Blade reflection suppression technology based on surface structured light on-machine detection

-

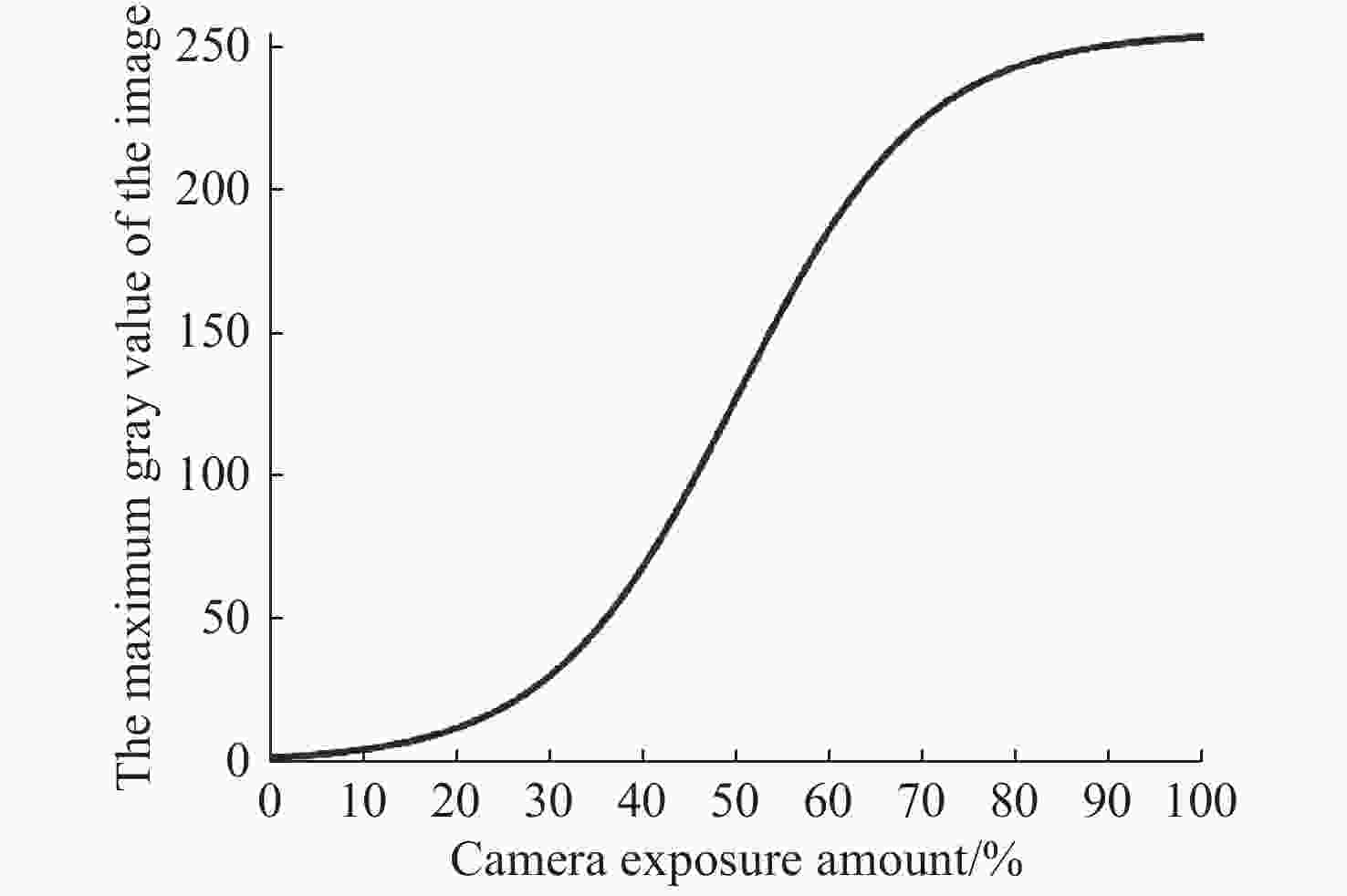

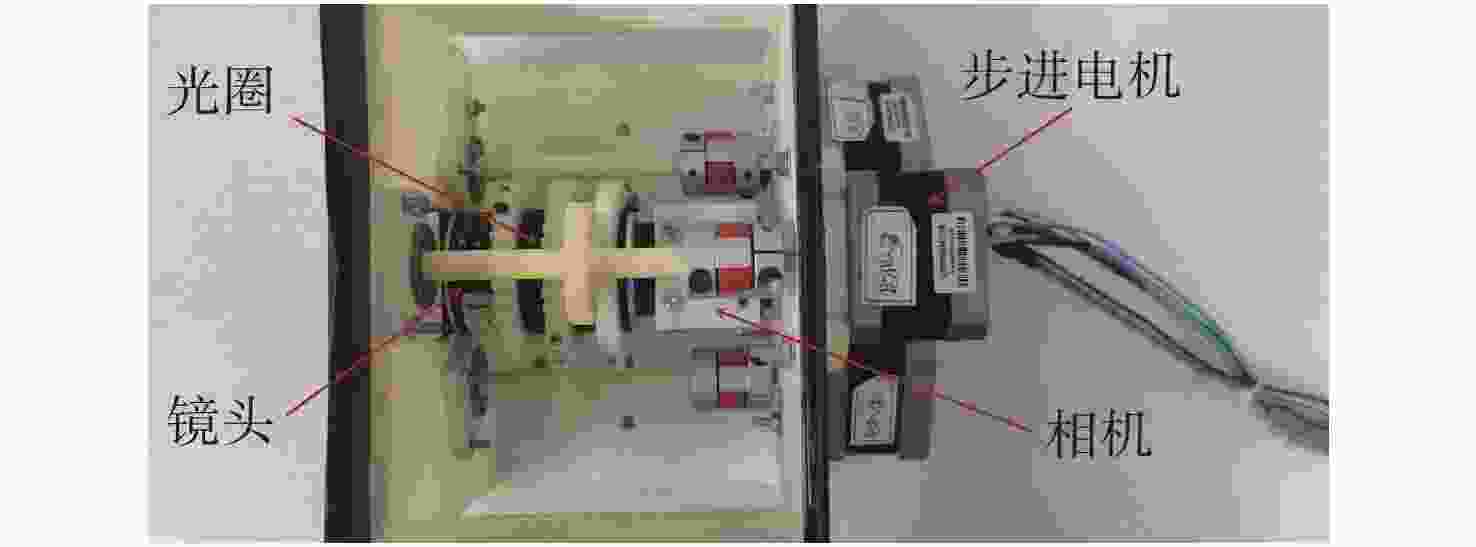

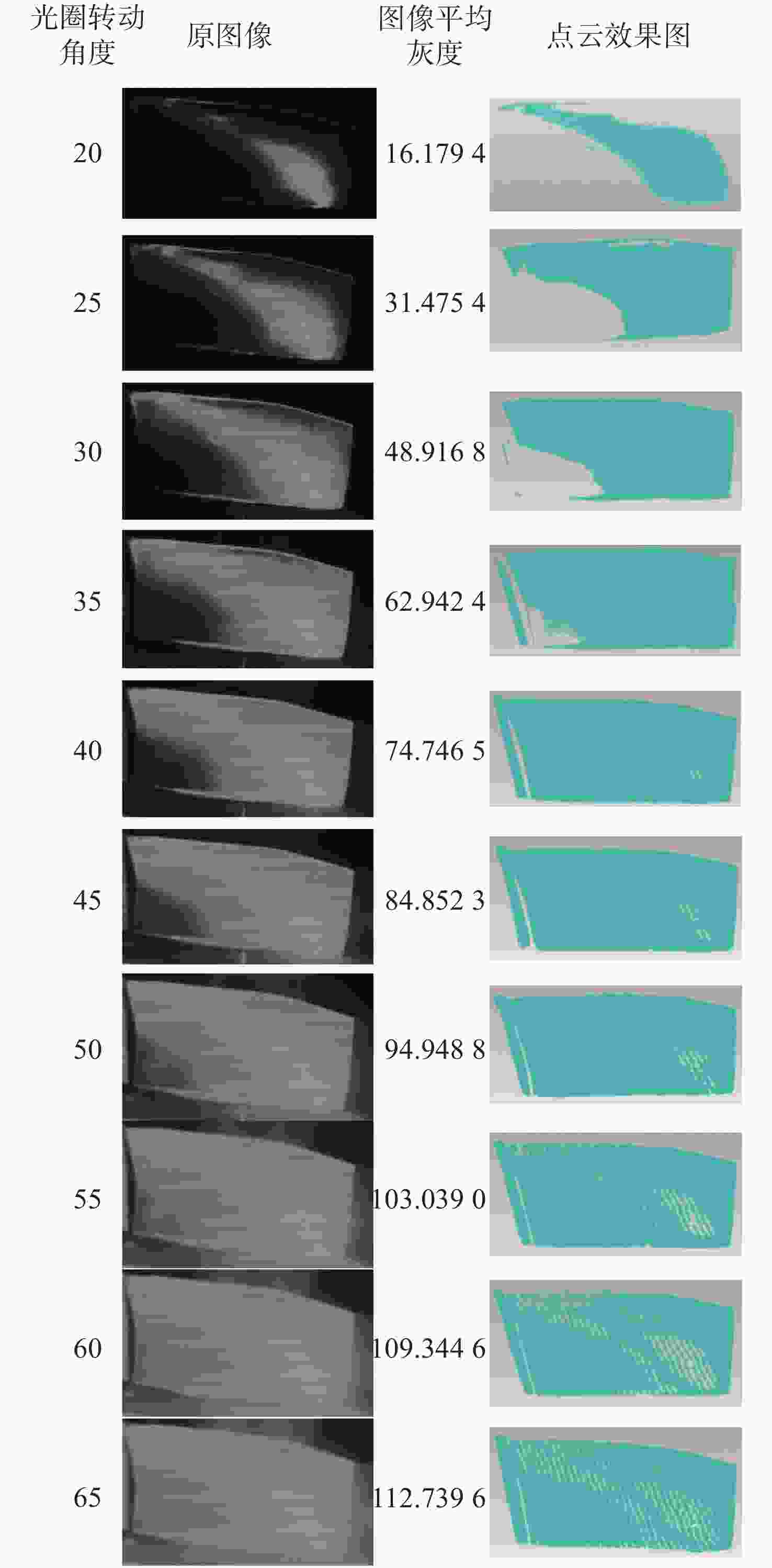

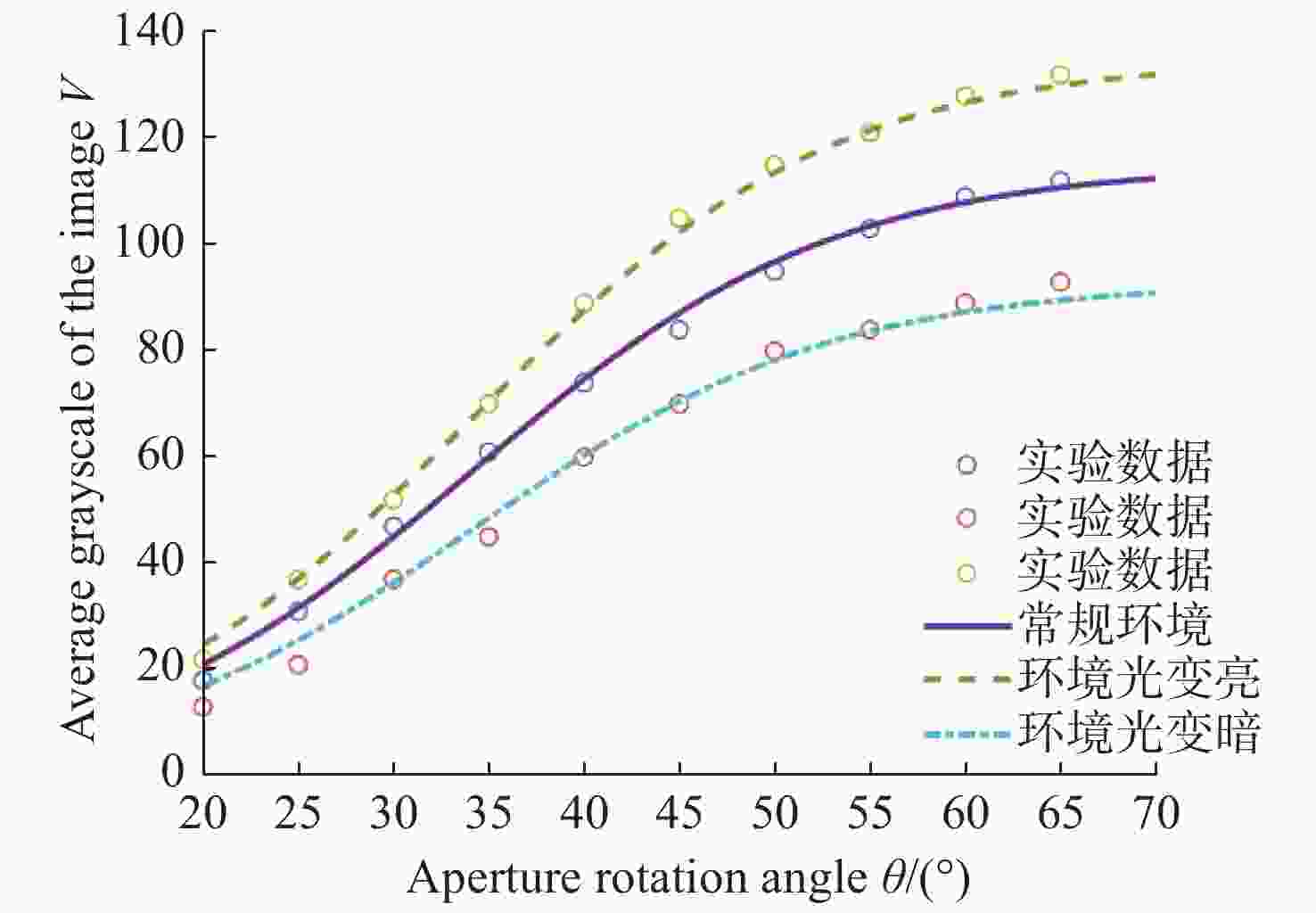

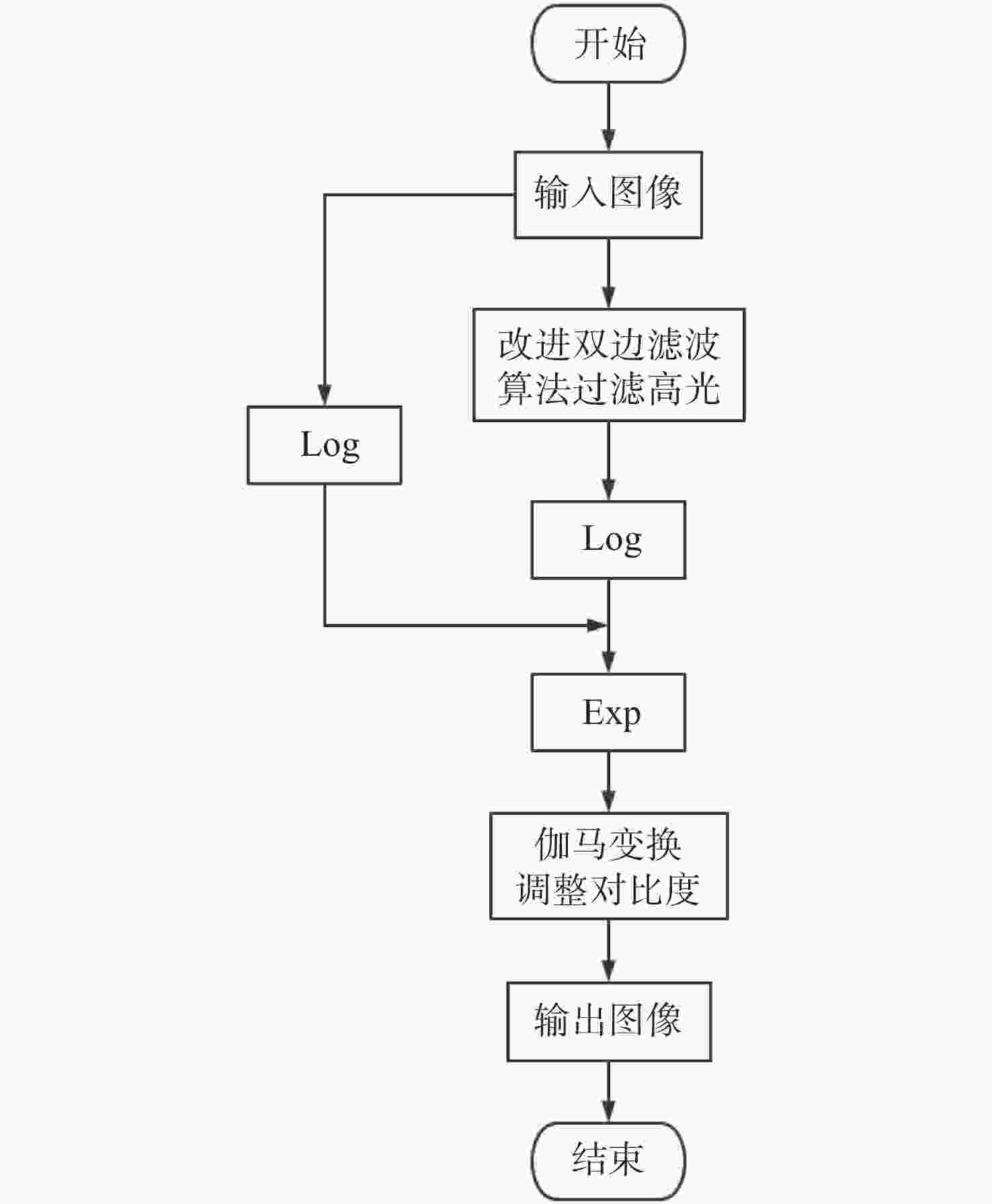

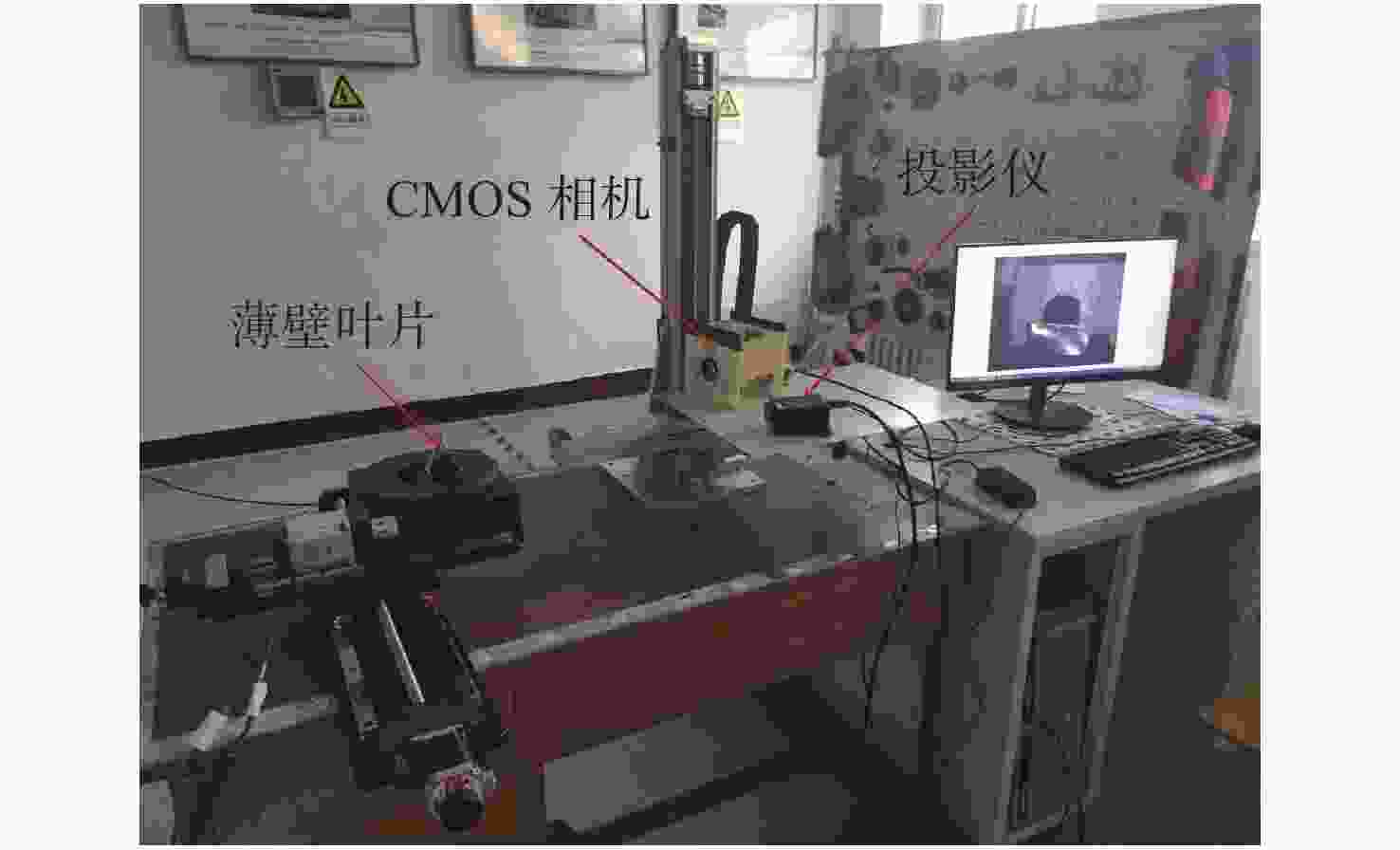

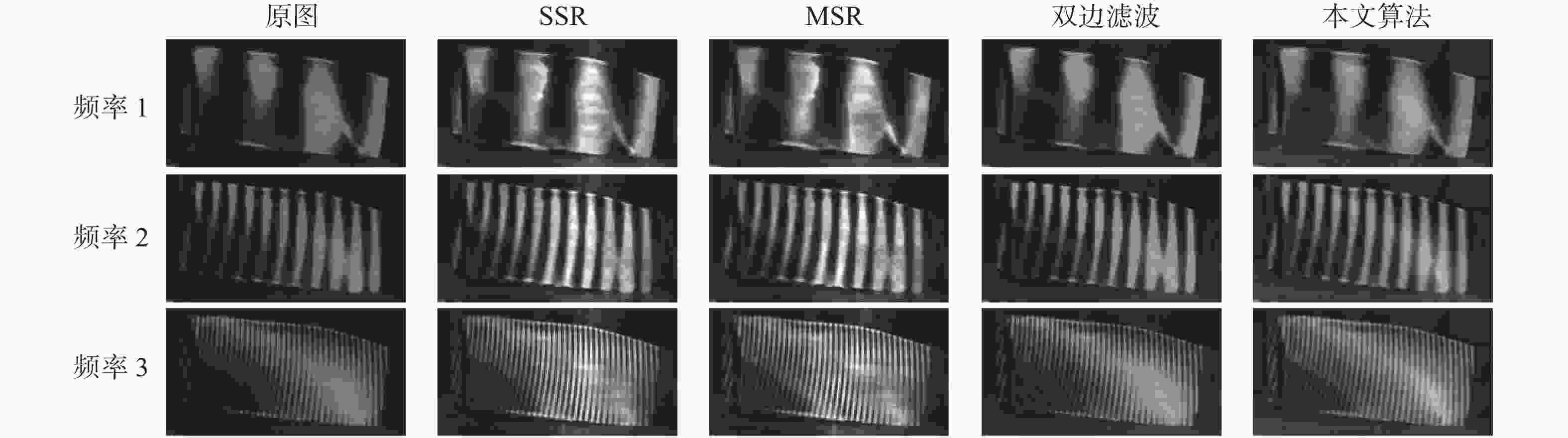

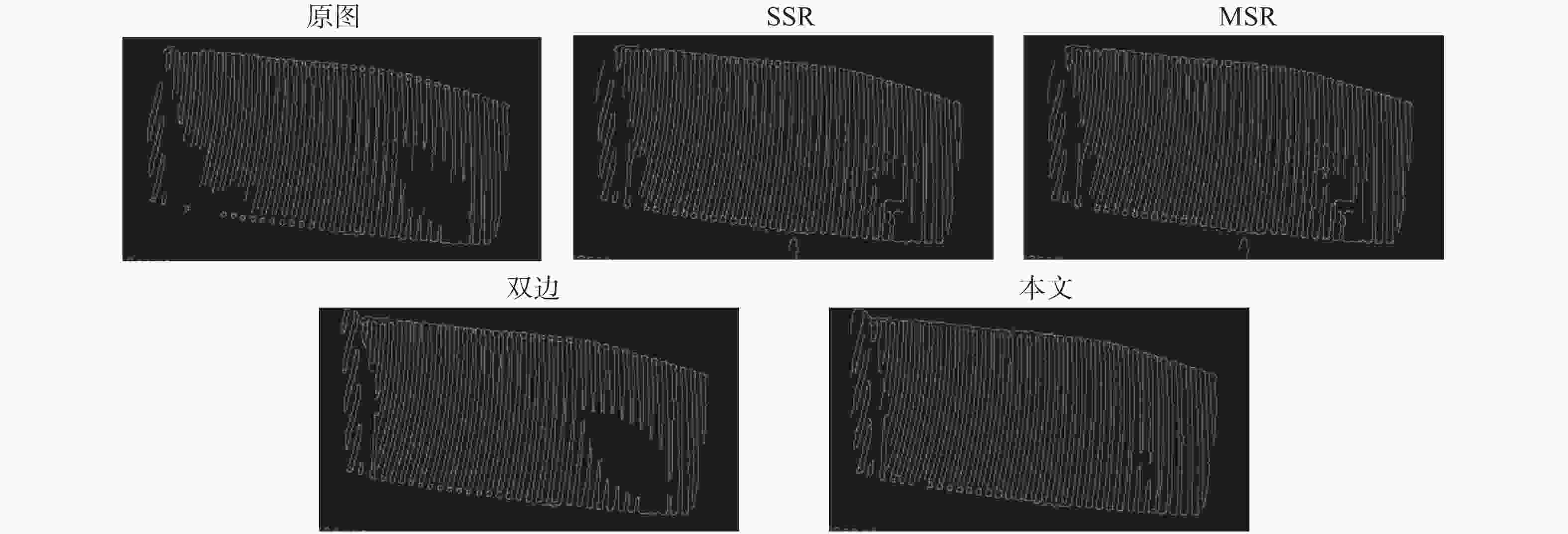

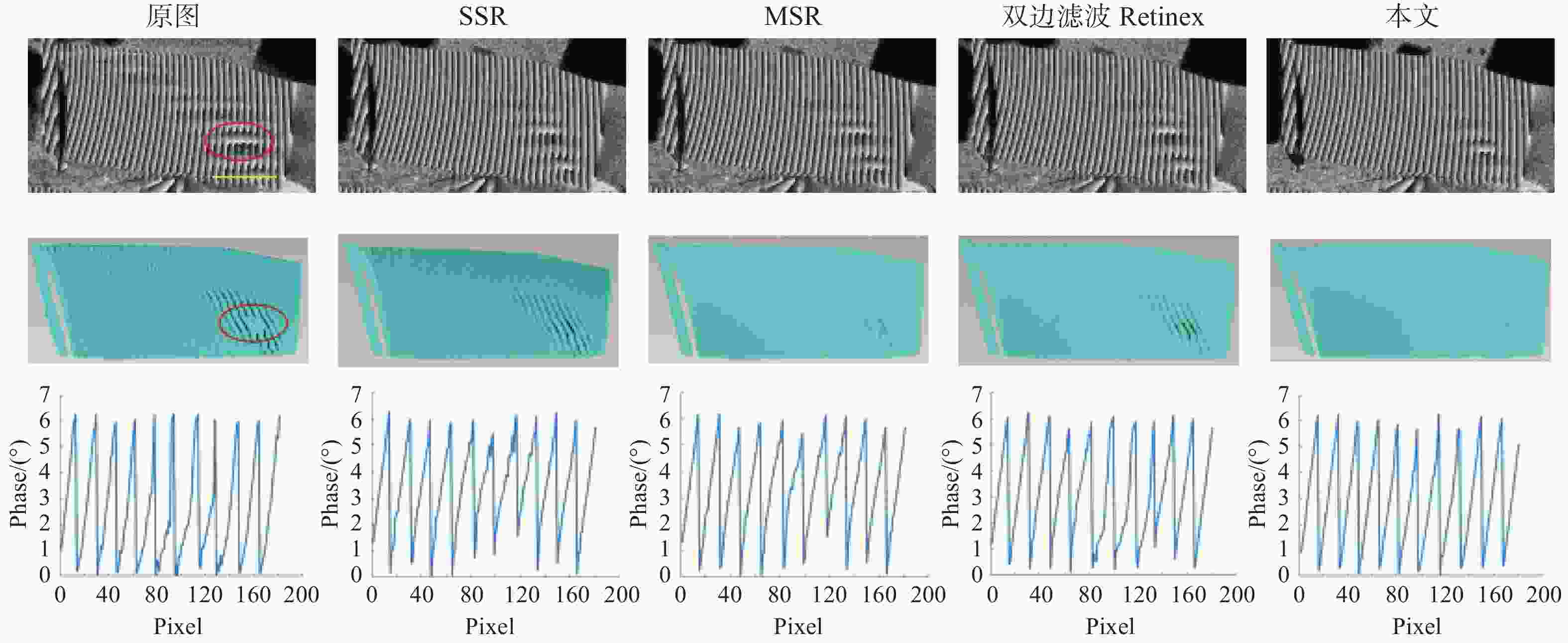

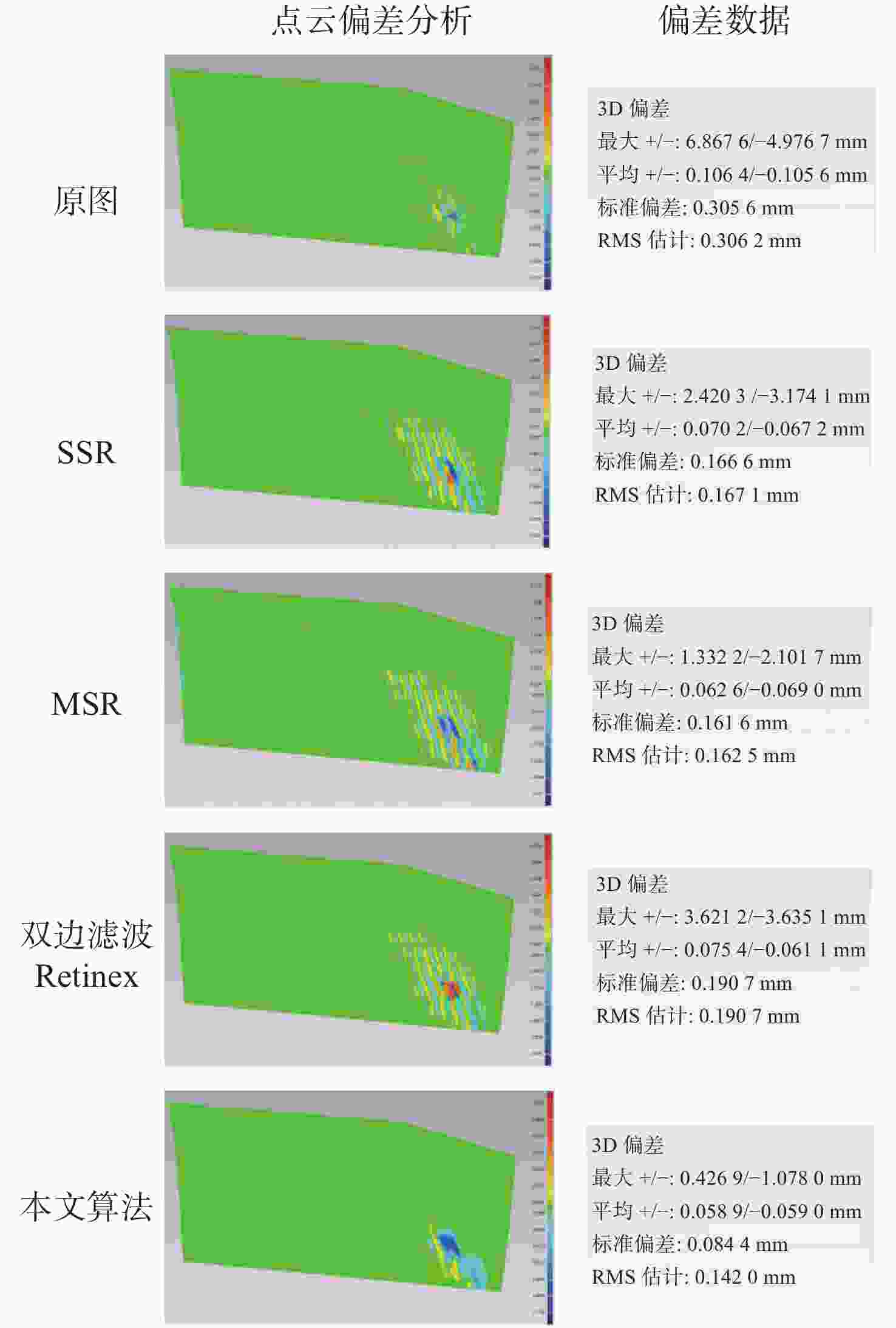

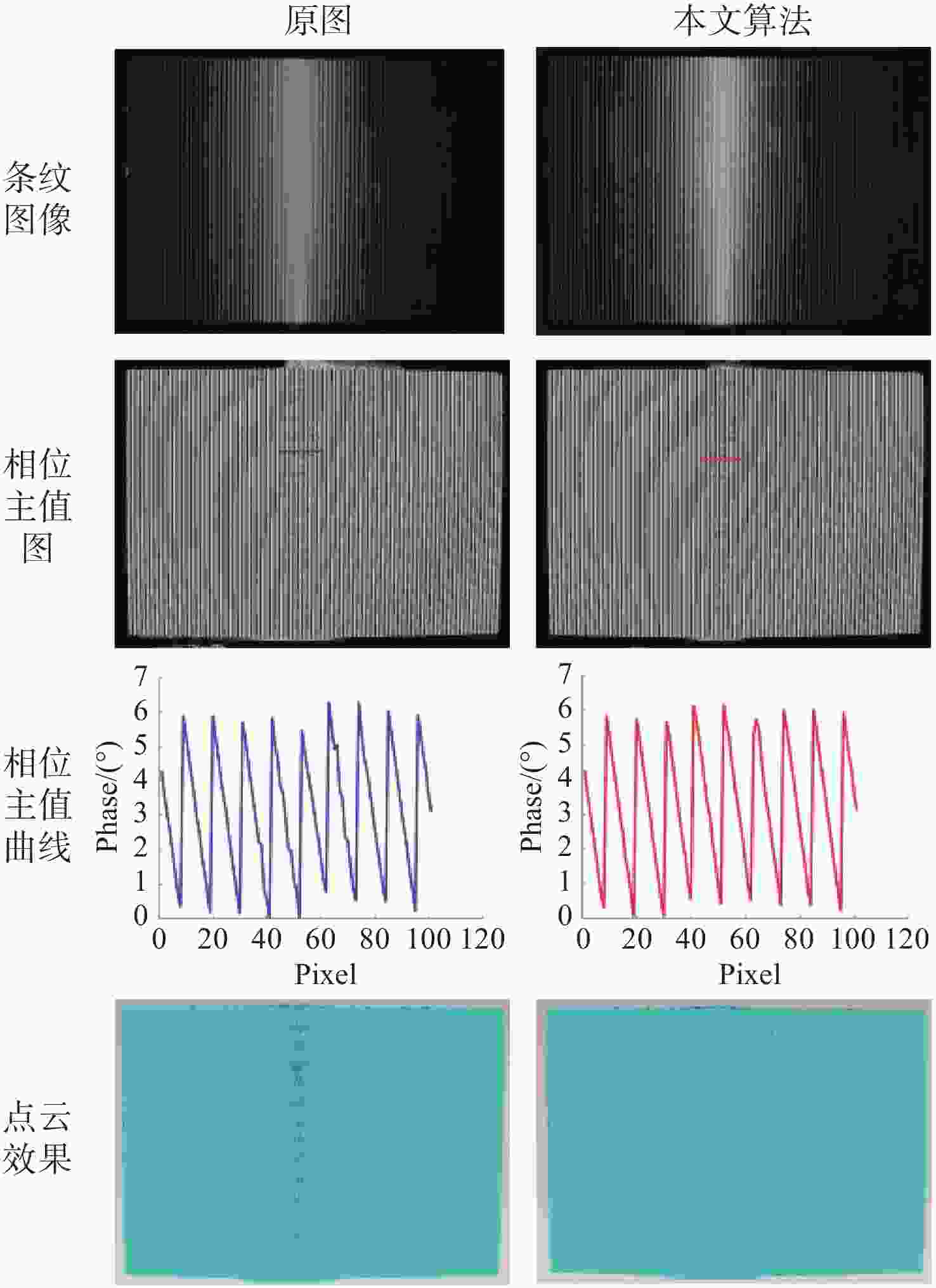

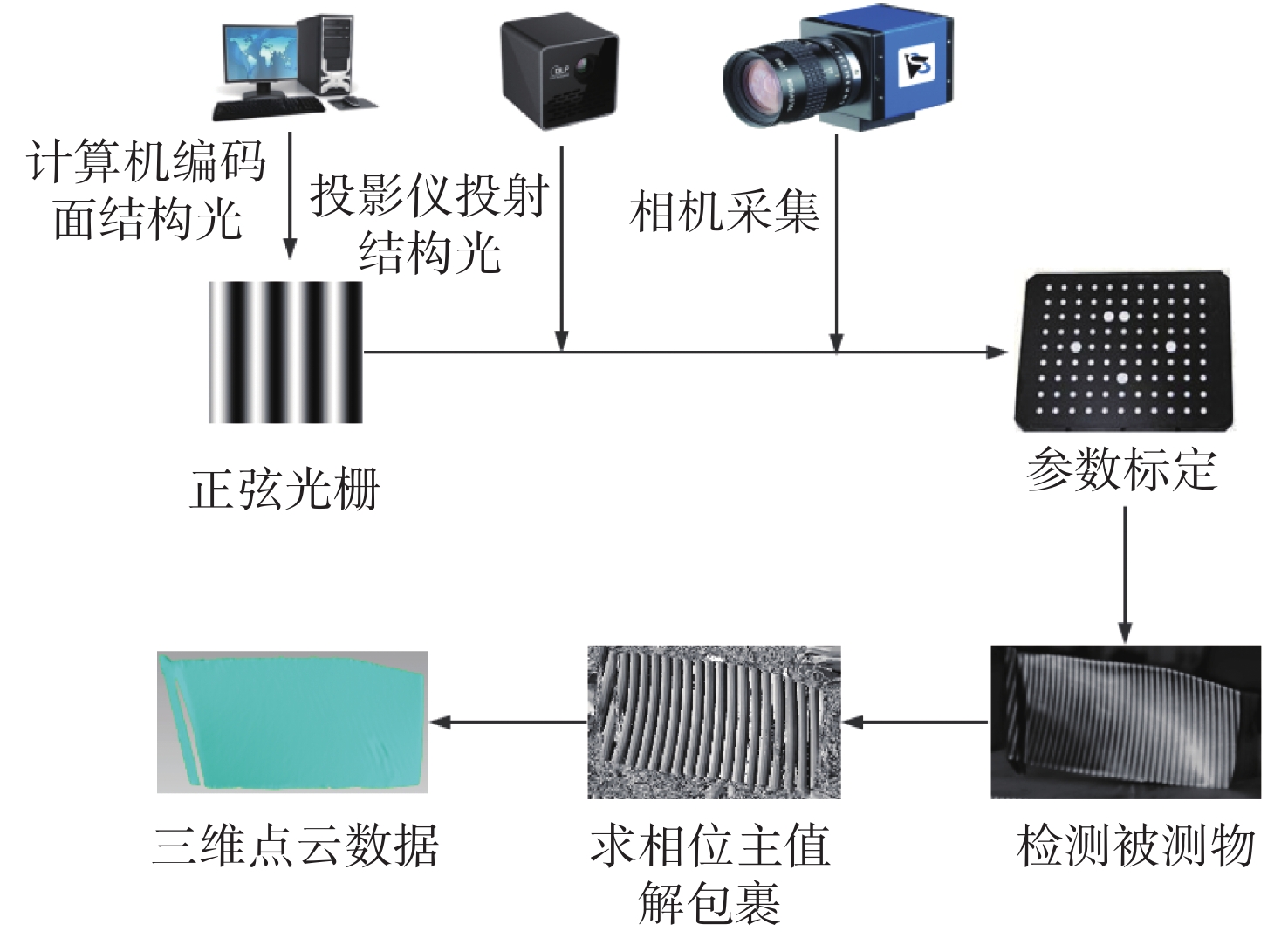

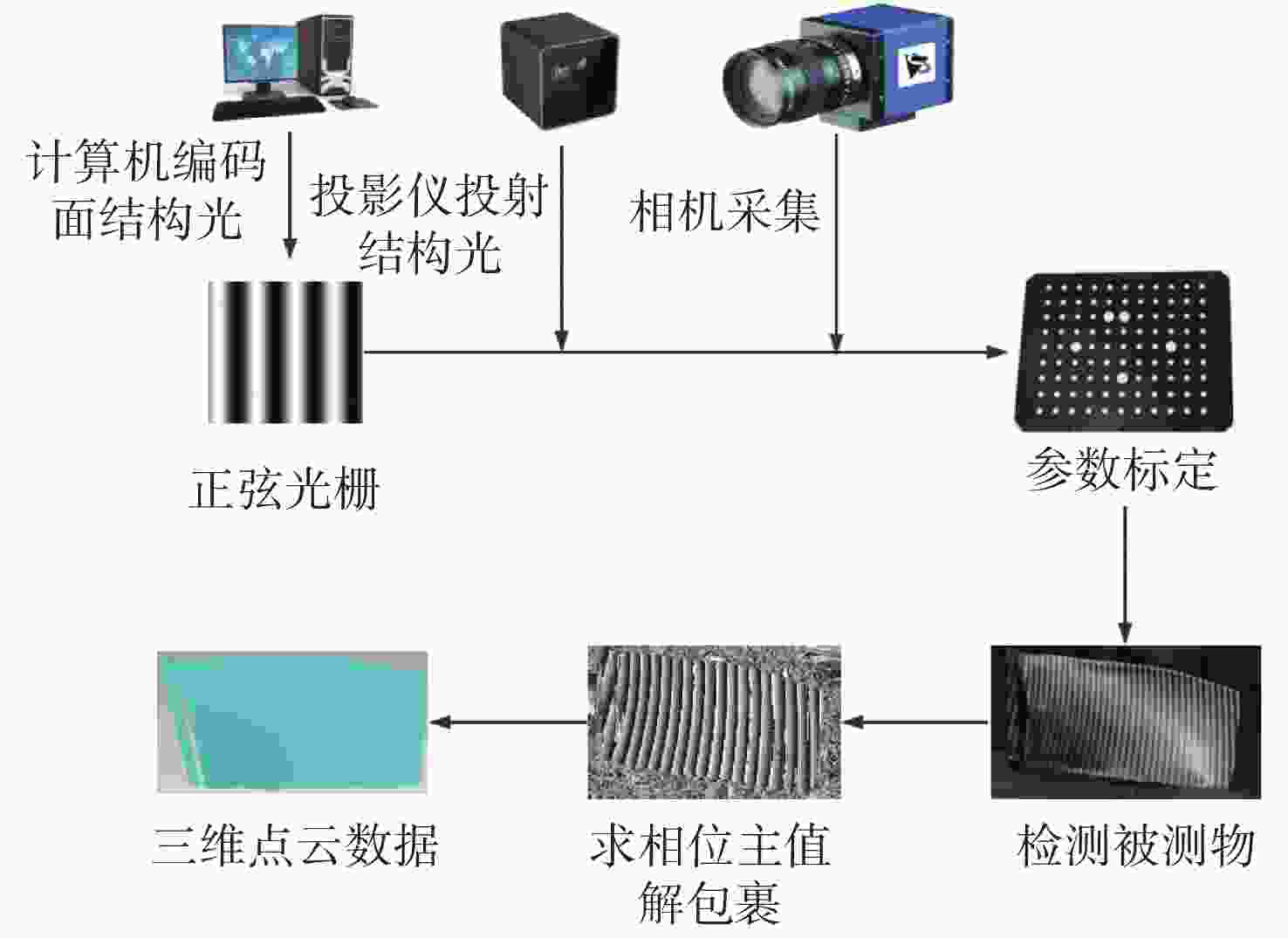

摘要: 薄壁叶片在结构光检测过程中,由于其表面粗糙度较小,易产生强烈的反光现象,影响求解条纹相位主值,进而无法准确重构出三维点云。本文以加工过程中的叶片作为研究对象,提出一种对在机检测过程中的条纹图像进行图像增强处理的Retinex算法,恢复条纹在高反光位置的信息。首先,对薄壁叶片的反光特性进行分析,通过实验标定出最优曝光的灰度区间和理想灰度值,建立了光圈转动角度与图像平均灰度的相机响应曲线模型,调节光圈和曝光时间至最优曝光的灰度区间并以此作为检测条件。其次,基于Retinex算法处理条纹图像,通过改进的双边滤波代替常用的高斯滤波,在去除光照的同时有效保留了条纹的边缘信息。最后,对薄壁叶片进行单目结构光检测。实验结果表明,经本文算法处理后的条纹图像,通过Canny算子检测出的条纹数量最多,图像信息熵平均增长率达18.21%,解算的相位主值误差最小,利用手持式激光扫描仪检测的标准点云进行偏差分析,点云的正、负偏差分别降至0.0589 mm和−0.0590 mm,与原点云的偏差值相比分别减少了44.6%和44.1%,表面质量得到明显改善。本文提出的图像增强算法有效抑制了面结构光检测过程中的金属表面反光。Abstract: In the process of structured light detection, the thin-walled blade is easy to produce a strong reflection due to its low surface roughness, which affects the solution of the principal value of the fringe phase. As a result, it cannot accurately reconstruct the three-dimensional point cloud. In this paper, the blade in the machining process is taken as the research object, and an image enhancement process based on the Retinex algorithm is proposed to restore the information of the stripes in the position with the highest reflectivity. Firstly, the reflective characteristics of thin-walled blades are analyzed. The gray range and ideal gray value of the optimal exposure are calibrated experimentally. The camera response curve model of the aperture rotation angle and the image’s average gray level is determined, and the gray level interval of the optimal exposure is used as the detection condition by adjusting the aperture and exposure time. Secondly, the fringe image is processed based on the Retinex algorithm. The improved bilateral filter replaces the commonly used Gaussian filter, which effectively retains the edge information of the fringe while removing its illumination. Finally, monocular structured light detection is carried out on the thin-walled blade. The experimental results show that, for the fringe image processed by this proposed algorithm, the number of stripes detected by the Canny operator is the largest, the average growth rate of image information entropy is 18.21%, and the phase principal value error of the solution is the smallest. Through the deviation analysis with the standard point cloud detected by the handheld laser scanner, the positive and negative deviations of the point cloud are reduced to 0.0589 mm and −0.0590 mm, which are reduced by 44.6% and 44.1% compared with the deviation of the origin cloud, respectively, and the surface quality is significantly improved. The image enhancement algorithm proposed effectively suppresses the reflection of the metal surface in the process of surface structured light detection.

-

Key words:

- structure light detection /

- metal reflection /

- image enhancement /

- bilateral filter /

- thin walled blade

-

表 1 工业相机主要参数

Table 1. Main parameters of the industrial camera

性能参数 参数值 分辨率 1280(H)×1024(V) 帧率/frame·s−1 30 传感器类型 CMOS 靶面尺寸/mm 7.2×5.3 像素尺寸/μm 5.2×5.2 表 2 不同方法处理前后的条纹图像信息熵

Table 2. Information entropies of fringe image by different processing methods

原图 SSR MSR 双边 本文 频率1 5.6929 6.8478 6.9348 6.2569 7.0843 频率2 5.9551 6.9611 7.0167 6.4442 7.2099 频率3 6.7478 7.1758 7.2466 6.7670 7.3638 -

[1] 李茂月, 马康盛, 许勇浩, 等. 基于单目结构光的形貌测量误差补偿方法研究[J]. 仪器仪表学报,2020,41(5):19-31.LI M Y, MA K SH, XU Y H, et al. Research on morphology measurement error compensation method based on the monocular structure light[J]. Chinese Journal of Scientific Instrument, 2020, 41(5): 19-31. (in Chinese) [2] 马国庆, 刘丽, 于正林, 等. 大型复杂曲面三维形貌测量及应用研究进展[J]. 中国光学,2019,12(2):214-228. doi: 10.3788/co.20191202.0214MA G Q, LIU L, YU ZH L, et al. Application and development of three-dimensional profile measurement for large and complex surface[J]. Chinese Optics, 2019, 12(2): 214-228. (in Chinese) doi: 10.3788/co.20191202.0214 [3] 张申华, 杨延西, 秦峤孟. 针对光栅图像的快速盲去噪方法[J]. 中国光学,2021,14(3):596-604. doi: 10.37188/CO.2020-0166ZHANG SH H, YANG Y X, QIN Q M. A fast blind denoising method for grating image[J]. Chinese Optics, 2021, 14(3): 596-604. (in Chinese) doi: 10.37188/CO.2020-0166 [4] PALOUSEK D, OMASTA M, KOUTNY D, et al. Effect of matte coating on 3D optical measurement accuracy[J]. Optical Materials, 2015, 40: 1-9. doi: 10.1016/j.optmat.2014.11.020 [5] ZHANG S, YAU S T. High dynamic range scanning technique[J]. Optical Engineering, 2009, 48(3): 033604. doi: 10.1117/1.3099720 [6] SONG ZH, JIANG H L, LIN H B, et al. A high dynamic range structured light means for the 3D measurement of specular surface[J]. Optics and Lasers in Engineering, 2017, 95: 8-16. doi: 10.1016/j.optlaseng.2017.03.008 [7] 李兆杰, 崔海华, 刘长毅, 等. 一种基于自动多次曝光面结构光的形貌测量方法[J]. 光学学报,2018,38(11):1112004. doi: 10.3788/AOS201838.1112004LI ZH J, CUI H H, LIU CH Y, et al. A shape measurement method based on automatic multiple exposure surface structured light[J]. Acta Optica Sinica, 2018, 38(11): 1112004. (in Chinese) doi: 10.3788/AOS201838.1112004 [8] WADDINGTON C J, KOFMAN J D. Modified sinusoidal fringe-pattern projection for variable illuminance in phase-shifting three-dimensional surface-shape metrology[J]. Optical Engineering, 2014, 53(8): 084109. doi: 10.1117/1.OE.53.8.084109 [9] LIN H, GAO J, MEI Q, et al. Adaptive digital fringe projection technique for high dynamic range three-dimensional shape measurement[J]. Optics Express, 2016, 24(7): 7703-7718. doi: 10.1364/OE.24.007703 [10] RAO L, DA F P. High dynamic range 3D shape determination based on automatic exposure selection[J]. Journal of Visual Communication and Image Representation, 2018, 50: 217-226. doi: 10.1016/j.jvcir.2017.12.003 [11] RIVIERE J, RESHETOUSKI I, FILIPI L, et al. Polarization imaging reflectometry in the wild[J]. ACM Transactions on Graphics, 2017, 36(6): 206. [12] SALAHIEH B, CHEN ZH Y, RODRIGUEZ J J, et al. Multi-polarization fringe projection imaging for high dynamic range objects[J]. Optics Express, 2014, 22(8): 10064-10071. doi: 10.1364/OE.22.010064 [13] 郝婧蕾, 赵永强, 赵海盟, 等. 偏振多光谱机器视觉的高反光无纹理目标三维重构方法[J]. 测绘学报,2018,47(6):816-824.HAO J L, ZHAO Y Q, ZHAO H M, et al. 3D reconstruction of high-reflective and textureless targets based on multispectral polarization and machine vision[J]. Acta Geodaetica et Cartographica Sinica, 2018, 47(6): 816-824. (in Chinese) [14] 王浩, 张叶, 沈宏海, 等. 图像增强算法综述[J]. 中国光学,2017,10(4):438-448. doi: 10.3788/co.20171004.0438WANG H, ZHANG Y, SHEN H H, et al. Review of image enhancement algorithms[J]. Chinese Optics, 2017, 10(4): 438-448. (in Chinese) doi: 10.3788/co.20171004.0438 [15] 王永红, 张倩, 胡寅, 等. 显微条纹投影小视场三维表面成像技术综述[J]. 中国光学,2021,14(3):447-457. doi: 10.37188/CO.2020-0199WANG Y H, ZHANG Q, HU Y, et al. 3D small-field surface imaging based on microscopic fringe projection profilometry: a review[J]. Chinese Optics, 2021, 14(3): 447-457. (in Chinese) doi: 10.37188/CO.2020-0199 [16] COOK R L, TORRANCE K E. A reflectance model for computer graphics[J]. ACM Transactions on Graphics, 1982, 1(1): 7-24. doi: 10.1145/357290.357293 [17] 张颖, 李金龙, 黄趾维, 等. 基于BRDF模型的金属表面反射特性及相变特性研究[J]. 光电技术应用,2017,32(3):32-35.ZHANG Y, LI J L, HUANG ZH W, et al. Research on reflection and phase shift characters of metal surface based on BRDF model[J]. Electro-optic Technology Application, 2017, 32(3): 32-35. (in Chinese) [18] 王金海, 李华, 魏力. 基于C-T模型的光学元件加工表面的光学特性研究[J]. 光学技术,2021,47(2):172-177.WANG J H, LI H, WEI L. Study on optical properties of machining surface of optical element based on C-T model[J]. Optical Technique, 2021, 47(2): 172-177. (in Chinese) [19] LAND E H, MCCANN J J. Lightness and retinex theory[J]. Journal of the Optical Society of America, 1971, 61(1): 1-11. doi: 10.1364/JOSA.61.000001 [20] 毛向向, 王红军. 薄壁零件复杂光照情况下的轮廓特征识别[J]. 电子测量与仪器学报,2021,35(3):137-143.MAO X X, WANG H J. Improved retinex and edge detection fusion of thin-walled complex part contour recognition algorithm[J]. Journal of Electronic Measurement and Instrumentation, 2021, 35(3): 137-143. (in Chinese) [21] 冯维, 吴贵铭, 赵大兴, 等. 多图像融合Retinex用于弱光图像增强[J]. 光学 精密工程,2020,28(3):736-744. doi: 10.3788/OPE.20202803.0736FENG W, WU G M, ZHAO D X, et al. Multi images fusion Retinex for low light image enhancement[J]. Optics and Precision Engineering, 2020, 28(3): 736-744. (in Chinese) doi: 10.3788/OPE.20202803.0736 [22] 石磊, 奚茂龙, 孙俊. 基于可控核双边滤波Retinex水下图像增强算法[J]. 量子电子学报,2018,35(1):7-12.SHI L, XI M L, SUN J. Underswater image enhancement algorithm based on controllable nuclear bilateral filtering Retinex[J]. Chinese Journal of Quantum Electronics, 2018, 35(1): 7-12. (in Chinese) [23] 王冬云, 唐楚, 鄂世举, 等. 基于导向滤波Retinex和自适应Canny的图像边缘检测[J]. 光学 精密工程,2021,29(2):443-451. doi: 10.37188/OPE.20212902.0443WANG D Y, TANG CH, E SH J, et al. Image edge detection based on guided filter Retinex and adaptive Canny[J]. Optics and Precision Engineering, 2021, 29(2): 443-451. (in Chinese) doi: 10.37188/OPE.20212902.0443 -

下载:

下载: