-

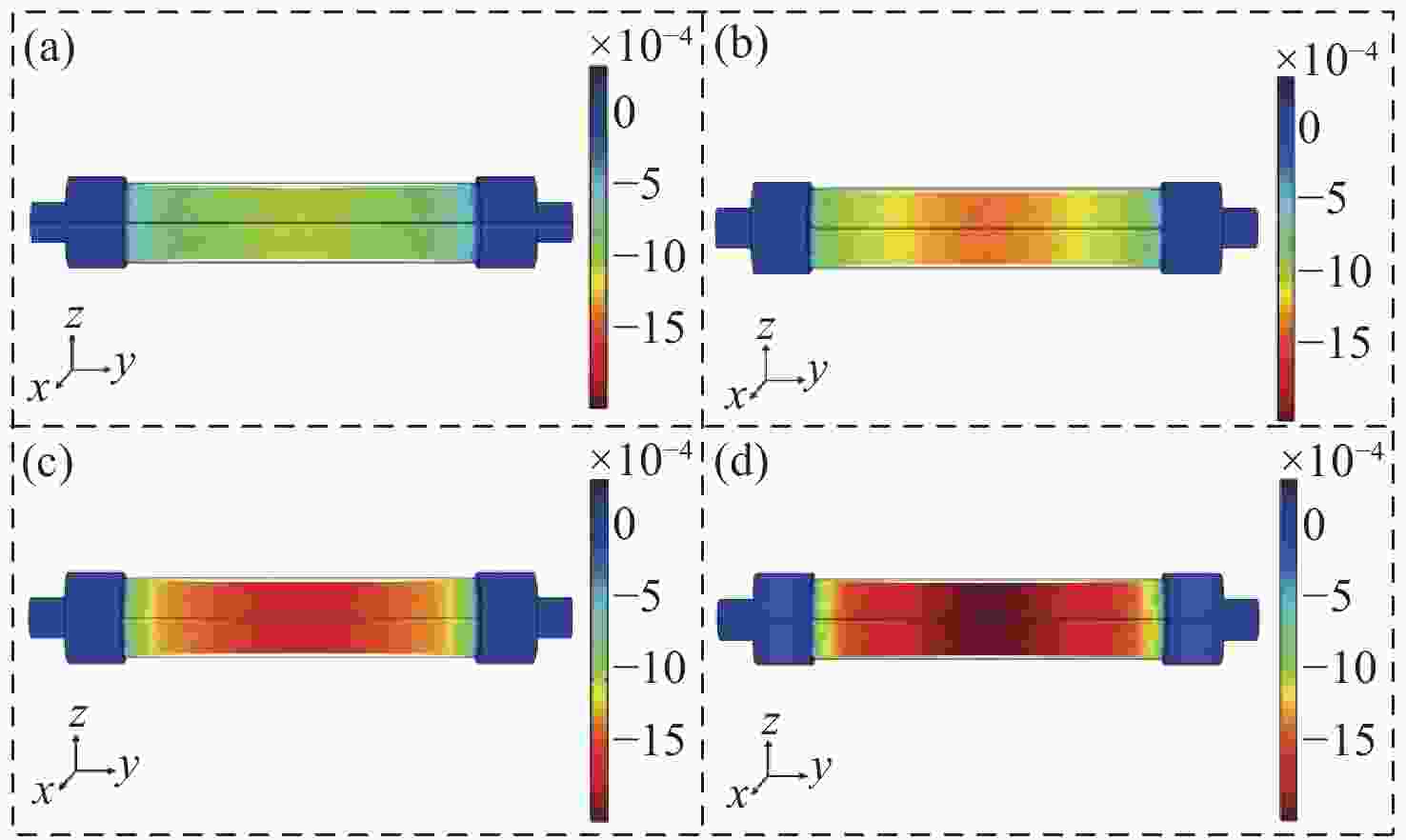

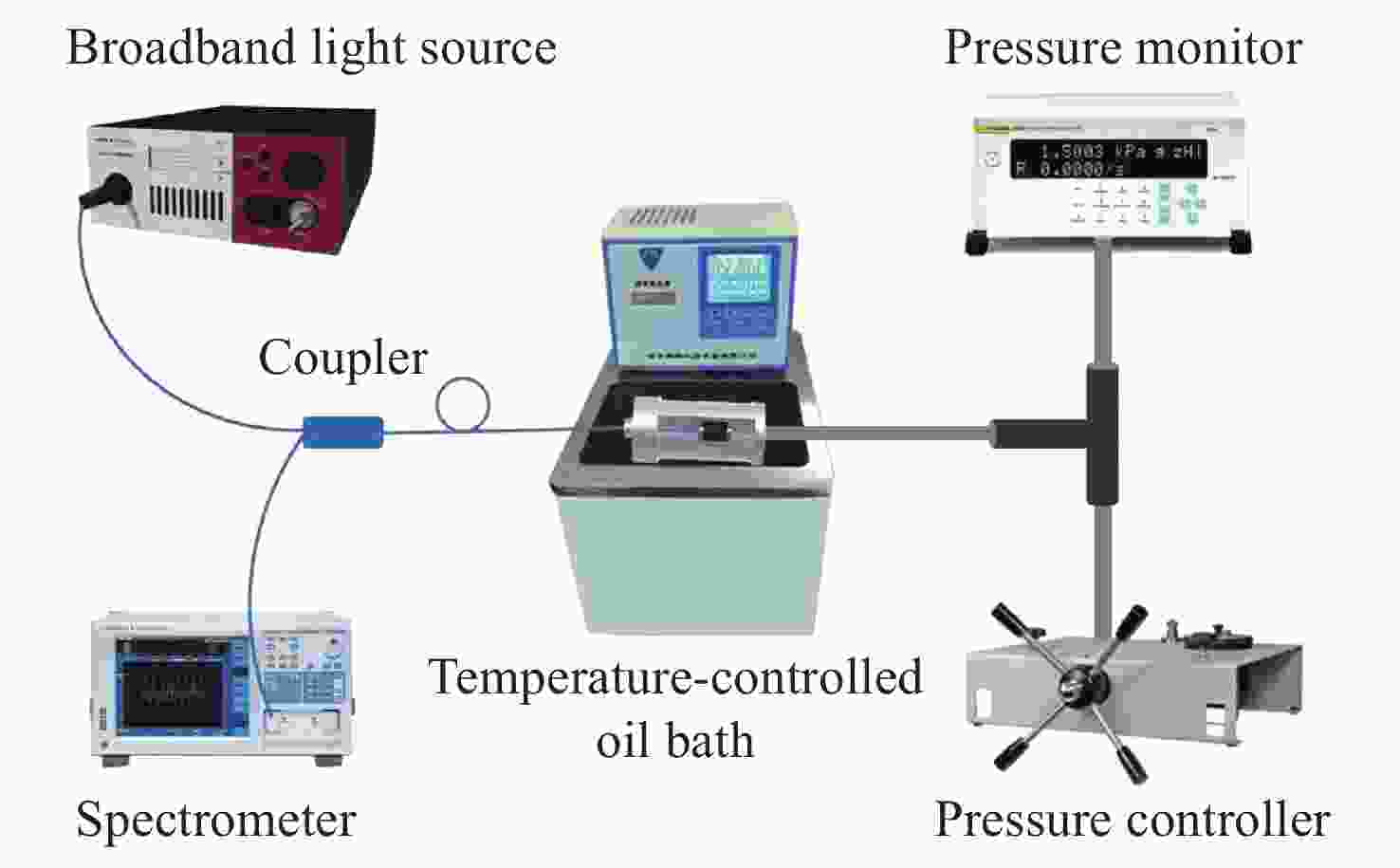

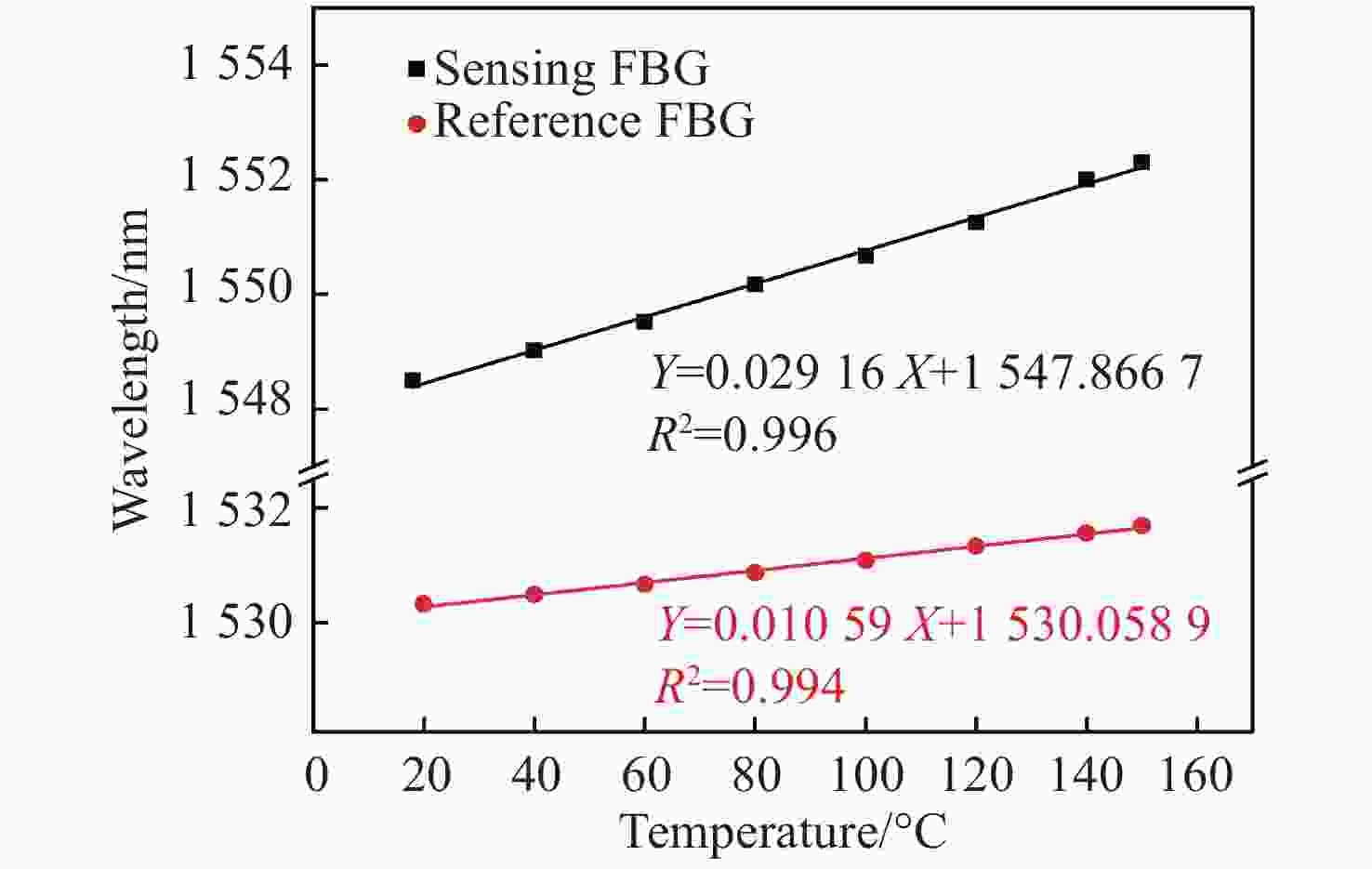

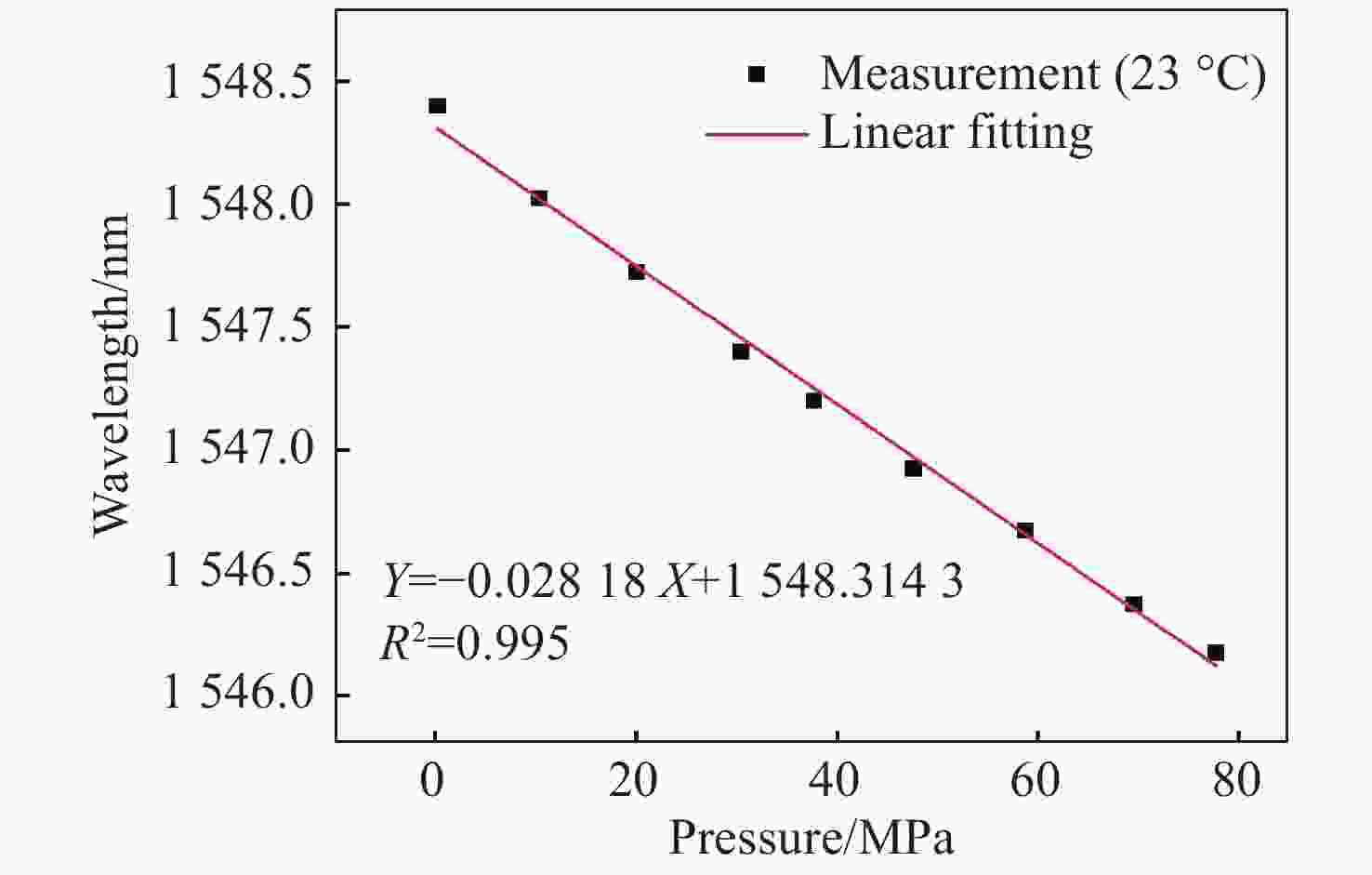

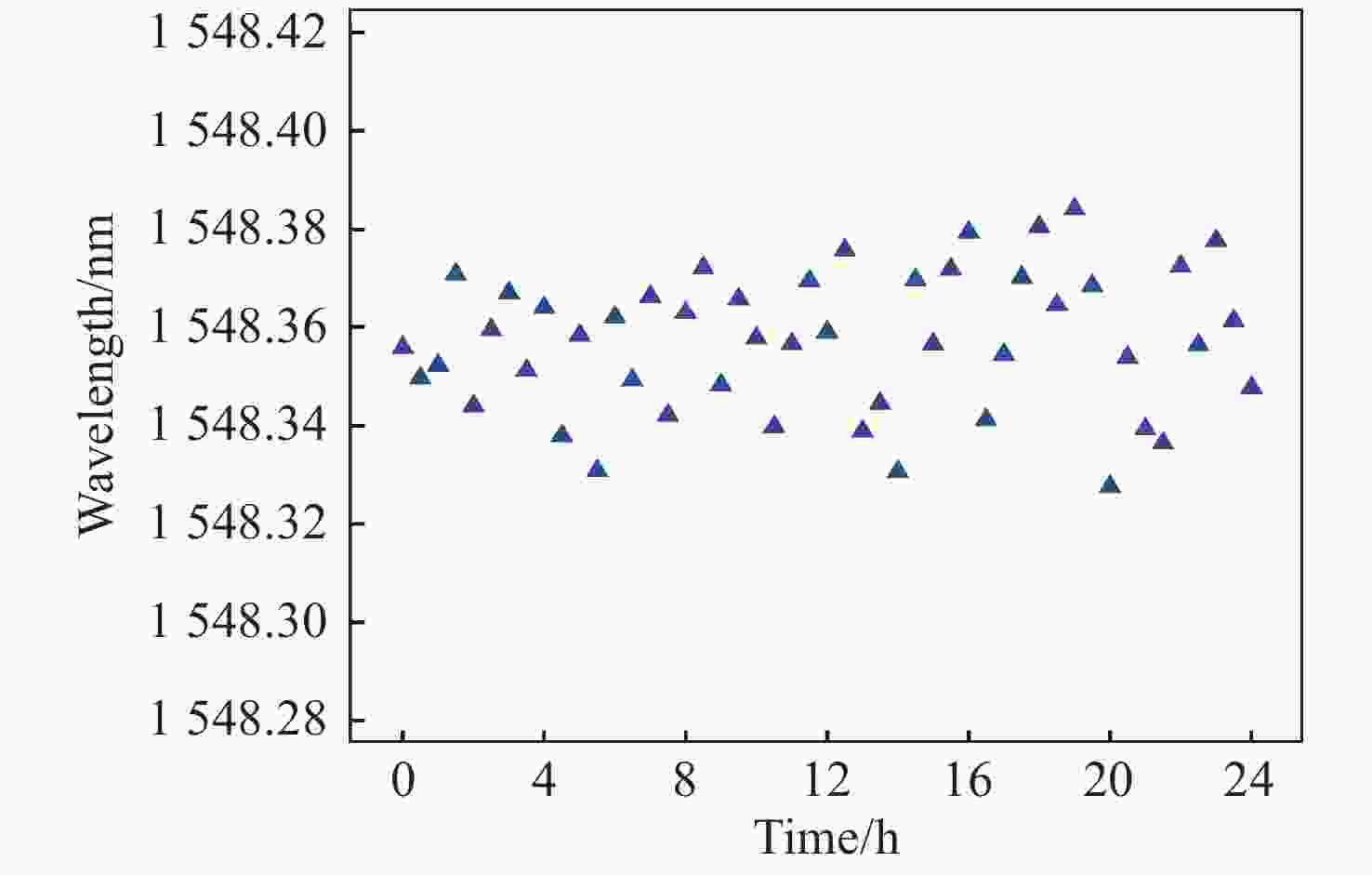

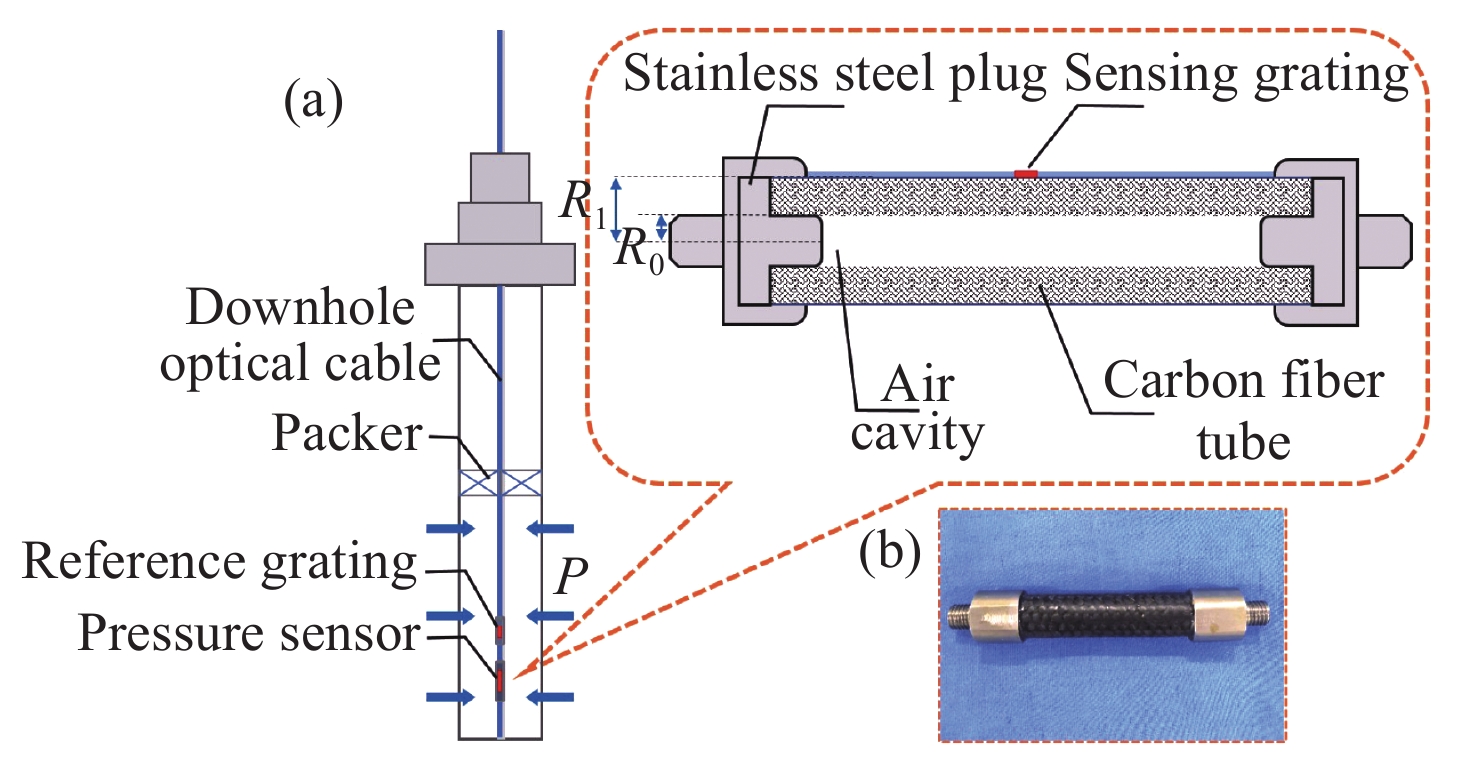

摘要: 温度和压力是石油开采过程中重要的参数,但油气井下高温高压环境苛刻,传统电子传感器很难实现长期稳定的工作。本文提出了一种基于碳纤维管增敏型的光纤光栅温度压力传感器。该传感器是以碳纤维丝编织成的中空管状结构作为骨架,通过耐高温环氧树脂固化成复合碳纤维管作为弹性体,并将表面嵌入耐高温光纤布拉格光栅作为感知元件,实现了井下温度和压力的同时测量。实验结果表明,该传感器可以在0~150 ℃和0~80 MPa环境下稳定工作,压力灵敏度最大可达到−50.02 pm/MPa,同时表现出很好的线性响应。通过外加参考光栅作为温度补偿光栅,解决了温度和压力同时测量过程中的交叉敏感问题,满足了井下开采过程中的精度要求,为油气井下高温高压光纤传感器的设计提供了实验依据。Abstract: Temperature and pressure are very important parameters in oil and gas well exploitation. The downhole environment is harsh so it is difficult for traditional electronic sensors to achieve long-term and stable monitoring of downhole parameters. In this paper, a fiber Bragg grating temperature and pressure sensor based on a carbon-fiber sensitized tube is proposed. The sensor is composed of a hollow tubular structure woven of carbon fibers as a skeleton. The composite carbon fiber tubes are cured by high-temperature resistant epoxy resin as an elastomer, and the high-temperature resistant fiber Bragg grating is embedded on the surface as a sensing element to realize the simultaneous measurement of downhole temperature and pressure. The experimental results show that the sensor can work stably in environments of 0~150 ℃ and 0~80 MPa, and the maximum pressure sensitivity can reach −50.02 pm/MPa. The sensor has a good linear response. By adding a reference grating as a temperature compensation grating, the cross-sensitivity problem in the process of the simultaneous measurement of temperature and pressure is solved, and the accuracy requirements in the process of underground mining are met. This technique provides an experimental basis for the design of high-temperature and high-pressure optical fiber sensors in oil and gas wells.

-

Key words:

- oil and gas well /

- carbon fiber tube /

- fiber bragg grating /

- pressure sensor

-

表 1 传感光栅在不同温度下的压力响应灵敏度

Table 1. Pressure response sensitivity of sensing grating at different temperatures

Temperature/℃ 23 30 40 50 60 70 80 90 100 110 120 130 140 150 Sensitivity/(pm/MPa) −28.18 −28.65 −29.03 −29.55 −29.87 −30.01 −30.36 −30.55 −30.91 −31.89 −38.53 −43.49 −47.56 −50.02 -

[1] QIAO X G, SHAO ZH H, BAO W J, et al. Fiber Bragg grating sensors for the oil industry[J]. Sensors, 2017, 17(3): 429. doi: 10.3390/s17030429 [2] ERLANDSEN S, VOLD G, MAKIN G D. World’s first multiple fiber-optic intelligent well: intelligent wells[J]. World Oil, 2003, 224(3): 29-32. [3] 丁润琪, 侯尚林, 雷景丽, 等. 太赫兹正六边形光子晶体光纤的液体传感[J]. 发光学报,2019,40(2):272-276. doi: 10.3788/fgxb20194002.0272DING R Q, HOU SH L, LEI J L, et al. Liquid sensing of hexagonal photonic crystal fibers for terahertz wave[J]. Chinese Journal of Luminescence, 2019, 40(2): 272-276. (in Chinese) doi: 10.3788/fgxb20194002.0272 [4] GUO Q, YU Y S, ZHENG ZH M, et al. Femtosecond laser inscribed sapphire fiber Bragg grating for high temperature and strain sensing[J]. IEEE Transactions on Nanotechnology, 2019, 18: 208-211. doi: 10.1109/TNANO.2018.2888536 [5] 陈静, 杨曌, 黄宇豪, 等. 基于荧光猝灭效应的光纤传感器研究进展[J]. 发光学报,2020,41(10):1269-1278. doi: 10.37188/CJL.20200206CHEN J, YANG ZH, HUANG Y H, et al. Research progress of optical fiber sensors based on fluorescence quenching effect[J]. Chinese Journal of Luminescence, 2020, 41(10): 1269-1278. (in Chinese) doi: 10.37188/CJL.20200206 [6] 张正义. 基于光纤光栅的一体式靶式流量传感技术[J]. 发光学报,2020,41(2):217-223.ZHANG ZH Y. One-piece flow target type based on fiber Bragg grating sensing technology[J]. Chinese Journal of Luminescence, 2020, 41(2): 217-223. (in Chinese) [7] 吴妮珊, 夏历. 基于微波光子学的准分布式光纤传感解调技术[J]. 中国光学,2021,14(2):245-263. doi: 10.37188/CO.2020-0121WU N SH, XIA L. Interrogation technology for quasi-distributed optical fiber sensing systems based on microwave photonics[J]. Chinese Optics, 2021, 14(2): 245-263. (in Chinese) doi: 10.37188/CO.2020-0121 [8] 饶春芳, 吴锴, 胡友德, 等. 光纤布拉格光栅在医用蒸汽灭菌器温度监测的应用[J]. 光学 精密工程,2020,28(9):1930-1938. doi: 10.37188/OPE.20202809.1930RAO CH F, WU K, HU Y D, et al. Application of fiber Bragg grating in temperature monitoring of medical steam sterilizer[J]. Optics and Precision Engineering, 2020, 28(9): 1930-1938. (in Chinese) doi: 10.37188/OPE.20202809.1930 [9] ZHOU X L, YU Q X, PENG W. Fiber-optic Fabry-Perot pressure sensor for down-hole application[J]. Optics and Lasers in Engineering, 2019, 121: 289-299. doi: 10.1016/j.optlaseng.2019.04.028 [10] 刘明尧, 杜常饶, 武育斌. 环氧树脂封装的EFPI-FBG复合压力温度传感器[J]. 光学 精密工程,2019,27(10):2080-2088. doi: 10.3788/OPE.20192710.2080LIU M Y, DU CH R, WU Y B. EFPI-FBG composite pressure and temperature sensor embedded in epoxy resin[J]. Optics and Precision Engineering, 2019, 27(10): 2080-2088. (in Chinese) doi: 10.3788/OPE.20192710.2080 [11] QI X G, WANG SH, JIANG J F, et al. Fiber optic Fabry-perot pressure sensor with embedded MEMS micro-cavity for ultra-high pressure detection[J]. Journal of Lightwave Technology, 2019, 37(11): 2719-2725. doi: 10.1109/JLT.2018.2876717 [12] PADIDAR S, AHMADI V, EBNALI-HEIDARI M. Design of high sensitive pressure and temperature sensor using photonic crystal fiber for downhole application[J]. IEEE Photonics Journal, 2012, 4(5): 1590-1599. doi: 10.1109/JPHOT.2012.2212242 [13] SADEGHI J, LATIFI H, SANTOS J L, et al. Behavior of a hollow core photonic crystal fiber under high radial pressure for downhole application[J]. Applied Physics Letters, 2014, 104(7): 071910. doi: 10.1063/1.4866334 [14] FU H Y, WU CH, TSE M L V, et al. High pressure sensor based on photonic crystal fiber for downhole application[J]. Applied Optics, 2010, 49(14): 2639-2643. doi: 10.1364/AO.49.002639 [15] ZHAO Y, LIAO Y B, LAI SH R. Simultaneous measurement of down-hole high pressure and temperature with a bulk-modulus and FBG sensor[J]. IEEE Photonics Technology Letters, 2002, 14(11): 1584-1586. doi: 10.1109/LPT.2002.803914 [16] RONG Q ZH, QIAO X G. FBG for oil and gas exploration[J]. Journal of Lightwave Technology, 2019, 37(11): 2502-2515. doi: 10.1109/JLT.2018.2866326 [17] 王宏亮, 宋娟, 冯德全, 等. 应用于特殊环境的光纤光栅温度压力传感器[J]. 光学 精密工程,2011,19(3):545-551. doi: 10.3788/OPE.20111903.0545WANG H L, SONG J, FENG D Q, et al. High temperature-pressure FBG sensor applied to special environments[J]. Optics and Precision Engineering, 2011, 19(3): 545-551. (in Chinese) doi: 10.3788/OPE.20111903.0545 [18] MACHAVARAM V R, BADCOCK R A, FERNANDO G F. Fabrication of intrinsic fibre Fabry-Perot sensors in silica fibres using hydrofluoric acid etching[J]. Sensors and Actuators A:Physical, 2007, 138(1): 248-260. doi: 10.1016/j.sna.2007.04.007 [19] ZHANG Y N, YUAN L, LAN X W, et al. High-temperature fiber-optic Fabry-Perot interferometric pressure sensor fabricated by femtosecond laser: erratum[J]. Optics Letters, 2014, 39(1): 17. doi: 10.1364/OL.39.000017 [20] ZHOU P, LIAO C R, LI ZH Y, et al. In-fiber cascaded FPI fabricated by chemical-assisted femtosecond laser micromachining for micro-fluidic sensing applications[J]. Journal of Lightwave Technology, 2019, 37(13): 3214-3221. doi: 10.1109/JLT.2019.2912835 [21] WANG Z, LIU H, MA Z, et al. High temperature strain sensing with alumina ceramic derived fiber based Fabry-Perot interferometer[J]. Optics Express, 2019, 27(20): 27691-27701. doi: 10.1364/OE.27.027691 [22] LI W CH, YUAN Y G, YANG J, et al. In-fiber integrated high sensitivity temperature sensor based on long Fabry-Perot resonator[J]. Optics Express, 2019, 27(10): 14675-14683. doi: 10.1364/OE.27.014675 [23] ZHANG ZH, HE J, DU B, et al. Measurement of high pressure and high temperature using a dual-cavity Fabry-Perot interferometer created in cascade hollow-core fibers[J]. Optics Letters, 2018, 43(24): 6009-6012. doi: 10.1364/OL.43.006009 [24] LIU Y G, WANG Y X, YANG D Q, et al. Hollow-core fiber-based all-fiber fpi sensor for simultaneous measurement of air pressure and temperature[J]. IEEE Sensors Journal, 2019, 19(23): 11236-11241. doi: 10.1109/JSEN.2019.2934738 [25] 吴晶, 吴晗平, 黄俊斌, 等. 光纤光栅传感信号解调技术研究进展[J]. 中国光学,2014,7(4):519-531.WU J, WU H P, HUANG J B, et al. Research progress in signal demodulation technology of fiber Bragg grating sensors[J]. Chinese Optics, 2014, 7(4): 519-531. (in Chinese) [26] ZHOU C M, PANG Y D, QIAN L, et al. Demodulation of a hydroacoustic sensor array of fiber interferometers based on ultra-weak fiber Bragg grating reflectors using a self-referencing signal[J]. Journal of Lightwave Technology, 2019, 37(11): 2568-2576. doi: 10.1109/JLT.2018.2884512 [27] XU M G, REEKIE L, CHOW Y T, et al. Optical in-fibre grating high pressure sensor[J]. Electronics Letters, 1993, 29(4): 398-399. doi: 10.1049/el:19930267 [28] 孙安, 乔学光, 贾振安, 等. 耐高压光纤Bragg光栅压力传感技术研究[J]. 光子学报,2004,33(7):823-825.SUN A, QIAO X G, JIA ZH A, et al. The study of fiber Bragg grating pressure sensor with high pressure-resistance[J]. Acta Photonica Sinica, 2004, 33(7): 823-825. (in Chinese) [29] 申人升, 于永森, 张金, 等. 薄壁应变筒式光纤光栅压力传感器的研究[J]. 光电子·激光,2008,19(11):1433-1436. doi: 10.3321/j.issn:1005-0086.2008.11.002SHEN R SH, YU Y S, ZHANG J, et al. Investigation of FBG pressure sensor based on thin wall strain tube[J]. Journal of Optoelectronics·Laser, 2008, 19(11): 1433-1436. (in Chinese) doi: 10.3321/j.issn:1005-0086.2008.11.002 [30] FENG P F, SONG G J, LI X R, et al. Effects of different "rigid-flexible" structures of carbon fibers surface on the interfacial microstructure and mechanical properties of carbon fiber/epoxy resin composites[J]. Journal of Colloid and Interface Science, 2021, 583: 13-23. doi: 10.1016/j.jcis.2020.09.005 [31] GUO F L, HUANG P, LI Y Q, et al. Multiscale modeling of mechanical behaviors of carbon fiber reinforced epoxy composites subjected to hygrothermal aging[J]. Composite Structures, 2021, 256: 113098. doi: 10.1016/j.compstruct.2020.113098 [32] 李科杰. 新编传感器技术手册[M]. 北京: 国防工业出版社, 2002.LI K J. New Sensor Technical Manual[M]. Beijing: National Defense Industry Press, 2002. (in Chinese) [33] GARCIA I, ZUBIA J, DURANA G, et al. Optical fiber sensors for aircraft structural health monitoring[J]. Sensors, 2015, 15(7): 15494-15519. doi: 10.3390/s150715494 [34] XIONG L, JIANG G ZH, GUO Y X, et al. Investigation of the temperature compensation of FBGs encapsulated with different methods and subjected to different temperature change rates[J]. Journal of Lightwave Technology, 2019, 37(3): 917-926. doi: 10.1109/JLT.2018.2883817 [35] 吕京生, 郭士生, 王昌, 等. 一种新型光纤油井井下压力传感器[J]. 山东科学,2011,24(2):47-50.LÜ J SH, GUO SH SH, WANG CH, et al. A new optical fiber pressure sensor for oil well application[J]. Shandong Science, 2011, 24(2): 47-50. (in Chinese) -

下载:

下载: