| [1] |

China Taiwan Semiconductor Manufacturing Company. TSMC’S 5 nm (FinFET) technology[EB/OL]. [2021-04-17] https://www.tsmc.com/english/dedicatedFoundry/technology/logic/l_5nm.

|

| [2] |

DAN HUTCHESON G. Moore’s law, lithography, and how optics drive the semiconductor industry[J]. Proceedings of SPIE, 2018, 10583: 1058303.

|

| [3] |

郭杰, 李世光, 赵焱, 等. 电子束硅片图形检测系统中的纳米级对焦控制技术[J]. 中国光学,2019,12(2):242-255. doi: 10.3788/co.20191202.0242GUO J, LI SH G, ZHAO Y, et al. Nano-scale focus control technology in electron beam wafer pattern inspection system[J]. Chinese Optics, 2019, 12(2): 242-255. (in Chinese) doi: 10.3788/co.20191202.0242

|

| [4] |

孙裕文, 李世光, 叶甜春, 等. 纳米光刻中调焦调平测量系统的工艺相关性[J]. 光学学报,2016,36(8):0812001. doi: 10.3788/AOS201636.0812001SUN Y W, LI SH G, YE T CH, et al. Process dependency of focusing and leveling measurement system in nanoscale lithography[J]. Acta Optica Sinica, 2016, 36(8): 0812001. (in Chinese) doi: 10.3788/AOS201636.0812001

|

| [5] |

SHUMWAY J, NEAL N, MEYERS S, et al. Reduction and control of intrafield focus variation on 7nm technology[J]. Proceedings of SPIE, 2018, 10147: 101470B.

|

| [6] |

JANG J H, PARK T, PARK K D, et al. Focus control budget analysis for critical layers of flash devices[J]. Proceedings of SPIE, 2014, 9050: 90502F.

|

| [7] |

段晨, 宗明成, 范伟, 等. 浸没式光刻机对焦控制技术研究[J]. 光学学报,2018,38(9):0912002. doi: 10.3788/AOS201838.0912002DUAN CH, ZONG M CH, FAN W, et al. Focus control technology in immersion lithography[J]. Acta Optica Sinica, 2018, 38(9): 0912002. (in Chinese) doi: 10.3788/AOS201838.0912002

|

| [8] |

姚长呈, 巩岩. 深紫外光刻投影物镜温度特性研究[J]. 中国激光,2016,43(5):0516001. doi: 10.3788/CJL201643.0516001YAO CH CH, GONG Y. Research on temperature distribution of deep ultraviolet lithographic projection objective[J]. Chinese Journal of Lasers, 2016, 43(5): 0516001. (in Chinese) doi: 10.3788/CJL201643.0516001

|

| [9] |

VAN HAREN R, STEINERT S, MOURAILLE O, et al. The mask contribution as part of the intra-field on-product overlay performance[J]. Proceedings of SPIE, 2018, 11518: 1151813.

|

| [10] |

MASTENBROEK M. EUV industrialization high volume manufacturing with NXE3400B[J]. Proceedings of SPIE, 2018, 10809: 1080904.

|

| [11] |

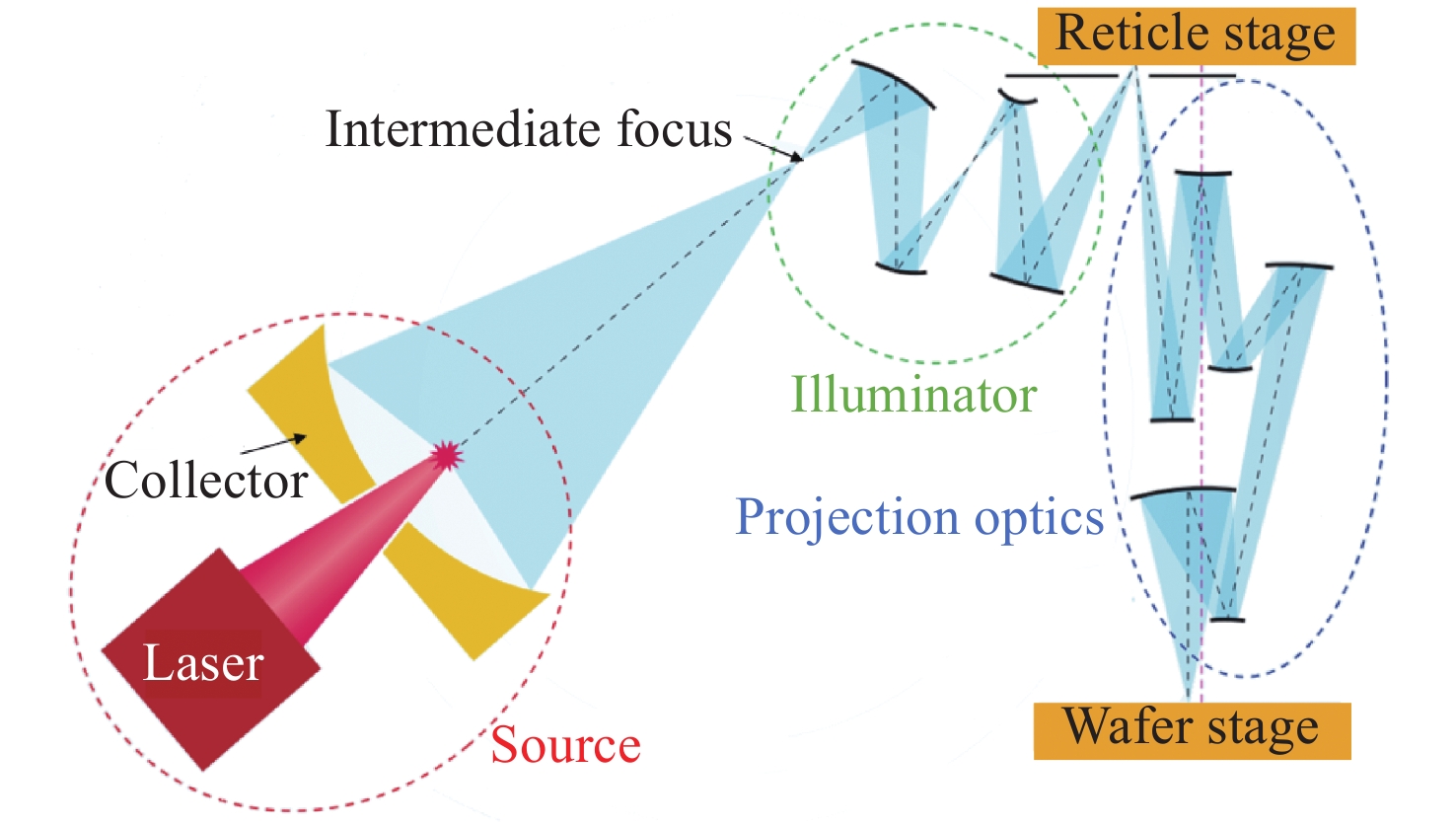

WAGNER C, HARNED N. Lithography gets extreme[J]. Nature Photonics, 2010, 4(1): 24-26. doi: 10.1038/nphoton.2009.251

|

| [12] |

甘雨, 张方, 朱思羽, 等. 光刻机照明系统光瞳特性参数的评估算法[J]. 中国激光,2019,46(3):0304007. doi: 10.3788/CJL201946.0304007GAN Y, ZHANG F, ZHU S Y, et al. Evaluation algorithm of pupil characteristic parameters in lithography illumination system[J]. Chinese Journal of Lasers, 2019, 46(3): 0304007. (in Chinese) doi: 10.3788/CJL201946.0304007

|

| [13] |

LOWISCH M, KUERZ P, CONRADI Q, et al.. Optics for ASML’s NXE: 3300B platform[C]. Proceedings of SPIE, 2013, 8679: 86791H.

|

| [14] |

HENDRICKX E, GRONHEID R, HERMANS J, et al. Readiness of EUV lithography for insertion into manufacturing: the IMEC EUV program[J]. Journal of Photopolymer Science and Technology, 2013, 26(5): 587-593. doi: 10.2494/photopolymer.26.587

|

| [15] |

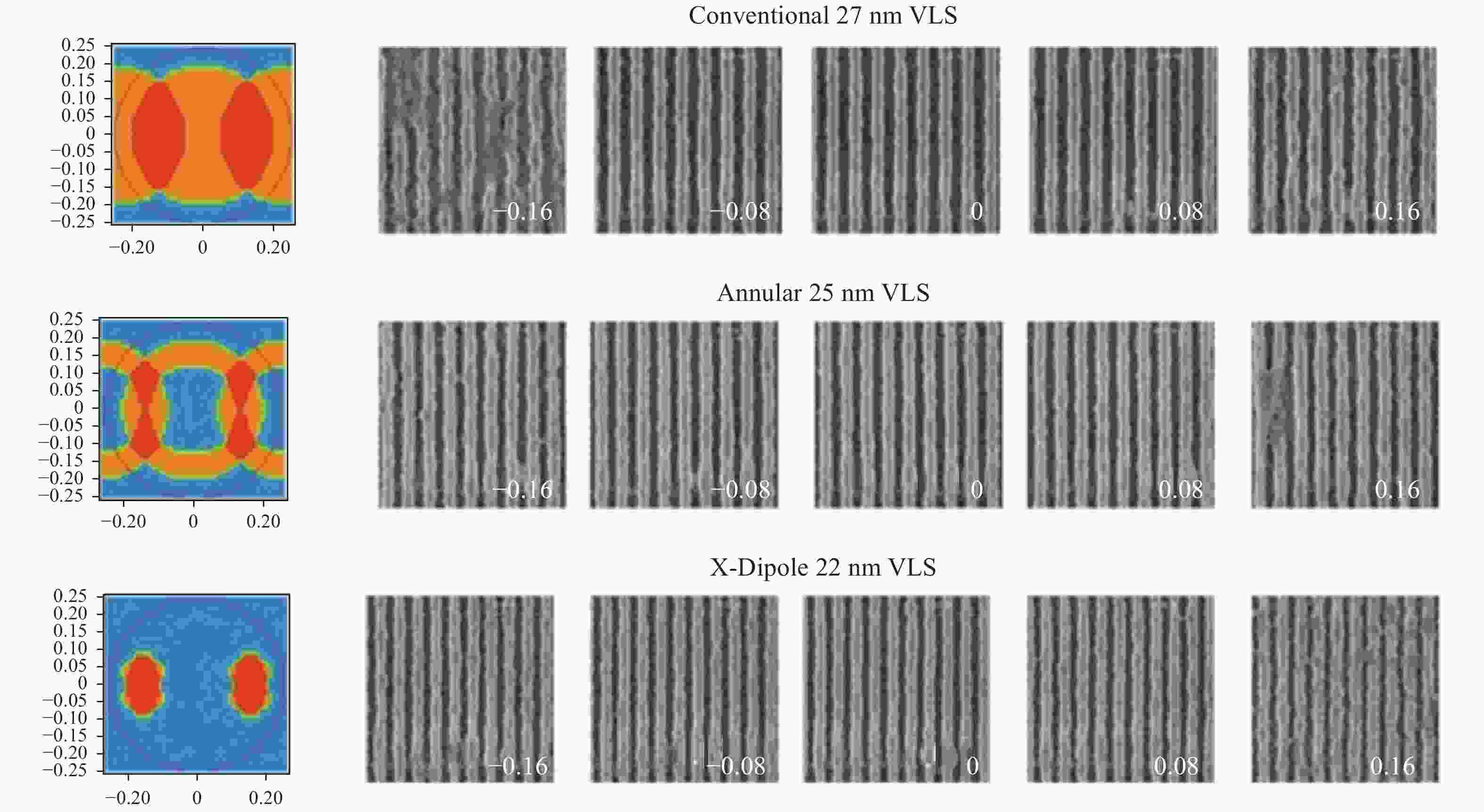

LEE S H, ZHANG ZH Y. Process window study with various illuminations for EUV lithography applications[J]. Proceedings of SPIE, 2007, 6517: 65172P. doi: 10.1117/12.713447

|

| [16] |

MACK C, CHICHESTER W. Fundamental Principles of Optical Lithography: the Science of Microfabrication[M]. Chichester: Wiley, 2008: 60.

|

| [17] |

ZHAI A P, CAO Y P, CHEN B, et al. A novel method of partial coherence measuring for the illumination system and its defocus performance analysis[J]. Optik, 2013, 124(23): 6313-6317. doi: 10.1016/j.ijleo.2013.06.009

|

| [18] |

DE SIMONE D, KLJUCAR L, DAS P, et al. 28 nm pitch single exposure patterning readiness by metal oxide resist on 0.33 NA EUV lithography[J]. Proceedings of SPIE, 2021, 11609: 116090Q.

|

| [19] |

KNEER B, MIGURA S, KAISER W, et al. EUV lithography optics for sub-9 nm resolution[J]. Proceedings of SPIE, 2015, 9422: 94221G. doi: 10.1117/12.2175488

|

| [20] |

CONLEY W, ALAGNA P, SHIEH J, et al. The impact of lower light source bandwidth on sub-10 nm process node features[J]. Proceedings of SPIE, 2017, 10147: 1014707.

|

| [21] |

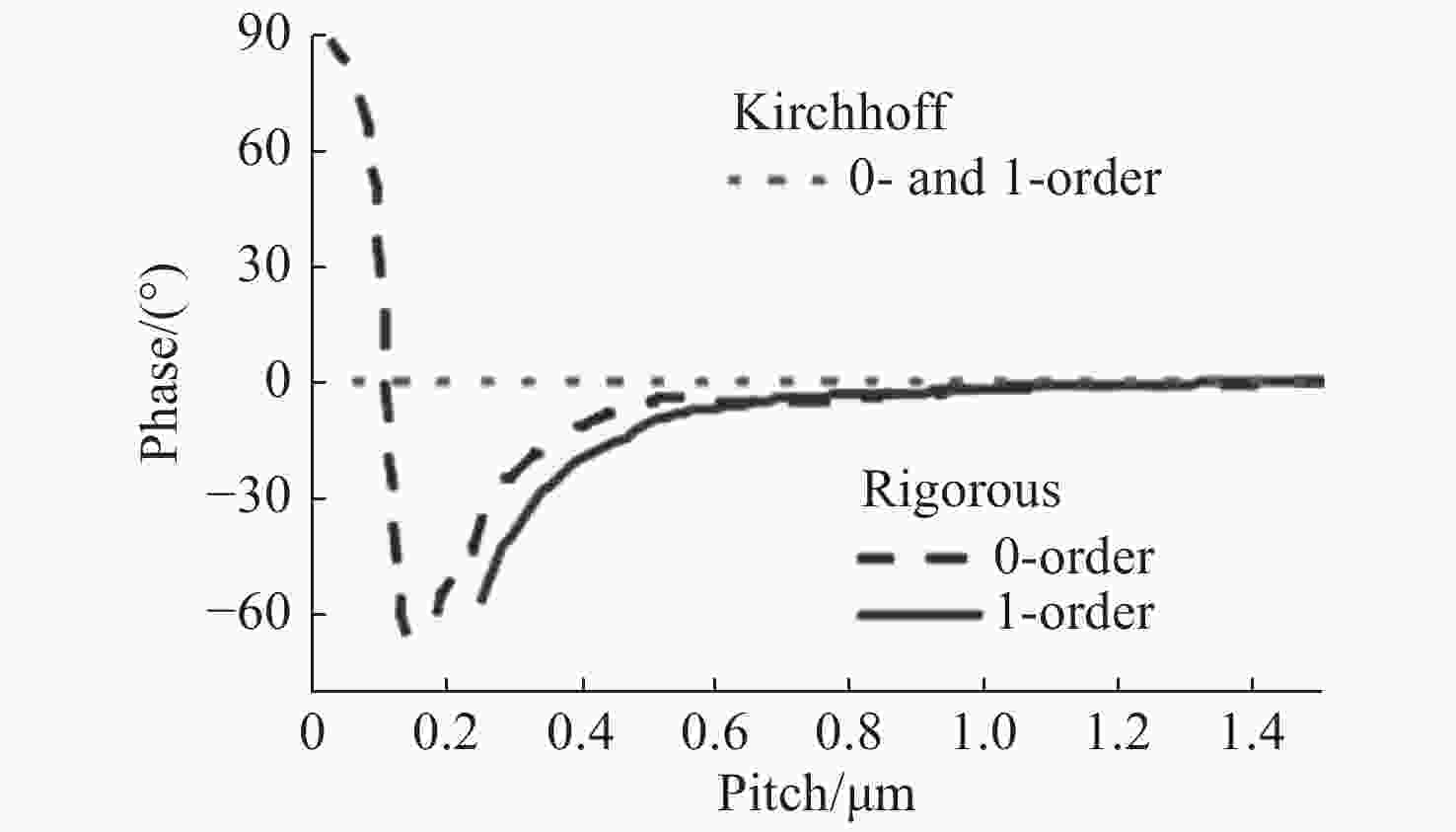

RUOFF V D M J, NEUMANN J T, SCHMITT-WEAVER E, et al. Polarization-induced astigmatism caused by topographic masks[J]. Proceedings of SPIE, 2007, 6730: 67301T.

|

| [22] |

TANABE H, SATO S, TAKAHASHI A. Fast 3D lithography simulation by convolutional neural network[J]. Proceedings of SPIE, 2020, 11518: 115180L.

|

| [23] |

HAO Y Y, LI Y Q, LI T, et al. The calculation and representation of polarization aberration induced by 3D mask in lithography simulation[J]. Proceedings of SPIE, 2017, 10460: 104601J.

|

| [24] |

韦亚一. 超大规模集成电路先进光刻理论与应用[M]. 北京: 科学出版社, 2016: 103-105.WEI Y Y. Advanced Lithography Theory and Application for VLSI[M]. Beijing: Science Press, 2016: 103-105. (in Chinese)

|

| [25] |

AZPIROZ J T, ROSENBLUTH A E. Impact of sub-wavelength electromagnetic diffraction in optical lithography for semiconductor chip manufacturing[C]. Proceedings of the 2013 SBMO/IEEE MTT-S International Microwave & Optoelectronics Conference, IEEE, 2013: 1-5.

|

| [26] |

SAIED M, FOUSSADIER F, BELLEDENT J, et al. Three-dimensional mask effects and source polarization impact on OPC model accuracy and process window[J]. Proceedings of SPIE, 2007, 6520: 65204Q. doi: 10.1117/12.715120

|

| [27] |

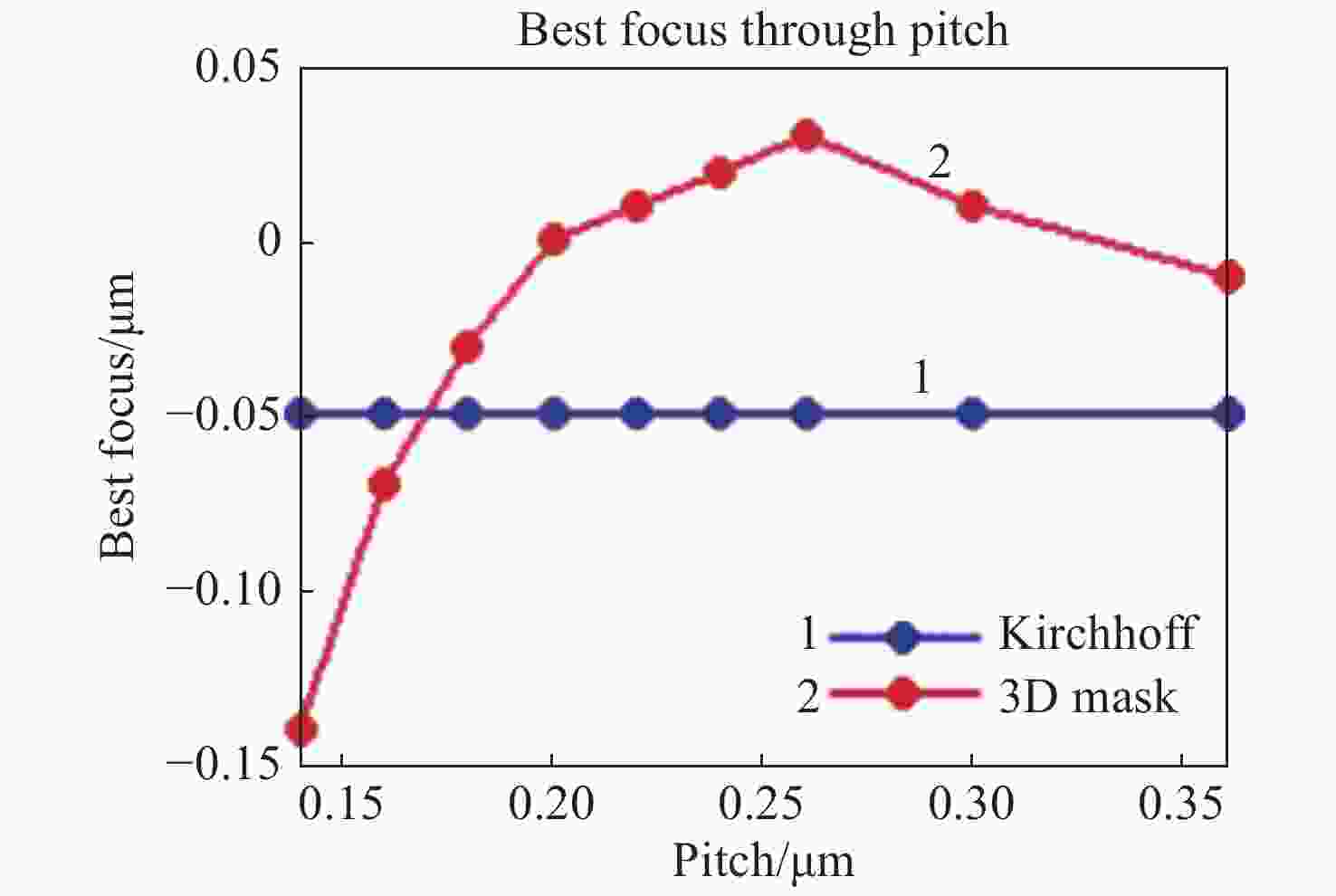

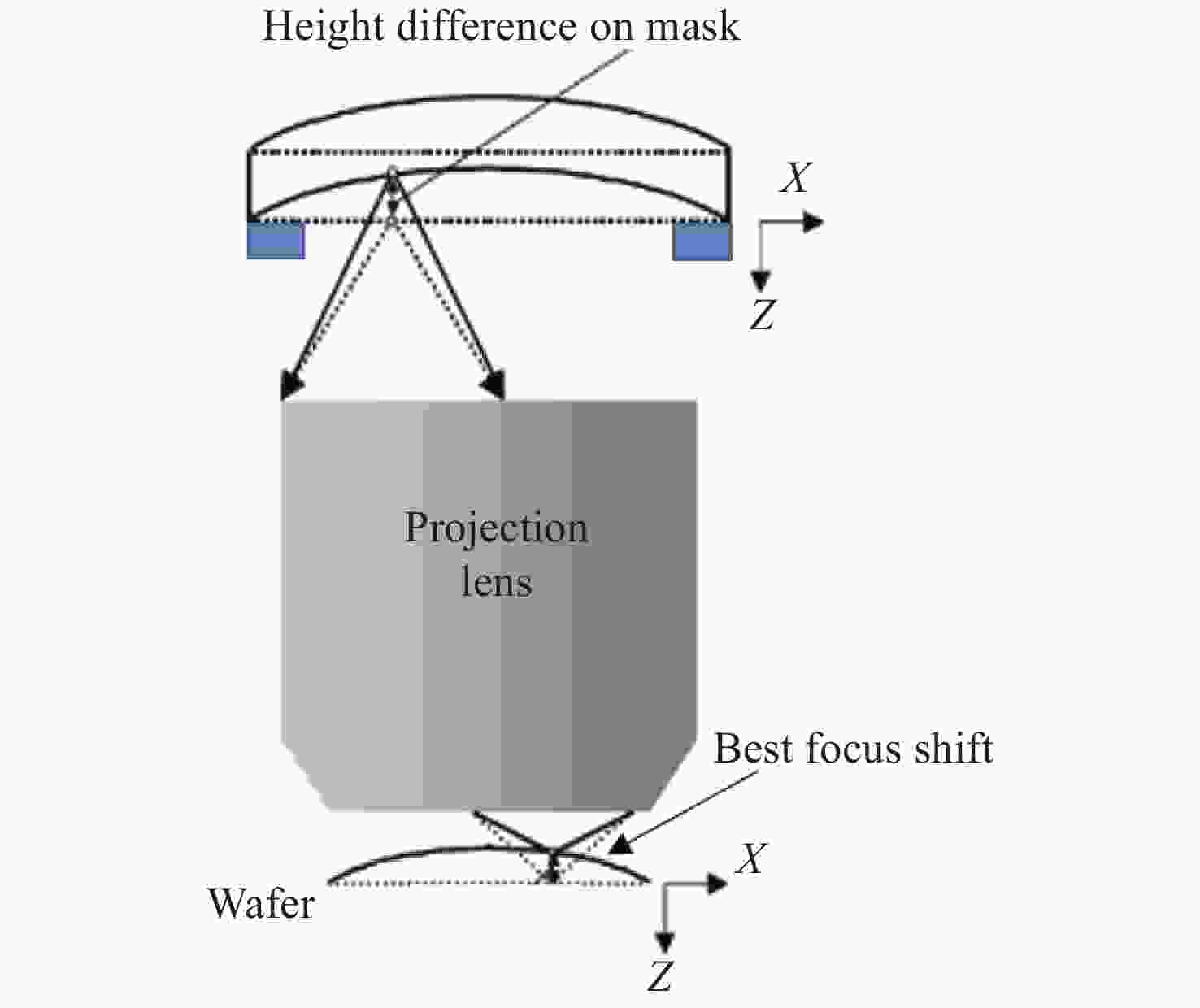

YAN P Y. Understanding Bossung curve asymmetry and focus shift effect in EUV lithography[J]. Proceedings of SPIE, 2002, 4562: 279-287. doi: 10.1117/12.458302

|

| [28] |

ERDMANN A. Topography effects and wave aberrations in advanced PSM technology[J]. Proceedings of SPIE, 2001, 4346: 345. doi: 10.1117/12.435734

|

| [29] |

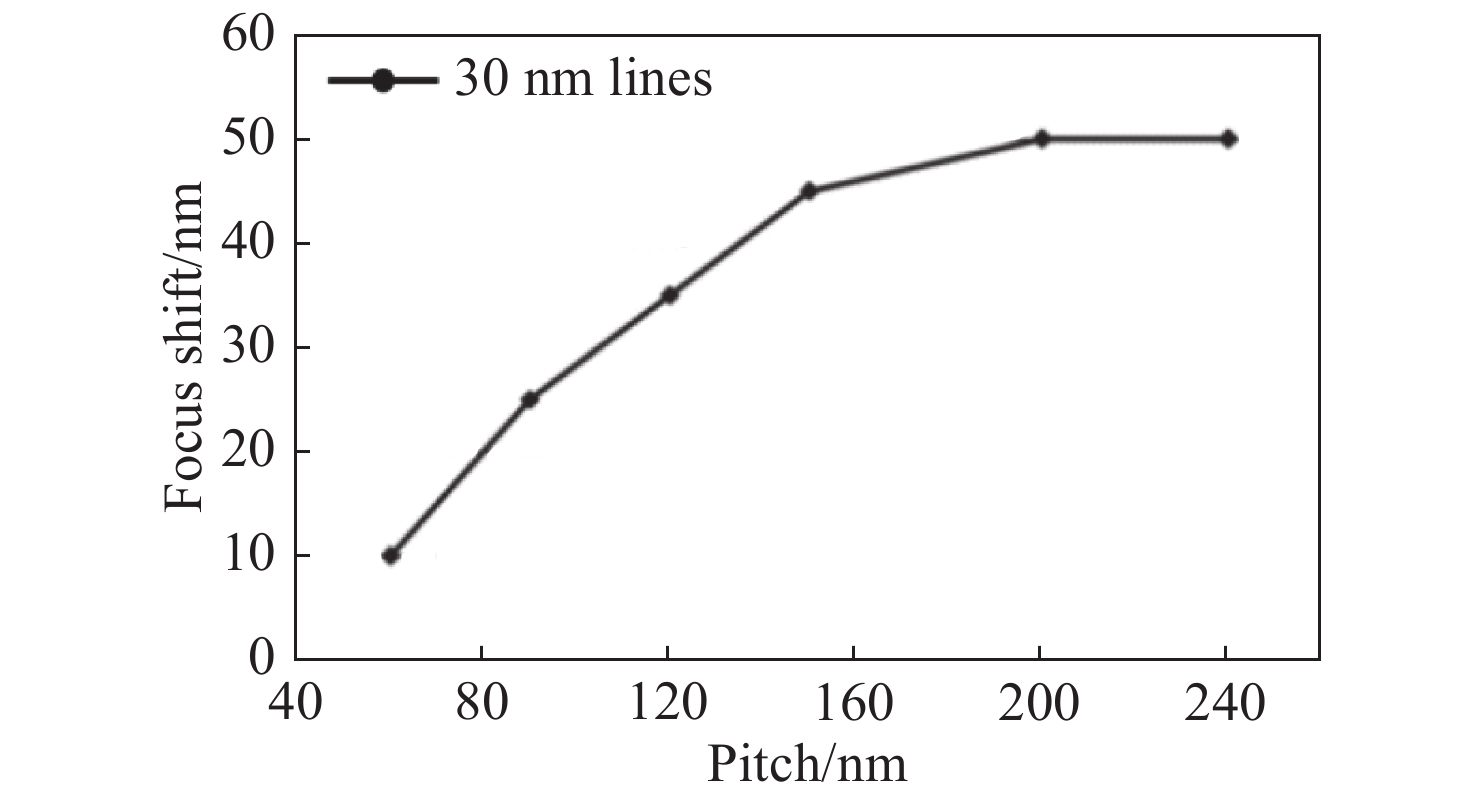

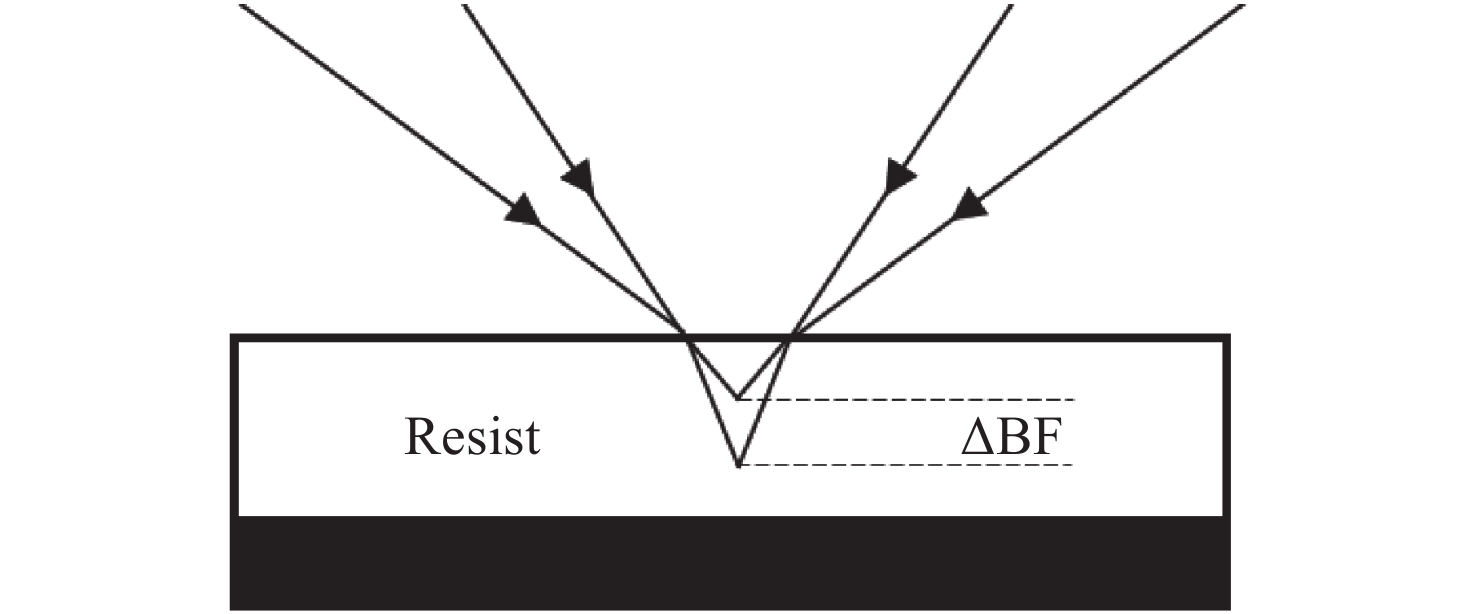

BURKHARDT M, RAGHUNATHAN A. Best focus shift mechanism for thick masks[J]. Proceedings of SPIE, 2015, 9422: 94220X.

|

| [30] |

NAKAJIMA Y, SATO T, INANAMI R, et al. Aberration budget in extreme ultraviolet lithography[J]. Proceedings of SPIE, 2008, 6921: 69211A.

|

| [31] |

ERDMANN A, EVANSCHITZKY P, FÜHNER T. Mask diffraction analysis and optimization for EUV masks[J]. Proceedings of SPIE, 2009, 7271: 72711E.

|

| [32] |

ERDMANN A, EVANSCHITZKY P, NEUMANN J T, et al. Mask-induced best-focus shifts in deep ultraviolet and extreme ultraviolet lithography[J]. Journal of Micro/Nanolithography, 2016, 15(2): 021205. doi: 10.1117/1.JMM.15.2.021205

|

| [33] |

HAQUE R R, LEVINSON Z, SMITH B W. 3D mask effects of absorber geometry in EUV lithography systems[J]. Proceedings of SPIE, 2016, 9776: 97760F.

|

| [34] |

MOCHI I, PHILIPSEN V, GALLAGHER E, et al. Assist features: placement, impact, and relevance for EUV imaging[J]. Proceedings of SPIE, 2016, 9776: 97761S. doi: 10.1117/12.2220025

|

| [35] |

BOUMA A, MIYAZAKI J, VAN VEEN M, et al. Impact of mask absorber and quartz over-etch on mask 3D induced best focus shifts[J]. Proceedings of SPIE, 2014, 9231: 92310S. doi: 10.1117/12.2068155

|

| [36] |

SZUCS A, PLANCHOT J, FARYS V, et al. Best focus shift mitigation for extending the depth of focus[J]. Proceedings of SPIE, 2013, 8683: 868313. doi: 10.1117/12.2011114

|

| [37] |

INOUE S, ITOH M, ASANO M, et al. Desirable reticle flatness from focus deviation standpoint in optical lithography[J]. Journal of Micro/Nanolithography,MEMS,and MOEMS, 2002, 1(3): 307. doi: 10.1117/1.1503806

|

| [38] |

LIU P, XIE X B, LIU W, et al. Fast 3D thick mask model for full-chip EUVL simulations[J]. Proceedings of SPIE, 2013, 8679: 86790W. doi: 10.1117/12.2010818

|

| [39] |

SEARS M K, SMITH B W. Modeling the effects of pupil-manipulated spherical aberration in optical nanolithography[J]. Journal of Micro/Nanolithography,MEMS,and MOEMS, 2013, 12(1): 013008. doi: 10.1117/1.JMM.12.1.013008

|

| [40] |

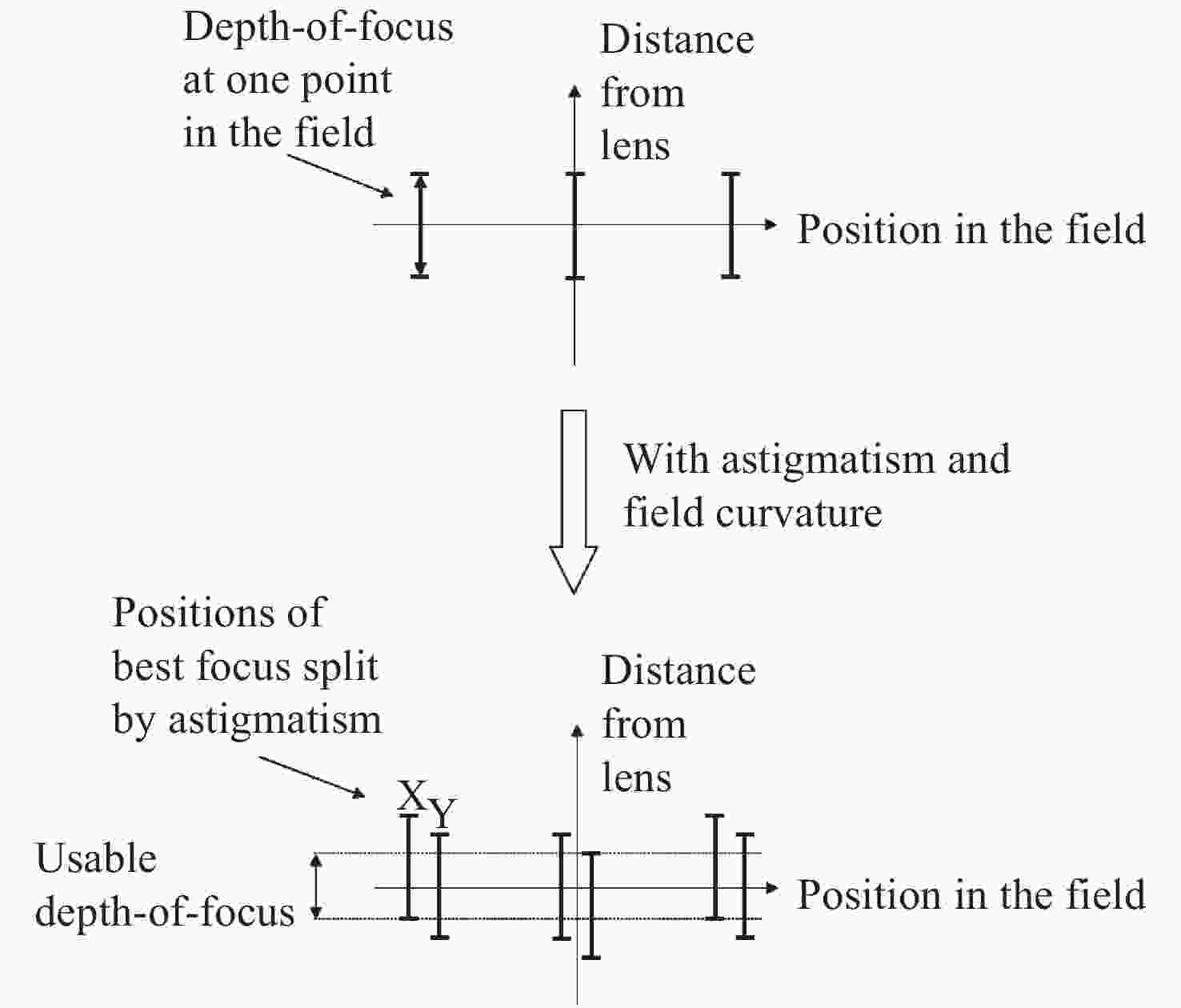

BRUNNER T A. Impact of lens aberrations on optical lithography[J]. IBM Journal of Research and Development, 1997, 41(1-2): 57-67.

|

| [41] |

BEKAERT J, VAN LOOK L, VANDENBERGHE G, et al. Characterization and control of dynamic lens heating effects under high volume manufacturing conditions[J]. Proceedings of SPIE, 2011, 7973: 79730V. doi: 10.1117/12.881609

|

| [42] |

LEVINSON H J. Principles of Lithography[M]. 3rd ed. Bellingham, WA: SPIE Press, 2011: 40-41.

|

| [43] |

李艳秋, 刘岩, 刘丽辉. 16 nm极紫外光刻物镜热变形对成像性能影响的研究[J]. 光学学报,2019,39(1):0122001. doi: 10.3788/AOS201939.0122001LI Y Q, LIU Y, LIU L H. Effect of thermal deformation on imaging performance for 16 nm extreme ultraviolet lithography objective[J]. Acta Optica Sinica, 2019, 39(1): 0122001. (in Chinese) doi: 10.3788/AOS201939.0122001

|

| [44] |

SEARS M K, BEKAERT J, SMITH B W. Lens wavefront compensation for 3D photomask effects in subwavelength optical lithography[J]. Applied Optics, 2013, 52(3): 314-322. doi: 10.1364/AO.52.000314

|

| [45] |

HO G H, CHENG A, CHEN CH J, et al. Lens-heating-induced focus drift of I-line step and scan: correction and control in a manufacturing environment[J]. Proceedings of SPIE, 2001, 4344: 289-296. doi: 10.1117/12.436722

|

| [46] |

王帆, 王向朝, 马明英, 等. 光刻机投影物镜像差的现场测量技术[J]. 激光与光电子学进展,2004,41(6):33-37.WANG F, WANG X ZH, MA M Y, et al. In-situ measurement methods of lens aberration[J]. Laser &Optoelectronics Progress, 2004, 41(6): 33-37. (in Chinese)

|

| [47] |

CUI Y T. Fine-tune lens-heating-induced focus drift with different process and illumination settings[J]. Proceedings of SPIE, 2001, 4346: 1369-1378. doi: 10.1117/12.435675

|

| [48] |

CHANG Y S, WU M J, HUNG M Y, et al. Polygate within wafer CD uniformity improvement by the minimization of lens heating effect[J]. Proceedings of SPIE, 2001, 4404: 26-32. doi: 10.1117/12.425219

|

| [49] |

CHENG B J, LIU H CH, CUI Y T, et al. Improving image control by correcting the lens-heating focus drift[J]. Proceedings of SPIE, 2000, 4000: 818-826. doi: 10.1117/12.389075

|

| [50] |

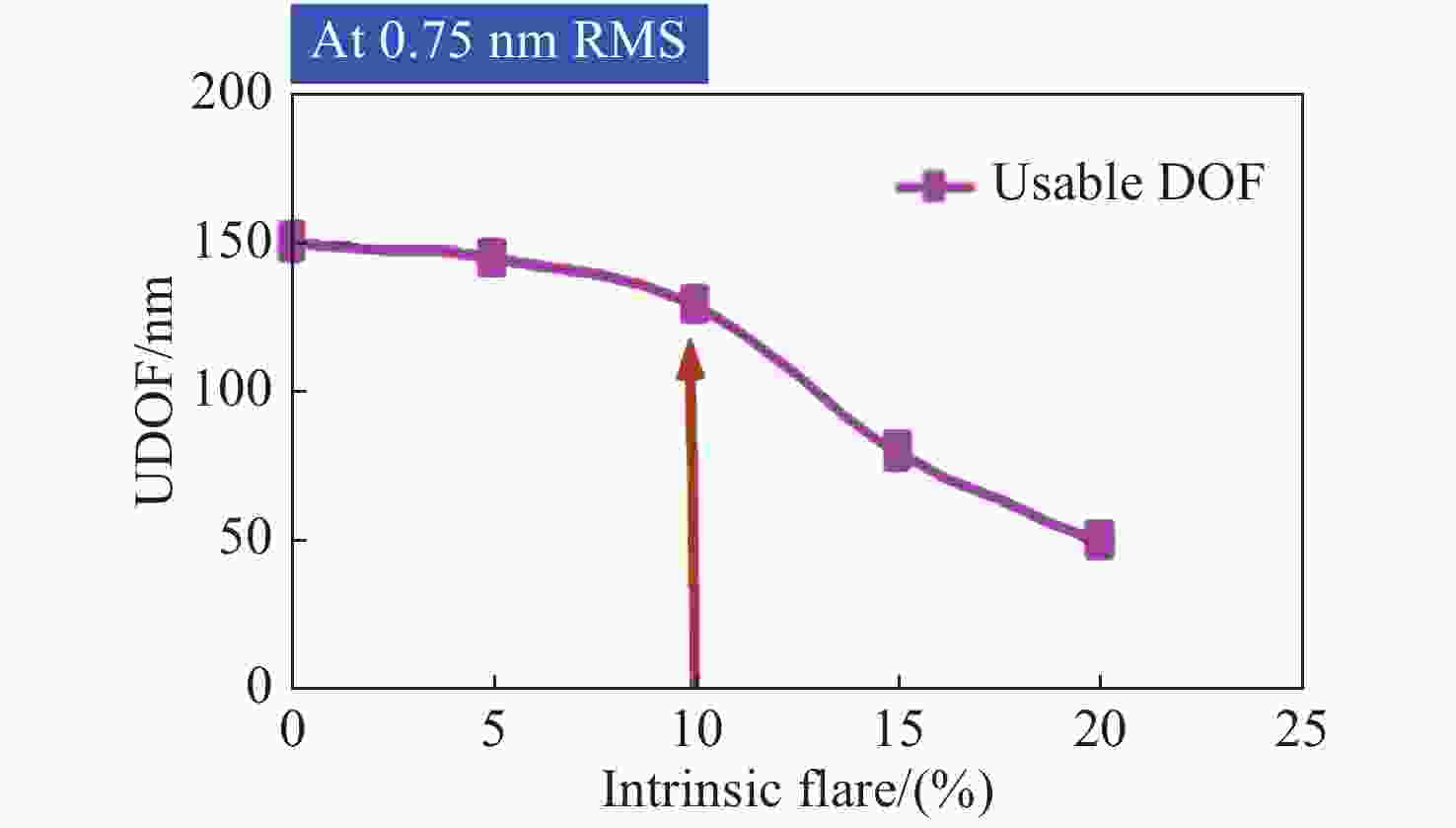

LEE S H, SHROFF Y, CHANDHOK M. Flare and lens aberration requirements for EUV lithographic tools[J]. Proceedings of SPIE, 2005, 5751: 707-714. doi: 10.1117/12.604870

|

| [51] |

MONTCALM C, BAJT S, MIRKARIMI P B, et al. Multilayer reflective coatings for extreme-ultraviolet lithography[J]. Proceedings of SPIE, 1998, 3331: 42-51. doi: 10.1117/12.309600

|

| [52] |

FINDERS J. The impact of Mask 3D and Resist 3D effects in optical lithography[J]. Proceedings of SPIE, 2014, 9052: 905205.

|

| [53] |

PENG A, HSU S D, HOWELL R C, et al. Lithography-defect-driven source-mask optimization solution for full-chip optical proximity correction[J]. Applied Optics, 2021, 60(3): 616-620. doi: 10.1364/AO.408405

|

| [54] |

LIU X F, HOWELL R, HSU S, et al. EUV source-mask optimization for 7nm node and beyond[J]. Proceedings of SPIE, 2014, 9048: 90480Q. doi: 10.1117/12.2047584

|

| [55] |

WU Q. Key points in 14 nm photolithographic process development, challenges and process window capability[C]. Proceedings of 2017 China Semiconductor Technology International Conference, IEEE, 2017: 1-6.

|

| [56] |

JIA N N, YANG S H, KIM S, et al. Study of lens heating behavior and thick mask effects with a computational method[J]. Proceedings of SPIE, 2014, 9052: 905209.

|

| [57] |

王丽萍. 长春光机所承担的国家科技重大专项项目“极紫外光刻关键技术研究”通过验收[J]. 分析仪器,2017(4):96.WANG L P. The project of “study of key technology for extreme-ultraviolet lithography” passed the acceptance inspection[J]. Analytical Instrumentation, 2017(4): 96. (in Chinese)

|

| [58] |

DENG X J, CHAO A, FEIKES J, et al. Experimental demonstration of the mechanism of steady-state microbunching[J]. Nature, 2021, 590(7847): 576-579. doi: 10.1038/s41586-021-03203-0

|

下载:

下载: