-

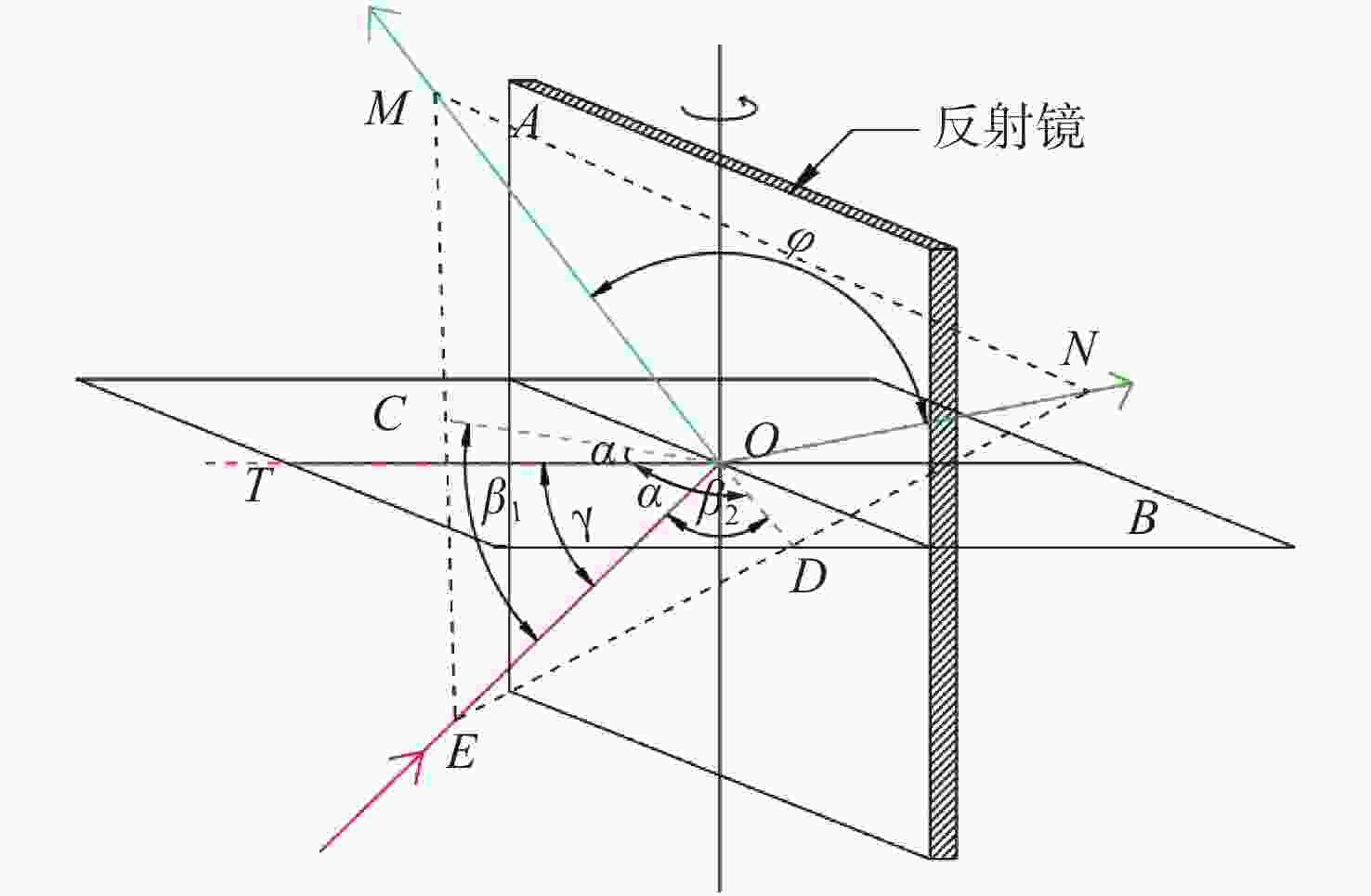

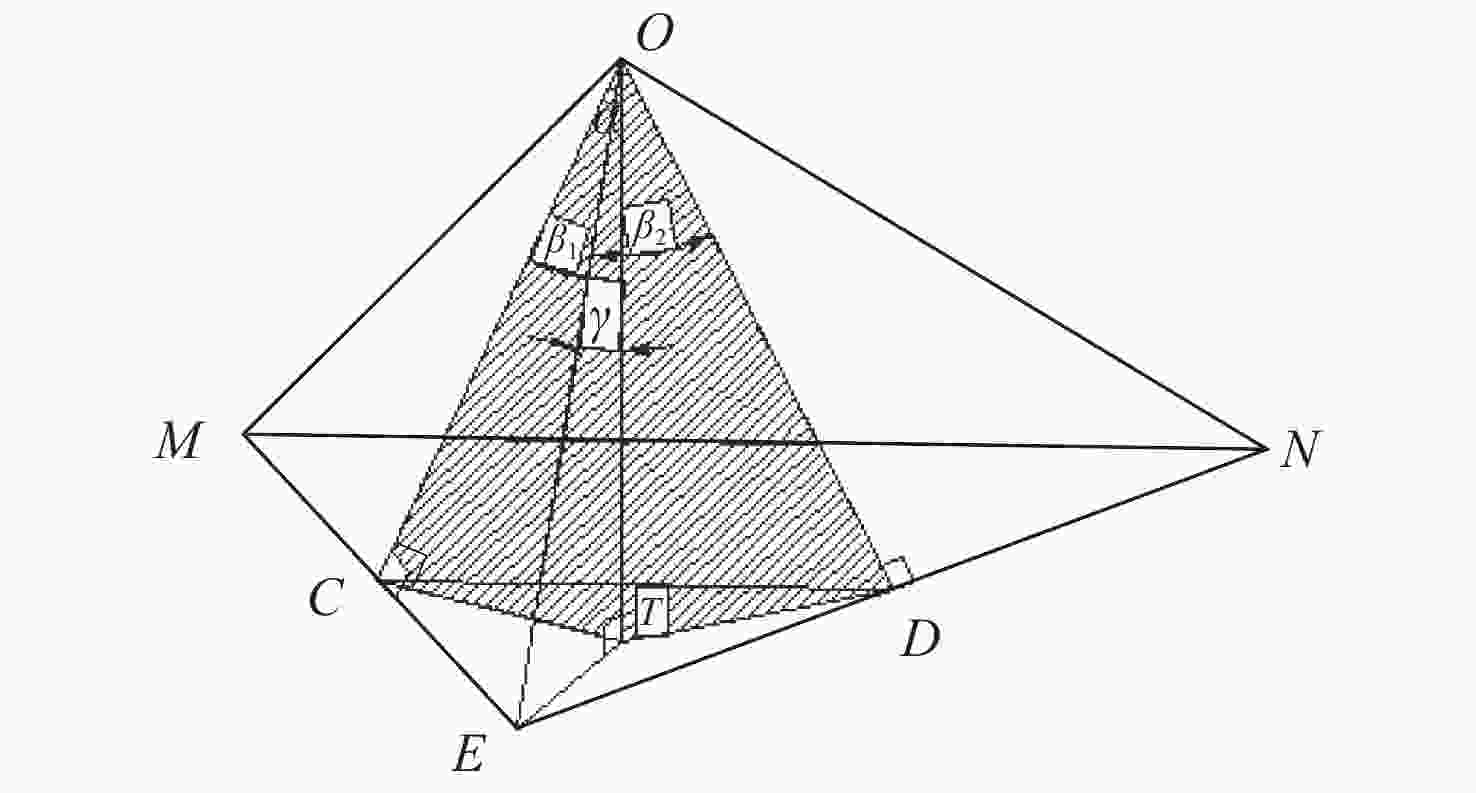

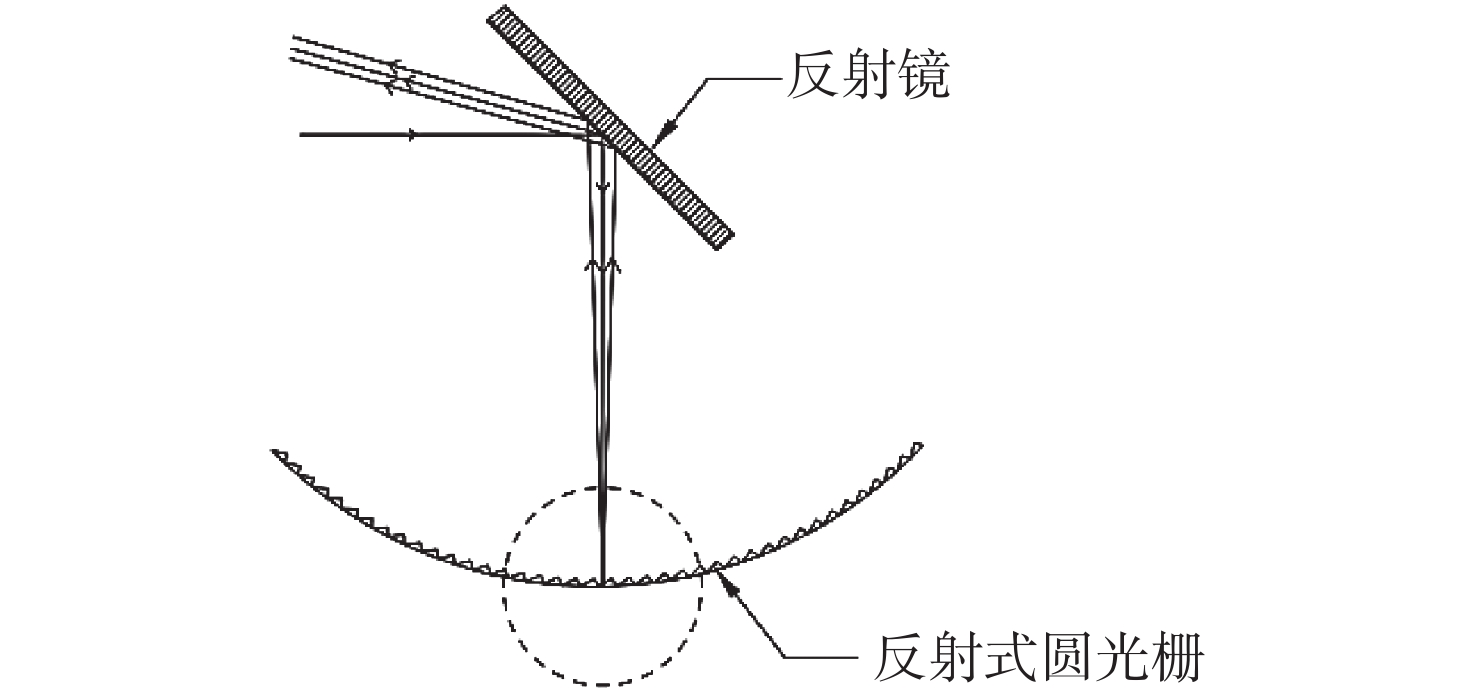

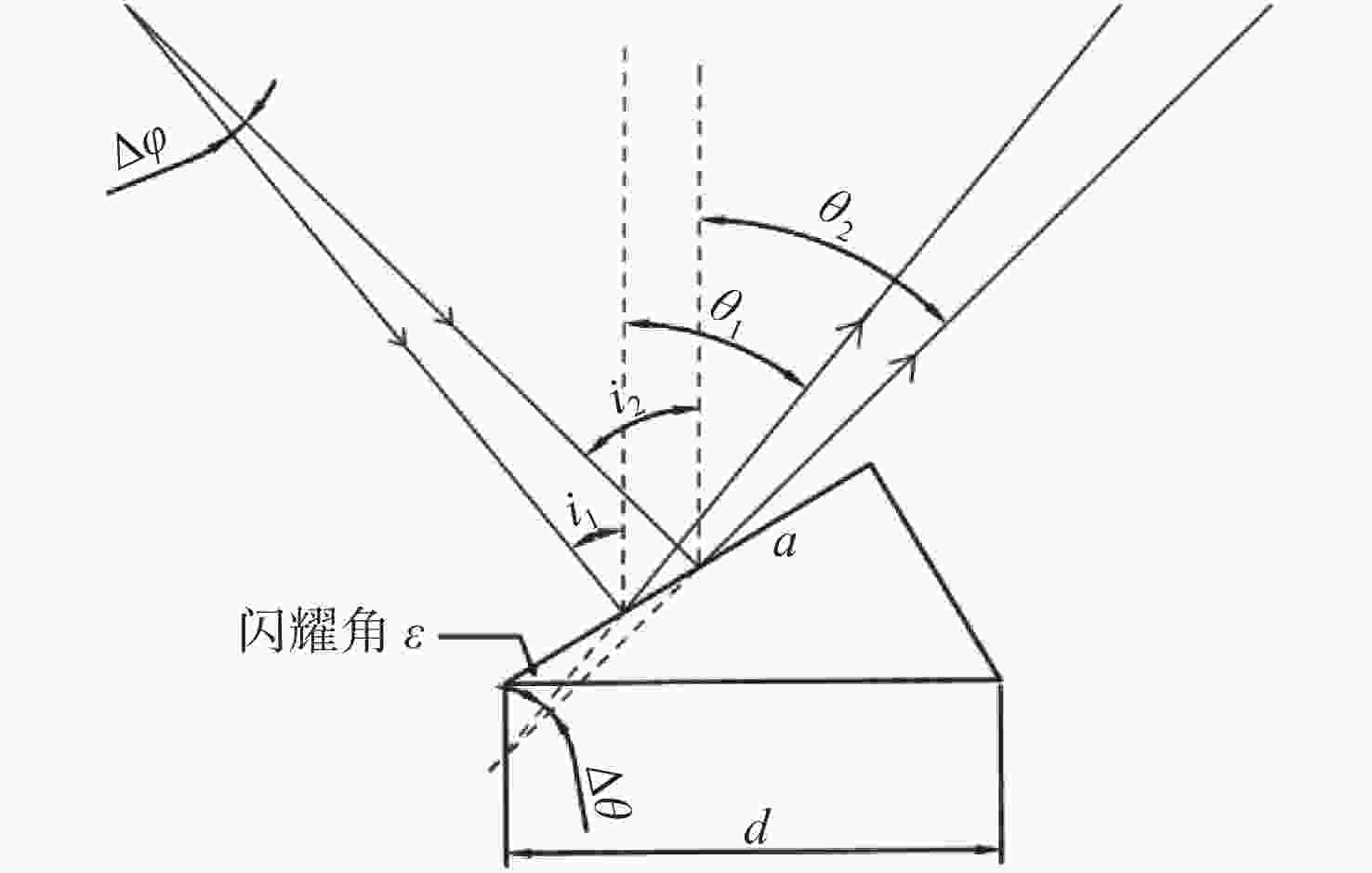

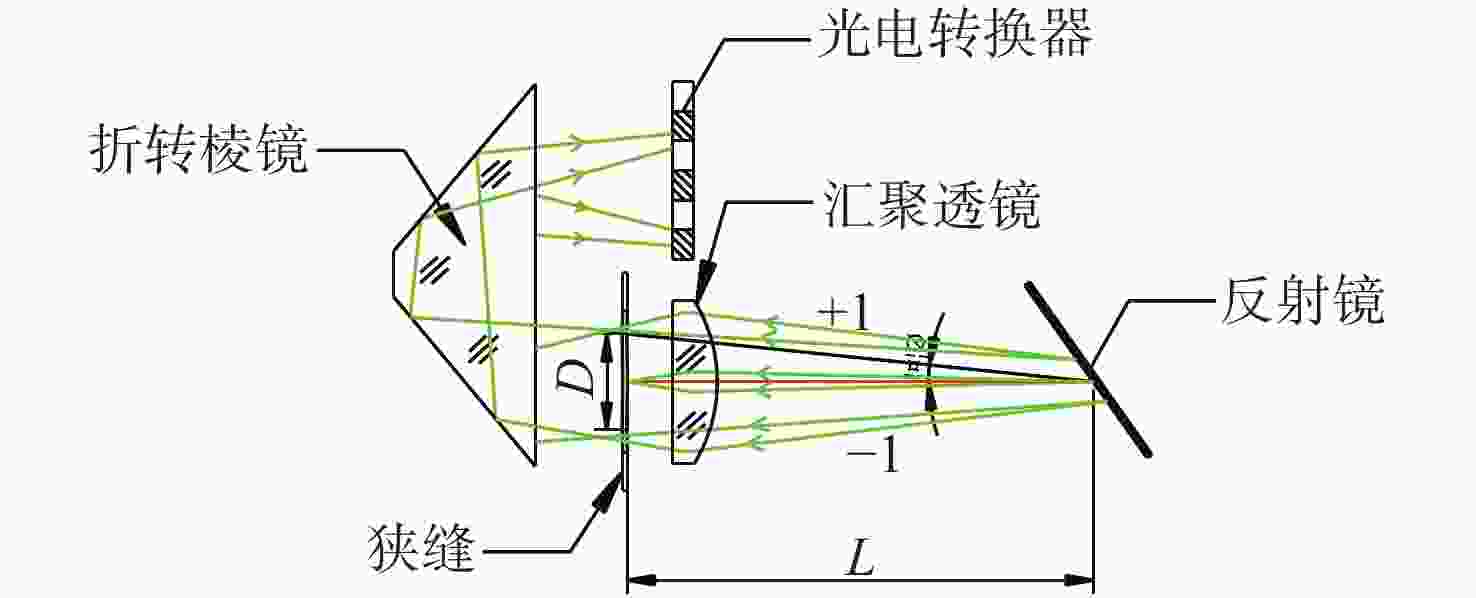

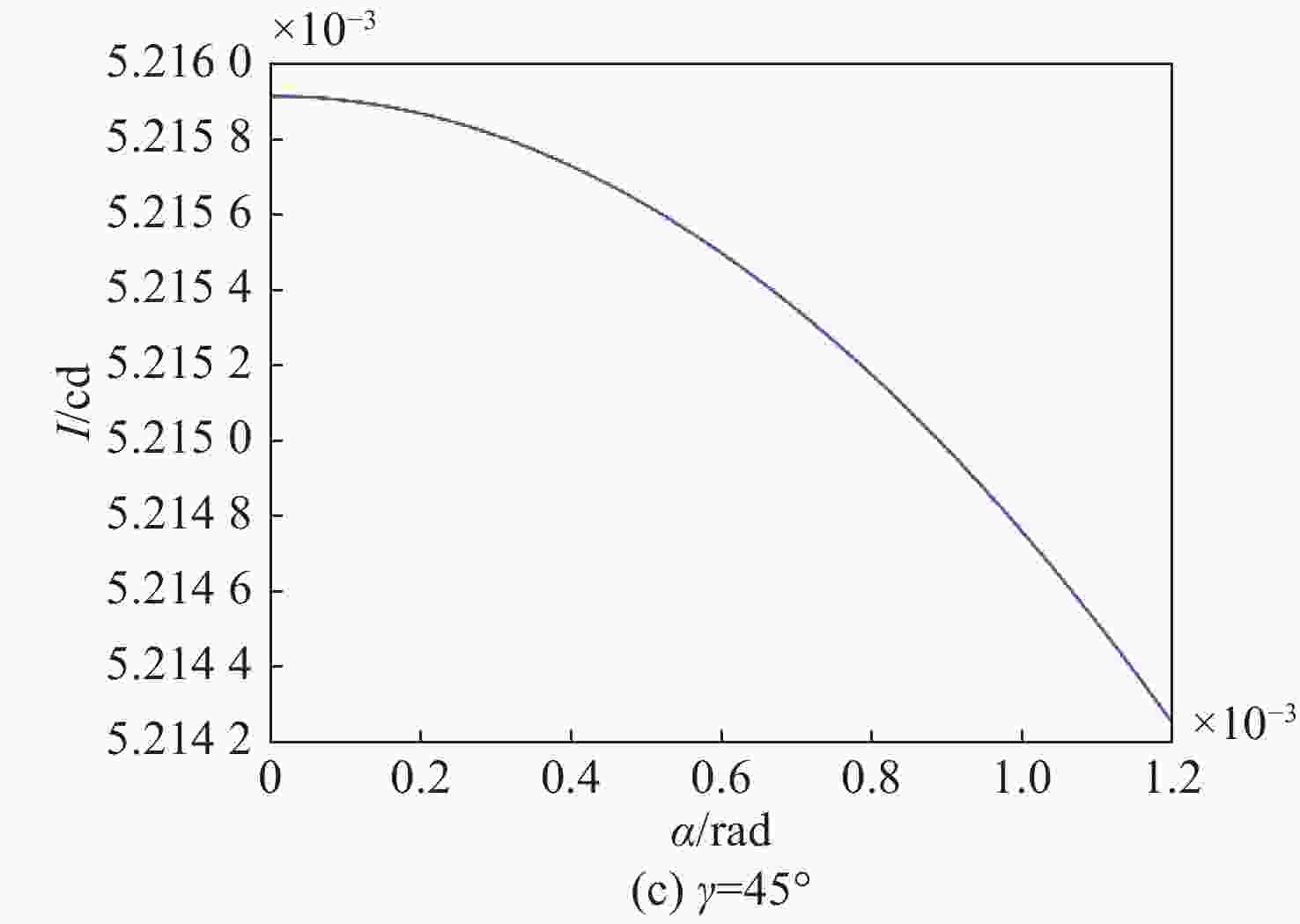

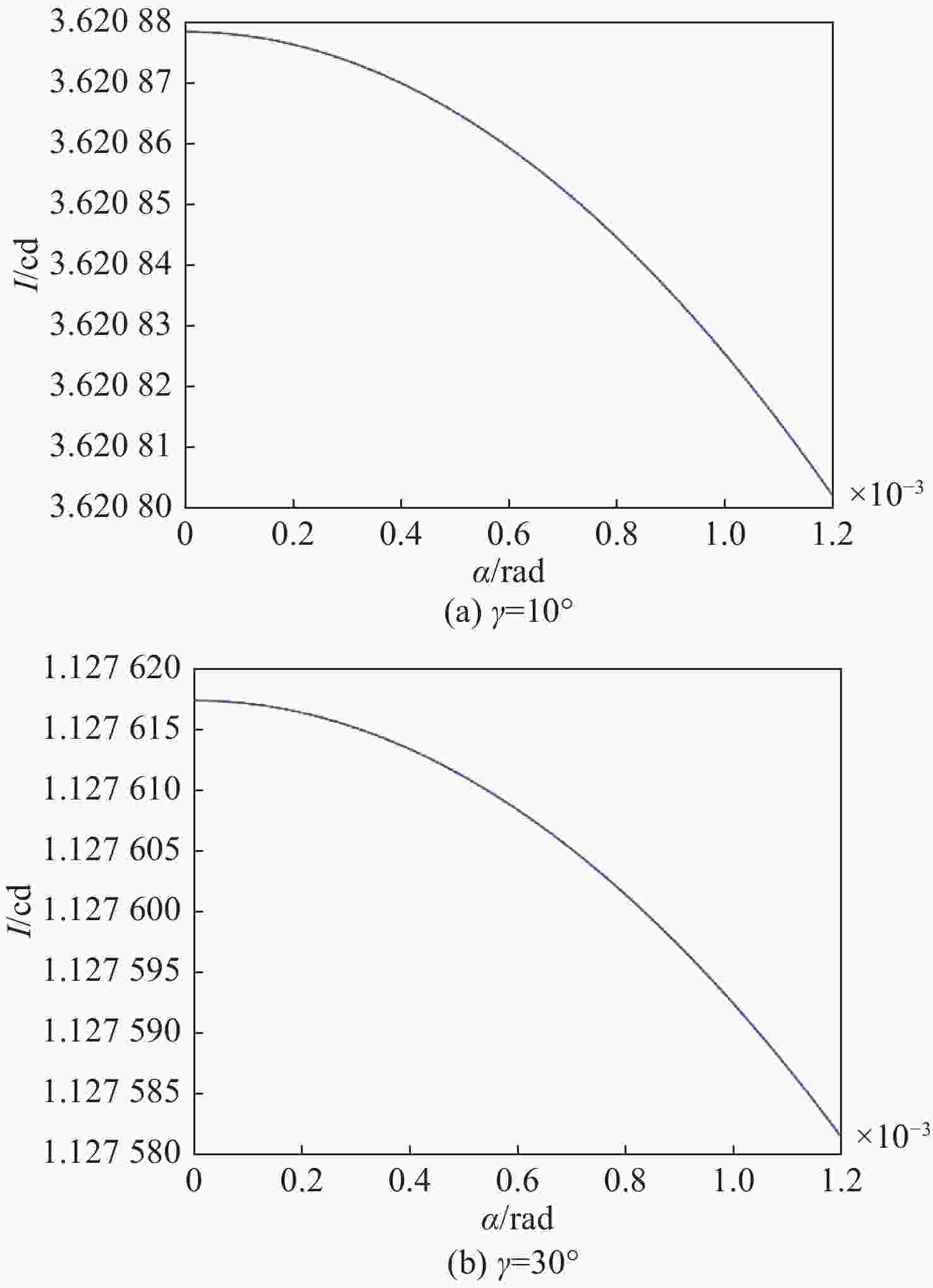

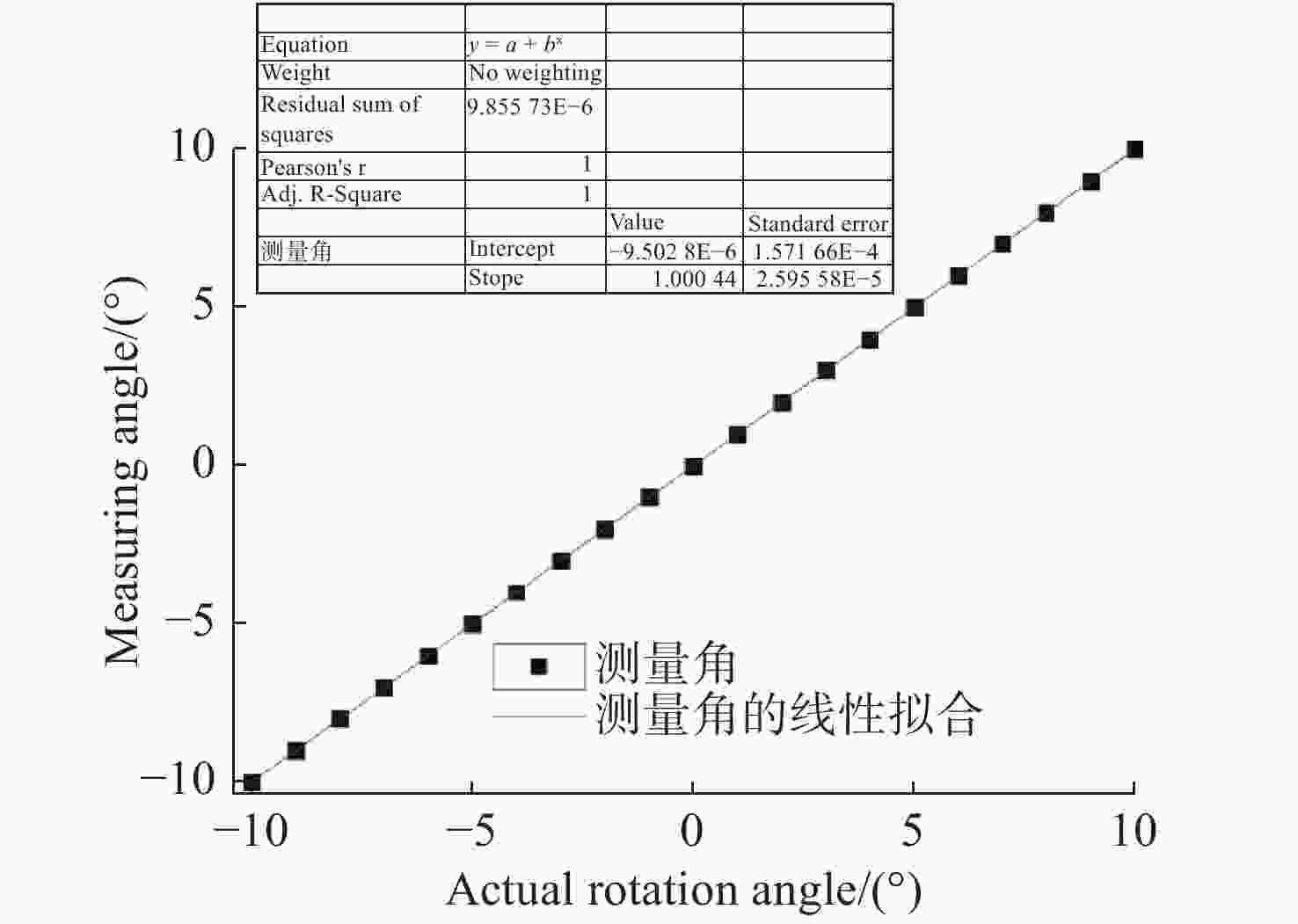

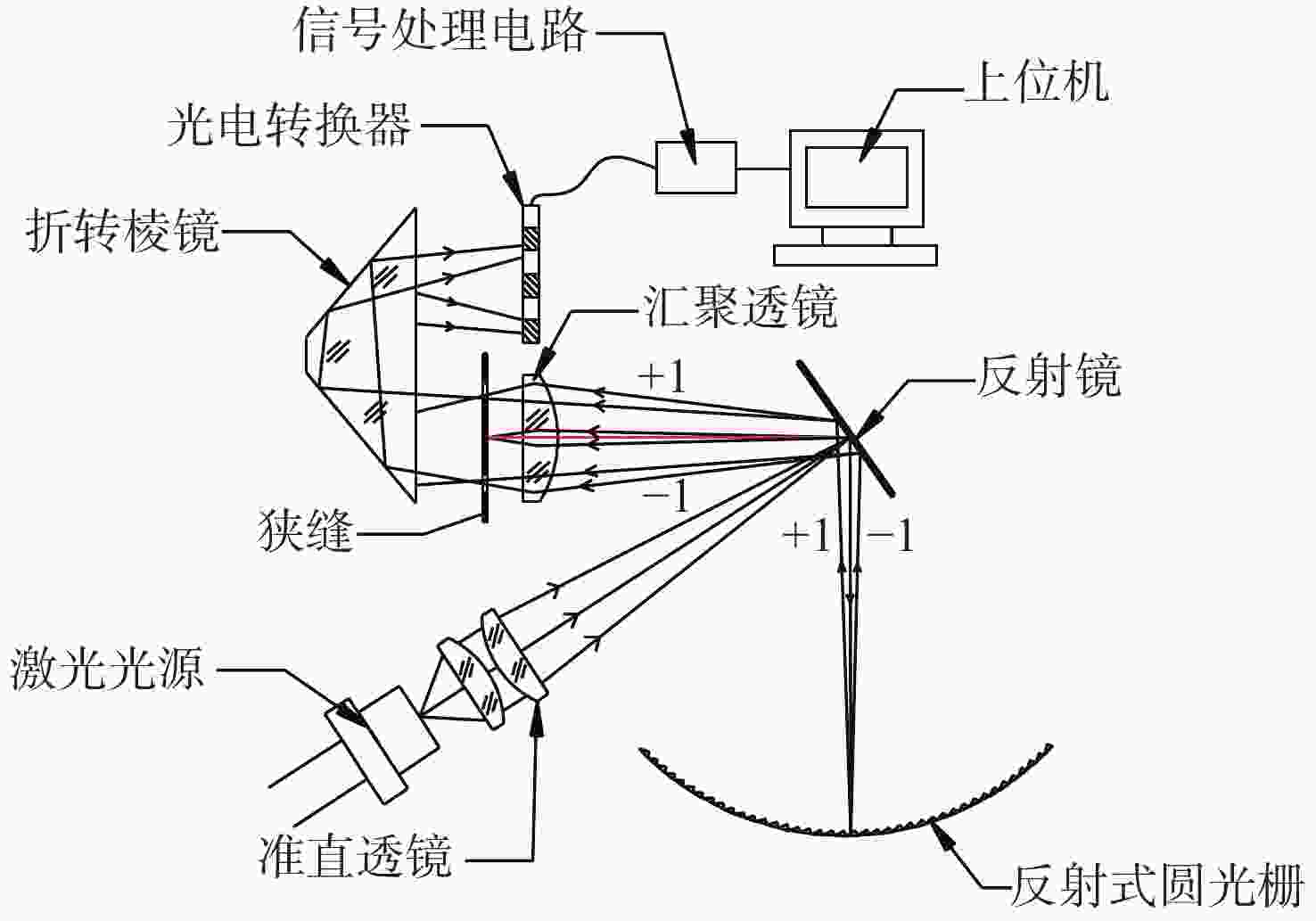

摘要: 为了实现振镜旋转角度的高精度测量,设计了一种利用反射式圆形衍射光栅的角度测量系统,对该系统的测量原理、测量过程、测量精度等进行了相应的设计、仿真与验证。设计与振镜同轴的反射镜,搭配反射式圆光栅以及光敏检测器件,利用反射式圆光栅产生的±1级衍射光干涉,把振镜转角位移量转化为干涉条纹光强的变化,以实现振镜转角的测量。实验结果表明:该测量系统能实现振镜±10°的角度测量,测量精度为10″。实现了振镜旋转角度的高精度测量,并且该装置结构紧凑,满足扫描振镜的小巧化设计需求。Abstract: In order to achieve high-precision measurement of the rotation angle of the galvanometer, an angle detection system using a reflective diffraction grating is designed, and its measuring principle, measuring process and measuring precision are designed, simulated and verified. Through a mirror designed coaxially with the galvanometer, with a reflective circular grating and a photosensitive detection device, the ±1st order diffracted light generated by the reflective circular grating is interfered to convert the angular displacement of the galvanometer into a change in the intensity of interference fringes. In this way, the measurement of the rotational angle of the galvanometer is realized. The experimental results show that the detection system can realize the measurement of the galvanometer's angle within ±10°, and the measurement accuracy is 10″. The high-precision measurement of the rotational angle of the galvanometer is realized, and the device has a compact structure to meet the requirements of the scanning galvanometer demand.

-

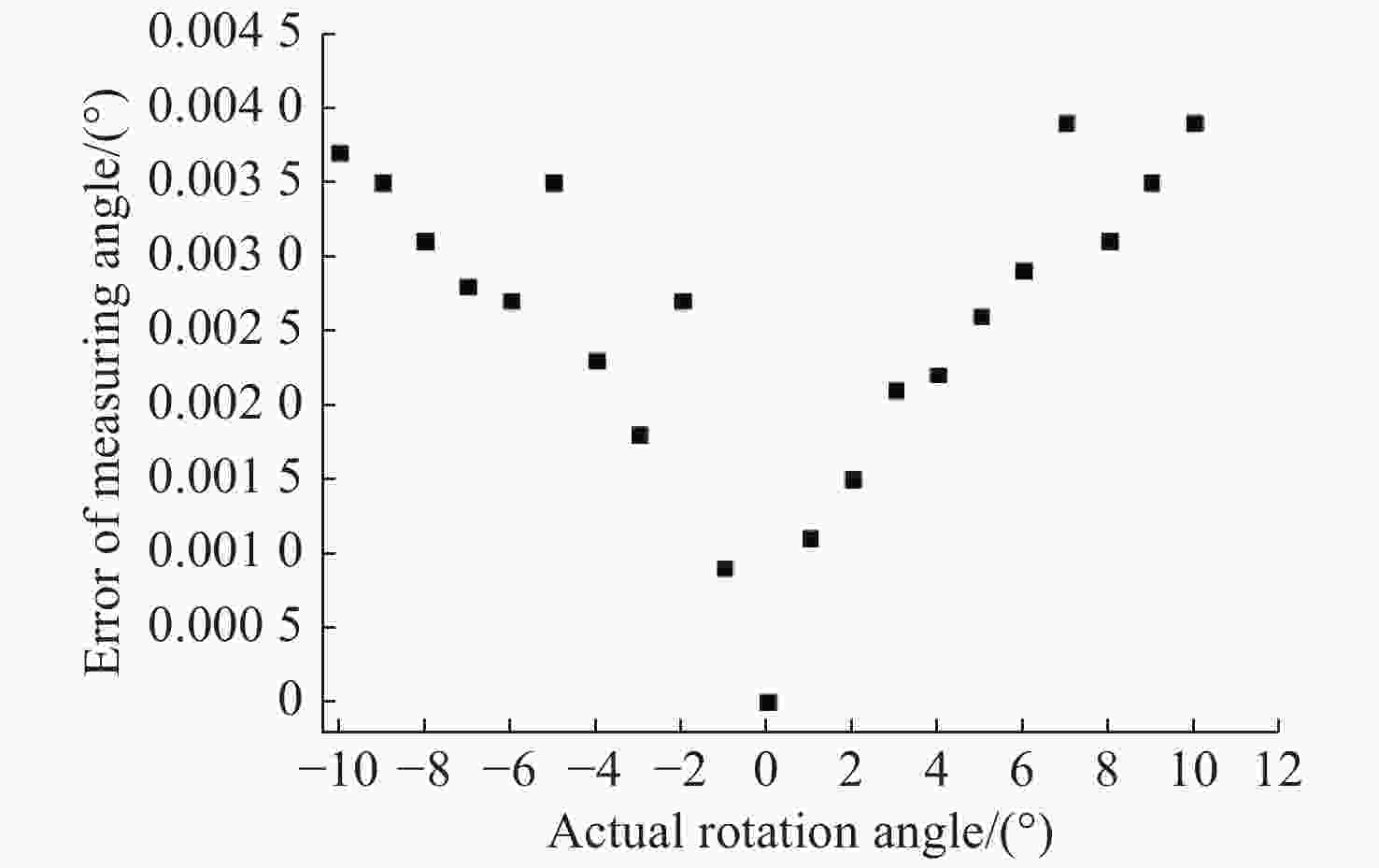

表 1 角度测量结果

Table 1. Angle measurement results

(°) 测量次数 实际转动角单位 测量角单位 误差值单位 1 −10.0005 −10.0042 0.0037 2 −8.9998 −9.0033 0.0035 3 −7.9999 −8.0030 0.0031 4 −7.0002 −7.0030 0.0028 5 −6.0000 −6.0027 0.0027 6 −4.9989 −5.0024 0.0035 7 −3.9995 −4.0018 0.0023 8 −2.9994 −3.0012 0.0018 9 −2.0000 −2.0027 0.0027 10 −1.0003 −1.0012 0.0009 11 0.9998 1.0009 0.0011 12 1.9997 2.0012 0.0015 13 3.0003 3.0024 0.0021 14 4.0002 4.0024 0.0022 15 4.9995 5.0021 0.0026 16 5.9998 6.0027 0.0029 17 6.9988 7.0027 0.0039 18 8.0002 8.0033 0.0031 19 8.9995 9.0030 0.0035 20 9.9997 10.0036 0.0039 均值 — — 0.00269 -

[1] 陶卫, 浦昭邦, 孙运斌. 角度测量技术的发展[J]. 激光杂志,2002,23(2):5-7. doi: 10.3969/j.issn.0253-2743.2002.02.002TAO W, PU ZH B, SUN Y B. The development of angle measurement technique[J]. Laser Journal, 2002, 23(2): 5-7. (in Chinese) doi: 10.3969/j.issn.0253-2743.2002.02.002 [2] 马爱民, 马忠臣. 超精密测量技术的应用进展[J]. 机械工程师,2013(6):3-5.MA A M, MA ZH CH. Advances in application of precision measurement technology[J]. Mechanical Engineer, 2013(6): 3-5. (in Chinese) [3] 刘焱, 王烨. 位移传感器的技术发展现状与发展趋势[J]. 自动化技术与应用,2013,32(6):76-80, 101.LIU Y, WANG Y. Present status and trend of technical development of displacement sensor[J]. Techniques of Automation &Applications, 2013, 32(6): 76-80, 101. (in Chinese) [4] 高旭, 李舒航, 马庆林, 等. 光栅精密位移测量技术发展综述[J]. 中国光学,2019,12(4):741-752. doi: 10.3788/co.20191204.0741GAO X, LI SH H, MA Q L, et al. Development of grating-based precise displacement measurement technology[J]. Chinese Optics, 2019, 12(4): 741-752. (in Chinese) doi: 10.3788/co.20191204.0741 [5] 江孝伟, 武华. 一维增透亚波长光栅的研究[J]. 发光学报,2017,38(2):177-181. doi: 10.3788/fgxb20173802.0177JIANG X W, WU H. Research of 1D sub-wavelength grating anti-reflection[J]. Chinese Journal of Luminescence, 2017, 38(2): 177-181. (in Chinese) doi: 10.3788/fgxb20173802.0177 [6] 吕强, 李文昊, 巴音贺希格, 等. 基于衍射光栅的干涉式精密位移测量系统[J]. 中国光学,2017,10(1):39-50. doi: 10.3788/co.20171001.0039LÜ Q, LI W H, BAYANHESHIG, et al. Interferometric precision displacement measurement system based on diffraction grating[J]. Chinese Optics, 2017, 10(1): 39-50. (in Chinese) doi: 10.3788/co.20171001.0039 [7] 李秋顺, 向栋, 陈超, 等. 单端面长周期光栅透射模式测量技术[J]. 发光学报,2017,38(8):1090-1096. doi: 10.3788/fgxb20173808.1090LI Q SH, XIANG D, CHEN CH, et al. Transmission mode measurement technique of long period grating based on a single end face[J]. Chinese Journal of Luminescence, 2017, 38(8): 1090-1096. (in Chinese) doi: 10.3788/fgxb20173808.1090 [8] 张爽, 朱万彬, 李健, 等. 激光位移传感器传感探头微小型光学系统设计[J]. 中国光学,2018,11(6):1001-1010. doi: 10.3788/co.20181106.1001ZHANG SH, ZHU W B, LI J, et al. Design of micro-optical system for laser displacement sensor sensing probe[J]. Chinese Optics, 2018, 11(6): 1001-1010. (in Chinese) doi: 10.3788/co.20181106.1001 [9] 王国超, 颜树华, 高雷, 等. 光栅干涉位移测量技术发展综述[J]. 激光技术,2010,34(5):661-664, 716. doi: 10.3969/j.issn.1001-3806.2010.05.023WANG G CH, YAN SH H, GAO L, et al. Development of displacement measurement technologies based on grating interferometry[J]. Laser Technology, 2010, 34(5): 661-664, 716. (in Chinese) doi: 10.3969/j.issn.1001-3806.2010.05.023 [10] 谢检来, 郝永芹, 张家斌, 等. 一种具有低折射率的高对比度光栅反射镜的设计[J]. 发光学报,2008,39(6):855-861.XIE J L, HAO Y Q, ZHANG J B, et al. Design of high contrast grating mirror with low index grating layer[J]. Chinese Journal of Luminescence, 2008, 39(6): 855-861. (in Chinese) [11] KAMAL M, NARAYANSWAMY S, PACKIRISAMY M. An off-axis cylindrical mirror focused line scanning system with high imaging quality for broad spectral band[J]. Journal of Optics, 2011, 13(10): 105502. doi: 10.1088/2040-8978/13/10/105502 [12] 王晓初, 朱照杨, 张国平. 高速振镜伺服驱动的PID加前馈控制[J]. 微电机,2013,46(5):61-64, 69. doi: 10.3969/j.issn.1001-6848.2013.05.014WANG X CH, ZHU ZH Y, ZHANG G P. High-speed galvanometer servo drive PID + feedforward control[J]. Micromotors, 2013, 46(5): 61-64, 69. (in Chinese) doi: 10.3969/j.issn.1001-6848.2013.05.014 [13] 刘琛. 高速扫描振镜控制系统设计研究[D]. 太原: 中北大学, 2018: 5.LIU CH. Research on the design of high-speed scanning control system[D]. Taiyuan: North University of China, 2018: 5. (in Chinese) [14] 王先起, 廖胜, 黄建明. 扫描振镜幅频特性测试及位置标定的研究[J]. 光电工程,2004,31(S1):73-75, 79.WANG X Q, LIAO SH, HUANG J M. Test of amplitude-frequency performance and position demarcation of an optical scanner[J]. Opto-Electronic Engineering, 2004, 31(S1): 73-75, 79. (in Chinese) [15] 叶乔. 高速振镜理论研究及实践[D]. 武汉: 华中科技大学, 2004.YE Q. A study of high speed galvanometer and practise[D]. Wuhan: Huazhong University of Science and Technology, 2004. (in Chinese). [16] 井峰. 数字式振镜控制系统的研究[D]. 西安: 中国科学院研究生院(西安光学精密机械研究所), 2012.JING F. Research on digital galvanometer control system[D]. Xi’an: Xi’an Institute of Optics and Precision Mechanics of CAS, 2012. (in Chinese). [17] 孙国斌, 弥谦. 光学振镜转角与扫描角度变化关系的研究[J]. 西安工业大学学报,2010,30(5):421-424. doi: 10.3969/j.issn.1673-9965.2010.05.003SUN G B, MI Q. Determination of the relation between the deflection angle and the scanning angle of an optical scanner[J]. Journal of Xi’an Technological University, 2010, 30(5): 421-424. (in Chinese) doi: 10.3969/j.issn.1673-9965.2010.05.003 [18] 赵伟, 张增明. 衍射光栅特性研究实验[J]. 物理实验,2017,37(10):22-25. doi: 10.3969/j.issn.1005-4642.2017.10.006ZHAO W, ZHANG Z M. Experiment of characteristics of diffraction grating[J]. Physics Experimentation, 2017, 37(10): 22-25. (in Chinese) doi: 10.3969/j.issn.1005-4642.2017.10.006 [19] 郁道银, 谈恒英. 工程光学[M]. 北京: 机械工业出版社, 2006.YU D Y, TAN H Y. Engineering Optics[M]. Beijing: Mechanical Industry Press, 2006. (in Chinese) [20] 王贵甫, 陈桂林, 陈雨良. 基于激光干涉仪的角度测量技术[J]. 传感器技术,2001,20(1):37-39.WANG G F, CHEN G L, CHEN Y L. An angle measurement technology besed on laser interferometer[J]. Journal of Transducer Technology, 2001, 20(1): 37-39. (in Chinese) [21] 曾建华, 曾伟, 王志峰, 等. 光的干涉与衍射的Matlab仿真及其实验观测[J]. 井冈山大学学报(自然科学版),2018,39(3):9-12.ZENG J H, ZENG W, WANG ZH F, et al. Matlab simulation and experimental observation on interference and diffraction of light[J]. Journal of Jinggangshan University (Natural Sciences Edition) , 2018, 39(3): 9-12. (in Chinese) [22] 张文颖, 朱浩然. 圆光栅测角系统误差分析与修正[J]. 应用光学,2019,40(3):399-403. doi: 10.5768/JAO201940.0301007ZHANG W Y, ZHU H R. Error analysis and correction of circular grating angle measurement system[J]. Journal of Applied Optics, 2019, 40(3): 399-403. (in Chinese) doi: 10.5768/JAO201940.0301007 -

下载:

下载: