-

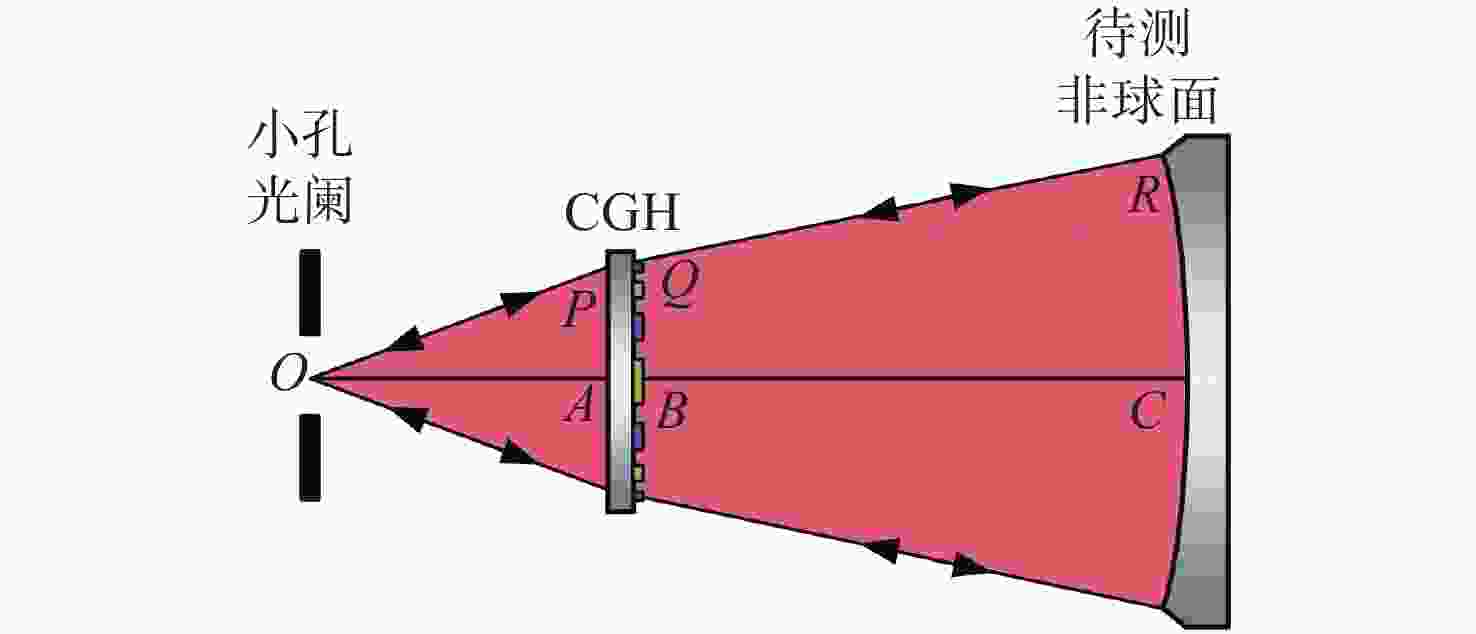

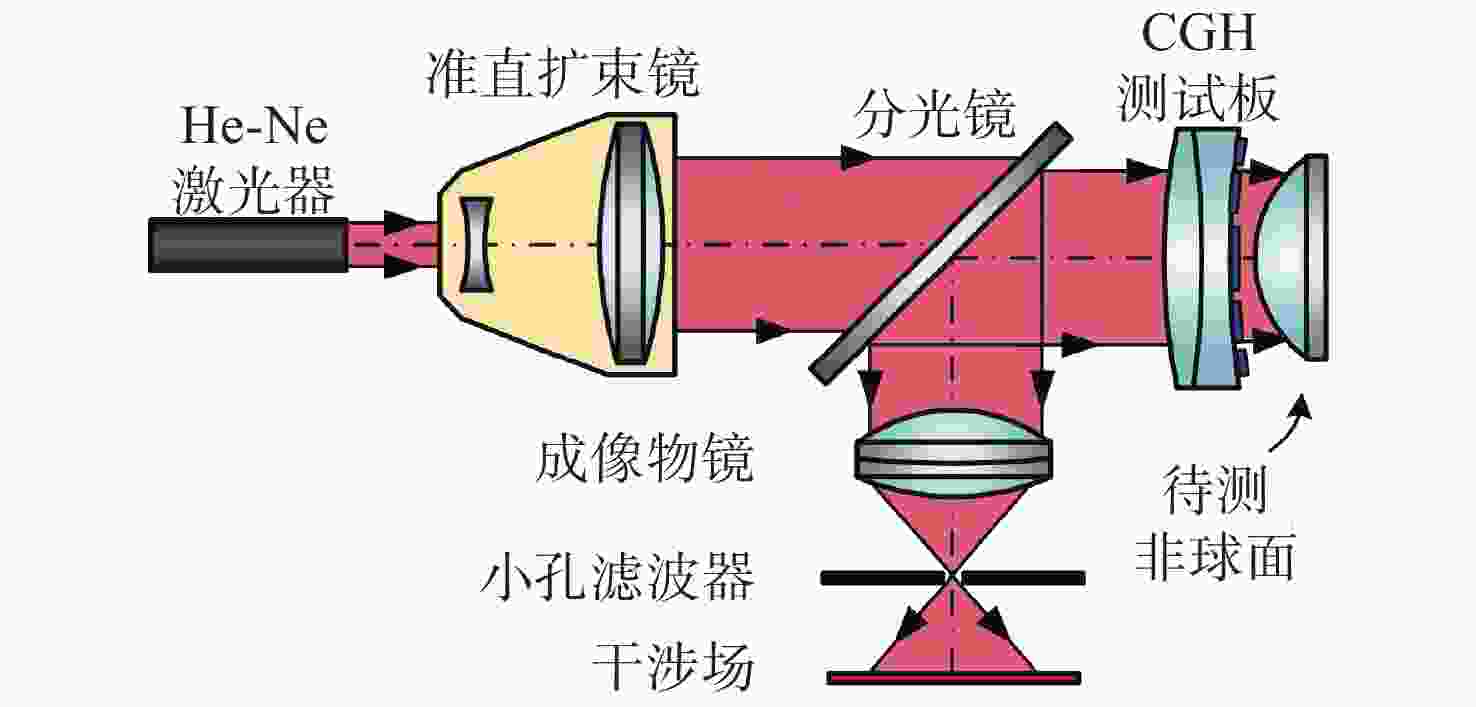

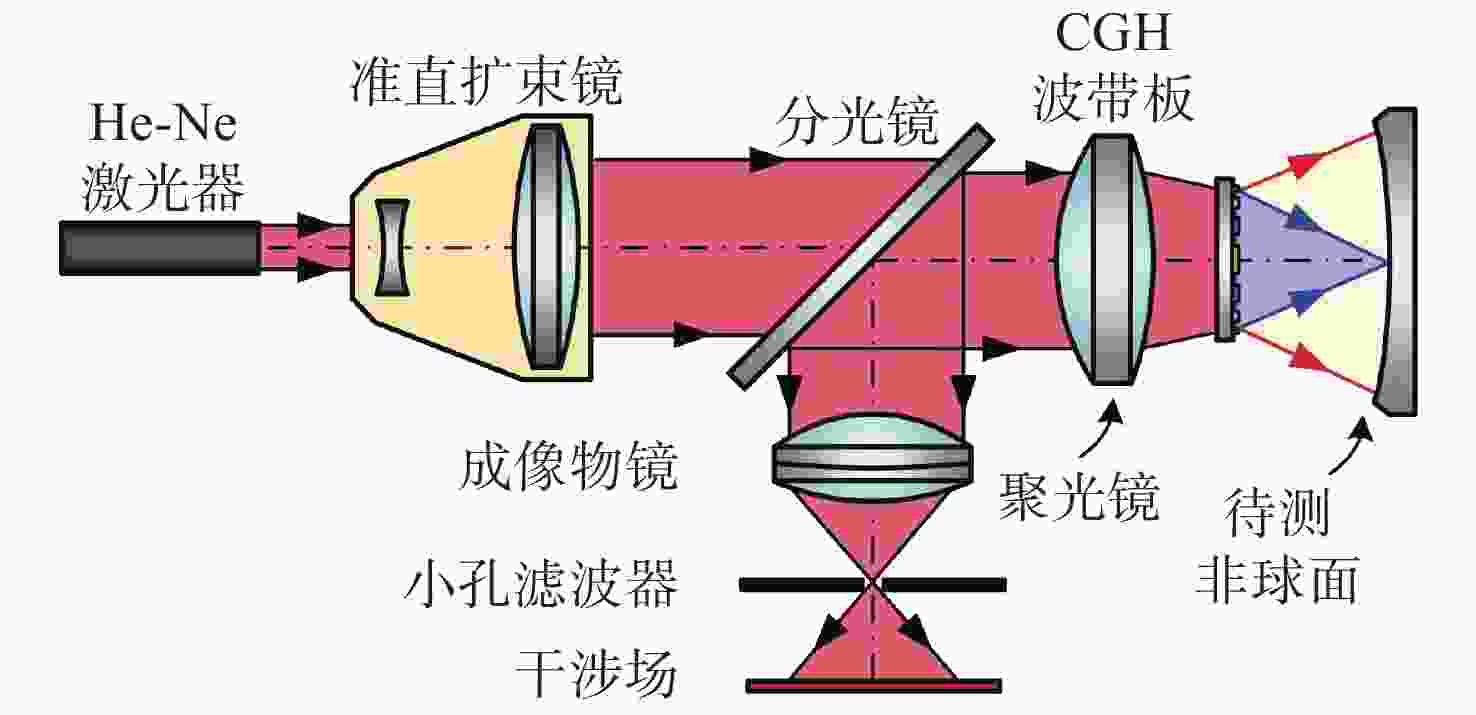

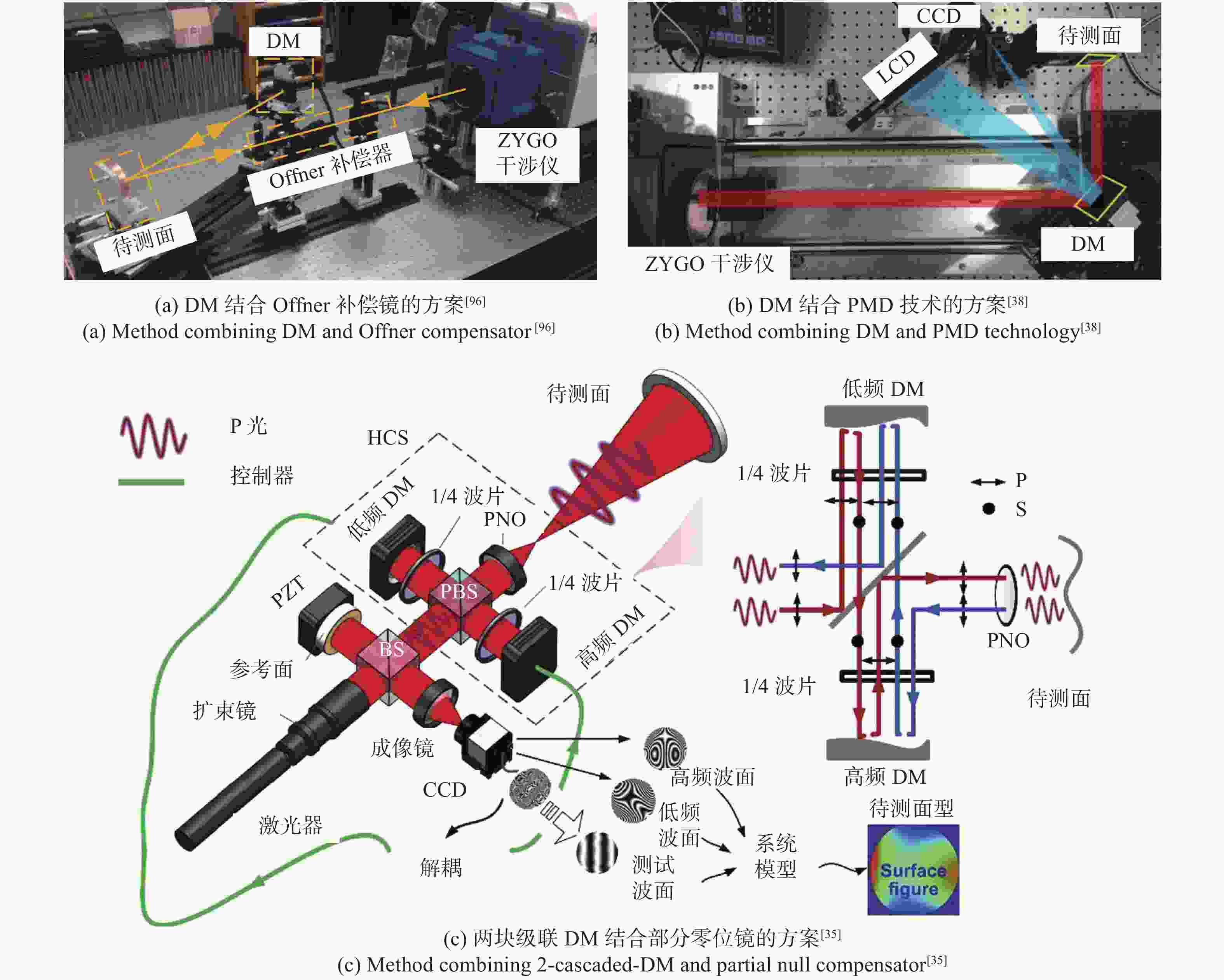

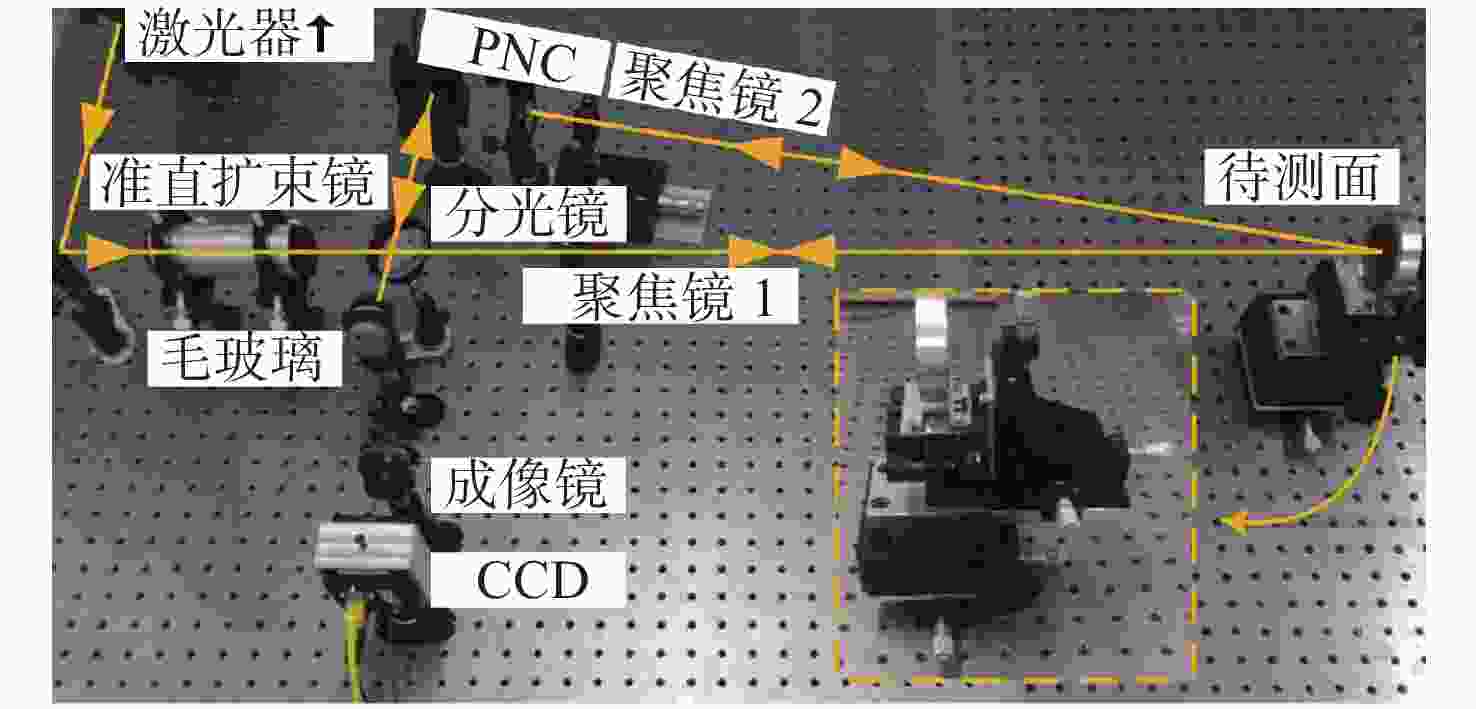

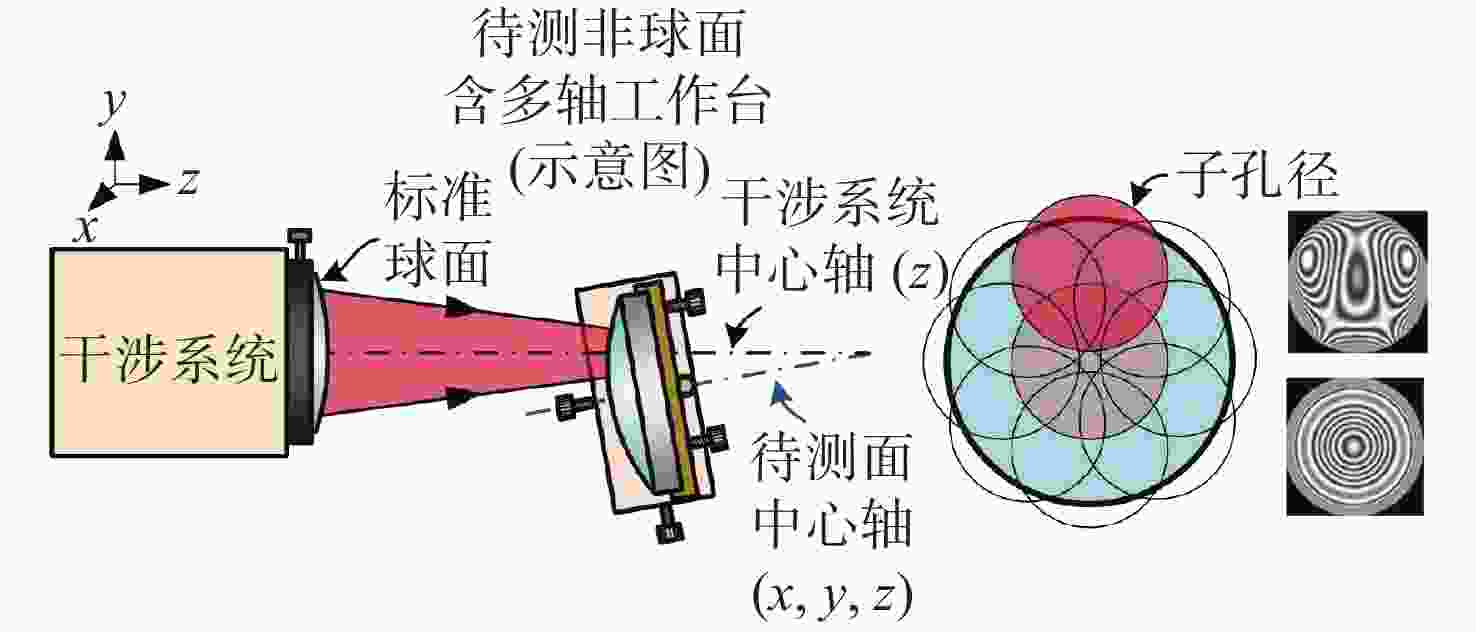

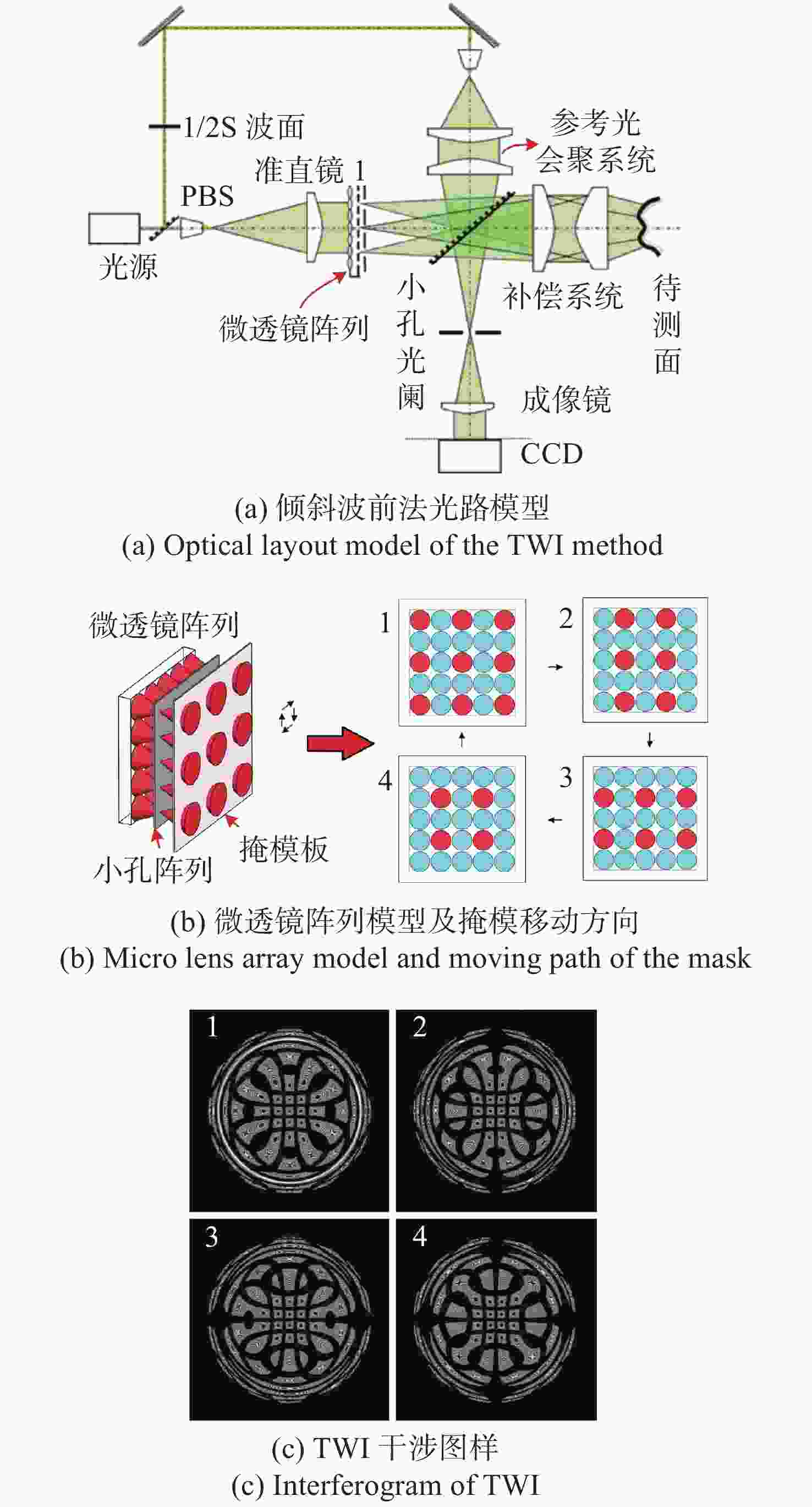

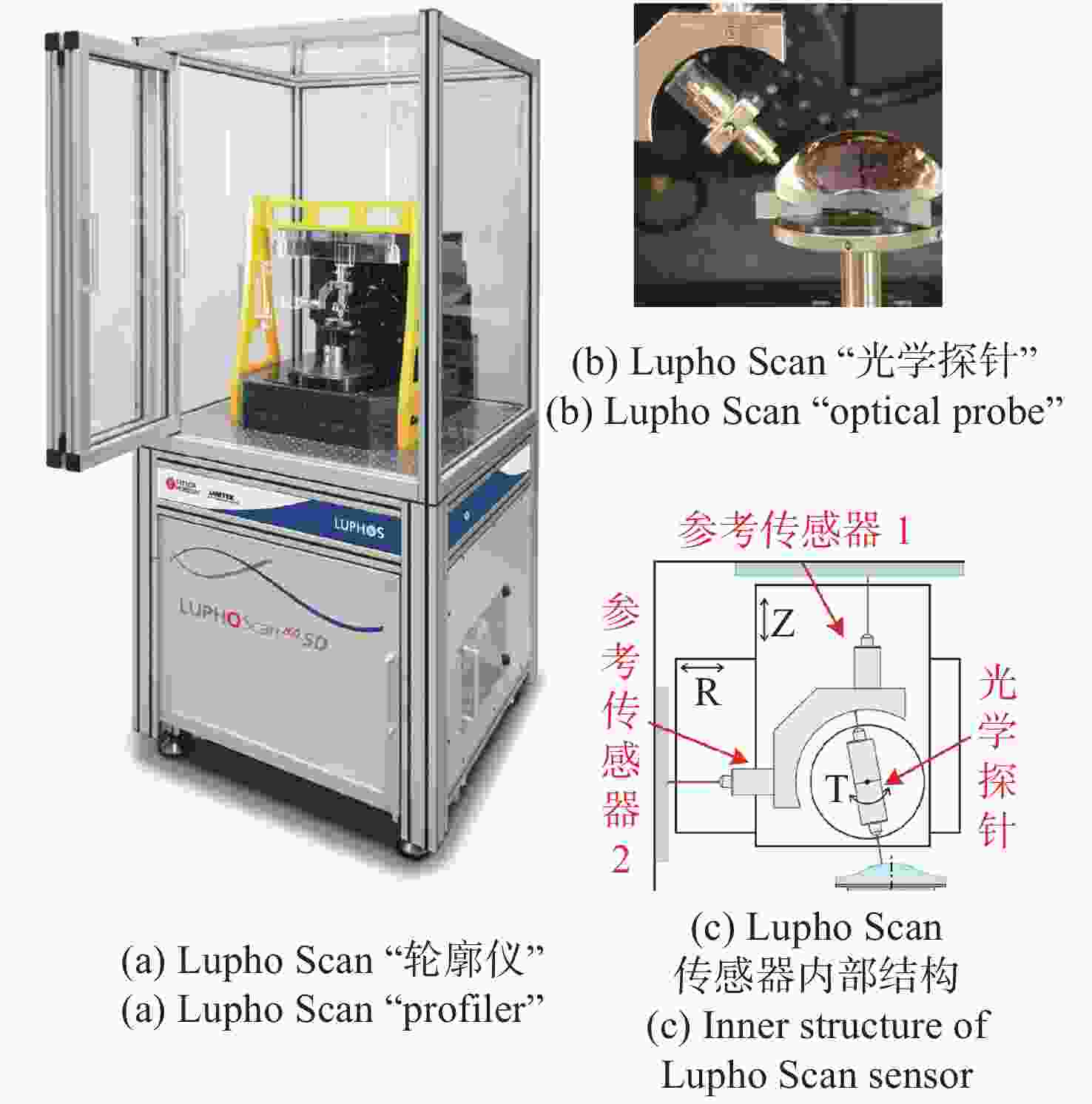

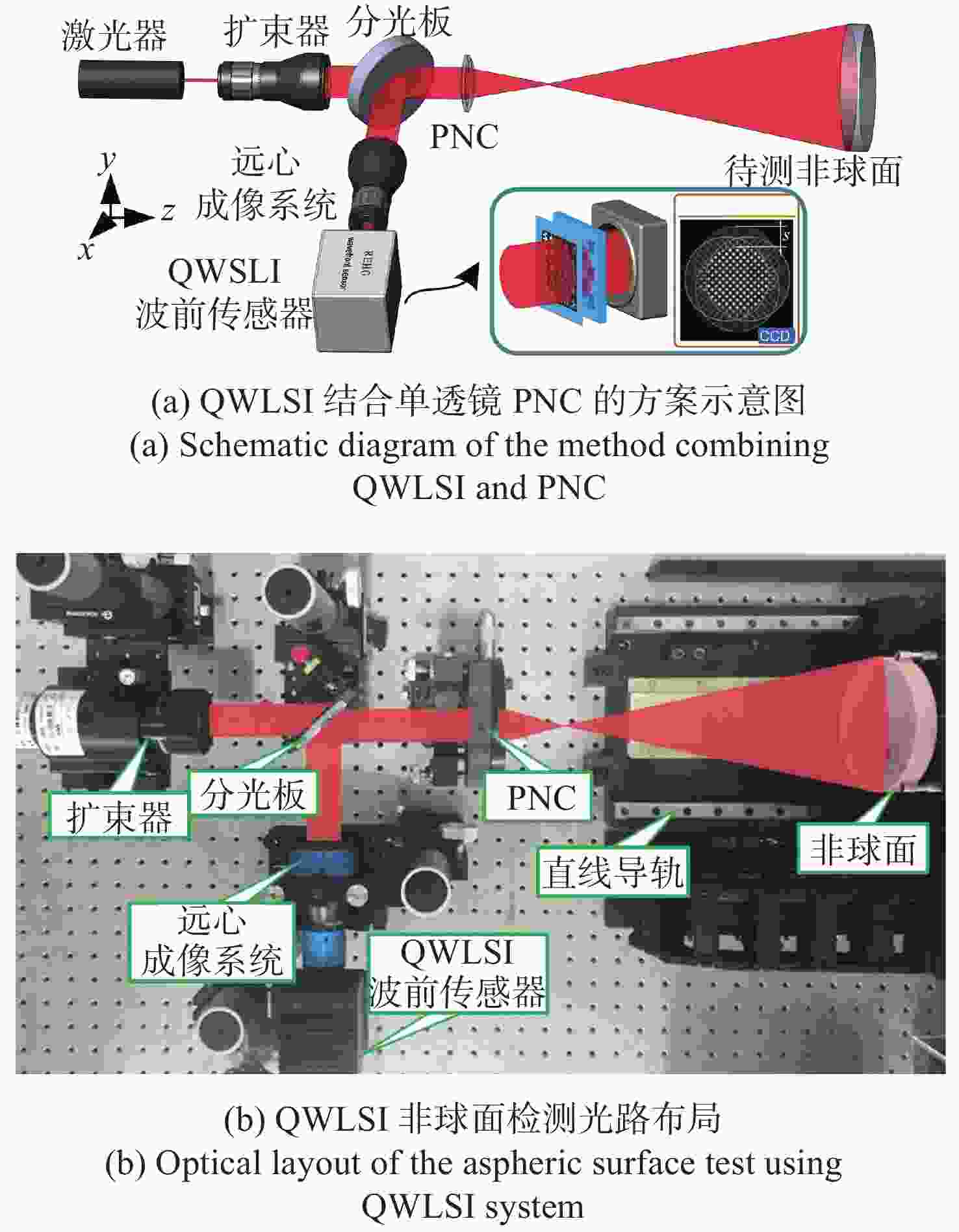

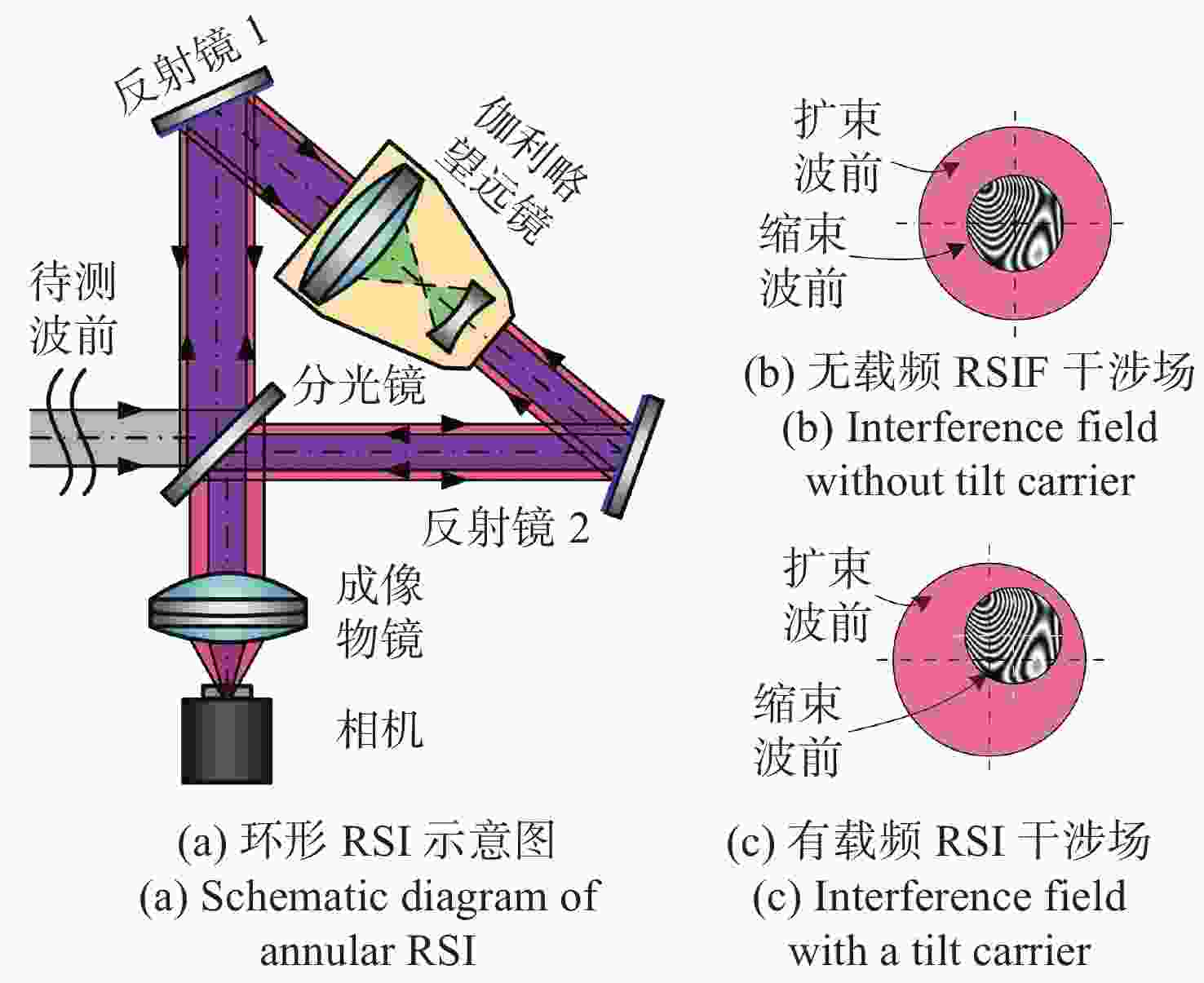

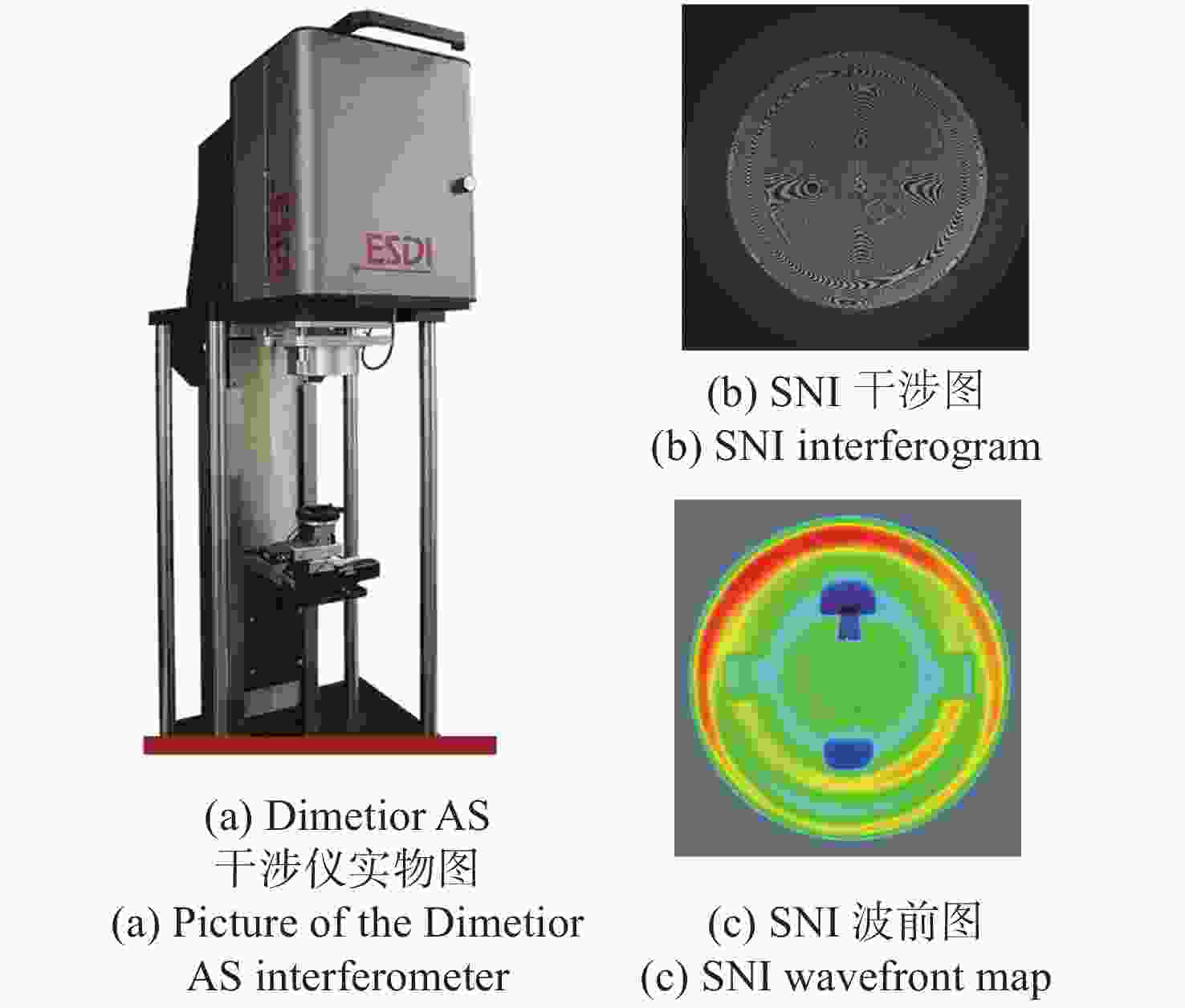

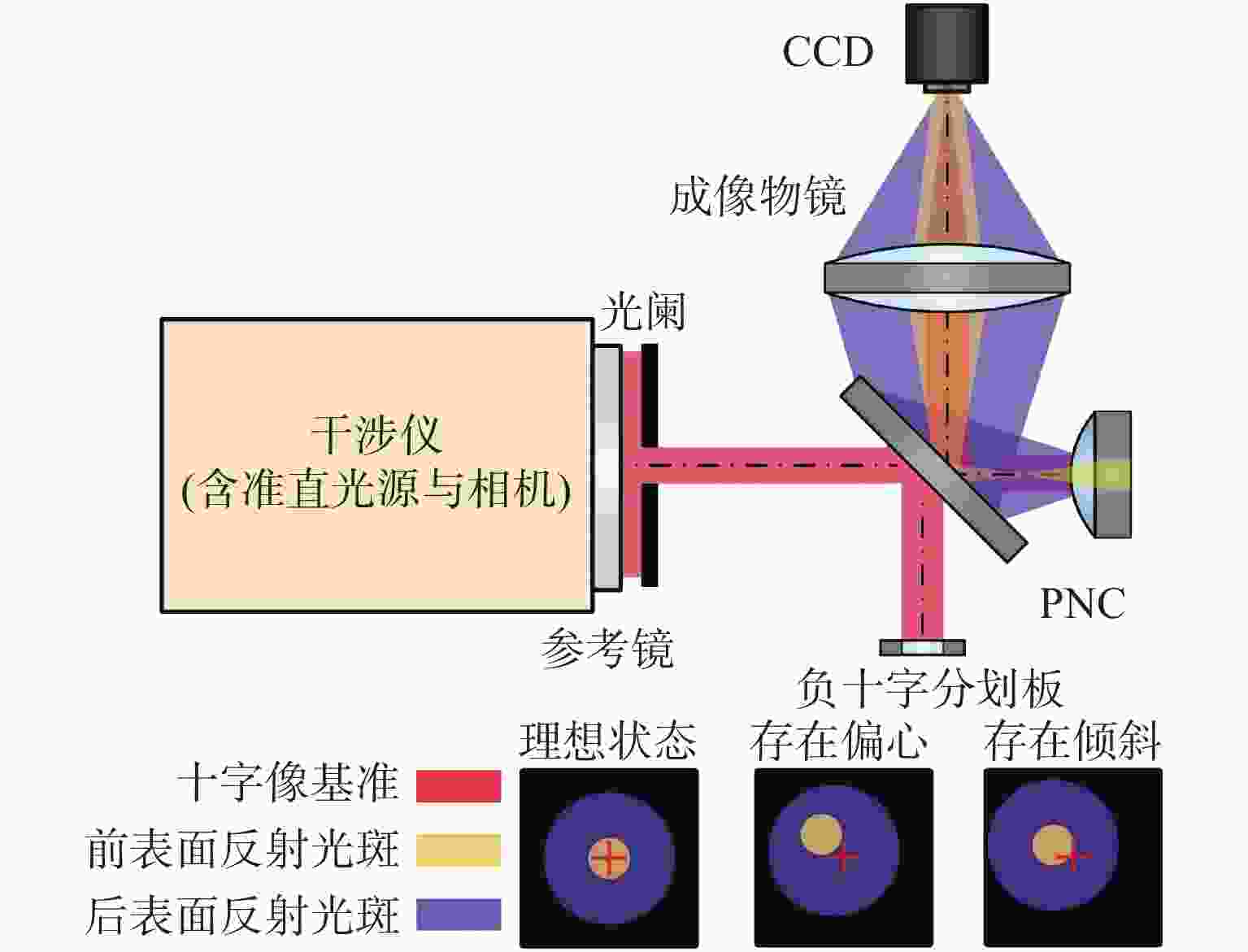

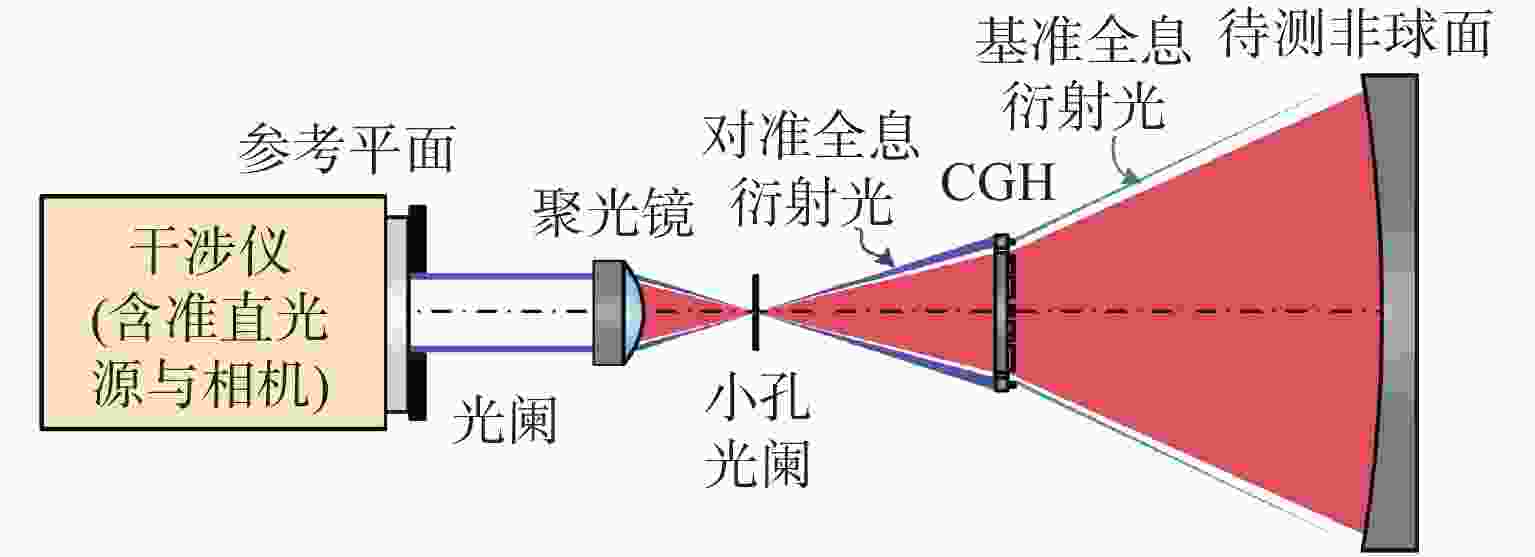

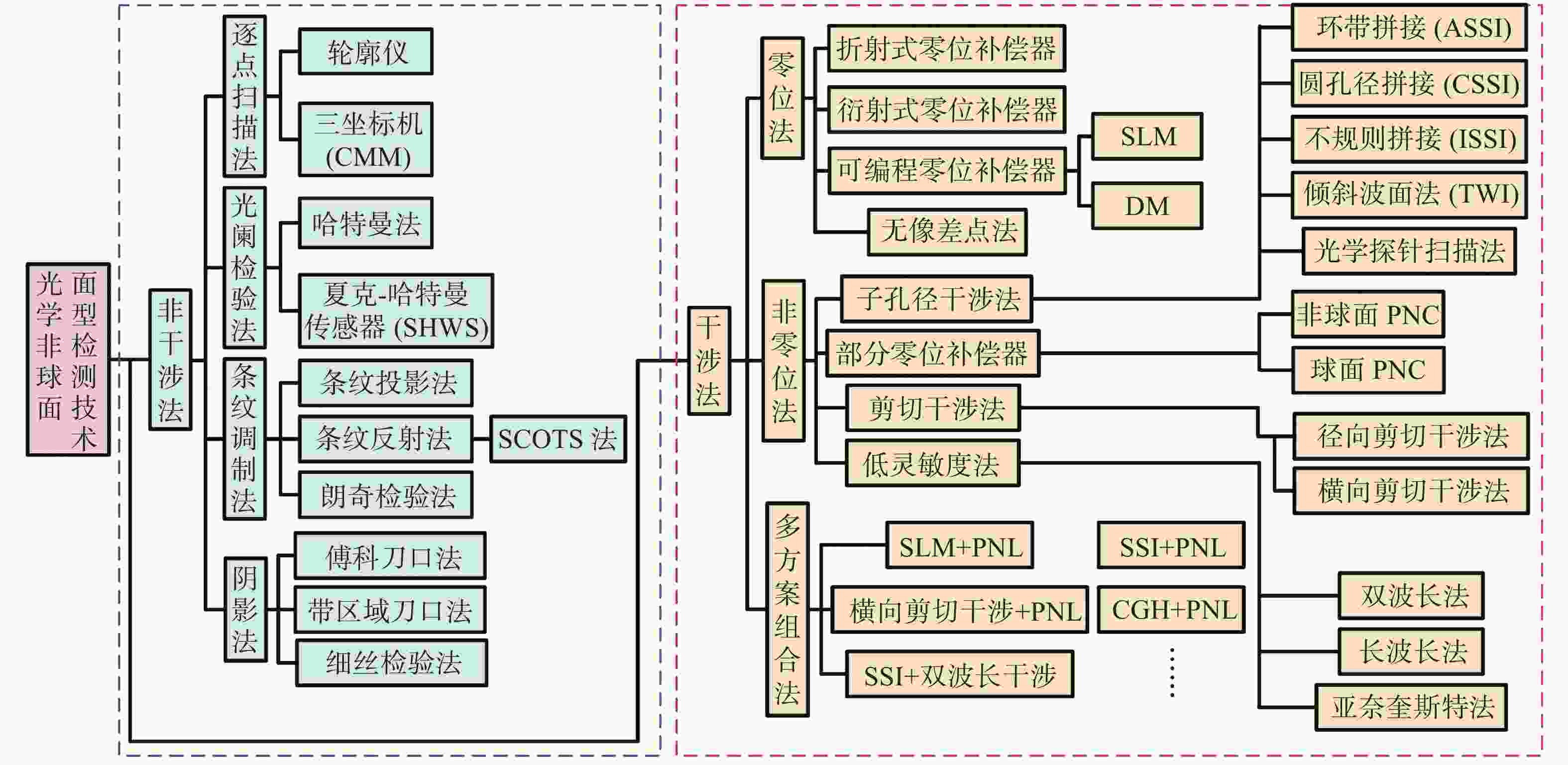

摘要: 非球面光学元件,特别是其中的自由曲面元件,在设计自由度上相比于球面具有很大的优势,基于非球面构建的光学系统能够以简单的光机结构实现复杂的设计目的。面型检测技术是保障光学非球面加工精度的关键,针对不同种类的非球面以及非球面加工的不同阶段对检测指标要求的多样性,现已发展出了种类繁多的检测方法。本文回顾了非球面光学元件面型检测技术的发展历程,分非干涉法与干涉法两大类整理了常用的检测技术,介绍了各自的技术指标与适用条件、研究进展与应用情况。本文重点讨论了基于干涉方法的非球面精密检测技术,举例说明了非零位与零位两条技术路线下各检测方法的基本原理、光路结构与检测能力,对比分析了各方法的优缺点与适用范围,介绍了一些配套算法以及检测光路的精密调节方法。Abstract: Optical Systems using aspheric components (especially for free-form ones) have remarkable advantages over traditional spherical systems in that they can satisfy complicated requirements with simple optical-mechanical structures relying on abundant optional design parameters. Surface testing is an essential process for ensuring accuracy in manufacturing. Therefore, plenty of testing methods have been developed to meet varying testing demands of different types of surfaces at different stages in manufacturing. This paper summarizes the history of aspheric surface testing technology, classifies available techniques by whether they use interferometry, then introduces corresponding technical indexes, applicable conditions, research progress and applications. This paper highlights the high-precision interferometric methods, basic principles, optical layout and testing performances of every measurement method classified into Null and Non-null testing. The pros and cons of each method are compared, relative algorithms are introduced and precise adjustment methods are discussed.

-

Key words:

- aspheric surface testing /

- free-form surface testing /

- interferometry /

- null testing /

- non-null testing

-

表 1 常用回程误差校正算法对比

Table 1. Comparison of common RE calibration algorithms

方法 理论 条件 精度 速度 GDI 小畸变近似理论 黑盒 较低 较快 TRW 参考波面替代理论 白盒 一般 较快 IRO 系统函数的不变性 白盒 高 较慢 表 2 非球面常用干涉检测方法总结

Table 2. Summary of widely used interferometric metrology methods of optics aspheric surfaces

方法类别 检测原理 通用性 检测精度 动态范围 检测效率 CGH零位补偿法 衍射补偿器 差 高 较小 高 PNC部分补偿法 部分补偿、回程误差校正 较好 较高,取决于回程误差校正 较大 高 子孔径拼接法(SSI) 子孔径检测、拼接算法 好 较高,取决于回程误差校正 大 低 自适应补偿法 自适应补偿器 好 较高 较大 高 TWI倾斜波前法 倾斜子光束检测不同区域 较好 较高,取决于回程误差校正 较小 较高 剪切干涉法 剪切率调节系统动态范围 较好 较高,取决于回程误差校正 可调 高 -

[1] 潘君骅. 光学非球面的设计、加工与检验[M]. 苏州: 苏州大学出版社, 2004.PAN J H. The Design, Manufacture and Test of the Aspherical Optical Surfaces[M]. Suzhou: Soochow University Press, 2004. (in Chinese) [2] 舒朝濂. 现代光学制造技术[M]. 北京: 国防工业出版社, 2008.SHU CH L. Modern optics manufacturing technology[M]. Beijing: National Defense Industry Press, 2008. (in Chinese) [3] BORN M, WOLF E. Principles of Optics[M]. Cambridge: Cambridge University Press, 2019. [4] JU G, MA H C, GU ZH Y, et al. Experimental study on the extension of nodal aberration theory to pupil-offset off-axis three-mirror anastigmatic telescopes[J]. Journal of Astronomical Telescopes,Instruments,and Systems, 2019, 5(2): 029001. [5] 李池娟, 孙昌锋, 席喆, 等. 非球面光学零件的应用[J]. 激光与红外,2013,43(3):244-247. doi: 10.3969/j.issn.1001-5078.2013.03.003LI CH J, SUN CH F, XI ZH, et al. Application of optical aspheric element[J]. Laser &Infrared, 2013, 43(3): 244-247. (in Chinese) doi: 10.3969/j.issn.1001-5078.2013.03.003 [6] LI SH P, ZHANG Y. Application of single point diamond turning in infrared optics[C]. Proceedings of the 2016 International Symposium on Advances in Electrical, Electronics and Computer Engineering, ISAEECE, 2016: 12-19. [7] LUO CH, SHI F, TIAN Y, et al. A combination process of magnetorheological finishing and computer controlled optical surfacing on single-crystal silicon surface[J]. Proceedings of SPIE, 2019, 10838: 108380A. [8] KARABYN V, POLÁK J, PROCHÁSKA F, et al. Ion beam figuring with using einzel lens[J]. Proceedings of SPIE, 2019, 11385: 1138508. [9] LIAO W L, DAI Y F, NIE X Q, et al. Rapid fabrication technique for nanometer-precision aspherical surfaces[J]. Applied Optics, 2015, 54(7): 1629-1638. doi: 10.1364/AO.54.001629 [10] BURGE J H. Certification of null correctors for primary mirrors[J]. Proceedings of SPIE, 1994, 1994: 248-259. doi: 10.1117/12.167975 [11] 朱日宏, 孙越, 沈华. 光学自由曲面面形检测方法进展与展望[J]. 光学学报,2021,41(1):0112001. doi: 10.3788/AOS202141.0112001ZHU R H, SUN Y, SHEN H. Progress and prospect of optical freeform surface measurement[J]. Acta Optica Sinica, 2021, 41(1): 0112001. (in Chinese) doi: 10.3788/AOS202141.0112001 [12] 师途, 杨甬英, 张磊, 等. 非球面光学元件的面形检测技术[J]. 中国光学,2014,7(1):26-46.SHI T, YANG Y Y, ZHANG L, et al. Surface testing methods of aspheric optical elements[J]. Chinese Optics, 2014, 7(1): 26-46. (in Chinese) [13] 侯溪, 张帅, 胡小川, 等. 超高精度面形干涉检测技术进展[J]. 光电工程,2020,47(8):200209.HOU X, ZHANG SH, HU X CH, et al. The research progress of surface interferometric measurement with higher accuracy[J]. Opto-Electronic Engineering, 2020, 47(8): 200209. (in Chinese) [14] 张磊, 刘东, 师途, 等. 光学自由曲面面形检测技术[J]. 中国光学,2017,10(3):283-299. doi: 10.3788/co.20171003.0283ZHANG L, LIU D, SHI T, et al. Optical free-form surfaces testing technologies[J]. Chinese Optics, 2017, 10(3): 283-299. (in Chinese) doi: 10.3788/co.20171003.0283 [15] ADACHI M, MIKI H, NAKAI Y, et al. Optical precision profilometer using the differential method[J]. Optics Letters, 1987, 12(10): 792-794. doi: 10.1364/OL.12.000792 [16] FANG X ZH, FENG X G, ZHANG J Y. Development of a virtual model of five-axis coordinate measuring machine[J]. Proceedings of SPIE, 2019, 11343: 1134307. [17] 李昂, 王永刚, 邬志强, 等. 光学加工过程中高次非球面的三坐标测量数据处理[J]. 中国光学,2020,13(2):302-312. doi: 10.3788/co.20201302.0302LI A, WANG Y G, WU ZH Q, et al. Data processing of high-order aspheric surface measurements using CMM in optical fabrication[J]. Chinese Optics, 2020, 13(2): 302-312. (in Chinese) doi: 10.3788/co.20201302.0302 [18] SHACK R V, PLATT B C. Production and use of a lenticular hartmann screen[J]. Journal of the Optical Society of America, 1971, 61(5): 656-661. [19] 张金平, 张学军, 张忠玉, 等. Shack-Hartmann波前传感器检测大口径圆对称非球面反射镜[J]. 光学 精密工程,2012,20(3):492-498. doi: 10.3788/OPE.20122003.0492ZHANG J P, ZHANG X J, ZHANG ZH Y, et al. Test of rotationally symmetric aspheric surface using Shack-Hartmann wavefront sensor[J]. Optics and Precision Engineering, 2012, 20(3): 492-498. (in Chinese) doi: 10.3788/OPE.20122003.0492 [20] FURUKAWA Y, TAKAIE Y, MAEDA Y, et al. Development of one-shot aspheric measurement system with a Shack Hartmann sensor[J]. Applied Optics, 2016, 55(29): 8138-8144. doi: 10.1364/AO.55.008138 [21] HÄUSLER G, FABER C, OLESCH E, et al. Deflectometry vs. interferometry[J]. Proceedings of SPIE, 2013, 8788: 87881C. [22] 刘东, 严天亮, 王道档, 等. 条纹投影与相位偏折测量技术研究进展[J]. 红外与激光工程,2017,46(9):0917001. doi: 10.3788/IRLA201746.0917001LIU D, YAN T L, WANG D D, et al. Review of fringe-projection profilometry and phase measuring deflectometry[J]. Infrared and Laser Engineering, 2017, 46(9): 0917001. (in Chinese) doi: 10.3788/IRLA201746.0917001 [23] DENG X T, GAO N, ZHANG Z H. A calibration method for system parameters in direct phase measuring deflectometry[J]. Applied Sciences, 2019, 9(7): 1444. doi: 10.3390/app9071444 [24] 郭春凤, 苏显渝, 陈文静, 等. 一种新的非球面零朗奇检测法[J]. 光学学报,2012,32(8):0812002. doi: 10.3788/AOS201232.0812002GUO CH F, SU X Y, CHEN W J, et al. A new null ronchi test for aspheric surfaces[J]. Acta Optica Sinica, 2012, 32(8): 0812002. (in Chinese) doi: 10.3788/AOS201232.0812002 [25] 雷柏平, 伍凡, 陈强. 大口径非球面Ronchi光栅测量方法[J]. 光电工程,2007,34(4):140-144.LEI B P, WU F, CHEN Q. Measurement of large-aperture aspheric surfaces with Ronchi grating test method[J]. Opto-Electronic Engineering, 2007, 34(4): 140-144. (in Chinese) [26] 王小鹏, 朱日宏, 王雷, 等. 数字刀口仪定量检验非球面光学元件面形[J]. 光学学报,2011,31(1):0112008. doi: 10.3788/AOS201131.0112008WANG X P, ZHU R H, WANG L, et al. Digitized foucault tester for quantitative evaluation the surface of aspheric optical elements[J]. Acta Optica Sinica, 2011, 31(1): 0112008. (in Chinese) doi: 10.3788/AOS201131.0112008 [27] 陈旭, 刘伟奇, 康玉思, 等. Offner补偿器的结构设计与装调[J]. 光学 精密工程,2010,18(1):88-93.CHEN X, LIU W Q, KANG Y S, et al. Design and tolerance analysis of Offner compensator[J]. Optics and Precision Engineering, 2010, 18(1): 88-93. (in Chinese) [28] OFFNER A. A null corrector for paraboloidal mirrors[J]. Applied Optics, 1963, 2(2): 153-155. doi: 10.1364/AO.2.000153 [29] BURGE J H, KOT L B, MARTIN H M, et al. Design and analysis for interferometric measurements of the GMT primary mirror segments[J]. Proceedings of SPIE, 2006, 6273: 62730M. doi: 10.1117/12.672484 [30] COYLE L E, DUBIN M B, BURGE J H. Design and analysis of an alignment procedure using computer-generated holograms[J]. Optical Engineering, 2013, 52(8): 084104. doi: 10.1117/1.OE.52.8.084104 [31] 席庆奎, 朱日宏, 陈磊, 等. 计算全息用于非球面检测的方法[J]. 激光杂志,2004,25(6):67-69. doi: 10.3969/j.issn.0253-2743.2004.06.027XI Q K, ZHU R H, CHEN L, et al. Methods on testing an aspheric with a computer generated hologram[J]. Laser Journal, 2004, 25(6): 67-69. (in Chinese) doi: 10.3969/j.issn.0253-2743.2004.06.027 [32] HE Y W, HUANG L, HOU X, et al. Modeling near-null testing method of a freeform surface with a deformable mirror compensator[J]. Applied Optics, 2017, 56(33): 9132-9138. doi: 10.1364/AO.56.009132 [33] ZHANG L, ZHOU SH, LI D, et al. Model-based adaptive non-null interferometry for freeform surface metrology[J]. Chinese Optics Letters, 2018, 16(8): 081203. doi: 10.3788/COL201816.081203 [34] ZHANG L, ZHOU SH, LI J S, et al. Model calibration by multi-null constraint for an optical freeform surface adaptive interferometer[J]. Applied Optics, 2020, 59(3): 726-734. doi: 10.1364/AO.380965 [35] ZHANG L, LI C, HUANG X L, et al. Compact adaptive interferometer for unknown freeform surfaces with large departure[J]. Optics Express, 2020, 28(2): 1897-1913. doi: 10.1364/OE.380889 [36] XUE SH, CHEN SH Y, FAN ZH B, et al. Adaptive wavefront interferometry for unknown free-form surfaces[J]. Optics Express, 2018, 26(17): 21910-21928. doi: 10.1364/OE.26.021910 [37] ZHANG L, LI D, LIU Y, et al. Flexible interferometry for optical aspheric and free form surfaces[J]. Optical Review, 2017, 24(6): 677-685. doi: 10.1007/s10043-017-0363-6 [38] HUANG L, CHOI H, ZHAO W CH, et al. Adaptive interferometric null testing for unknown freeform optics metrology[J]. Optics Letters, 2016, 41(23): 5539-5542. doi: 10.1364/OL.41.005539 [39] GRAVES L R, CHOI H, ZHAO W CH, et al. Model-free deflectometry for freeform optics measurement using an iterative reconstruction technique[J]. Optics Letters, 2018, 43(9): 2110-2113. doi: 10.1364/OL.43.002110 [40] CHAUDHURI R, PAPA J, ROLLAND J P. System design of a single-shot reconfigurable null test using a spatial light modulator for freeform metrology[J]. Optics Letters, 2019, 44(8): 2000-2003. doi: 10.1364/OL.44.002000 [41] 陈善勇, 卢劲丰, 薛帅. 波面干涉测量中的可变像差补偿技术[J]. 激光与光电子学进展,2017,54(4):51-62.CHEN SH Y, LU J F, XUE SH. Variable aberration compensation techniques in wavefront interferometry[J]. Laser &Optoelectronics Progress, 2017, 54(4): 51-62. (in Chinese) [42] 马啸, 刘世杰, 张志刚, 等. 空间光调制器像素尺寸对非球面检测误差影响分析[J]. 中国激光,2017,44(1):0104002. doi: 10.3788/CJL201744.0104002MA X, LIU SH J, ZHANG ZH G, et al. Impact of spatial light modulator pixel pitch on the accuracy of aspheric testing[J]. Chinese Journal of Lasers, 2017, 44(1): 0104002. (in Chinese) doi: 10.3788/CJL201744.0104002 [43] HAO Q, NING Y, HU Y, et al. Simultaneous phase-shifting interferometer with a monitored spatial light modulator flexible reference mirror[J]. Applied Optics, 2021, 60(6): 1550-1557. doi: 10.1364/AO.414810 [44] HAO Q, NING Y, HU Y. Applications of wavefront modulation devices in aspheric and freeform measurement[J]. Proceedings of SPIE, 2018, 11053: 110530N. [45] 师途. 基于部分零位补偿透镜的非球面通用化检测技术研究[D]. 杭州: 浙江大学, 2017.SHI T. General interferometric aspheric testing with partial null lens[D]. Hangzhou: Zhejiang University, 2017. (in Chinese) [46] ZHANG L, TIAN CH, LIU D, et al. Non-null annular subaperture stitching interferometry for steep aspheric measurement[J]. Applied Optics, 2014, 53(25): 5755-5762. doi: 10.1364/AO.53.005755 [47] WEN Y F, CHENG H B, TAM H Y, et al. Modified stitching algorithm for annular subaperture stitching interferometry for aspheric surfaces[J]. Applied Optics, 2013, 52(23): 5686-5694. doi: 10.1364/AO.52.005686 [48] 张磊, 田超, 刘东, 等. 非球面非零位环形子孔径拼接干涉检测技术[J]. 光学学报,2014,34(8):0812003. doi: 10.3788/AOS201434.0812003ZHANG L, TIAN CH, LIU D, et al. Non-null annular subaperture stitching interferometry for aspheric test[J]. Acta Optica Sinica, 2014, 34(8): 0812003. (in Chinese) doi: 10.3788/AOS201434.0812003 [49] YAN L S, WANG X K, ZHENG L G, et al. Experimental study on subaperture testing with iterative triangulation algorithm[J]. Optics Express, 2013, 21(19): 22628-22644. doi: 10.1364/OE.21.022628 [50] 闫公敬, 张宪忠. 非零位凸非球面子孔径拼接检测技术研究[J]. 中国光学,2018,11(5):798-803. doi: 10.3788/co.20181105.0798YAN G J, ZHANG X ZH. Research on non-null convex aspherical sub-aperture stitching detection technology[J]. Chinese Optics, 2018, 11(5): 798-803. (in Chinese) doi: 10.3788/co.20181105.0798 [51] CHEN SH Y, DAI Y F, LI SH Y, et al. Calculation of subaperture aspheric departure in lattice design for subaperture stitching interferometry[J]. Optical Engineering, 2010, 49(2): 023601. doi: 10.1117/1.3314297 [52] ZHANG L, LIU D, SHI T, et al. Aspheric subaperture stitching based on system modeling[J]. Optics Express, 2015, 23(15): 19176-19188. doi: 10.1364/OE.23.019176 [53] GARBUSI E, PRUSS C, LIESENER J, et al. New technique for flexible and rapid measurement of precision aspheres[J]. Proceedings of SPIE, 2007, 6616: 61629. [54] BAER G, SCHINDLER J, PRUSS C, et al. Fast and flexible non-null testing of aspheres and free-form surfaces with the tilted-wave-interferometer[J]. International Journal of Optomechatronics, 2014, 8(4): 242-250. doi: 10.1080/15599612.2014.942925 [55] 刘璐. 径向剪切干涉误差综合分析[D]. 西安: 西安工业大学, 2019.LIU L. Comprehensive analysis of radial shear interference errors[D]. Xi'an: Xi'an Technological University, 2019. (in Chinese) [56] WANG M, ZHANG B, NIE S P, et al. Radial shearing interferometer for aspheric surface testing[J]. Proceedings of SPIE, 2002, 4927: 673-676. doi: 10.1117/12.471690 [57] ZHANG R, YANG Y Y, ZHAO H Y, et al. Non-Null testing of the aspheric surface using a quadriwave lateral shearing interferometer[J]. Applied Optics, 2020, 59(18): 5447-5456. doi: 10.1364/AO.391263 [58] 杨甬英, 凌曈. 新型共路干涉仪[M]. 杭州: 浙江大学出版社, 2020.YANG Y Y, LING T. Novel Common-Path Interferometers[M]. Hangzhou: Zhejiang Universisty Press, 2020. (in Chinese) [59] 贺俊, 陈磊. 使用红外干涉仪测量非球面面形[J]. 光学 精密工程,2010,18(1):69-74.HE J, CHEN L. Measurement of aspheric surfaces by infrared interferometer[J]. Optics and Precision Engineering, 2010, 18(1): 69-74. (in Chinese) [60] 杨甬英. 先进干涉检测技术与应用[M]. 杭州: 浙江大学出版社, 2017.YANG Y Y. Advanced Interferometry and Application[M]. Hangzhou: Zhejiang University Press, 2017. (in Chinese) [61] TAO W, VALERA J D, MOORE A J. High-speed, sub-Nyquist interferometry[J]. Optics Express, 2011, 19(11): 10111-10123. doi: 10.1364/OE.19.010111 [62] 刘东, 杨甬英, 田超, 等. 非球面非零位检测中的回程误差分析与校正[J]. 光学学报,2009,29(3):688-696. doi: 10.3788/AOS20092903.0688LIU D, YANG Y Y, TIAN CH, et al. Analysis and correction of retrace error for nonnull aspheric testing[J]. Acta Optica Sinica, 2009, 29(3): 688-696. (in Chinese) doi: 10.3788/AOS20092903.0688 [63] Taylor-Hobson, Inc. Taylsurf profiler[EB/OL]. [2021-08-31]. https://www.taylor-hobson.com/products/surface-profilers/optics-pgi/pgi-freeform. [64] ZEISS, Inc. XENOS[EB/OL]. [2021-08-31]. https://www.zeiss.com/metrology/products/systems/coordinate-measuring-machines/bridge-type-cmms/xenos.html. [65] MALACARA D. Optical Shop Testing[M]. 3rd ed. Hoboken: Wiley, 2007. [66] NEAL D R, ARMSTRONG D J, TURNER W T. Wavefront sensors for control and processing monitoring in optics manufacture[J]. Proceedings of SPIE, 1997, 2933: 211-220. [67] 饶学军, 凌宁, 王成, 等. 哈特曼-夏克传感器在非球面加工中的应用[J]. 光学学报,2002,22(4):491-494. doi: 10.3321/j.issn:0253-2239.2002.04.024RAO X J, LING N, WANG CH, et al. Application of hartmann-shack sensor in aspheric process[J]. Acta Optica Sinica, 2002, 22(4): 491-494. (in Chinese) doi: 10.3321/j.issn:0253-2239.2002.04.024 [68] GUO W J, ZHAO L P, TONG C S, et al. Adaptive centroid-finding algorithm for freeform surface measurements[J]. Applied Optics, 2013, 52(10): D75-D83. doi: 10.1364/AO.52.000D75 [69] KNAUER M C, KAMINSKI J, HAUSLER G. Phase measuring deflectometry: a new approach to measure specular free-form surfaces[J]. Proceedings of SPIE, 2004, 5457: 366-376. doi: 10.1117/12.545704 [70] TANG Y, SU X Y, LIU Y K, et al. 3D shape measurement of the aspheric mirror by advanced phase measuring deflectometry[J]. Optics Express, 2008, 16(19): 15090-15096. doi: 10.1364/OE.16.015090 [71] SU P, KHREISHI M, SU T Q, et al. Aspheric and freeform surfaces metrology with software configurable optical test system: a computerized reverse Hartmann test[J]. Optical Engineering, 2014, 53(3): 031305. [72] SU P, PARKS R E, WANG L R, et al. Software configurable optical test system: a computerized reverse Hartmann test[J]. Applied Optics, 2010, 49(23): 4404-4412. doi: 10.1364/AO.49.004404 [73] 袁婷. 基于条纹反射法的大口径非球面反射镜面形检测技术研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2016.YUAN T. Study on fringe-reflection optical surface shape measurement technology for large aspheric mirror[D]. Changchun: Changchun Institute of Optics, Fine Mehcanics and Physics, Chinese Academy of Sciences, 2016. (in Chinese) [74] CORNEJO-RODRIGUEZ A, CORDERO-DAVILA A, CARDONA-NUNEZ O. Ronchi and Hartman tests: a null Hartman test[J]. Proceedings of SPIE, 1990, 1319: 650. doi: 10.1117/12.34908 [75] BROWN B R, LOHMANN A W. Complex spatial filtering with binary masks[J]. Applied Optics, 1966, 5(6): 967-969. doi: 10.1364/AO.5.000967 [76] MACGOVERN A J, WYANT J C. Computer generated holograms for testing optical elements[J]. Applied Optics, 1971, 10(3): 619-624. doi: 10.1364/AO.10.000619 [77] ONO A, WYANT J C. Aspherical mirror testing using a CGH with small errors[J]. Applied Optics, 1985, 24(4): 560-563. doi: 10.1364/AO.24.000560 [78] ONO A, WYANT J C. Plotting errors measurement of CGH using an improved interferometric method[J]. Applied Optics, 1984, 23(21): 3905-3910. doi: 10.1364/AO.23.003905 [79] WYANT J C, O'NEILL P K. Computer generated hologram; null lens test of aspheric wavefronts[J]. Applied Optics, 1974, 13(12): 2762-2765. doi: 10.1364/AO.13.002762 [80] TAMURA H, ISHII Y. Computer-generated hologram fabricated by electron-beam lithography for noise reduction[J]. Optical Review, 2012, 19(2): 50-57. doi: 10.1007/s10043-012-0012-z [81] BURGE J H, ANDERSON D S. Full-aperture interferometric test of convex secondary mirrors using holographic test plates[J]. Proceedings of SPIE, 1994, 2199: 181-192. doi: 10.1117/12.176188 [82] ZHOU P, SHU Y, ZHAO CH Y, et al. Diffraction effects for interferometric measurements due to imaging aberrations[J]. Optics Express, 2012, 20(4): 4403-4418. doi: 10.1364/OE.20.004403 [83] CAI W R, ZHOU P, ZHAO CH Y, et al. Diffractive optics calibrator: measurement of etching variations for binary computer-generated holograms[J]. Applied Optics, 2014, 53(11): 2477-2486. doi: 10.1364/AO.53.002477 [84] CAI W R, ZHOU P, ZHAO CH Y, et al. Analysis of wavefront errors introduced by encoding computer-generated holograms[J]. Applied Optics, 2013, 52(34): 8324-8331. doi: 10.1364/AO.52.008324 [85] ZEHNDER R, BURGE J H, ZHAO CH Y. Use of computer generated holograms for alignment of complex null correctors[J]. Proceedings of SPIE, 2006, 6273: 62732S. doi: 10.1117/12.672139 [86] DUBIN M B, SU P, BURGE J H. Fizeau interferometer with spherical reference and CGH correction for measuring large convex aspheres[J]. Proceedings of SPIE, 2009, 7426: 74260S. doi: 10.1117/12.829053 [87] REICHELT S, PRUSS C, TIZIANI H J. Absolute interferometric test of aspheres by use of twin computer-generated holograms[J]. Applied Optics, 2003, 42(22): 4468-4479. doi: 10.1364/AO.42.004468 [88] BEYERLEIN M, LINDLEIN N, SCHWIDER J. Dual-wave-front computer-generated holograms for quasi-absolute testing of aspherics[J]. Applied Optics, 2002, 41(13): 2440-2447. doi: 10.1364/AO.41.002440 [89] 王成军. 双重计算全息图用于非球面绝对检验的研究[D]. 南京: 南京理工大学, 2008.WANG CH J. Research on dual CGH using for absolute test of aspherics[D]. Nanjing: Nanjing University of Science and Technology, 2008. (in Chinese) [90] 冯婕. 基于CGH高精度非球面检测技术研究[D]. 成都: 中国科学院研究生院(光电技术研究所), 2014.FENG J. Highly accuracy aspheric surface testing based on computer-generated hologram[D]. Chengdu: Institute of Optics and Electronics, Chinese Academy of Sciences, 2014. (in Chinese) [91] POLESHCHUK A G, NASYROV R K, ASFOUR J M. Combined computer-generated hologram for testing steep aspheric surfaces[J]. Optics Express, 2009, 17(7): 5420-5425. doi: 10.1364/OE.17.005420 [92] 李明. 基于CGH的非球面混合补偿检测及离轴光学系统装调的关键技术研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2015.LI M. Research on key technology of hybrid null testing of aspheric mirrorand off-axis optical system alignment based on CGH[D]. Changchun: Changchun Institute of Optics, Fine Mehcanics and Physics, Chinese Academy of Sciences, 2015. (in Chinese) [93] 高松涛. 超高精度非球面面形检测技术研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2014.GAO S T. Research on ultra-precise aspheric surface testing[D]. Changchun: Changchun Institute of Optics, Fine Mehcanics and Physics, Chinese Academy of Sciences, 2014. (in Chinese) [94] CAO ZH L, XUAN L, HU L F, et al. Investigation of optical testing with a phase-only liquid crystal spatial light modulator[J]. Optics Express, 2005, 13(4): 1059-1065. doi: 10.1364/OPEX.13.001059 [95] PRUSS C, TIZIANI H J. Dynamic null lens for aspheric testing using a membrane mirror[J]. Optics Communications, 2004, 233(1-3): 15-19. doi: 10.1016/j.optcom.2004.01.030 [96] FUERSCHBACH K, THOMPSON K P, ROLLAND J P. Interferometric measurement of a concave, φ-polynomial, Zernike mirror[J]. Optics Letters, 2014, 39(1): 18-21. doi: 10.1364/OL.39.000018 [97] HÄLLSTIG E, STIGWALL J, MARTIN T, et al. Fringing fields in a liquid crystal spatial light modulator for beam steering[J]. Journal of Modern Optics, 2004, 51(8): 1233-1247. doi: 10.1080/09500340408230419 [98] 师途, 臧仲明, 刘东, 等. 光学非球面面形非零位检测的回程误差校正[J]. 光学学报,2016,36(8):0812006. doi: 10.3788/AOS201636.0812006SHI T, ZANG ZH M, LIU D, et al. Retrace error correction for non-null testing of optical aspheric surface[J]. Acta Optica Sinica, 2016, 36(8): 0812006. (in Chinese) doi: 10.3788/AOS201636.0812006 [99] BEAR G, SCHINDLER J, PRUSS C, et al. Calibration of a non-null test interferometer for the measurement of aspheres and free-form surfaces[J]. Optics Express, 2014, 22(25): 31200-31211. doi: 10.1364/OE.22.031200 [100] SHI T, LIU D, ZHOU Y, H et al. Practical retrace error correction in non-null aspheric testing: a comparison[J]. Optics Communications, 2017, 383: 378-385. doi: 10.1016/j.optcom.2016.09.034 [101] 任王涛. 基于逆向迭代法对离轴非球面的面形检测[D]. 成都: 电子科技大学, 2020.REN W T. Surface shape detection of off-axis aspheric surface based on reverse iteration method[D]. Chengdu: University of Electronic Science and Technology of China, 2020. (in Chinese) [102] LIU H L, ZHU Q D, HAO Q, et al. Design of novel part-compensating lens used in aspheric testing[J]. Proceedings of SPIE, 2003, 5253: 480-484. doi: 10.1117/12.521761 [103] SULLIVAN J J, GREIVENKAMP J E. Design of partial nulls for testing of fast aspheric surfaces[J]. Proceedings of SPIE, 2007, 6671: 66710W. doi: 10.1117/12.734874 [104] 刘东, 杨甬英, 田超, 等. 用于非球面通用化检测的部分零位透镜[J]. 红外与激光工程,2009,38(2):322-325. doi: 10.3969/j.issn.1007-2276.2009.02.029LIU D, YANG Y Y, TIAN CH, et al. Partial null lens for general aspheric testing[J]. Infrared and Laser Engineering, 2009, 38(2): 322-325. (in Chinese) doi: 10.3969/j.issn.1007-2276.2009.02.029 [105] ZANG ZH M, XU ZH R, PENG SH J, et al. Non-null interferometers for irregular surface measurement with system modeling[J]. Measurement Science and Technology, 2021, 32(4): 045205. doi: 10.1088/1361-6501/abd11f [106] XUE SH, CHEN SH Y, TIE G P. Near-null interferometry using an aspheric null lens generating a broad range of variable spherical aberration for flexible test of aspheres[J]. Optics Express, 2018, 26(24): 31172-31189. doi: 10.1364/OE.26.031172 [107] DOU Y M, YUAN Q, GAO ZH SH, et al. Partial null astigmatism-compensated interferometry for a concave freeform Zernike mirror[J]. Journal of Optics, 2018, 20(6): 065702. doi: 10.1088/2040-8986/aac1db [108] LIU Y M, LAWRENCE G N, KOLIOPOULOS C L. Subaperture testing of aspheres with annular zones[J]. Applied Optics, 1988, 27(21): 4504-4513. doi: 10.1364/AO.27.004504 [109] HOU X, WU F, YANG L, et al. Experimental study on measurement of aspheric surface shape with complementary annular subaperture interferometric method[J]. Optics Express, 2007, 15(20): 12890-12899. doi: 10.1364/OE.15.012890 [110] 闫力松. 子孔径拼接干涉检测光学镜面算法的研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2015.YAN L S. Research on the algorithm testing optical mirror by subaperture stitching interferometry[D]. Changchun: Changchun Institute of Optics, Fine Mehcanics and Physics, Chinese Academy of Sciences, 2015. (in Chinese) [111] ZYGO, Inc. Verifire[EB/OL]. [2021-08-31]. https://www.zygo.com.cn/products/metrology-systems/laser-interferometers/verifire. [112] KIN C J, WYANT J C. Subaperture test of a large flat or a fast aspheric surface[J]. Journal of the Optical Society of America, 1981, 71(12): 1587. [113] CHEN SH Y, WU CH CH, TIE G P, et al. Stitching test of large flats by using two orthogonally arranged wavefront interferometers[J]. Applied Optics, 2017, 56(33): 9193-9198. doi: 10.1364/AO.56.009193 [114] GARBUSI E, PRUSS C, OSTEN W. Interferometer for precise and flexible asphere testing[J]. Optics Letters, 2008, 33(24): 2973-2975. doi: 10.1364/OL.33.002973 [115] SCHINDLER J, PRUSS C, OSTEN W. Simultaneous removal of nonrotationally symmetric errors in tilted wave interferometry[J]. Optical Engineering, 2019, 58(7): 074105. [116] MIKŠ A, NOVAK J. Noncontact interferometric optical probe for calibration of coordinate measuring machines[J]. Applied Optics, 2011, 50(5): 671-678. doi: 10.1364/AO.50.000671 [117] SU P, WANG Y H, OH C J, et al. Swing arm optical CMM: self calibration with dual probe shear test[J]. Proceedings of SPIE, 2011, 8126: 81260W. doi: 10.1117/12.894203 [118] WANG Y H, SU P, PARKS R E, et al. Swing arm optical coordinate-measuring machine: high precision measuring ground aspheric surfaces using a laser triangulation probe[J]. Optical Engineering, 2012, 51(7): 073603. doi: 10.1117/1.OE.51.7.073603 [119] SU P, OH C J, ZHAO CH Y, et al. Optical testing for meter size aspheric optics[J]. Proceedings of SPIE, 2012, 8466: 84660S. doi: 10.1117/12.930513 [120] SU P, PARKS R E, WANG Y H, et al. Swing-arm optical coordinate measuring machine: modal estimation of systematic errors from dual probe shear measurements[J]. Optical Engineering, 2012, 51(4): 043604. doi: 10.1117/1.OE.51.4.043604 [121] 凌曈. 基于多波前剪切干涉与光学层析技术三维折射率场重构研究[D]. 杭州: 浙江大学, 2016.LING T. Reconstruction of three-dimensional refractive index field based on multi-wave shearing interferometry and optical tomography[D] Hangzhou: Zhejiang University, 2016. (in Chinese) [122] 张锐. 基于随机编码混合光栅横向剪切干涉的波前检测技术关键参数与应用研究[D]. 杭州: 浙江大学, 2020.ZHANG R. Research on key parameters and application of wavefront metrology based on the randomly encoded hybrid grating lateral shearing interferometry[D]. Hangzhou: Zhejiang University, 2020. (in Chinese) [123] 邵锋. 角膜地形图测量装置的技术研究[D]. 南京: 南京理工大学, 2008.SHAO F. Research on testing equipment of corneal topography[D]. Nanjing: Nanjing University of Science and Technology, 2008. (in Chinese) [124] GREIVENKAMP J E. Sub-Nyquist interferometry[J]. Applied Optics, 1987, 26(24): 5245-5258. doi: 10.1364/AO.26.005245 -

下载:

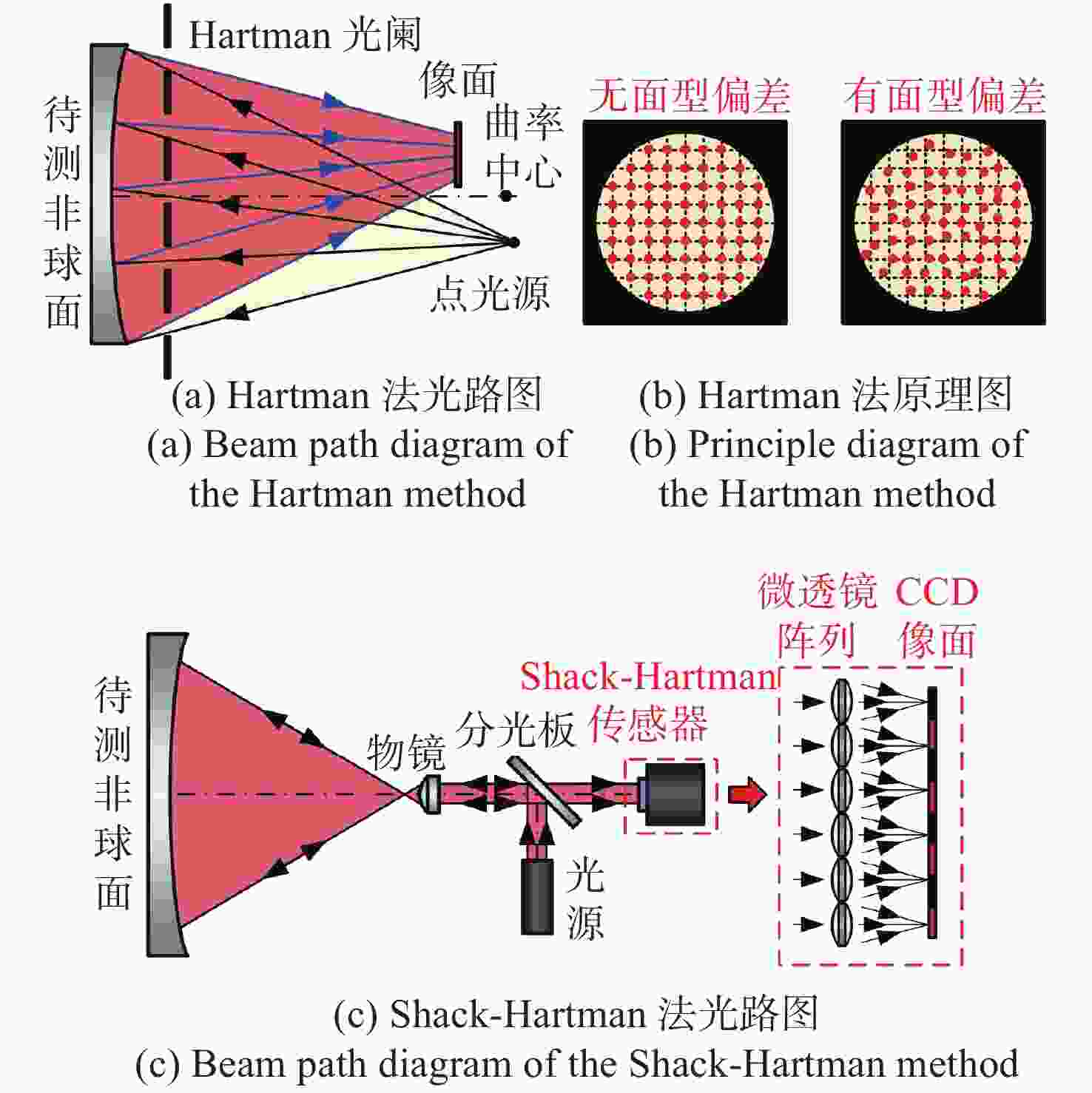

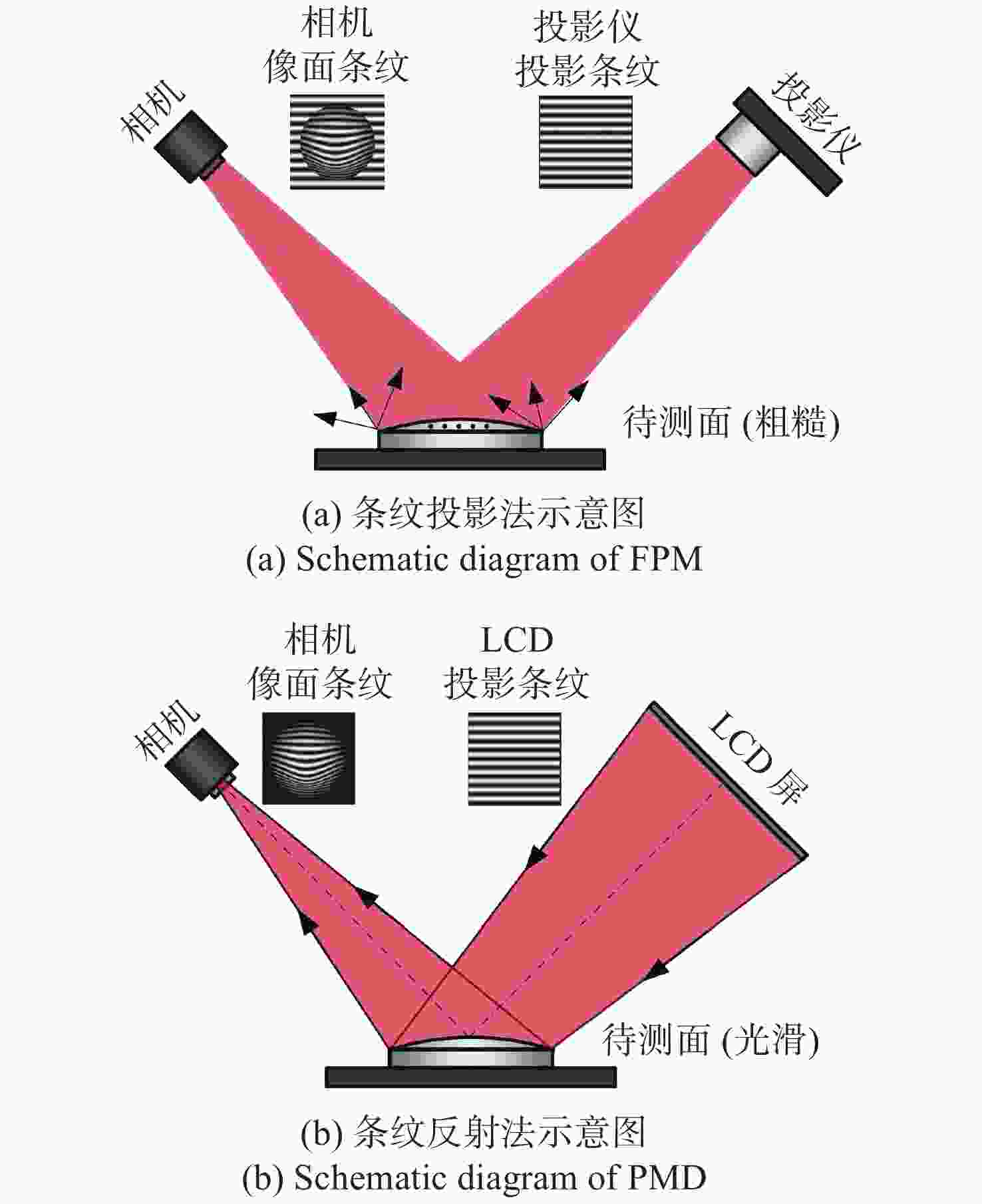

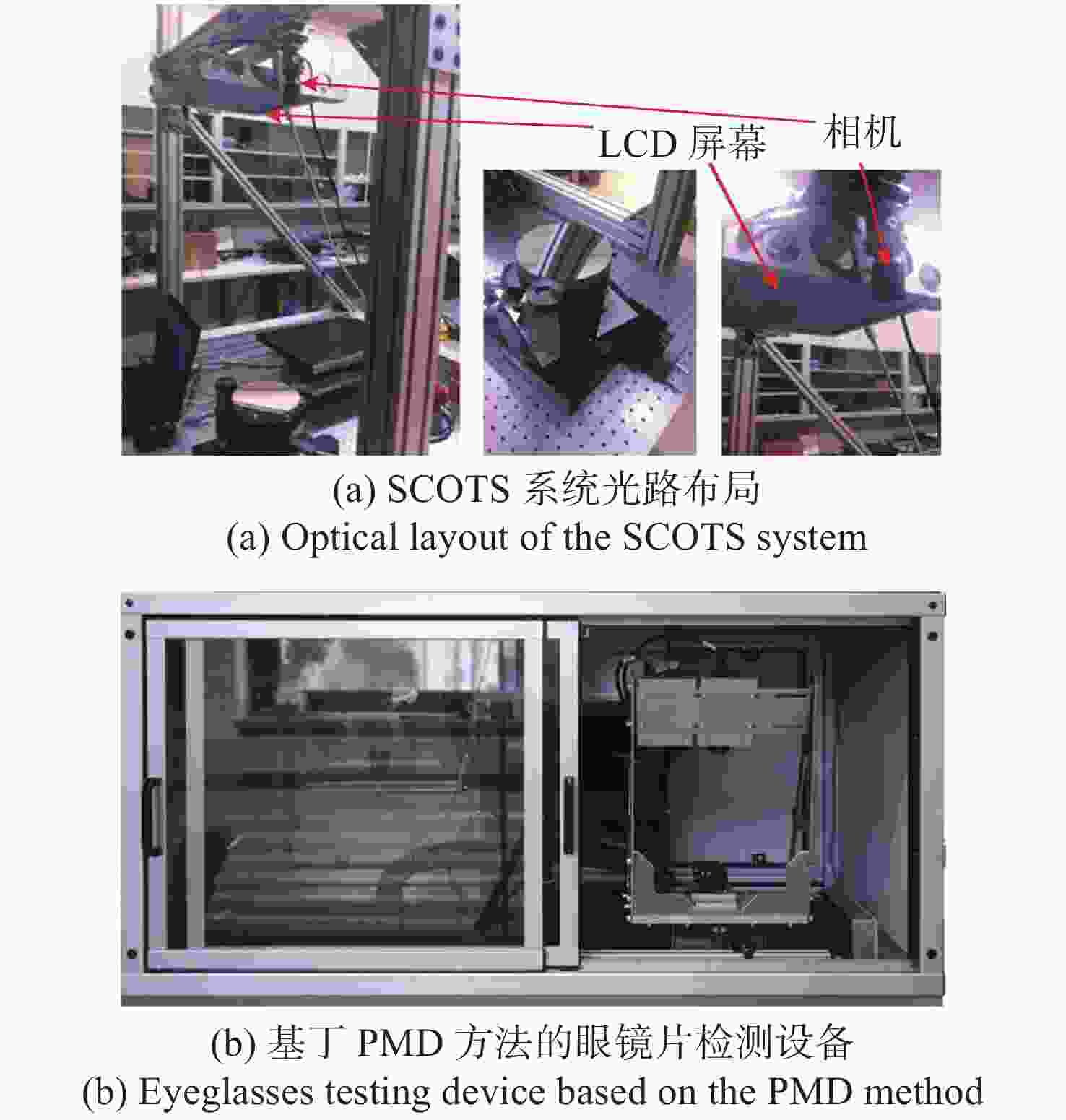

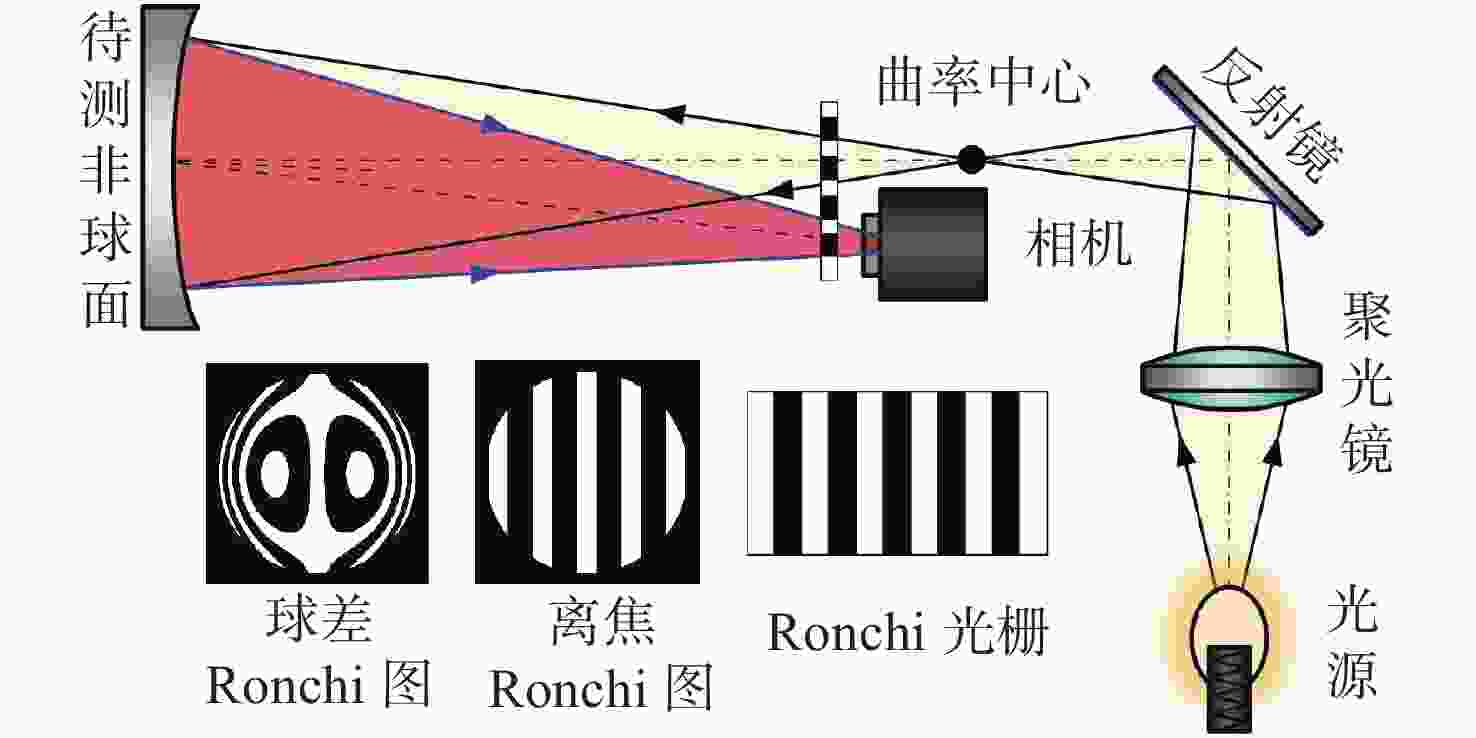

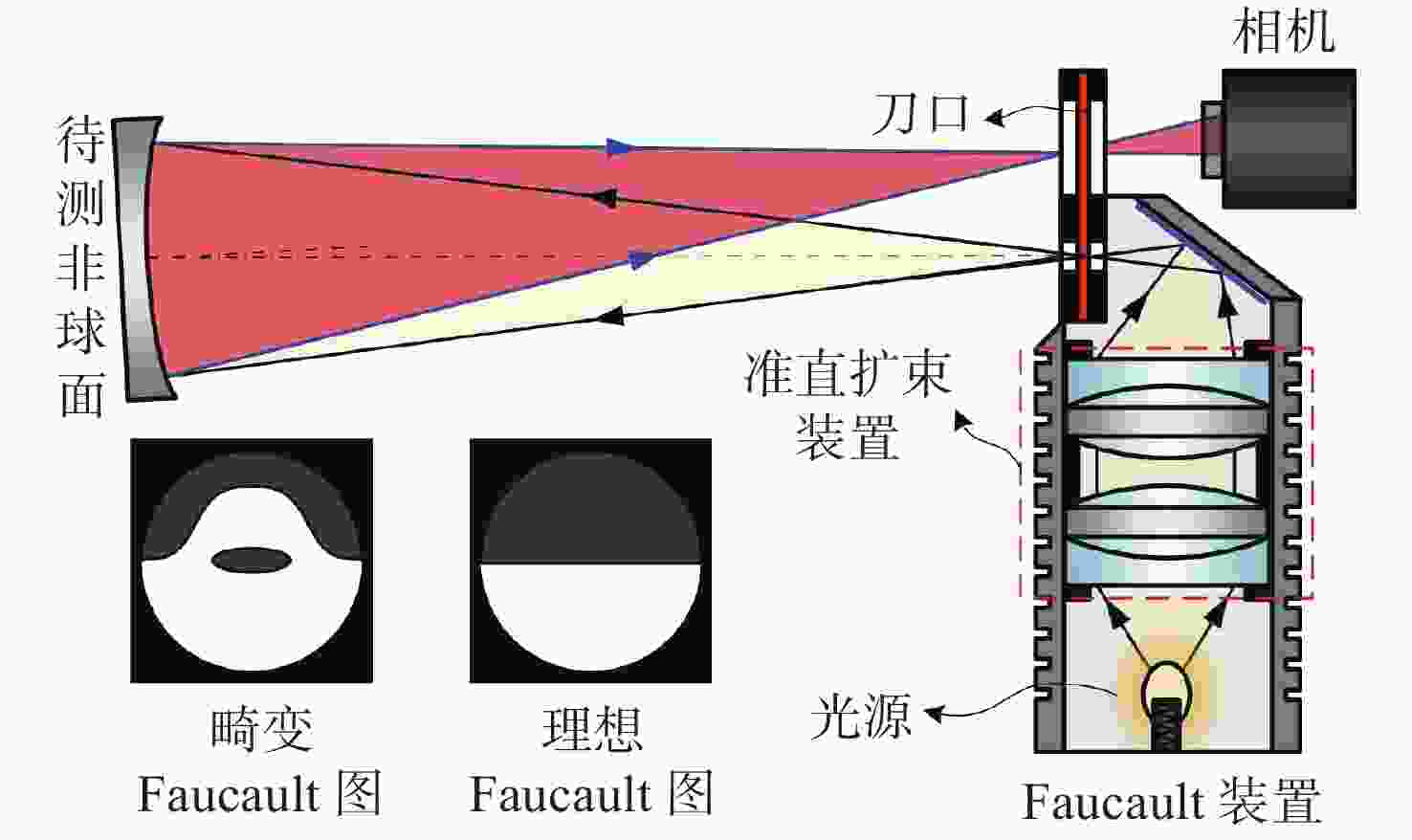

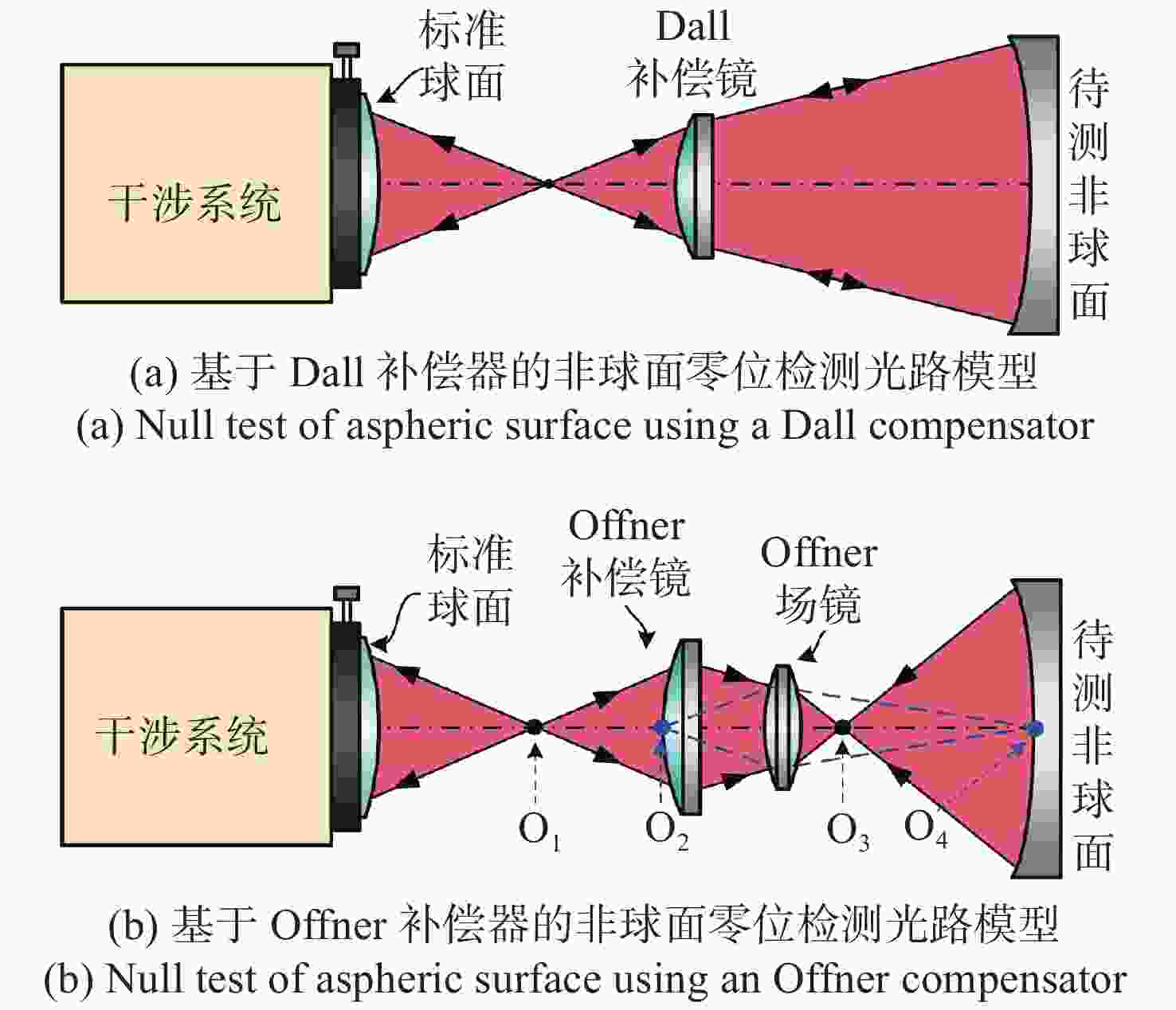

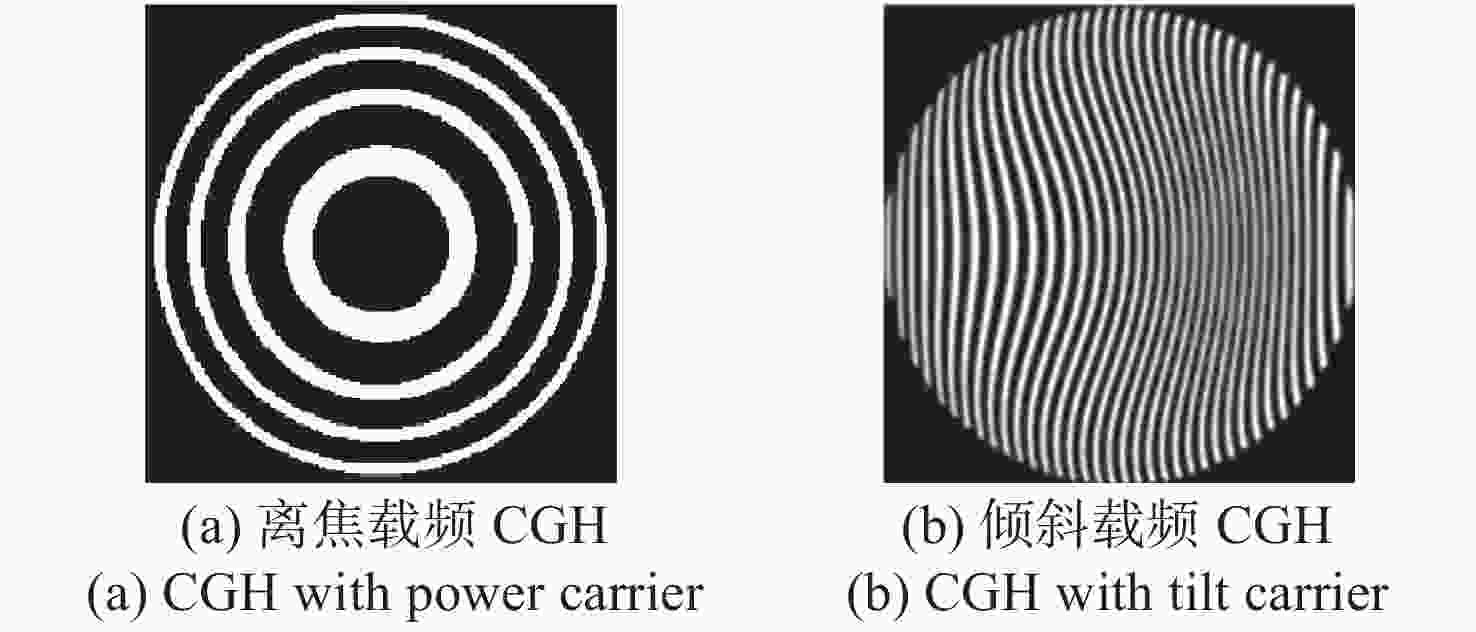

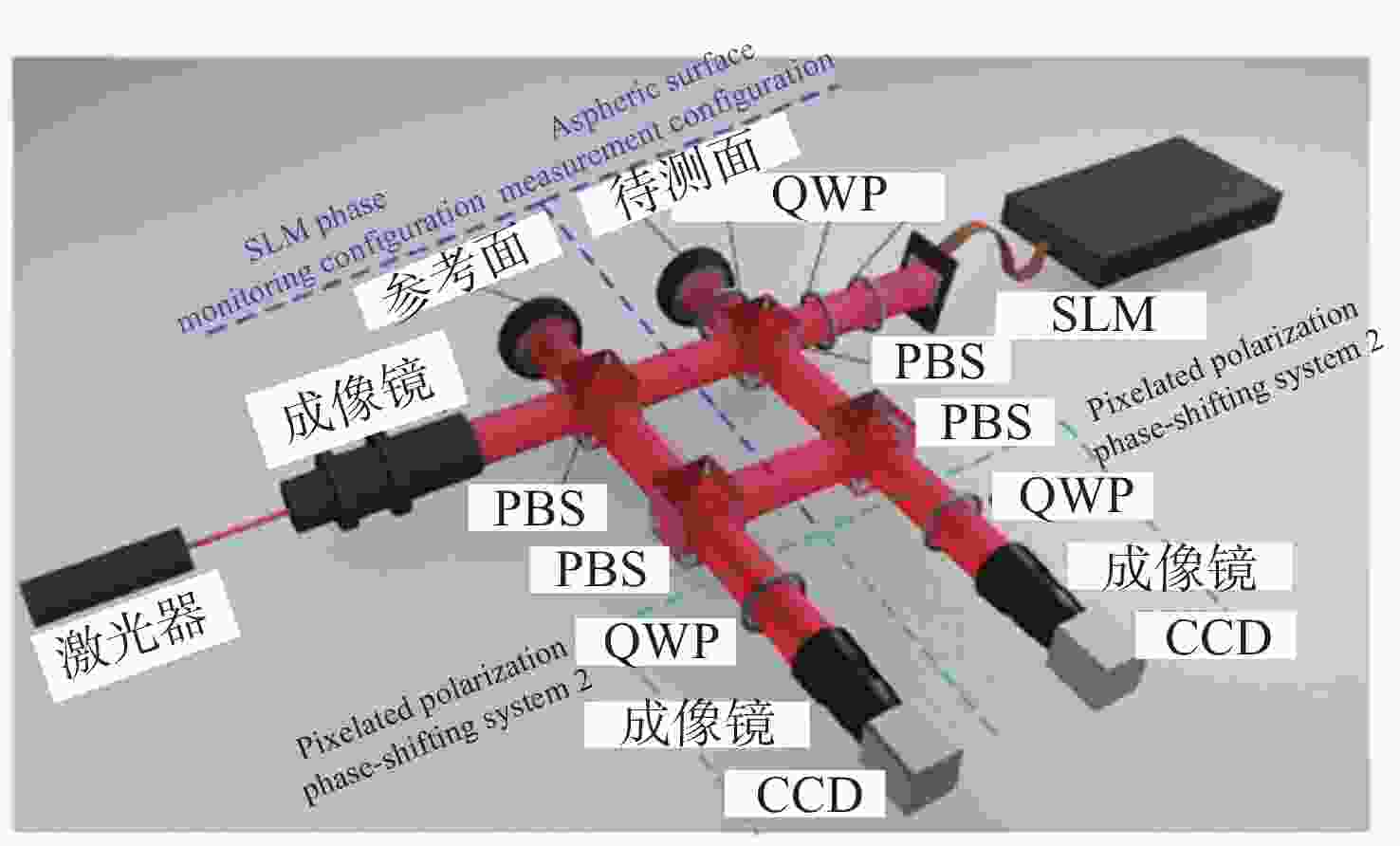

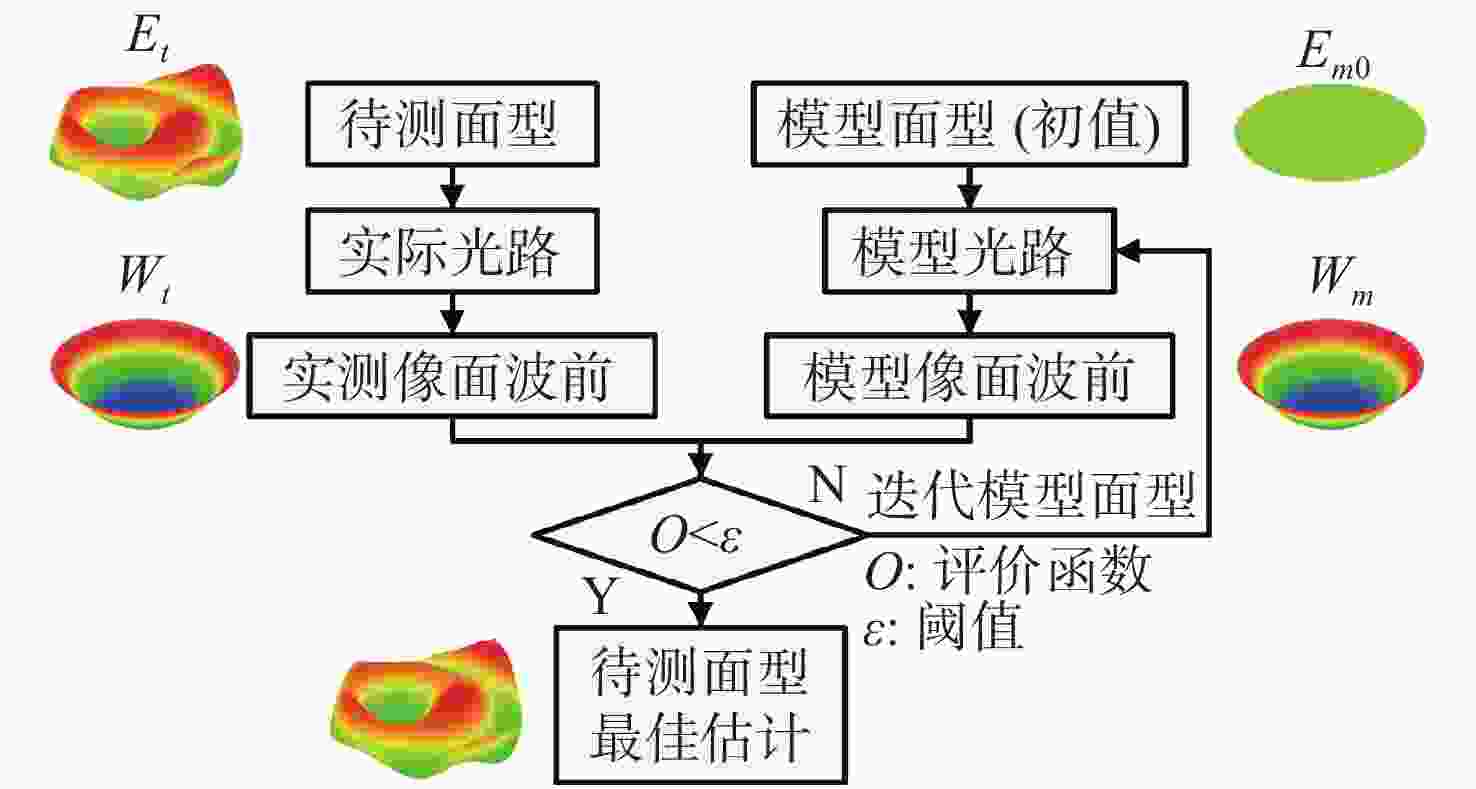

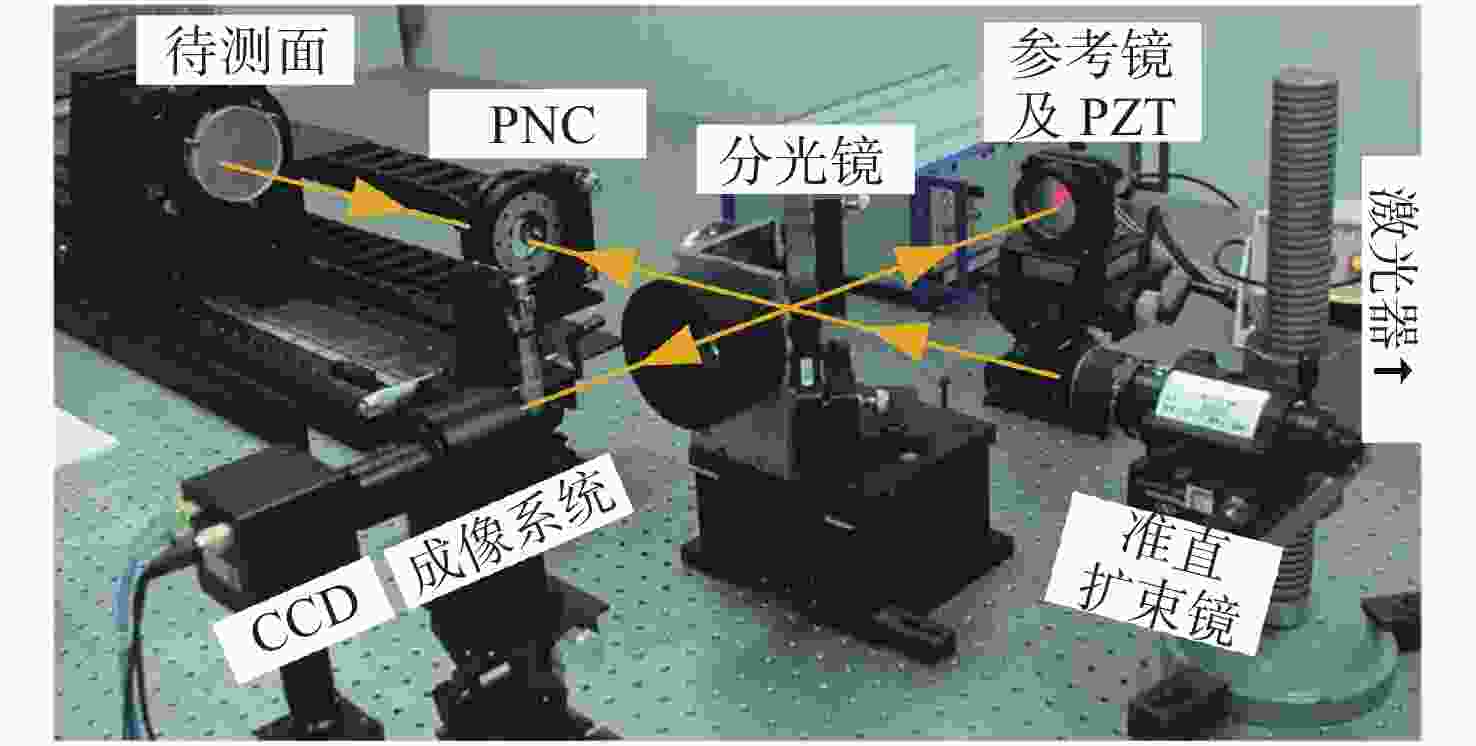

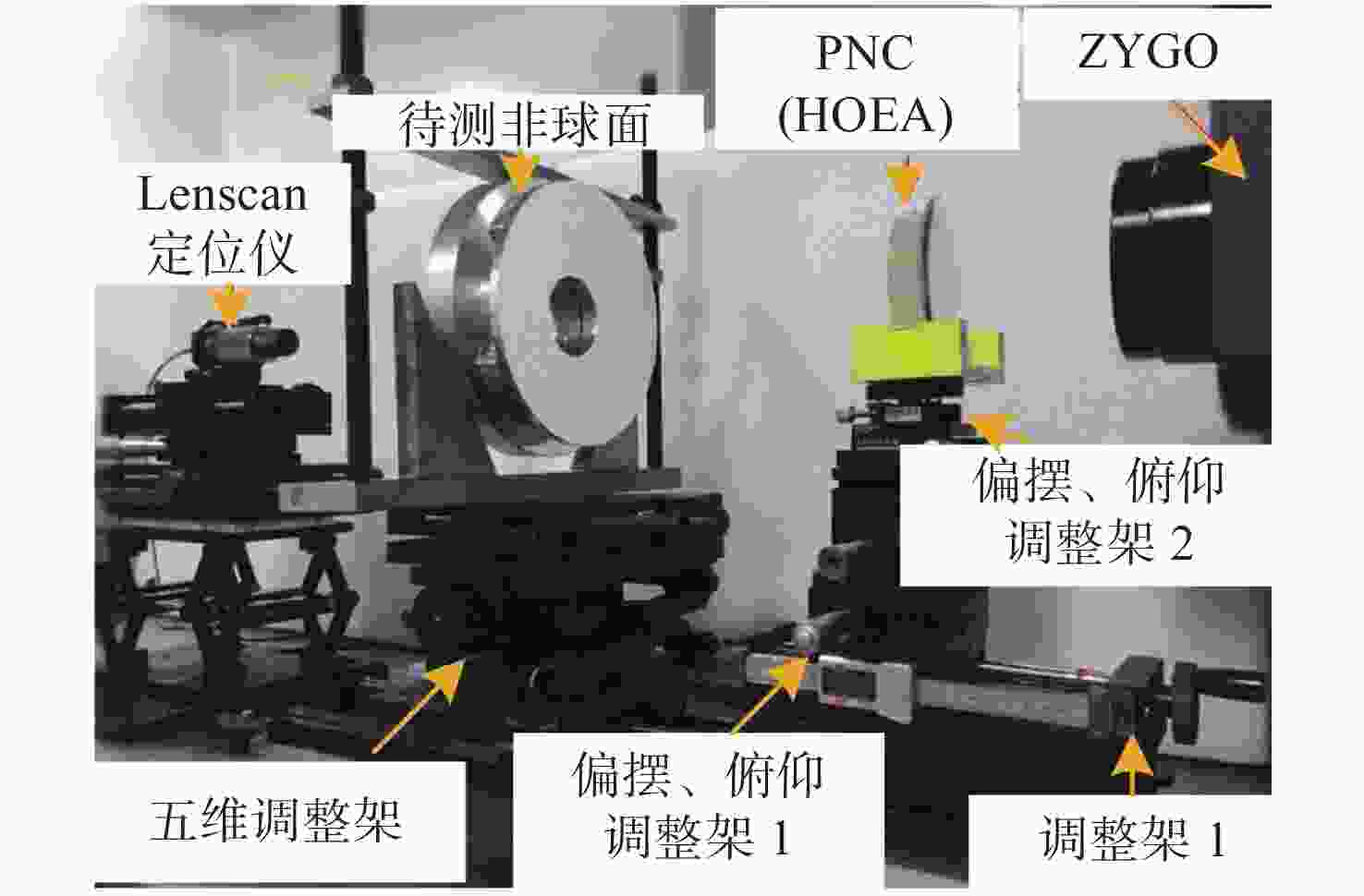

下载: