-

摘要: 为了满足图案胶体光子晶体在实际应用中的需要,提出旋涂这种简单胶体光子晶体环的快速制备方法。基底为圆型图案光刻胶结构,乳胶球为疏水核亲水壳结构聚(苯乙烯-甲基丙烯酸甲酯-丙烯酸)乳胶球。对所制备的样品进行形貌和光学性能表征,研究了旋涂速度、乳胶球浓度和不同圆型光刻胶图案基底对旋涂过程中乳胶球组装形貌的影响。结果表明制备胶体光子晶体环的最佳参数如下:旋速为2000 r/min,乳胶球质量百分比浓度为7.5%,圆型光刻胶结构的直径约为22.8 µm;环中乳胶球进行相对有序组装,这与光谱图中峰的位置和宽度相一致,分析原因可能是由于组装时间太短导致的。这种快速的胶体光子晶体环的成功构筑归因于图案基底的物理限域和浸润性差异,这种方法可能在光学器件、传感和防伪方面有着广泛的应用前景。Abstract: The quick fabrication of ring-shaped colloidal photonic crystal was demonstrated on the circle-patterned photoresist substrate by spin-coating, which is promising for practical application. Latex spheres were designed with a hydrophobic core and a hydrophilic shell of poly(styrene-methyl methacrylate-acrylic acid). Scanning Electron Microscopy (SEM) images and reflectance spectra of the as-prepared ring-shaped colloidal photonic crystals were acquired. The influences of spinning speed, latex sphere concentration and different circle-patterned photoresist substrates on the morphology of the ring-shaped colloidal photonic crystal were investigated. The results indicate that the optimal parameters for preparing a ring-shaped colloidal photonic crystal are achieved with a spinning speed of 2000 r/min, a latex sphere concentration of 7.5% and a circle-patterned photoresist structure (diameter: 22.8 µm). The SEM images showed that the latex spheres were almost all deposited at the periphery of the ring and were dispersed with relative order, which was attributed to fast evaporation. This fast self-assembly method for preparing ring-shaped colloidal photonic crystals was achieved by spin-coating and relied on the physical confinement of patterned photoresist substrates and their wettability difference. It will have important applications in optical devices, sensing materials and anti-counterfeiting.

-

Key words:

- colloidal photonic crystal /

- spin coating /

- pattern

-

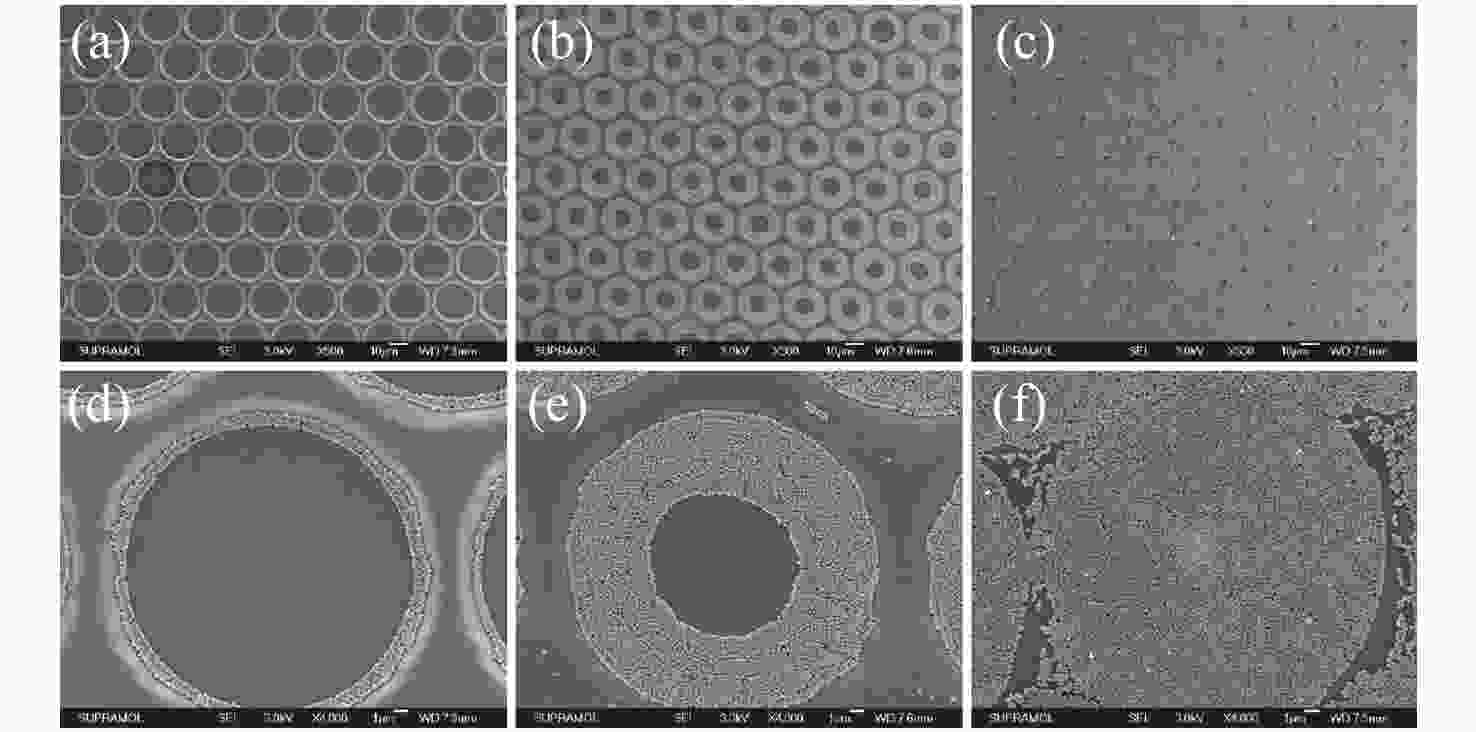

图 1 不同旋涂速度制备的胶体光子晶体环的扫描电镜图。(a, d)1000 r/min;(b, e)2000 r/min;(c, f)3000 r/min。(d),(e)和(f)是相应(a),(b)和(c)的放大扫描电镜图

Figure 1. SEM images of the ring-shaped colloidal photonic crystal deposited at different spinning speeds. (a, d) 1000 r/min; (b, e) 2000 r/min; (c, f) 3000 r/min. (d), (e) and (f) are corresponding magnification SEM images of (a), (b) and (c).

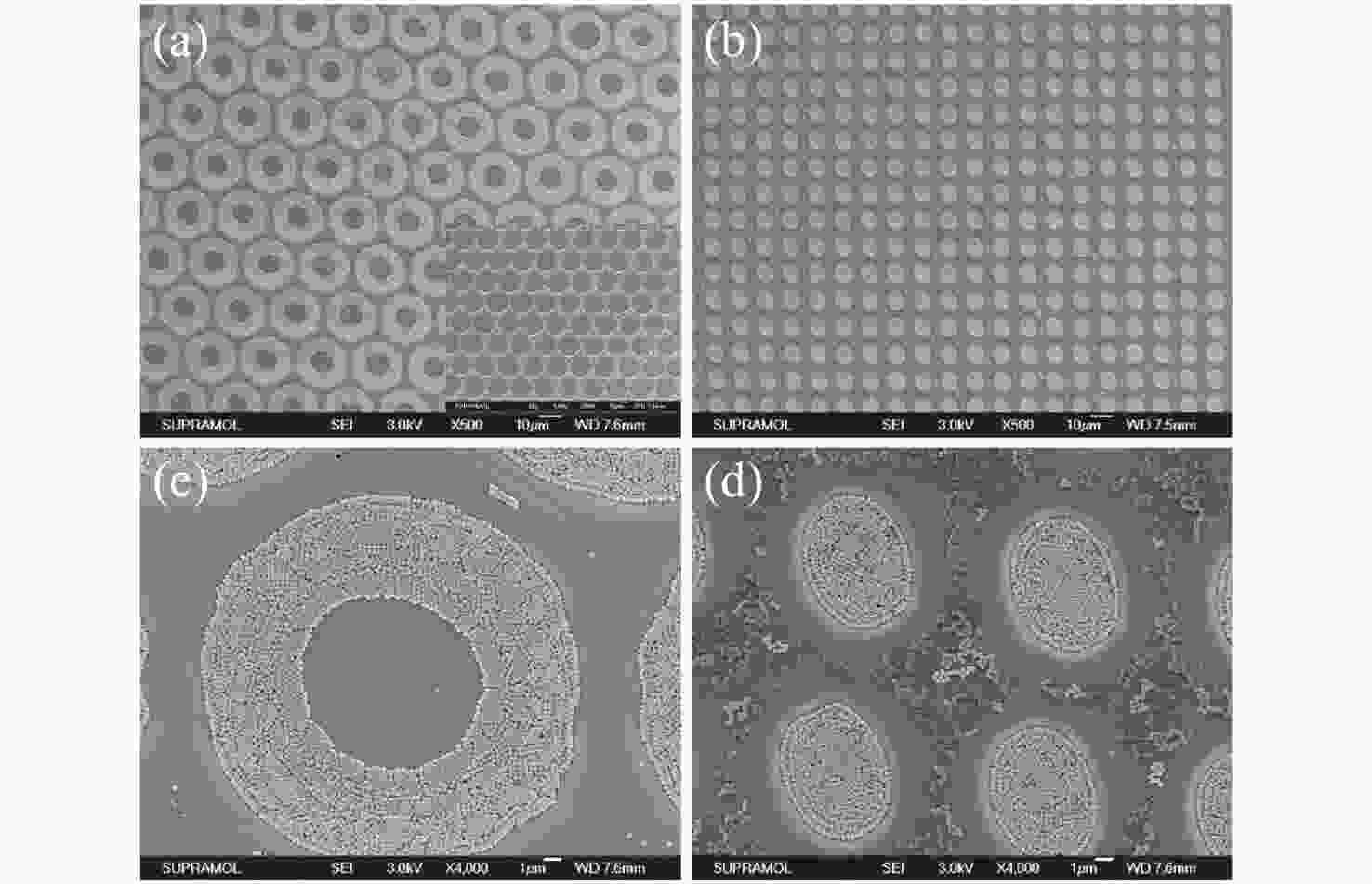

图 2 不同乳胶球浓度旋涂法制备的胶体光子晶体环的扫描电镜图。(a, d)质量百分比浓度为1%;(b, e)质量百分比浓度为7.5%;(c, f)质量百分比浓度为13.4%。(d),(e)和(f)是相应(a),(b)和(c)的放大扫描电镜图

Figure 2. SEM images of the spin-coated ring-shaped colloidal photonic crystal deposited with different latex sphere concentrations. (a, d) Mass percentage concentration is 1%; (b, e) mass percentage concentration is 7.5%; (c, f) mass percentage concentration is 13.4%. (d), (e) and (f) are corresponding magnification SEM images of (a), (b) and (c).

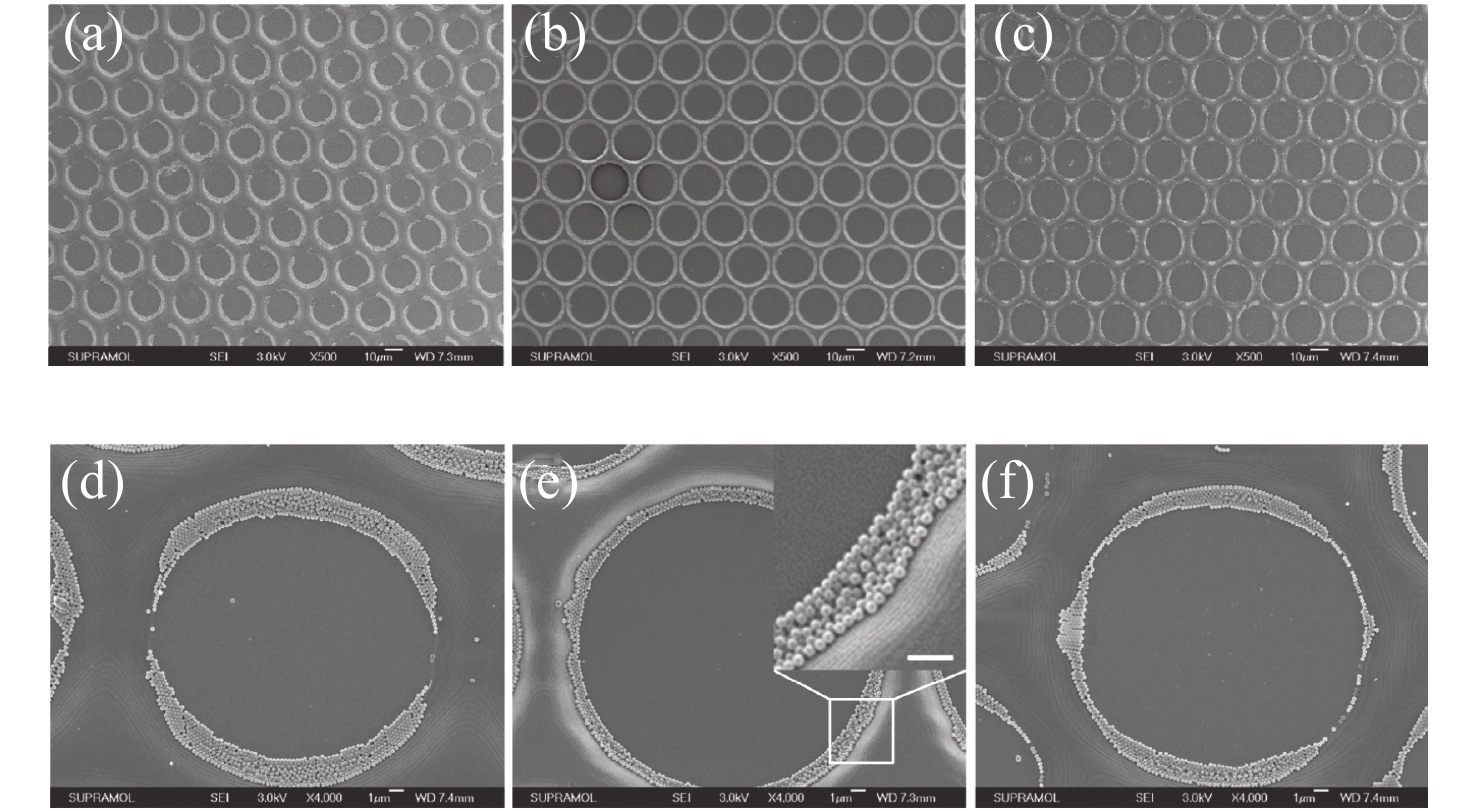

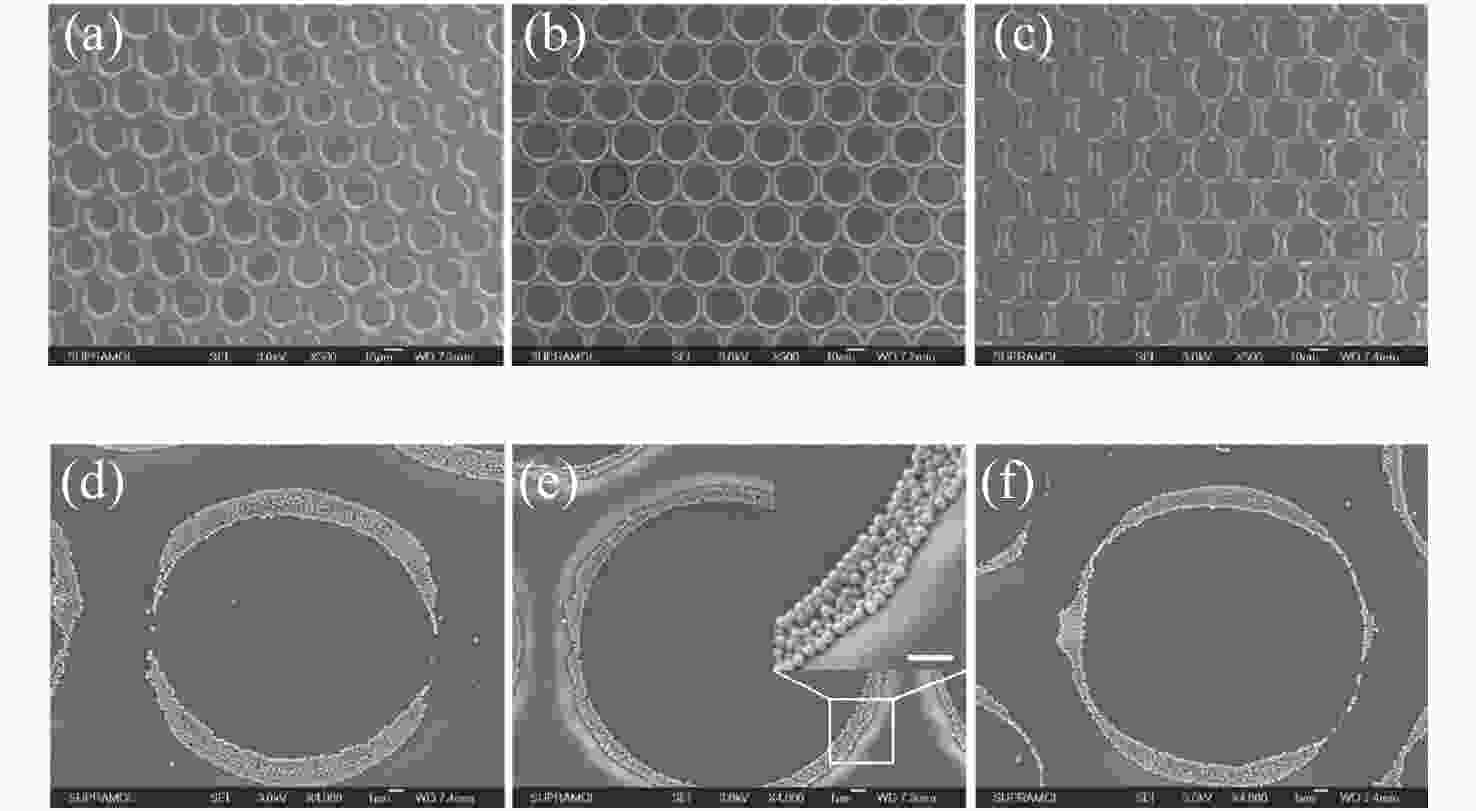

图 3 不同直径圆型光刻胶结构基底旋涂法制备的胶体光子晶体环的扫描电镜图。制备光刻胶结构所使用掩版(a, c)直径为20 µm;(b, d)直径为5 µm。(c)和(d)是相应(a)和(b)的放大扫描电镜图。(a)中插图为所使用的圆型光刻胶结构的扫描电镜图

Figure 3. SEM images of spin-coated ring-shaped colloidal photonic crystals on circle-patterned photoresist structures obtained with diameters of mask (a, c) 20 µm and (b, d) 5 µm. (c) and (d) are corresponding magnification SEM images of (a) and (b). The inset of (a) is the SEM image of the circle-patterned photoresist structure.

-

[1] WANG J X, WANG L B, SONG L Y, et al. Patterned photonic crystals fabricated by inkjet printing[J]. Journal of Materials Chemistry C, 2013, 1(38): 6048-6058. doi: 10.1039/c3tc30728j [2] 董贤子, 段宣明. 双光子三维微结构快速制备技术[J]. 光学 精密工程,2007,15(4):441-446.DONG X Z, DUAN X M. High speed two-photon laser nanofabrication of three-dimensional microstructures[J]. Optics and Precision Engineering, 2007, 15(4): 441-446. (in Chinese) [3] 叶鑫, 倪锐芳, 黄进, 等. 自组装法制备的亚波长纳米多孔二氧化硅薄膜[J]. 光学 精密工程,2015,23(5):1233-1239. doi: 10.3788/OPE.20152305.1233YE X, NI R F, HUANG J, et al. Sub-wavelength nano-porous silica anti-reflection coatings fabricated by dip coating method[J]. Optics and Precision Engineering, 2015, 23(5): 1233-1239. (in Chinese) doi: 10.3788/OPE.20152305.1233 [4] 毛小洁. 高功率皮秒紫外激光器新进展[J]. 中国光学,2015,8(2):182-190. doi: 10.3788/co.20150802.0182MAO X J. New progress in high-power picosecond ultraviolet laser[J]. Chinese Optics, 2015, 8(2): 182-190. (in Chinese) doi: 10.3788/co.20150802.0182 [5] 冯迪, 赵正琪, 房启蒙, 等. 光子晶体光纤端面研磨损伤的分析[J]. 光学 精密工程,2017,25(11):2895-2903. doi: 10.3788/OPE.20172511.2895FENG D, ZHAO ZH Q, FANG Q M, et al. Analysis of end face damage in lapping for photonic crystal fiber[J]. Optics and Precision Engineering, 2017, 25(11): 2895-2903. (in Chinese) doi: 10.3788/OPE.20172511.2895 [6] 杨晶, 龚诚, 赵佳宇, 等. 利用3D打印技术制备太赫兹器件[J]. 中国光学,2017,10(1):77-85. doi: 10.3788/co.20171001.0077YANG J, GONG CH, ZHAO J Y, et al. Fabrication of terahertz device by 3D printing technology[J]. Chinese Optics, 2017, 10(1): 77-85. (in Chinese) doi: 10.3788/co.20171001.0077 [7] 李天琦, 毛小洁, 雷健, 等. 固体激光器与光纤激光器对光子晶体光纤棒耦合的分析与对比[J]. 中国光学,2018,11(6):958-973. doi: 10.3788/co.20181106.0958LI T Q, MAO X J, LEI J, et al. Analysis and comparison of solid-state lasers and fiber lasers on the coupling of rod-type photonic crystal fiber[J]. Chinese Optics, 2018, 11(6): 958-973. (in Chinese) doi: 10.3788/co.20181106.0958 [8] OZIN G A, YANG S M. The race for the photonic chip: colloidal crystal assembly in silicon wafers[J]. Advanced Functional Materials, 2001, 11(2): 95-104. doi: 10.1002/1616-3028(200104)11:2<95::AID-ADFM95>3.0.CO;2-O [9] GU ZH Z, FUJISHIMA A, SATO O. Patterning of a colloidal crystal film on a modified hydrophilic and hydrophobic surface[J]. Angewandte Chemie International Edition, 2002, 41(12): 2067-2070. doi: 10.1002/1521-3773(20020617)41:12<2067::AID-ANIE2067>3.0.CO;2-Z [10] SUN W, JIA F, SUN ZH Q, et al. Manipulation of cracks in three-dimensional colloidal crystal films via recognition of surface energy patterns: an approach to regulating crack patterns and shaping microcrystals[J]. Langmuir, 2011, 27(13): 8018-8026. doi: 10.1021/la2002207 [11] WU L, DONG ZH CH, KUANG M X, et al. Printing patterned fine 3D structures by manipulating the three phase contact line[J]. Advanced Functional Materials, 2015, 25(15): 2237-2242. doi: 10.1002/adfm.201404559 [12] SU M, HUANG ZH D, LI Y F, et al. A 3D self-shaping strategy for nanoresolution multicomponent architectures[J]. Advanced Materials, 2018, 30(3): 1703963. doi: 10.1002/adma.201703963 [13] GUO D, LI CH, WANG Y, et al. Precise assembly of particles for zigzag or linear patterns[J]. Angewandte Chemie International Edition, 2017, 56(48): 15348-15352. doi: 10.1002/anie.201709115 [14] DUO D, ZHENG X, WANG X H, et al. Formation of multicomponent size-sorted assembly patterns by tunable templated dewetting[J]. Angewandte Chemie International Edition, 2018, 57(49): 16126-16130. doi: 10.1002/anie.201810728 [15] GUO D, LI Y N, ZHENG X, et al. Programmed coassembly of one-dimensional binary superstructures by liquid soft confinement[J]. Journal of the American Chemical Society, 2018, 140(1): 18-21. doi: 10.1021/jacs.7b09738 [16] SU M, QIN F F, ZHANG Z Y, et al. Non-lithography hydrodynamic printing of micro/nanostructures on curved surfaces[J]. Angewandte Chemie International Edition, 2020, 59(34): 14234-14240. doi: 10.1002/anie.202007224 [17] CUI L Y, LI Y F, WANG J X, et al. Fabrication of large-area patterned photonic crystals by ink-jet printing[J]. Journal of Materials Chemistry, 2009, 19(31): 5499-5502. [18] 邝旻翾, 王京霞, 王利彬, 等. 喷墨打印高精度图案研究进展[J]. 化学学报,2012,70(18):1889-1896. doi: 10.6023/A12050199KUANG M X, WANG J X, WANG L B, et al. Research progress of high-precision patterns by directly inkjet printing[J]. Acta Chimica Sinica, 2012, 70(18): 1889-1896. (in Chinese) doi: 10.6023/A12050199 [19] LIU M J, WANG J X, HE M, et al. Inkjet printing controllable footprint lines by regulating the dynamic wettability of coalescing ink droplets[J]. ACS Applied Materials &Interfaces, 2014, 6(16): 13344-13348. [20] KUANG M X, WANG J X, BAO B, et al. Inkjet printing patterned photonic crystal domes for wide viewing-angle displays by controlling the sliding three phase contact line[J]. Advanced Optical Materials, 2014, 2(1): 34-38. doi: 10.1002/adom.201300369 [21] SHEN W ZH, LI M ZH, YE CH Q, et al. Direct-writing colloidal photonic crystal microfluidic chips by inkjet printing for label-free protein detection[J]. Lab on a Chip, 2012, 12(17): 3089-3095. doi: 10.1039/c2lc40311k [22] HOU J, ZHANG H CH, YANG Q, et al. Hydrophilic–hydrophobic patterned molecularly imprinted photonic crystal sensors for high-sensitive colorimetric detection of tetracycline[J]. Small, 2015, 11(23): 2738-2742. doi: 10.1002/smll.201403640 [23] HOU J, ZHANG H CH, YANG Q, et al. Bio-inspired photonic-crystal microchip for fluorescent ultratrace detection[J]. Angewandte Chemie International Edition, 2014, 53(23): 5791-5795. doi: 10.1002/anie.201400686 [24] XIE ZH Y, LI L L, LIU P M, et al. Self-assembled coffee-ring colloidal crystals for structurally colored contact lenses[J]. Small, 2015, 11(8): 926-930. doi: 10.1002/smll.201402071 [25] DING H B, ZHU C, TIAN L, et al. Structural color patterns by electrohydrodynamic jet printed photonic crystals[J]. ACS Applied Materials &Interfaces, 2017, 9(13): 11933-11941. [26] KAWAMURA A, KOHRI M, YOSHIOKA S, et al. Structural color tuning: mixing melanin-like particles with different diameters to create neutral colors[J]. Langmuir, 2017, 33(15): 3824-3830. doi: 10.1021/acs.langmuir.7b00707 [27] WANG Y ZH, WEI C, CONG H L, et al. Hybrid top-down/bottom-up strategy using superwettability for the fabrication of patterned colloidal assembly[J]. ACS Applied Materials &Interfaces, 2016, 8(7): 4985-4993. [28] ZHANG B, MENG F SH, FENG J G, et al. Manipulation of colloidal particles in three dimensions via microfluid engineering[J]. Advanced Materials, 2018, 30(22): 1707291. doi: 10.1002/adma.201707291 [29] 黄雪雯, 许升, 赵伟, 等. 聚合物纳米组装体修饰丝网印刷电极构建过氧化氢传感器[J]. 应用化学,2020,37(2):235-241.HUANG X W, XU S, ZHAO W, et al. Hydrogen peroxide sensor based on a polymeric self-assembled nanoparticles-modified screen-printed electrode[J]. Chinese Journal of Applied Chemistry, 2020, 37(2): 235-241. (in Chinese) [30] 孙振龙, 闫顺杰, 周容涛, 等. 基于抗菌肽的智能型抗菌涂层研究进展[J]. 应用化学,2020,37(8):865-876.SUN Z L, YAN S J, ZHOU R T, et al. Recent progress in the development of smart coatings based on antimicrobial peptides[J]. Chinese Journal of Applied Chemistry, 2020, 37(8): 865-876. (in Chinese) [31] 张哲烽, 黄小东, 闻利平. 受荷叶自清洁效应启发的手术服表面改性与防污染性能[J]. 应用化学,2019,36(1):34-40.ZHANG Z F, HUANG X D, WEN L P. Surface modification and antifouling performance with surgical clothing[J]. Chinese Journal of Applied Chemistry, 2019, 36(1): 34-40. (in Chinese) [32] 杨正军, 刘博, 黄湃, 等. 多孔聚合物微球孔结构对丙烯催化聚合性能的影响[J]. 应用化学,2020,37(7):746-755.YANG Z J, LIU B, HUANG P, et al. Effect of pore structures of porous polymer microspheres on catalytic propylene polymerization[J]. Chinese Journal of Applied Chemistry, 2020, 37(7): 746-755. (in Chinese) [33] 黄河, 李雅瑜, 郭子砚, 等. 双重响应性生物基自修复凝胶的制备及其性能[J]. 应用化学,2019,36(2):146-154.HUANG H, LI Y Y, GUO Z Y, et al. Preparation and properties of dual responsive self-healing bio-based hydrogels[J]. Chinese Journal of Applied Chemistry, 2019, 36(2): 146-154. (in Chinese) [34] SHI Y L, FENG X J, YANG R H, et al. Preparation of superhydrophobic and superoleophilic corn straw fibers oil absorbents and application to the removal of spilled oil from water[J]. Chinese Journal of Applied Chemistry, 2020, 37(7): 793-802. -

下载:

下载: