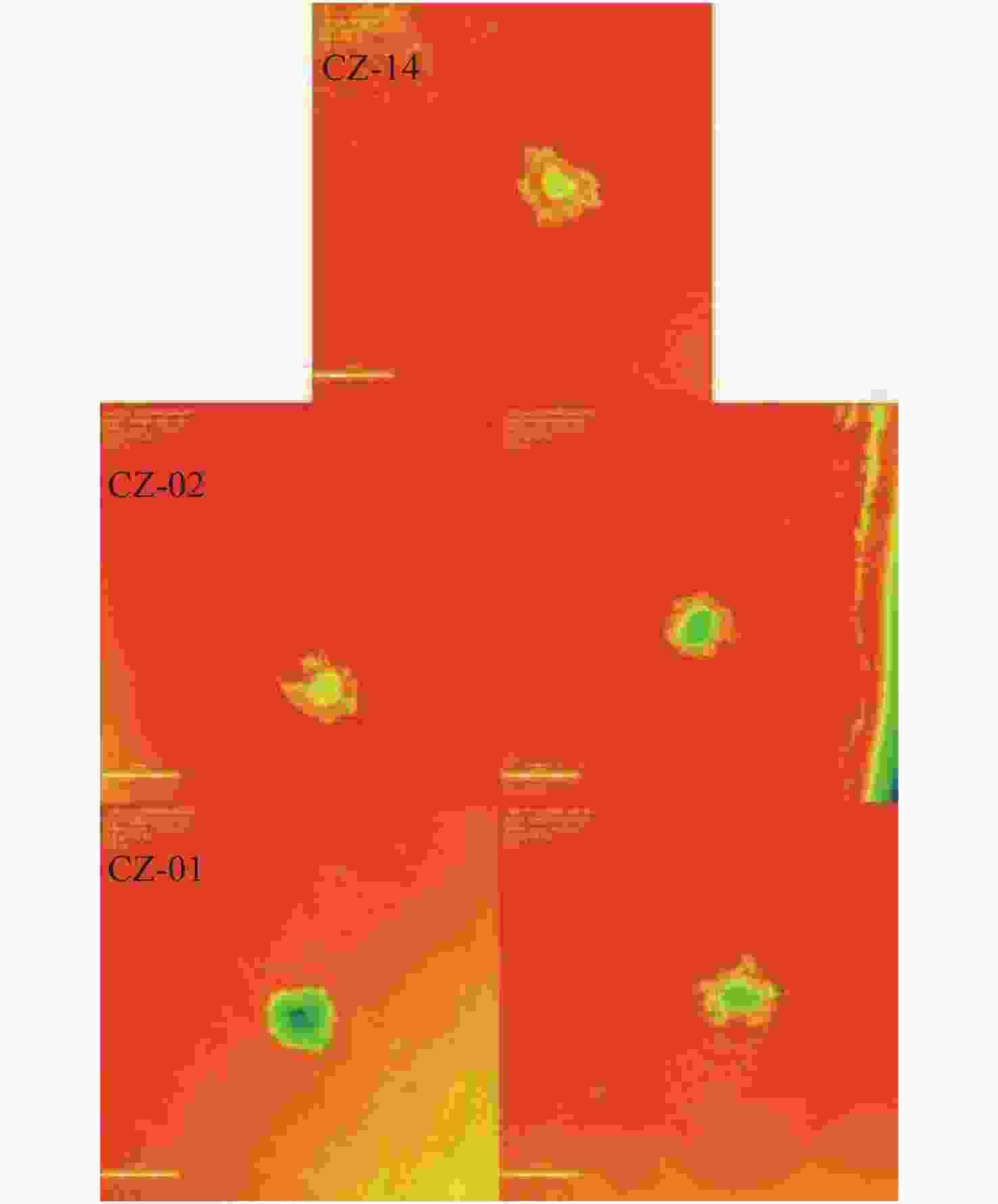

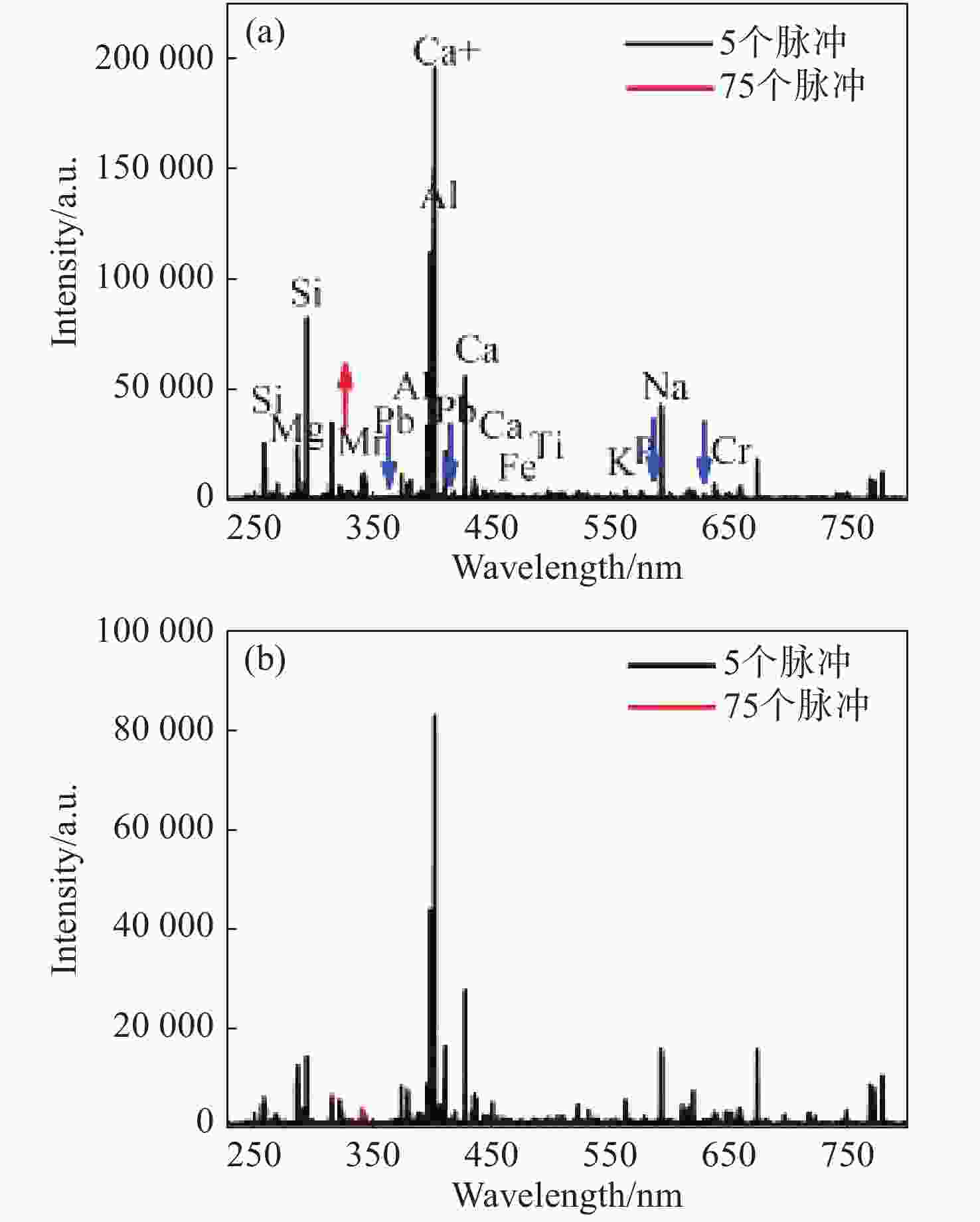

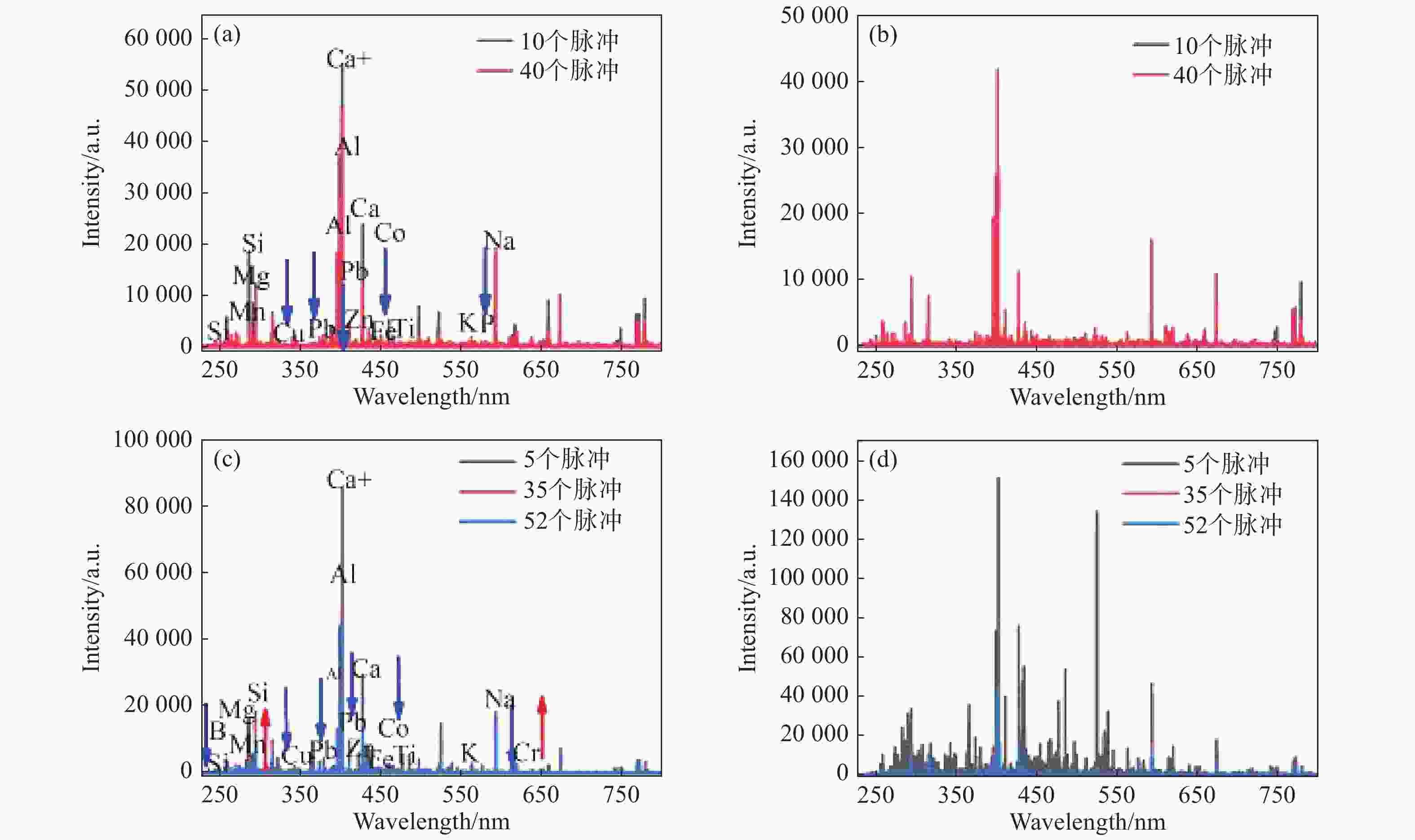

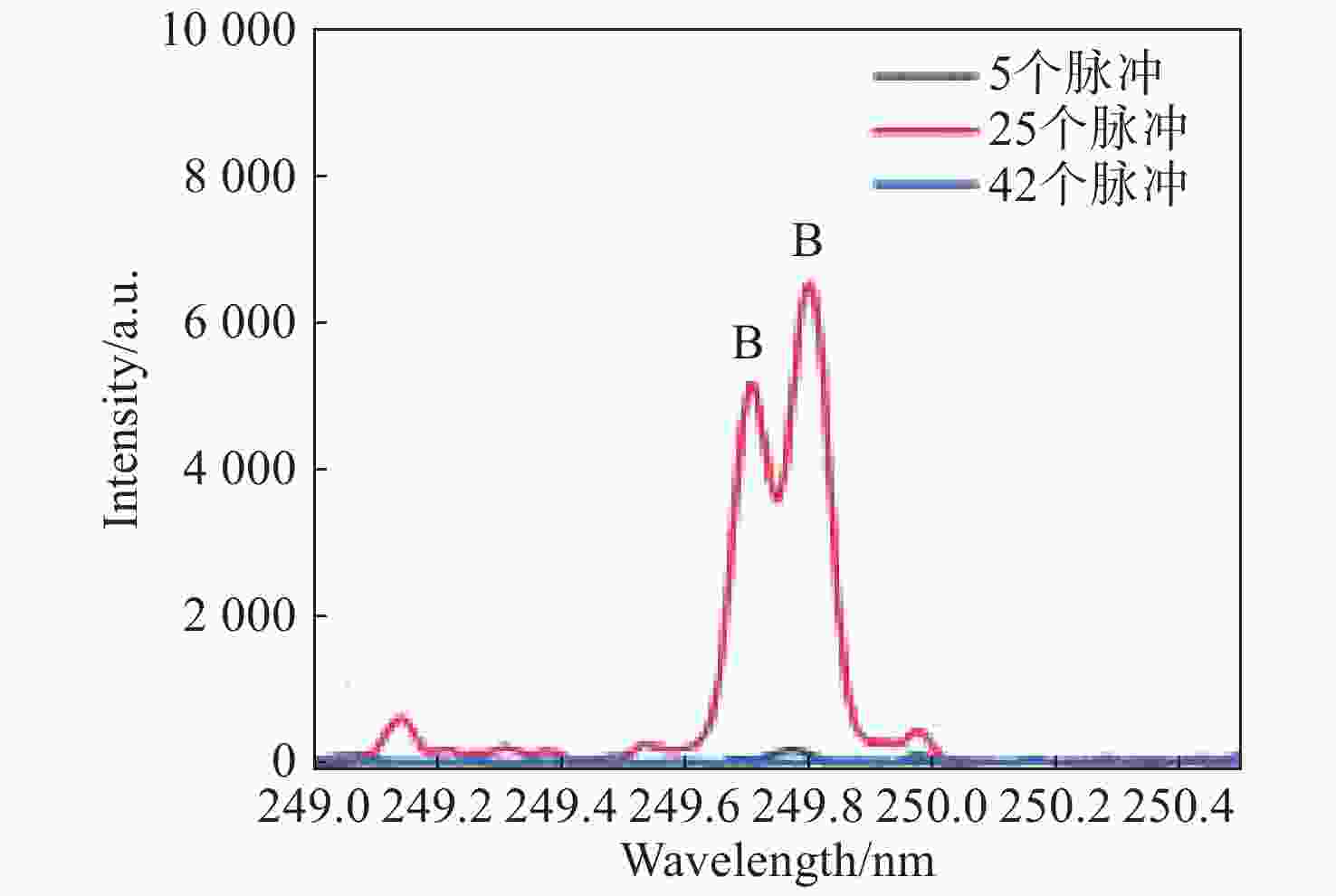

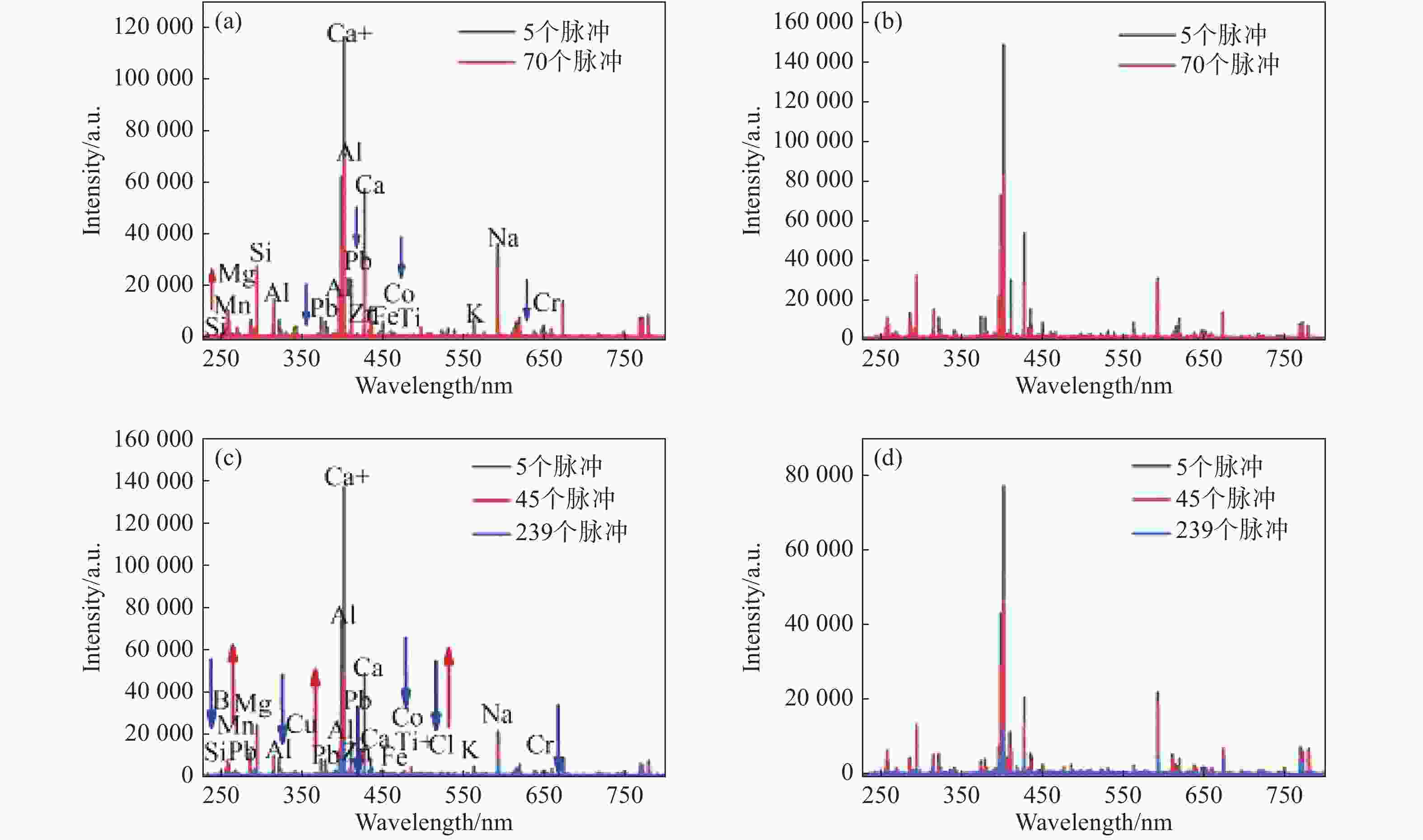

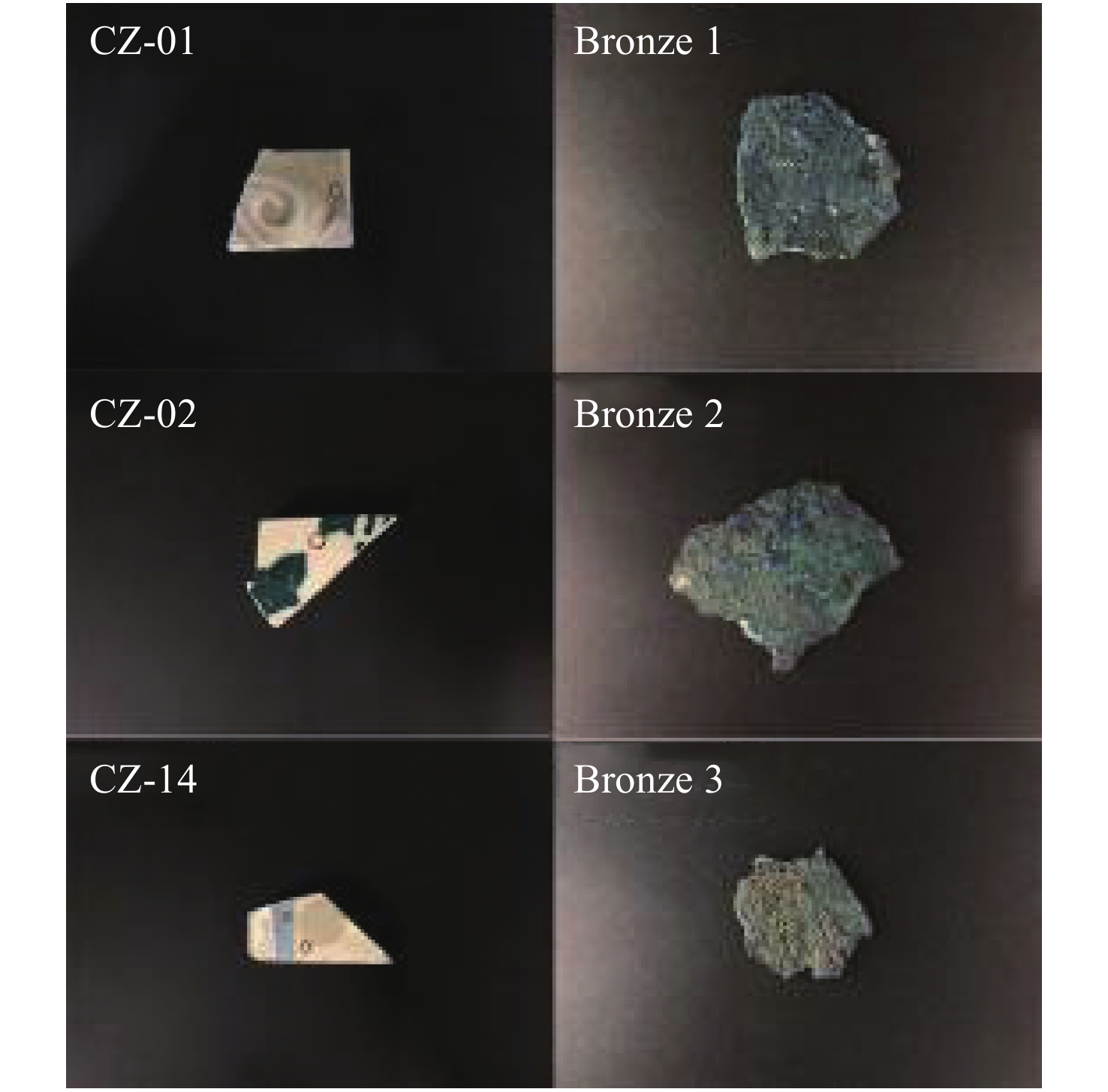

摘要: 采用激光诱导击穿光谱结合激光共聚焦显微镜,对河南省上蔡郭庄楚国墓葬群出土的青铜器和故宫博物院灵沼轩的陶瓷砖成分进行表面及深度分布分析。研究表明,青铜器表面的腐蚀层元素分布不均匀,可能源于周围的土壤环境和周围器物,或者从内部到外部的离子外移等,但基体组成相对比较简单。通过分析青铜器腐蚀层成分的深度分布可以了解腐蚀层的腐蚀机理,从而为青铜器的保护提供科学方法;陶瓷的透明釉层和釉彩料层元素分布均匀,釉彩料层存在一定的硼元素,而透明釉中则不含硼元素,原因在于硼元素可有效降低釉的熔融温度范围和表面张力。进一步利用共聚焦显微镜测试剥蚀深度,结合得到的光谱估算出了不同釉层的大概厚度。Abstract: Composition analysis of the surface and depth distribution of bronze artifacts excavated from the Chu Tomb in Guozhuang Shangcai, Henan Province and ceramic tiles of Lingzhaoxuan from the Palace Museum are carried out by laser-induced breakdown spectroscopy and laser scanning confocal microscopy. Studies have shown that the elemental distribution of the corroded layer on the surface of bronze is uneven. This corrosion might originate from the surrounding soil environment and surrounding artifacts or ion migration from the artifacts’ insides to their outsides. Luckily, the composition of bronze is relatively simple. The corrosion mechanism of the corroded layer can be understood by analyzing the depth distribution of the composition in bronze, thereby providing a scientific method for its protection. The elemental distribution of ceramic is homogeneous in transparent and colored glaze. Colored glaze includes Boron (B), which could effectively reduce its melting temperature range and surface tension, but there is no boron (B) in transparent glaze. Furthermore, confocal microscope tests of the depth of erosion combined with its spectra can be used to estimate the approximate thickness of different glaze layers.

-

Key words:

- laser-induced breakdown spectroscopy /

- surface and depth distribution /

- bronze /

- ceramic

-

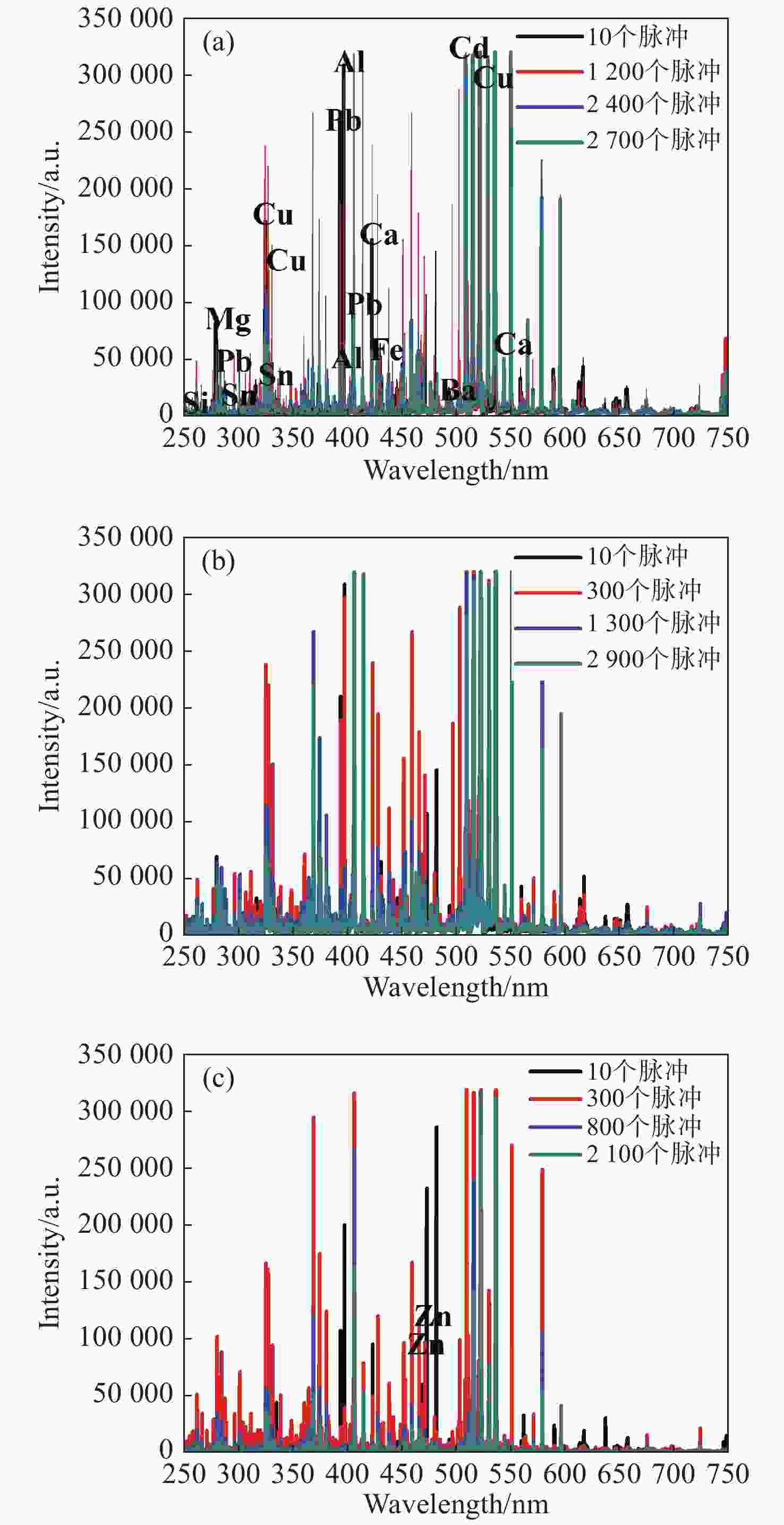

表 1 bronze 1表面及深度的元素分布结果

Table 1. Surface and depth distribution of different elements of bronze 1

编号 bronze 1 点位1 表面 Cu、Pb、Mg、Al、Ca、Fe、Si、O、Cl、Cd、Ba 深度1 Cu、Pb、Mg、Al、Ca、Fe、Si、O、Cl、Cd、Ba、Sn 深度2 Cu、Pb、Mg、Al、Ca、Cd、Ba、Sn 点位2 表面 Cu、Pb、Mg、Al、Ca、Fe、Si、O、Cl、Cd、Ba、Zn 深度1 Cu、Pb、Mg、Al、Ca、Fe、Si、O、Cl、Cd、Ba、Sn、Zn 深度2 Cu、Pb、Mg、Al、Ca、Cd、Ba、Sn 点位3 表面 Cu、Pb、Mg、Al、Ca、Fe、O、Cl、Cd、Ba、Si、Zn 深度1 Cu、Pb、Mg、Al、Ca、Fe、Si、O、Cl、Cd、Ba、Sn、Zn 深度2 Cu、Pb、Mg、Al、Ca、Cd、Ba、Sn 表 2 bronze 2的元素表面及深度分布的结果

Table 2. Surface and depth distribution of different elements of bronze 2

编号 bronze 2 点位1 表面 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、Si、Cl、Ni、Cd、O、Sn、Ni、Eu、Cd、Rh、Nb、Ru、Th、Dy 深度1 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、Si、Cl、Ni、Cd、O、Sn、Ni、Eu、Cd、Rh、Nb、Ru、Th、Dy 深度2 Cu、Pb、Sn、Mg、Na、Al、Ca、Cd、Sn 点位2 表面 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、Si、Cl、Ni、Cd、O、Sn、Ni、Eu、Cd、Rh、Nb、Ru、Th、Dy 深度1 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、Si、Cl、Ni、Cd、O、Sn、Ni、Eu、Cd、Rh、Nb、Ru、Th、Dy 深度2 Cu、Pb、Sn、Mg、Na、Al、Ca、Cd、Sn 点位3 表面 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、Si、Cl、Ni、Cd、O、Sn、Zn、Ni、Eu、Cd、Rh、Nb、Ru、Th、Dy 深度1 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、Si、Cl、Ni、Cd、O、Sn、Ni、Eu、Cd、Rh、Nb、Ru、Th、Dy 深度2 Cu、Pb、Sn、Mg、Na、Al、Ca、Cd、Sn 表 3 bronze 3的元素表面及深度分布结果

Table 3. Surface and depth distribution of different elements of bronze 3

编号 bronze 3 点位1 表面 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、 Si、Cl、Ni、

Cd、O、Sn、Ni、Eu、 Cd、Rh、Nb、Ru、Th、Dy深度1 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、 Si、Cl、Ni、

Cd、O、Sn、Ni、Eu、 Cd、Rh、Nb、Ru、Th、Dy深度2 Cu、Pb、Sn、Mg、Na、Al、Ca、Cd、Sn 点位2 表面 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、 Si、Cl、Ni、

Cd、O、Sn、Ni、Eu、 Cd、Rh、Nb、Ru、Th、Dy深度1 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、 Si、Cl、Ni、

Cd、O、Sn、Ni、Eu、 Cd、Rh、Nb、Ru、Th、Dy深度2 Cu、Pb、Sn、Mg、Na、Al、Ca、Cd、Sn 点位3 表面 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、 Si、Cl、Ni、

Cd、O、Sn、Ni、Eu、 Cd、Rh、Nb、Ru、Th、Dy深度1 Cu、Pb、Sn、Mg、Na、Al、Ca、Fe、 Si、Cl、Ni、

Cd、O、Sn、Ni、Eu、 Cd、Rh、Nb、Ru、Th、Dy深度2 Cu、Pb、Sn、Mg、Na、Al、Ca、Cd、Sn 表 4 陶瓷砖样品不同点位的平均剥蚀深度

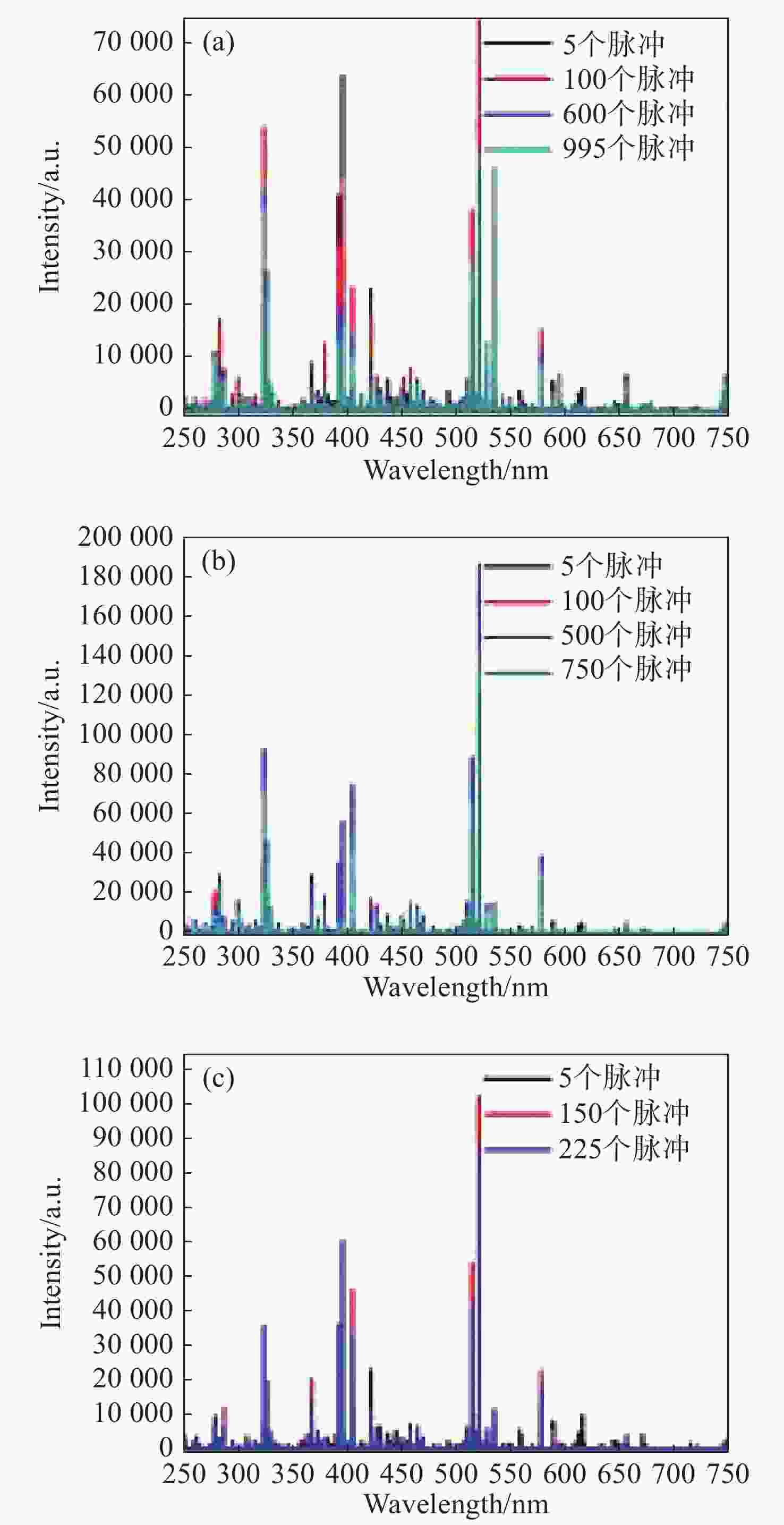

Table 4. The average denudation depths of ceramic tile samples at different points (μm)

编号 宽度 高度 长度 CZ-14白色 1027.888 42.381 1028.907 CZ-01白色 1027.888 82.791 1031.621 CZ-01绿色 1027.888 78.458 1031.862 CZ-02白色 1027.888 53.414 1029.743 CZ-02蓝色 1027.888 64.516 1030.202 表 5 CZ-14的元素表面及深度分布结果

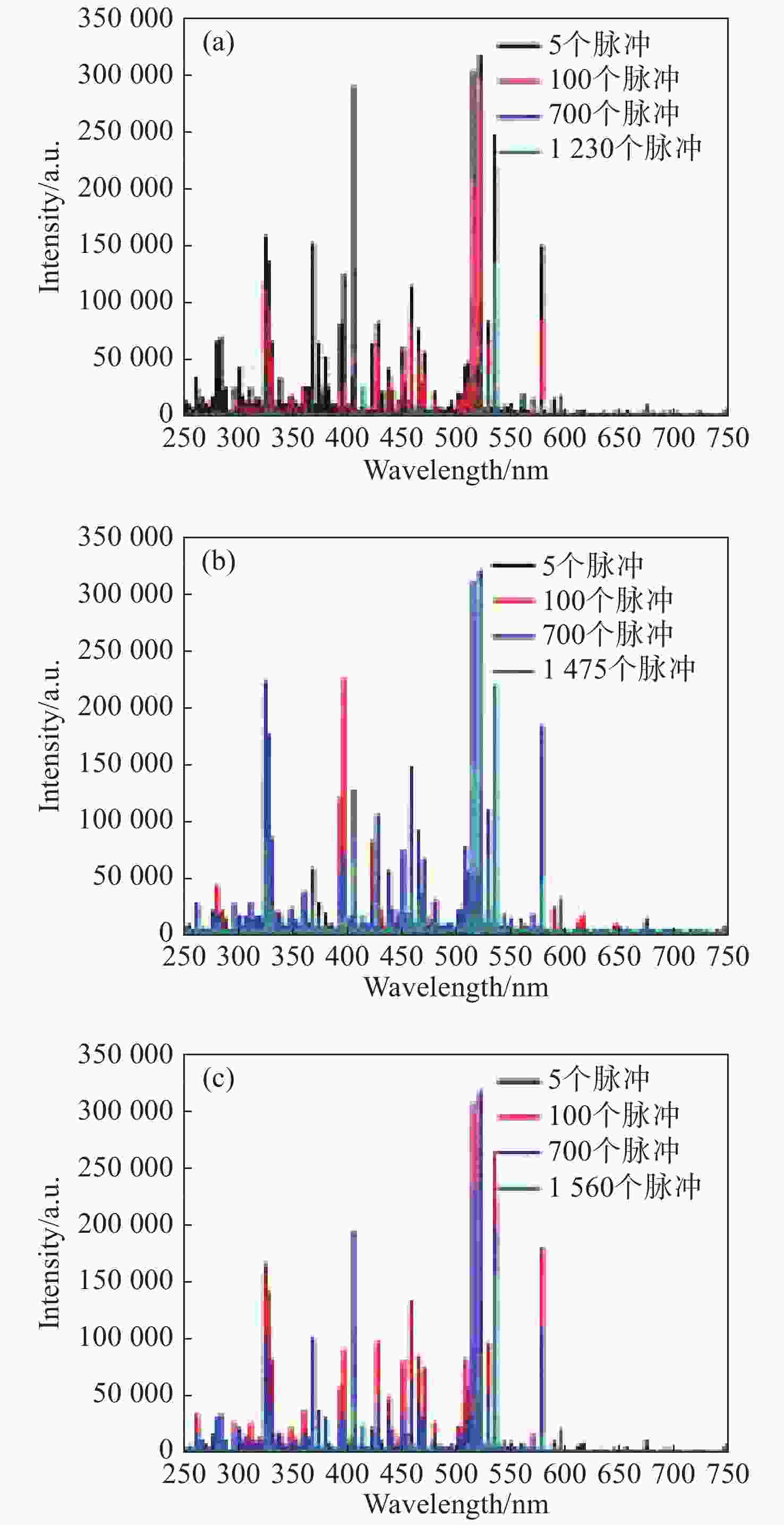

Table 5. Elemental surface and depth distribution of CZ-14

编号 CZ-14 分析点位 表面(5个脉冲) (透明釉)Na、Mg、Al、Si、K、Ca、Cr、P、Ti、Fe、O、Pb、Cu、Mn、Co 深度64 µm(75或者76个脉冲) Na、Mg、Al、Si、K、Ca、Ti、Fe、O、Mn、(胎体)Rb、Sr、Y和Zr 表 6 CZ-01的元素表面及深度分布结果

Table 6. Surface and depth distribution of different elements of CZ-01

编号 CZ-01 白色部分分析点位 表面(5个脉冲) (透明釉)Na、Mg、Al、Si、K、Ca、Ca+、Ti、Fe、O、Co、Zn、Cu、Pb、Mn、P、Cr 深度67 µm(40或41个脉冲) Na、Mg、Al、Si、K、Ca、Ca+、Ti、Fe、O、Mn、Cr、(胎体元素)Sr、Rb、Y和Zr 绿色部分分析点位 表面(5或6个脉冲) (透明釉)Na、Mg、Al、Si、K、Ca、Ca+、Fe、O、Zn、Cu、Ti、Pb、Co、Cr、Mn、P 深度40 µm(25或者26个脉冲) (绿色釉彩)Na、Mg、Al、Si、K、Ca、Ca+、Fe、O、Zn、Ti、Pb、Co、Cr、Mn、B 深度56 µm(42或43个脉冲) (透明釉)Na、Mg、Al、Si、K、Ca、Ca+、Fe、O、Zn、Cu、Ti、Pb、Co、Cr、Mn、P 深度84 µm(52或53个脉冲) Na、Mg、Al、Si、K、Ca、Ca+、Fe、O、Ti、Co、Mn、(胎体)Rb、Sr、Y和Zr 表 7 CZ-02的元素表面及深度分布结果

Table 7. Surface and depth distribution of different elements of CZ-02

编号 CZ-02 白色部分分析点位 表面(5个脉冲) (透明釉)Na、Mg、Al、Si、K、Ca、Ca+、Ti、Fe、O、Cr、Co、Zn、Pb、P、Cu 深度75 µm(70或者71个脉冲) Na、Mg、Al、Si、K、Ca、Ca+、Ti、Fe、O、Mn、(胎体)Sr、Rb、Y、Zr 蓝色部分分析点位 表面(5个脉冲) (透明釉)Na、Mg、Al、Si、K、Ca、Ca+、Ti、Fe、O、Co、Zn、Pb、Cu、P、Cr 深度59 µm(45或者46个脉冲) (蓝色釉彩)Na、Mg、Al、Si、K、Ca、Ca+、Ti、Fe、O、Co、Zn、Pb、Cu、B、Cl、Mn 深度308 µm(253或者254个脉冲) Na、Mg、Al、Si、K、Ca、Ca+、Ti、Fe、O、Mn、(胎体)Sr、Rb、Y、Zr -

[1] 陈卉. 青铜器和陶瓷在文化艺术形态上的比较[J]. 艺苑,2012(1):93-98.CHEN H. A comparison of the cultural and artistic forms of bronzes and ceramics[J]. Forum of Arts, 2012(1): 93-98. (in Chinese) [2] 任佳, 高勋. 飞秒细丝-纳秒激光诱导击穿光谱技术对土壤重金属Pb元素检测[J]. 光学 精密工程,2019,27(5):1069-1074. doi: 10.3788/OPE.20192705.1069REN J, GAO X. Detection of heavy metal Pb in soil by filament-nanosecond laser induced breakdown spectroscopy[J]. Optics and Precision Engineering, 2019, 27(5): 1069-1074. (in Chinese) doi: 10.3788/OPE.20192705.1069 [3] 王慧丽, 王建伟, 周强, 等. 激光诱导击穿光谱法定量分析水泥中的铜元素[J]. 发光学报,2017,38(11):1553-1558. doi: 10.3788/fgxb20173811.1553WANG H L, WANG J W, ZHOU Q, et al. Quantitative analysis of Cu in cement by laser induced breakdown spectroscopy[J]. Chinese Journal of Luminescence, 2017, 38(11): 1553-1558. (in Chinese) doi: 10.3788/fgxb20173811.1553 [4] 刘津, 孙通, 甘兰萍. 基于内标法和CARS变量优选的倍硫磷含量LIBS检测[J]. 发光学报,2018,39(5):737-744. doi: 10.3788/fgxb20183905.0737LIU J, SUN T, GAN L P. Detection of fenthion content by LIBS combined with internal standard and CARS variable selection method[J]. Chinese Journal of Luminescence, 2018, 39(5): 737-744. (in Chinese) doi: 10.3788/fgxb20183905.0737 [5] ALBERGHINA M F, BARRACO R, BRAI M, et al. Integrated analytical methodologies for the study of corrosion processes in archaeological bronzes[J]. Spectrochimica Acta Part B:Atomic Spectroscopy, 2011, 66(2): 129-137. doi: 10.1016/j.sab.2010.12.010 [6] ABERKANE S M, ABDELHAMID M, YAHIAOUI K, et al. Depth profiling of alumina thin films using laser induced breakdown spectroscopy: structural and morphological dependence[J]. Thin Solid Films, 2018, 653: 293-300. doi: 10.1016/j.tsf.2018.03.052 [7] KE CH, LI Y, LIU X, et al. Application of laser induced breakdown spectroscopy for fast depth profiling analysis of type 316 stainless steel parts corroded by liquid lithium[J]. Fusion Engineering and Design, 2018, 136: 1647-1652. doi: 10.1016/j.fusengdes.2018.07.004 [8] MATEO M, BECERRA J, ZADERENKO A P, et al. Laser-induced breakdown spectroscopy applied to the evaluation of penetration depth of bactericidal treatments based on silver nanoparticles in limestones[J]. Spectrochimica Acta Part B:Atomic Spectroscopy, 2018, 152: 44-51. doi: 10.1016/j.sab.2018.11.010 [9] SUCHOŇOVÁ M, VEIS P, KARHUNEN J, et al. Determination of deuterium depth profiles in fusion-relevant wall materials by nanosecond LIBS[J]. Nuclear Materials and Energy, 2017, 12: 611-616. doi: 10.1016/j.nme.2017.05.013 [10] 张晓梅, 原思训, 刘煜, 等. 周原遗址及?国墓地出土青铜器锈蚀研究[J]. 文物保护与考古科学,1999,11(2):7-18.ZHANG X M, YUAN S X, LIU Y, et al. Research on the corrosion of bronzes from Zhouyuan site and Yu State cemeteries[J]. Sciences of Conservation and Archaeology, 1999, 11(2): 7-18. (in Chinese) [11] 胡志孟, 邹惠良, 彭适凡, 等. 新干商代不锈青铜器的表层元素研究[J]. 兵器材料科学与工程,1997,20(6):44-48.HU ZH M, ZOU H L, PENG SH F, et al. Study on surface layer elements for stainless bronze ware of Xingan in Shang Dynasty[J]. Ordnance Material Science and Engineering, 1997, 20(6): 44-48. (in Chinese) [12] 何文权, 熊樱菲. 古陶瓷元素成分分析技术定量方法的探讨[J]. 文物保护与考古科学,2003,15(3):13-20. doi: 10.3969/j.issn.1005-1538.2003.03.003HE W Q. XIONG Y F. Quantitative analysis of ancient ceramic by X-ray spectroscopy techniques[J]. Sciences of Conservation and Archaeology, 2003, 15(3): 13-20. (in Chinese) doi: 10.3969/j.issn.1005-1538.2003.03.003 [13] 郑乃章, 吴军明, 吴隽, 等. 古陶瓷研究和鉴定中的化学组成仪器分析法[J]. 中国陶瓷,2007,43(5):52-54. doi: 10.3969/j.issn.1001-9642.2007.05.015ZHENG N ZH, WU J M, WU J, et al. Chemical composition analytical methods be instruments on the identifications and studies of ancient ceramics by instruments[J]. China Ceramics, 2007, 43(5): 52-54. (in Chinese) doi: 10.3969/j.issn.1001-9642.2007.05.015 [14] 阎宏涛, 昌征. 激光诱导击穿光谱分析法及其在彩绘文物分析与表征中的应用[J]. 西北大学学报(自然科学版),2009,39(4):586-590.YAN H T, CHANG ZH. The laser-induced breakdown spectroscopy and its applications in the polychrome cultural relics[J]. Journal of Northwest University (Natural Science Edition) , 2009, 39(4): 586-590. (in Chinese) [15] 李涛. 山东蓬莱出土古代青铜器的腐蚀研究[D]. 合肥: 中国科学技术大学, 2007.LI T. The corrosion study of ancient bronzes excavated from penglai, Shandong province[D]. Hefei: University of Science and Technology of China, 2007. (in Chinese). [16] 王菊琳, 许淳淳. 青铜在土壤中局部腐蚀过程的化学行为[J]. 化工学报,2004,55(7):1135-1139. doi: 10.3321/j.issn:0438-1157.2004.07.020WANG J L, XU CH CH. Chemical behavior of bronze localized corrosion in soil[J]. Journal of Chemical Industry and Engineering (China) , 2004, 55(7): 1135-1139. (in Chinese) doi: 10.3321/j.issn:0438-1157.2004.07.020 [17] 汤琪, 王菊琳, 马菁毓. 土壤腐蚀过程中高锡青铜的形貌变化和元素迁移[J]. 中国有色金属学报,2011,21(12):3175-3181.TANG Q, WANG J L, MA J Y. Morphology change and elements migration of bronze with high tin content after soil corrosion[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(12): 3175-3181. (in Chinese) [18] 孙晓强. 青铜器的腐蚀与保护探讨[J]. 文物世界,2002(6):56-60. doi: 10.3969/j.issn.1009-1092.2002.06.022SUN X Q. A probe into the corrosion and the protection of bronzes[J]. World of Antiquity, 2002(6): 56-60. (in Chinese) doi: 10.3969/j.issn.1009-1092.2002.06.022 [19] 刘薇, 陈建立. 古代青铜器表面高锡锈层研究综述[J]. 中国国家博物馆馆刊,2019(5):146-160.LIU W, CHEN J L. The advances in the study of tin-rich patina on the surface of ancient bronzes[J]. Journal of National Museum of China, 2019(5): 146-160. (in Chinese) [20] 杨菊. 赤峰地区青铜时代晚期铜器的科学分析研究[D]. 北京: 北京科技大学, 2015.YANG J. Scientific study on the late bronze age bronzes from Chifeng region[D]. Beijing: University of Science and Technology Beijing, 2015. (in Chinese). [21] THORNTON C P, REHREN T, PIGOTT V C. The production of speiss (iron arsenide) during the early bronze age in Iran[J]. Journal of Archaeological Science, 2009, 36(2): 308-316. doi: 10.1016/j.jas.2008.09.017 [22] REHREN T, BOSCHER L, PERNICKA E. Large scale smelting of speiss and arsenical copper at early bronze age Arisman, Iran[J]. Journal of Archaeological Science, 2012, 39(6): 1717-1727. doi: 10.1016/j.jas.2012.01.009 [23] 魏国锋. 古代青铜器矿料来源与产地研究的新进展[D]. 合肥: 中国科学技术大学, 2007.WEI G F. New progress in the study of the origin and origin of ancient bronze ores[D]. Hefei: University of Science and Technology of China, 2007. (in Chinese) [24] 李冬玲, 张勇, 鹿锋华. 激光诱导击穿光谱法对焊接接头表面渗铜区铜元素的深度分布分析[J]. 冶金分析,2015,35(1):19-25.LI D L, ZHANG Y, LU F H. Depth distribution analysis of copper in copper infiltration zone of welding joint surface by laser induced breakdown spectrometry[J]. Metallurgical Analysis, 2015, 35(1): 19-25. (in Chinese) [25] 段鸿莺, 赵鹏, 黄超, 等. 故宫博物院灵沼轩陶瓷砖的分析研究[J]. 故宫学刊,2019:524-535.DUAN H Y, ZHAO P, HUANG CH, et al. Analysis and research on Lingzhaoxuan ceramic tiles in the palace museum[J]. Journal of Gugong Studies, 2019: 524-535. (in Chinese) -

下载:

下载: