Displacement compensation method for in-situ observation of micro orthogonal cutting process

-

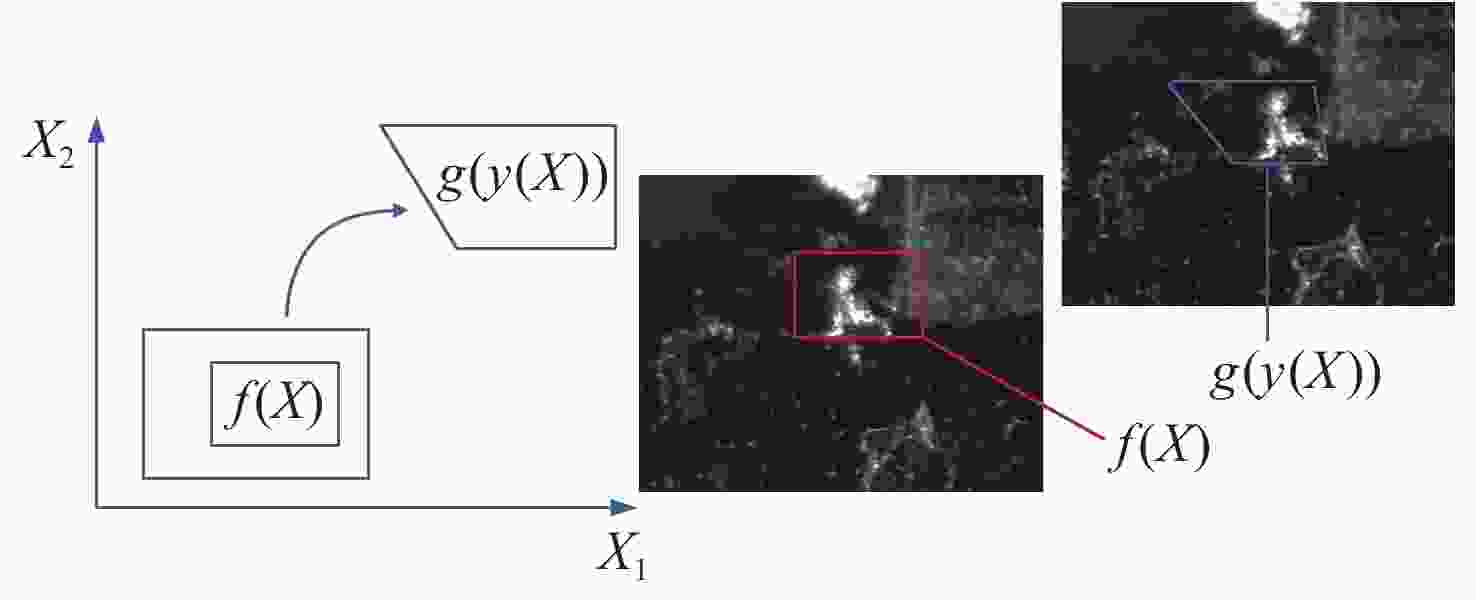

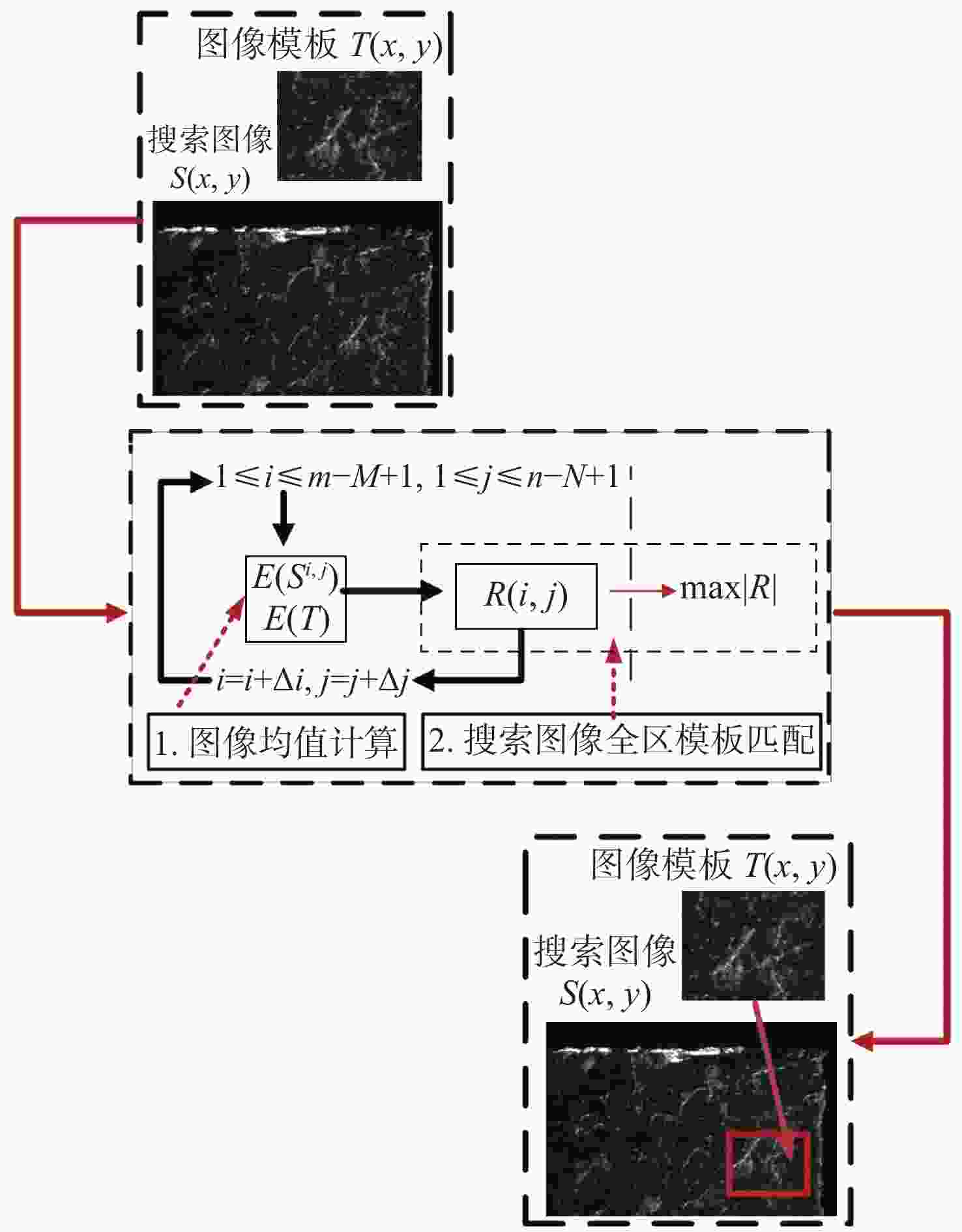

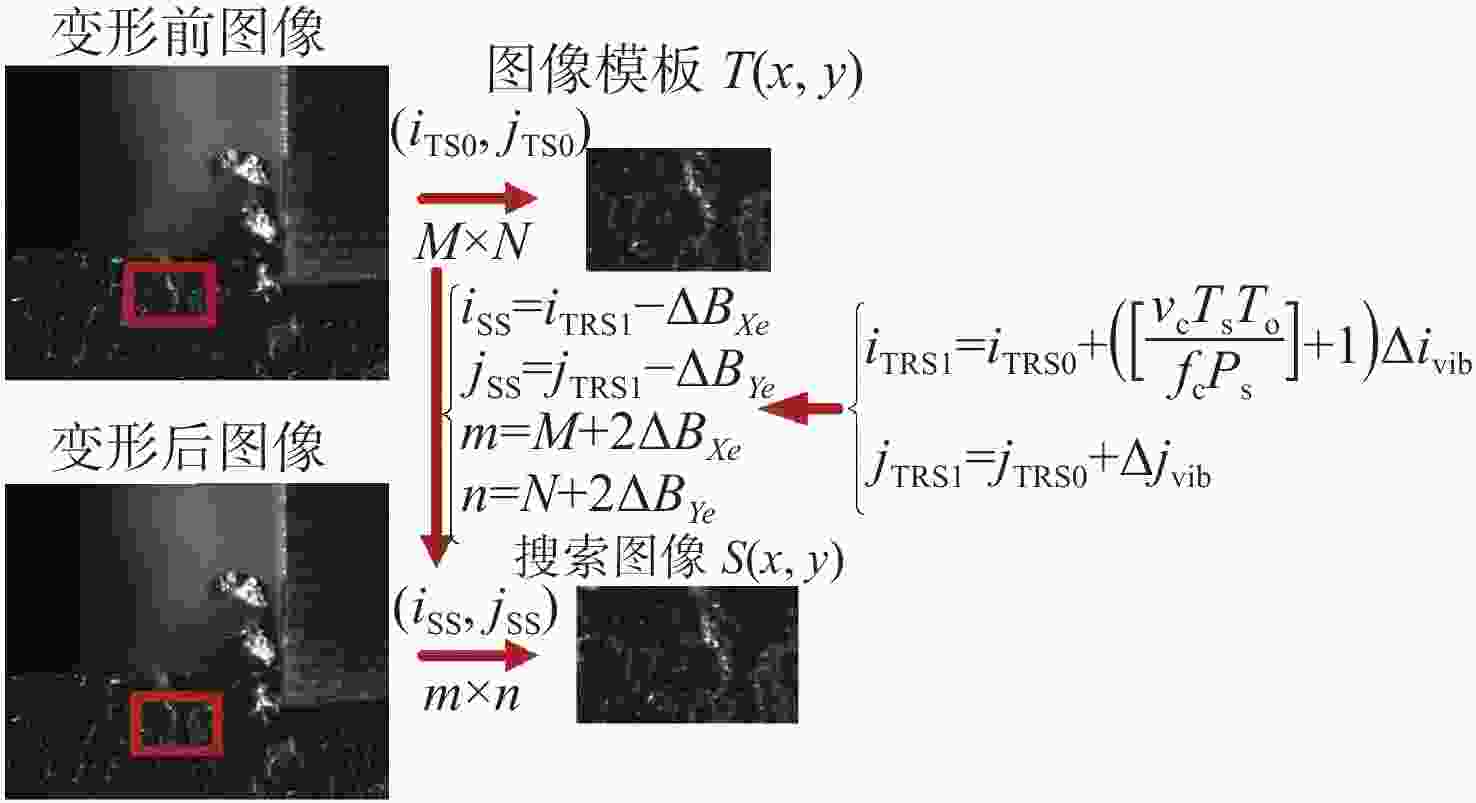

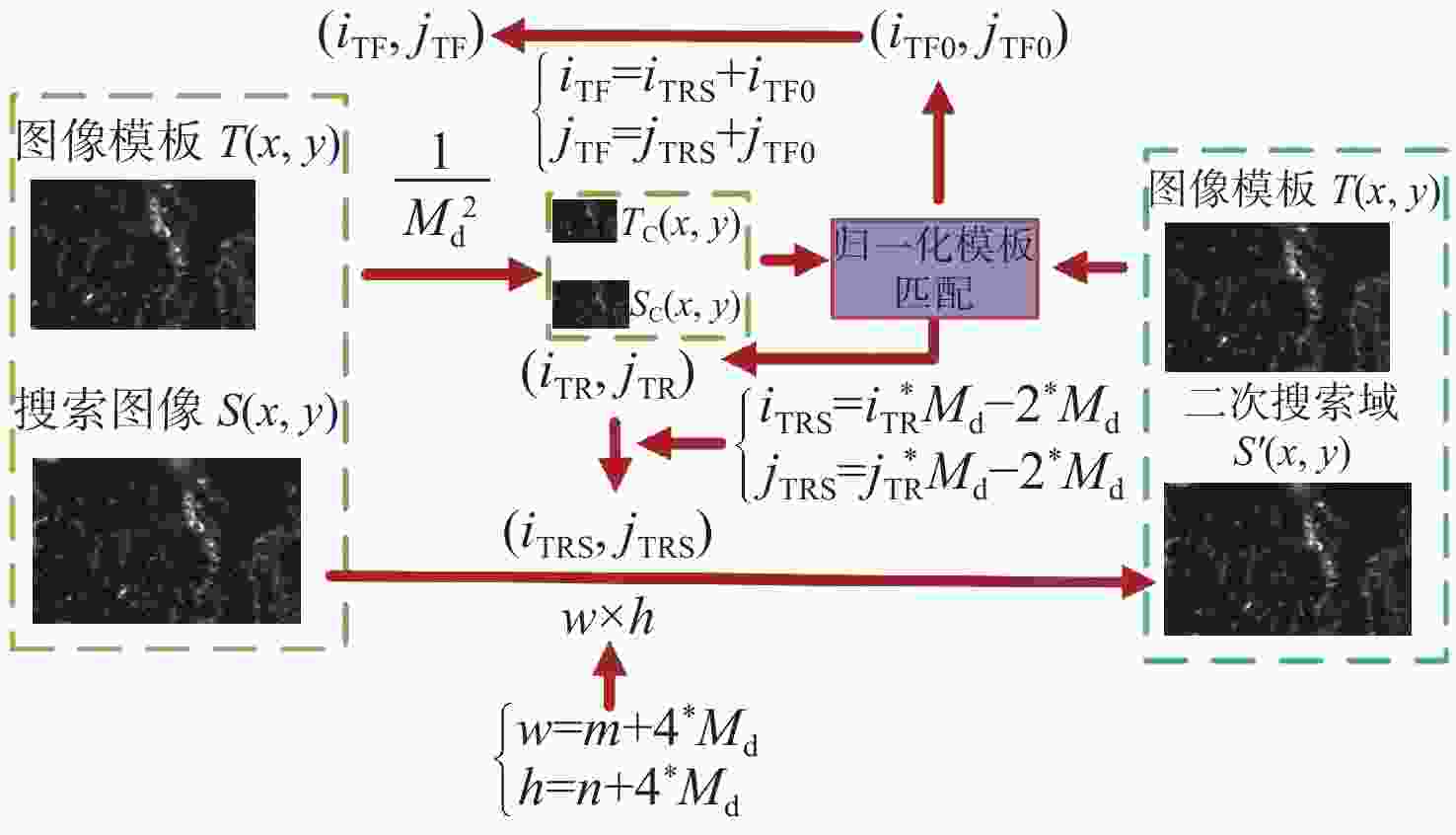

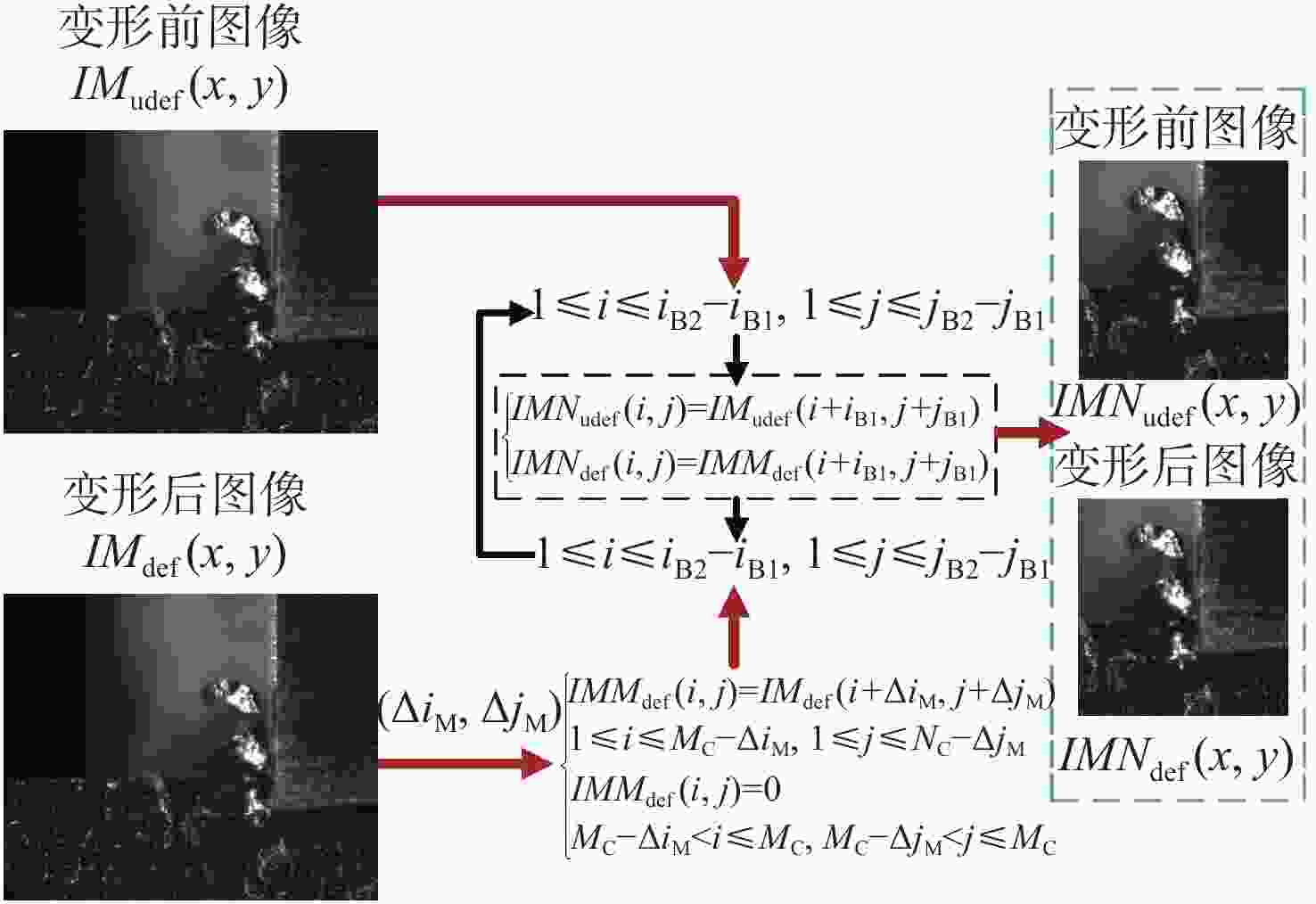

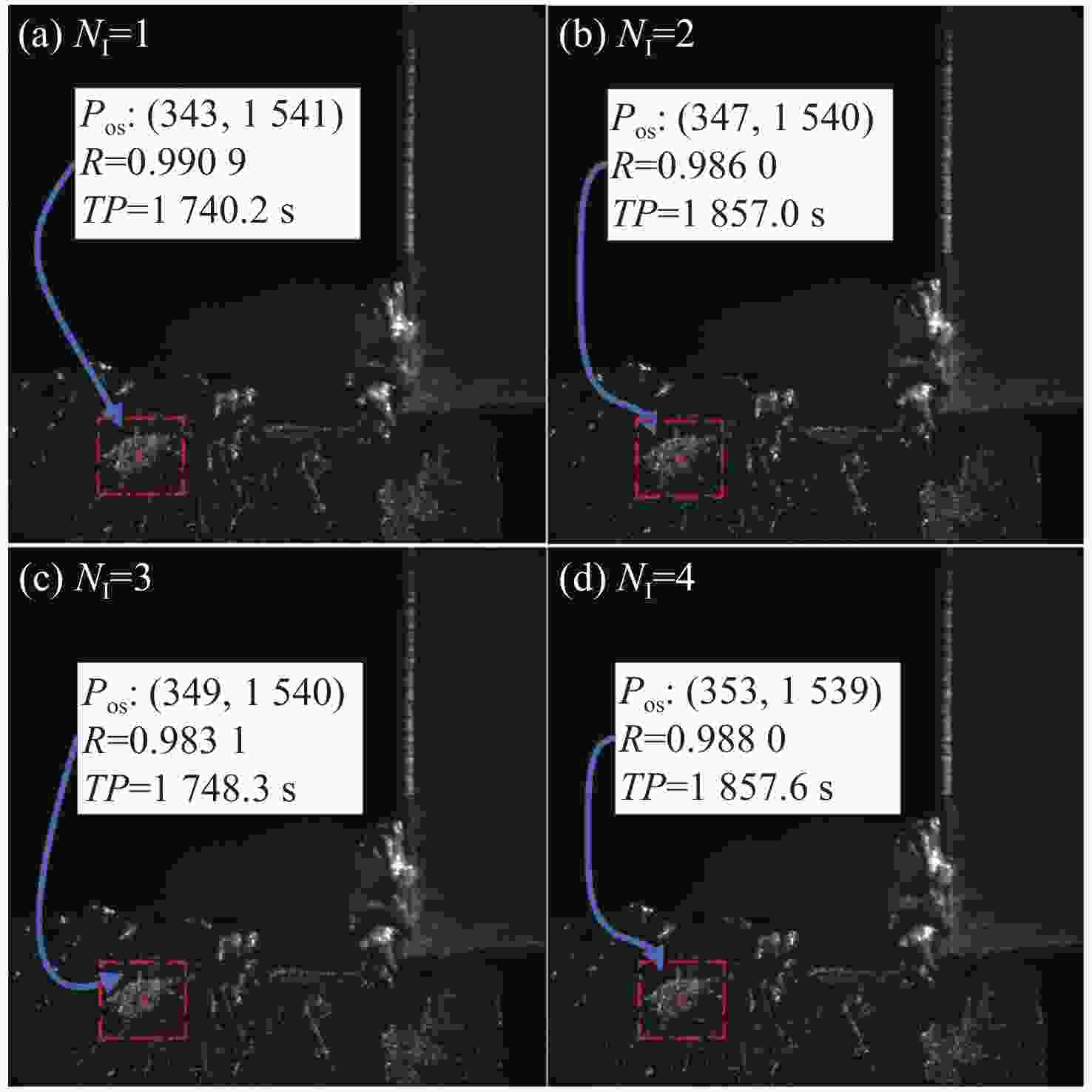

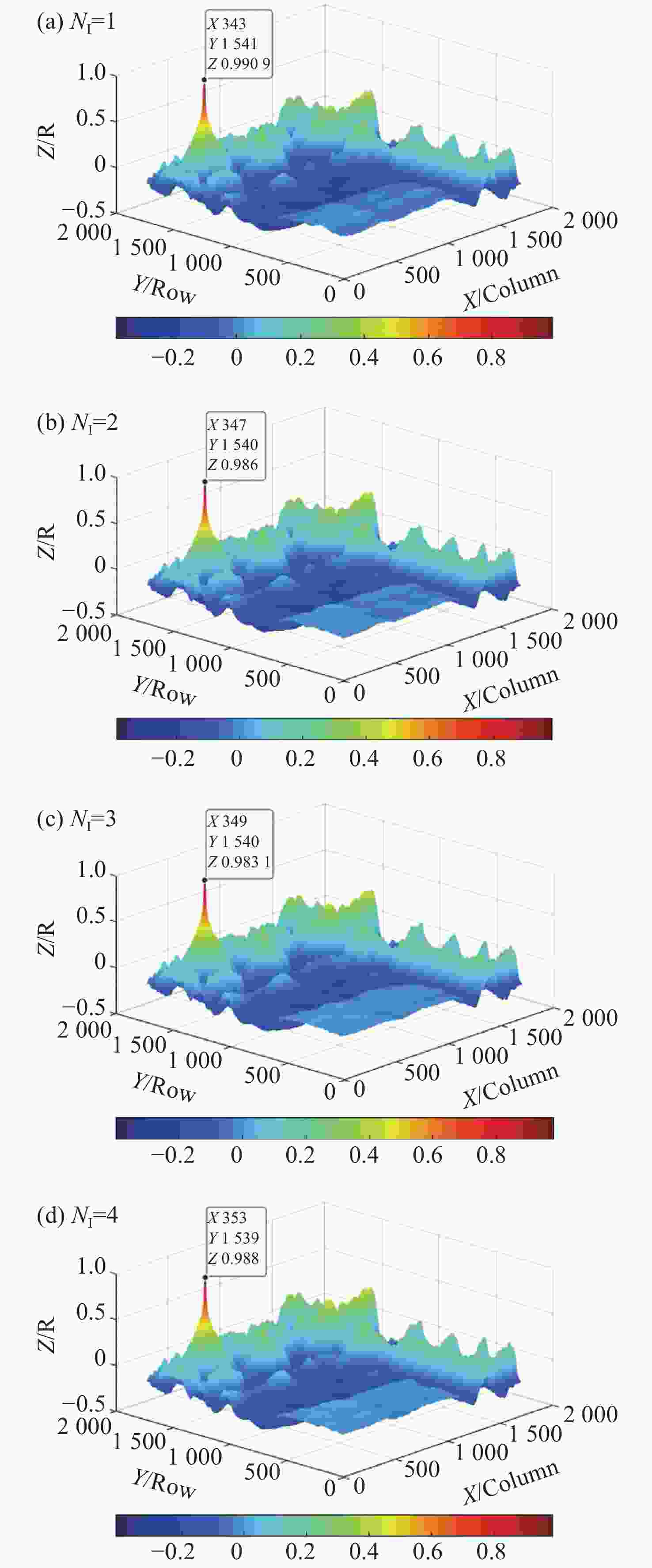

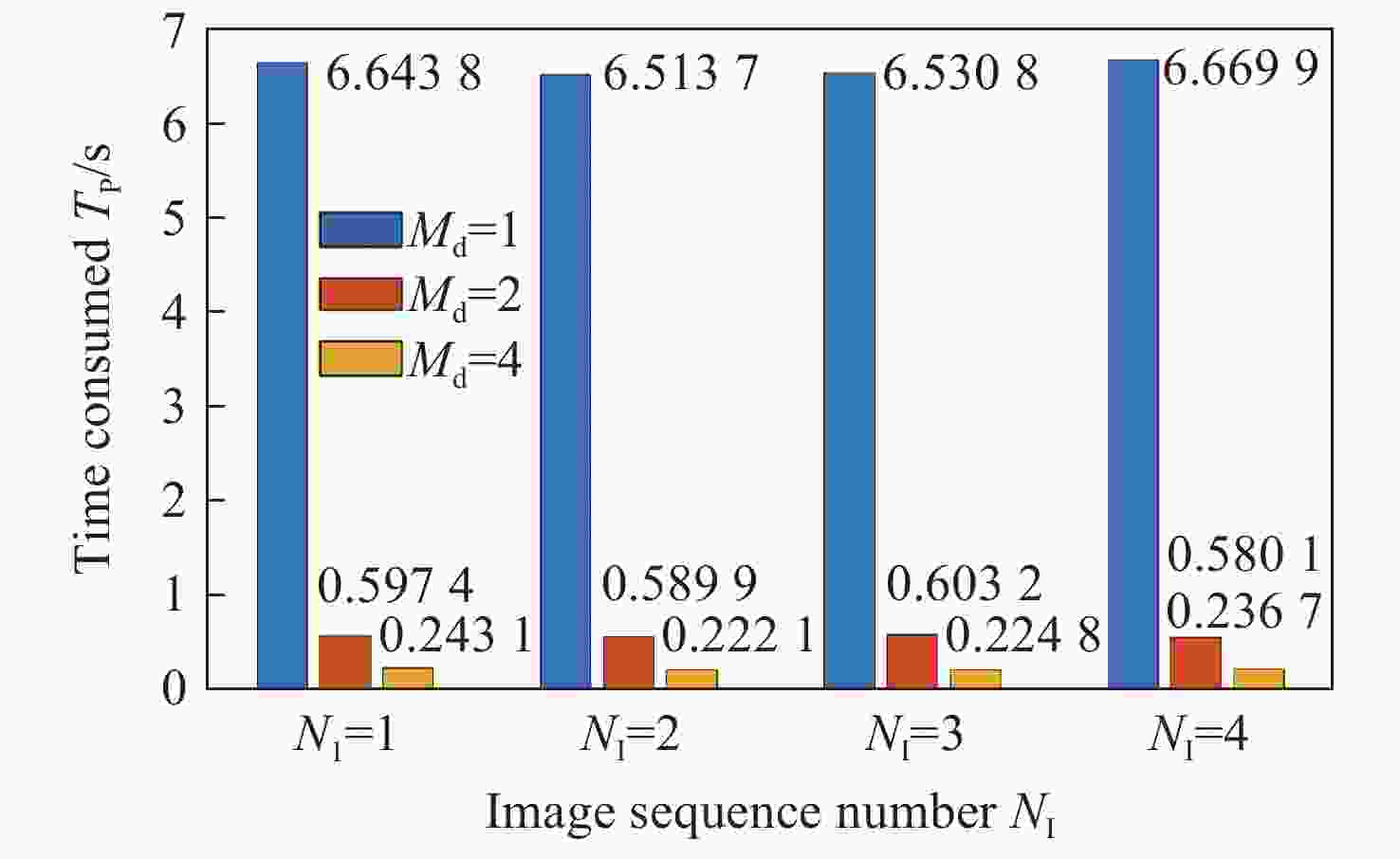

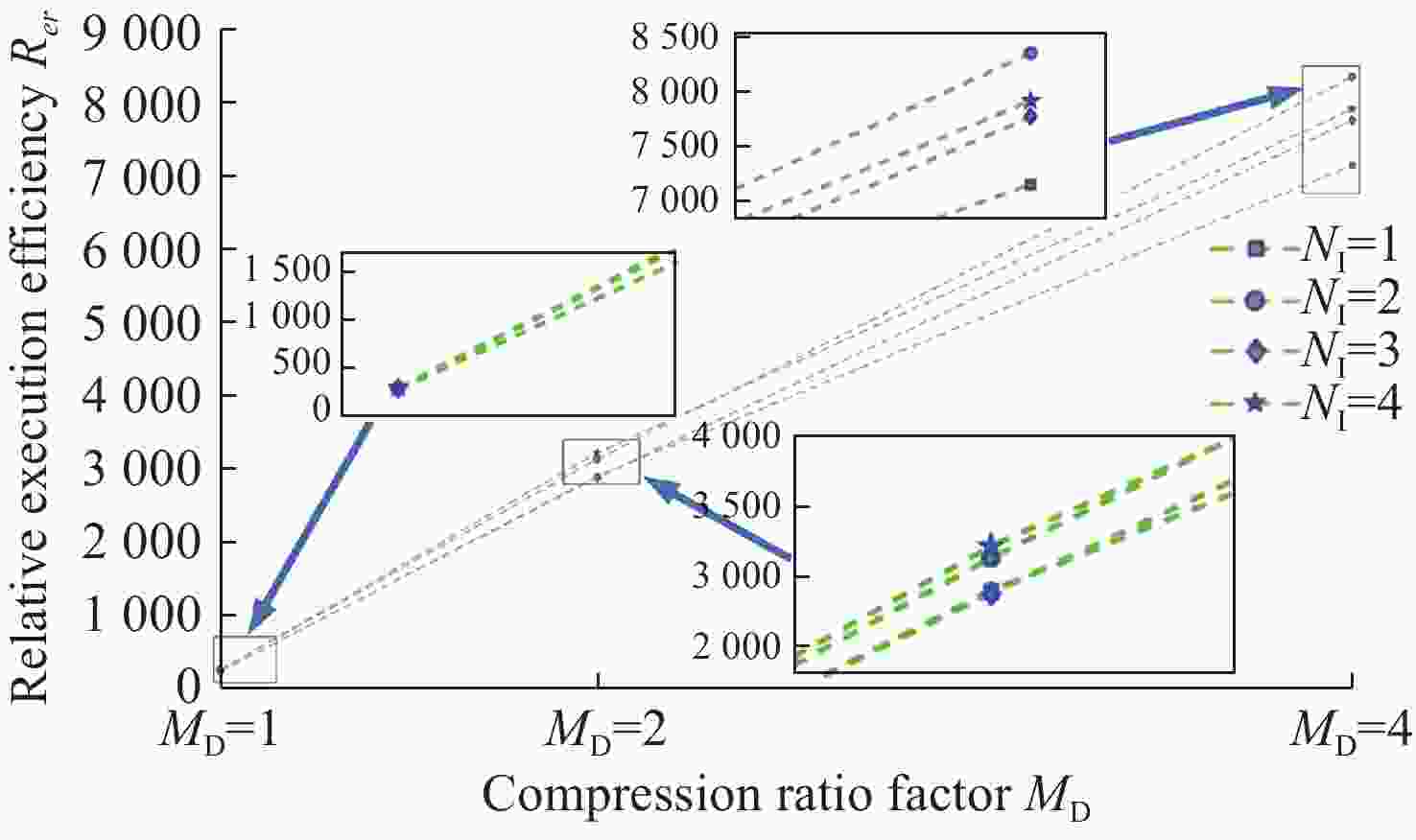

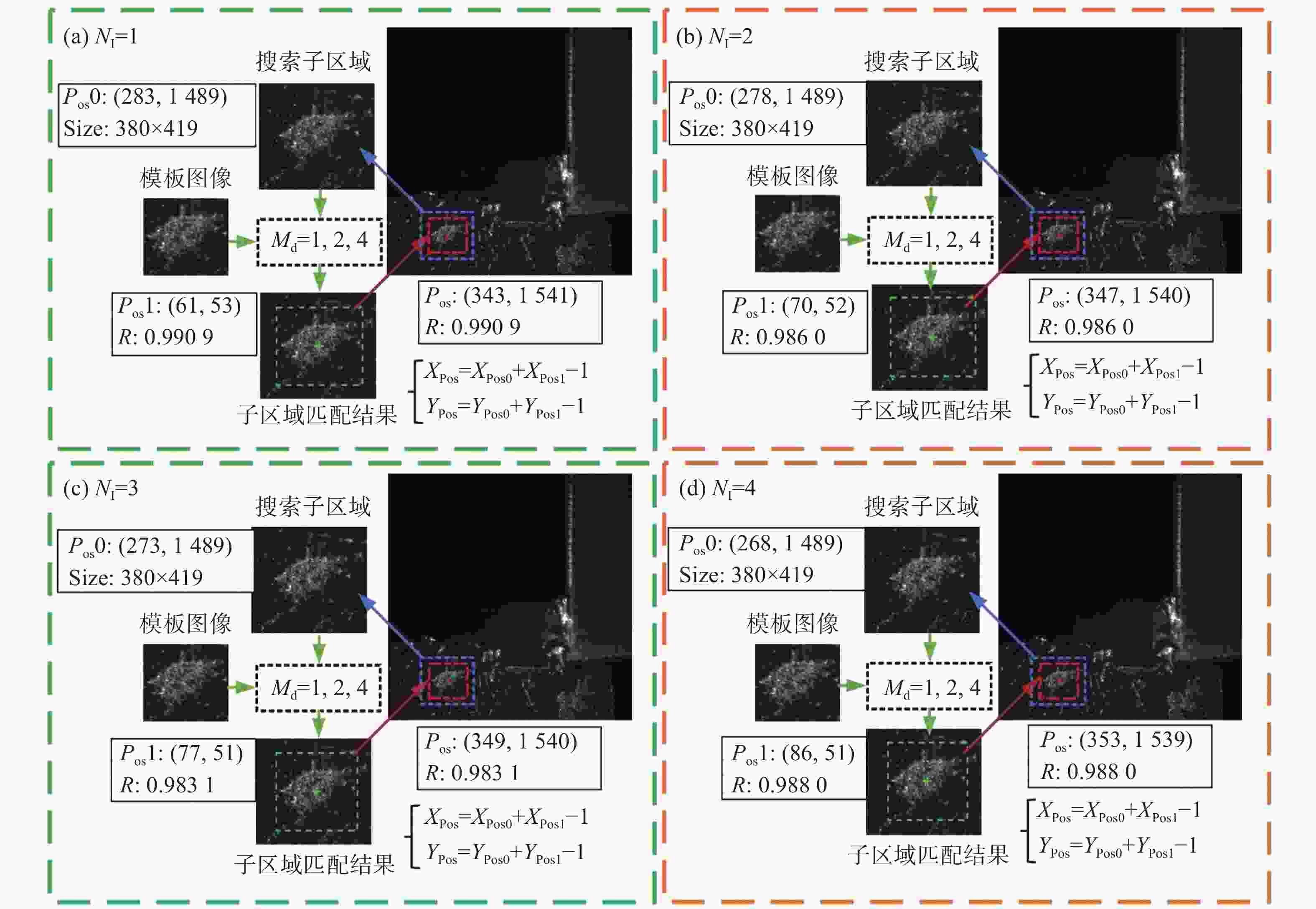

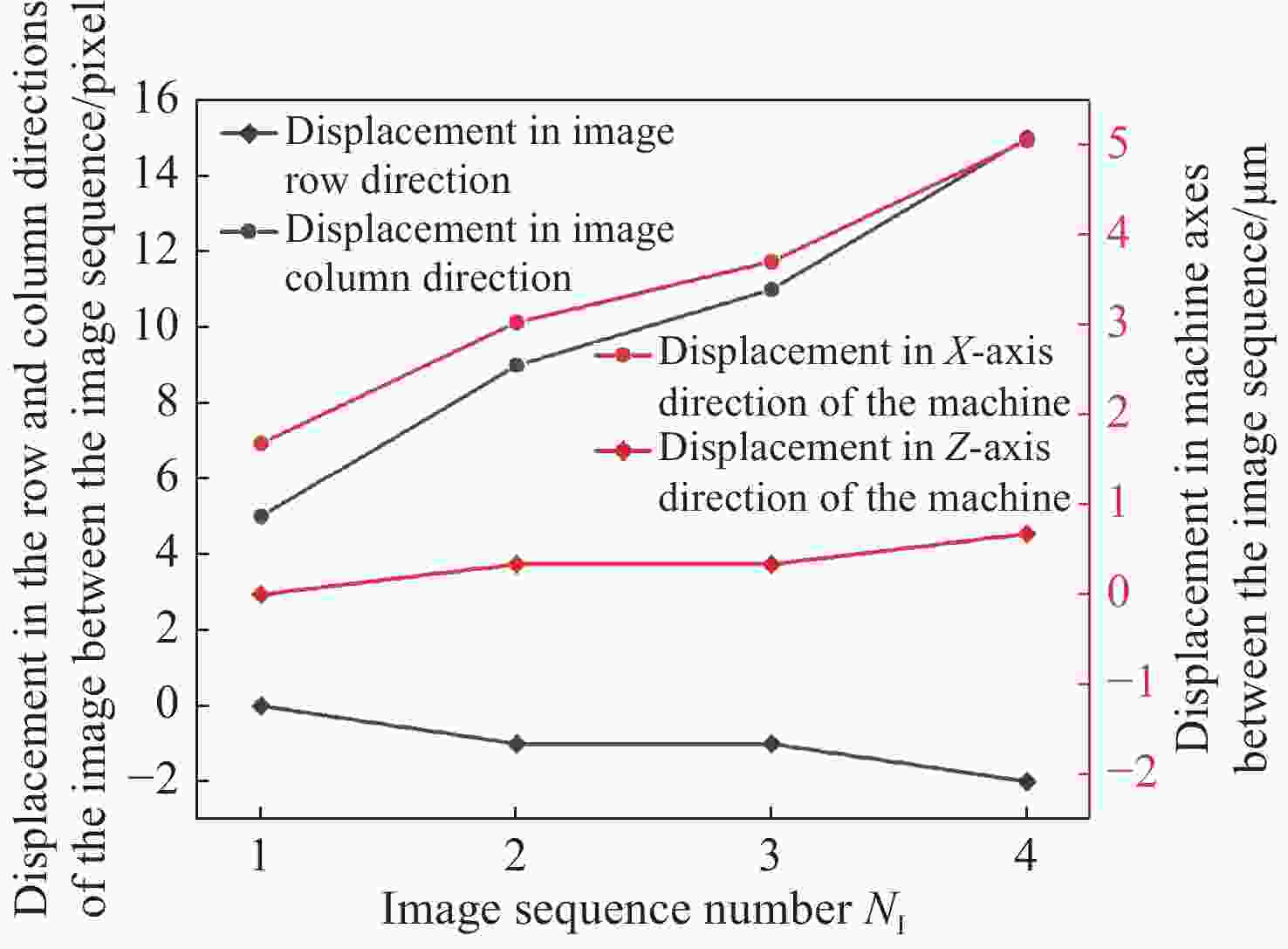

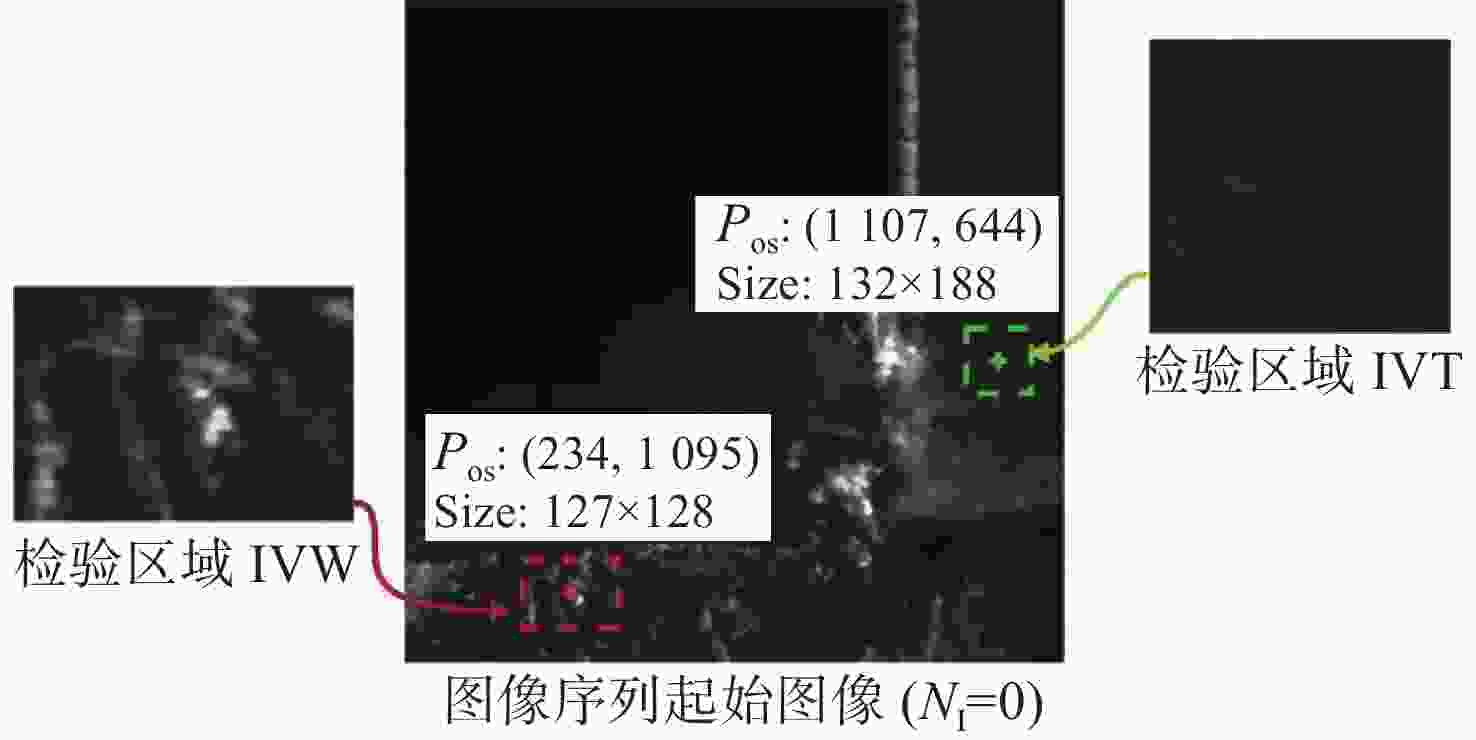

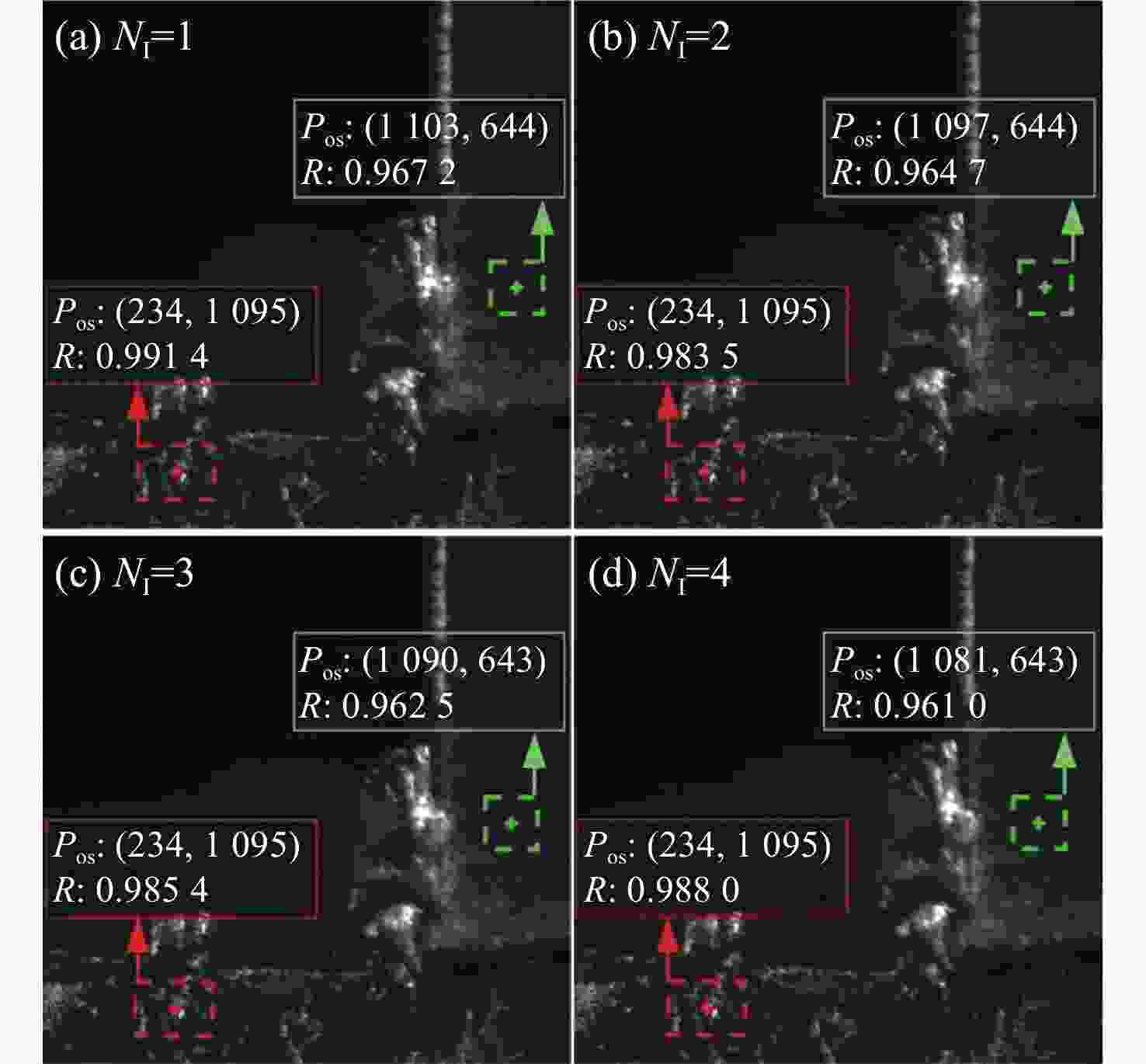

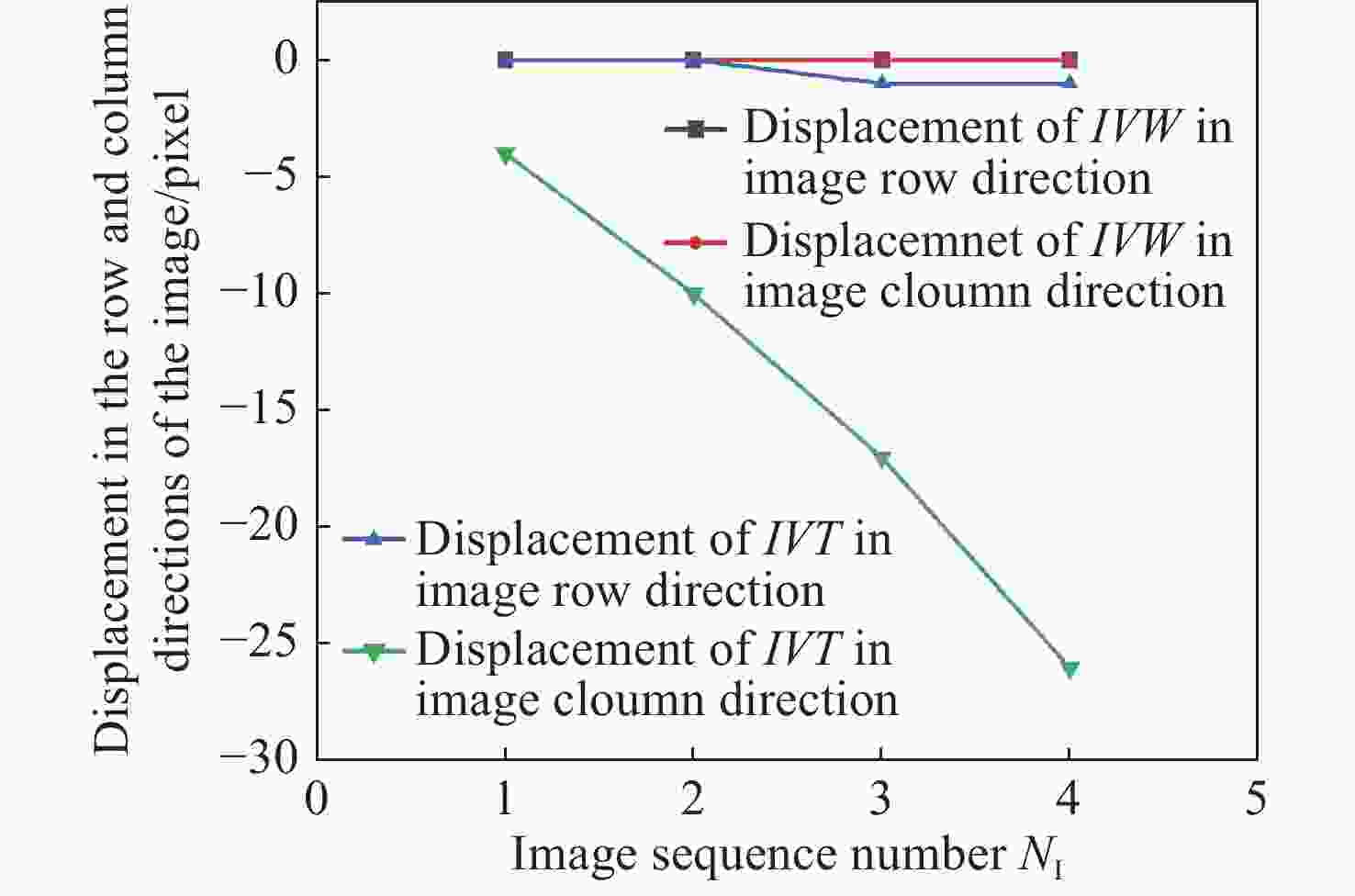

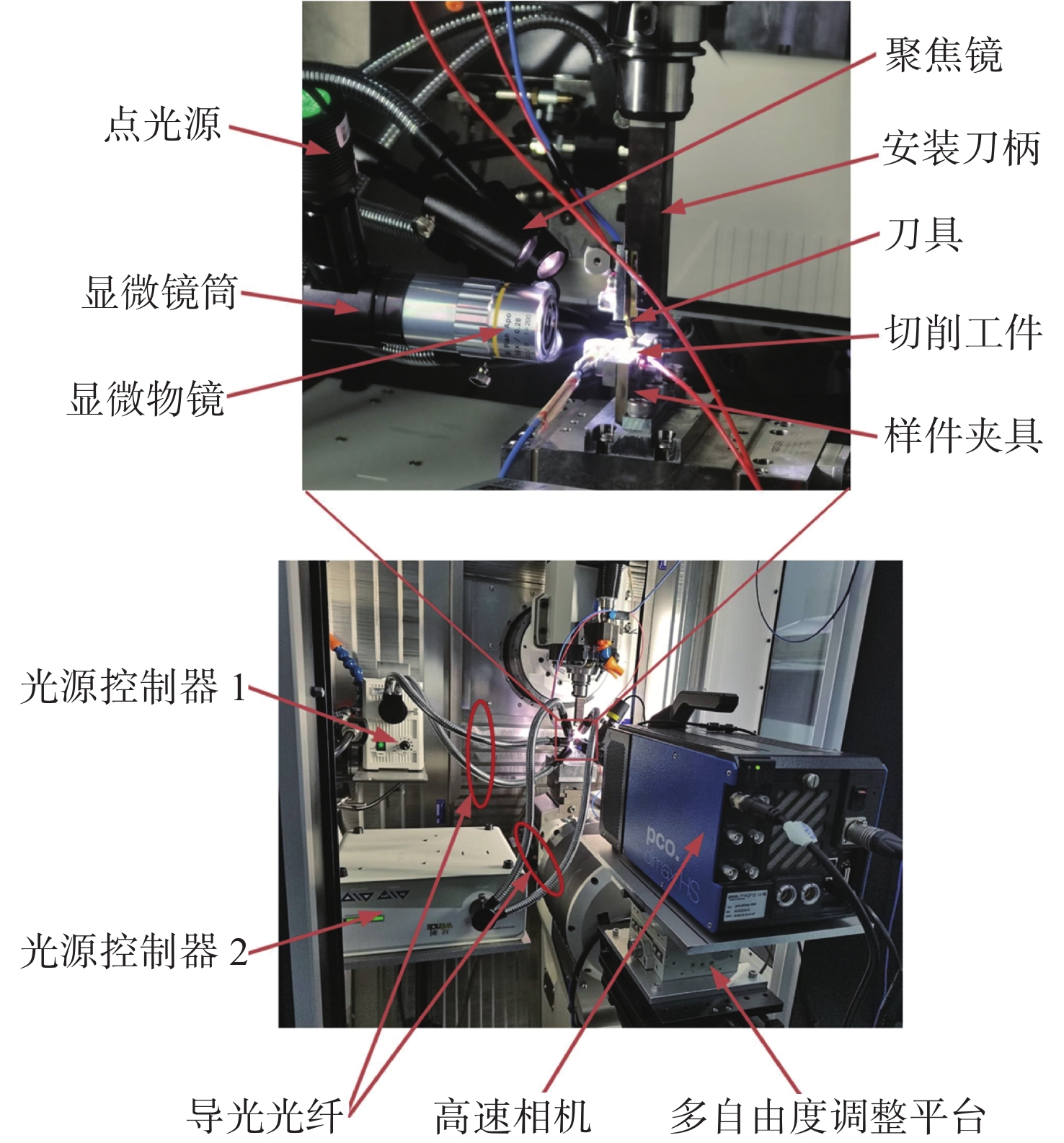

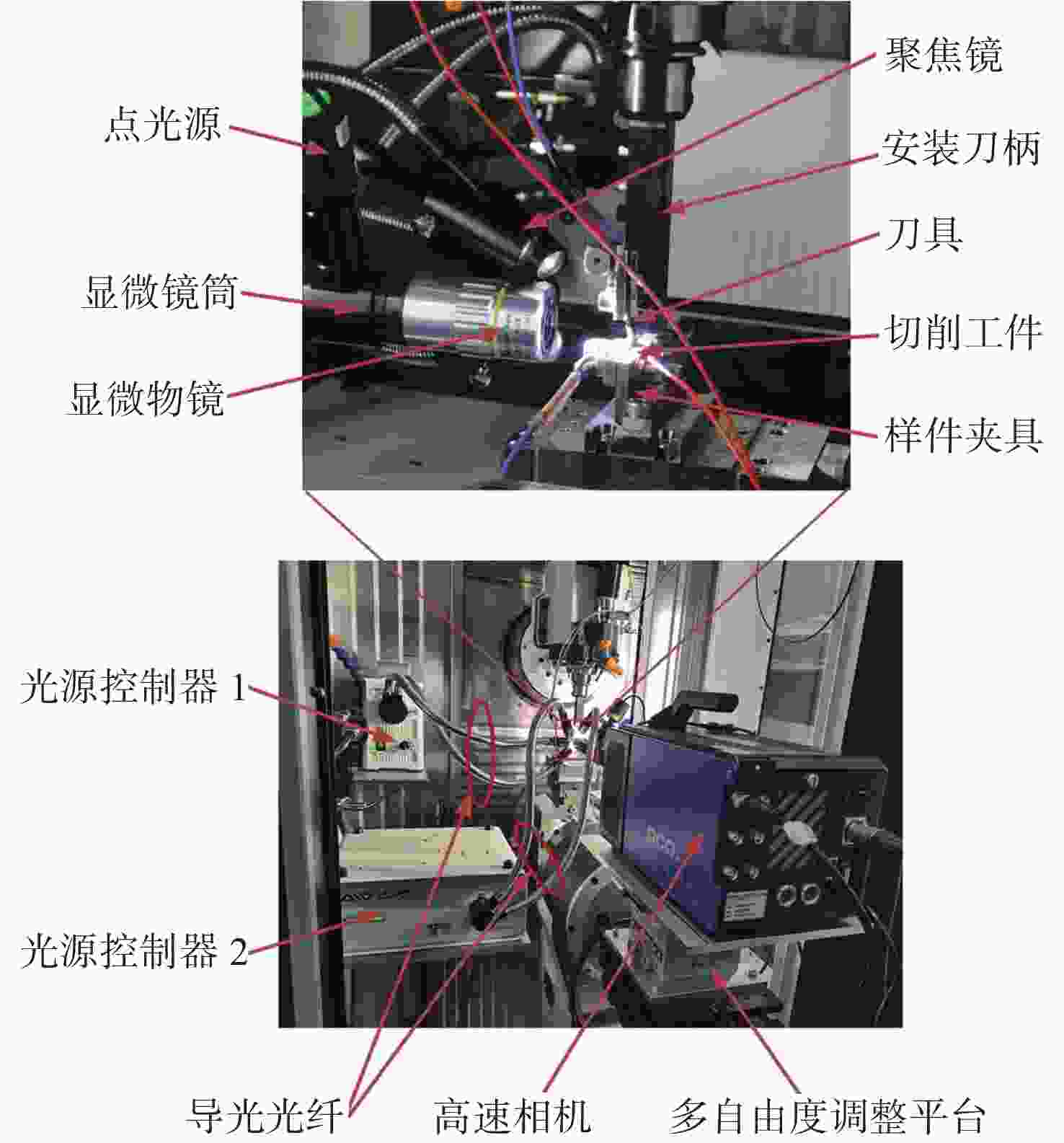

摘要: 原位观测和数字图像相关(DIC)分析法逐步在金属切削加工过程的塑性变形分析中得到广泛应用,其测量分析过程直观准确,已经成为一种主要的材料变形分析手段。为了在金属微细正交切削原位显微成像分析时,既能获得大观测视野又能使位移场分析结果清晰直观,本文提出改进型图像尺寸压缩匹配搜索算法对图像序列间的位移偏差进行检测补偿,将切削工况由工件做进给运动转化为刀具做进给运动。与归一化积相关匹配搜索算法进行对比验证,结果显示,所提出算法在大幅度提高执行效率的同时还具有很高的搜索精度。最后,在图像序列间选取两张图像进行位移偏差补偿以及变形区位移场DIC分析,结果显示本文补偿方法可以对工件进给运动和外界环境中振动引起的位移偏差进行有效补偿,使得变形区位移场分析结果中工件材料间的相对运动趋势更为直观。Abstract: In-situ observation and Digital Image Correlation (DIC) analysis have gradually been widely used in the analysis of plastic deformation in metal cutting processes and become a major means of material deformation analysis due to the intuitive and accurate process of measurement and analysis. In order to meet the demand of obtaining a large observation field and making the displacement field analysis results clear and intuitive when analyzing metal micro orthogonal cutting in-situ microscopy, we propose an improved image size compression matching algorithm to detect and compensate for the displacement deviation between image sequences, and transform the cutting condition from the workpiece to the tool to conduct the feed motion. In comparing with the normalized product correlation matching algorithm, it is concluded that the proposed image size compression matching algorithm can significantly improve the execution efficiency and achieve high search accuracy at the same time. Finally, two images are extracted from the image sequence, and the displacement deviation compensation and DIC analysis of the displacement field in the deformation zone are performed. It is concluded that the compensation method in this paper can effectively compensate for the displacement deviation caused by the feed motion of the workpiece and the vibration in the external environment, and make the relative motion trend between the sample materials in the deformation zone displacement field analysis more intuitive.

-

图 18 位移补偿前DIC分析变形区位移场分布结果。(a)列方向位移场变形参考图像中显示;(b)列方向位移场二维云图;(c)列方向位移场三维曲面图;(d)行方向位移场变形参考图像中显示;(e)行方向位移场二维云图;(f)行方向位移场三维曲面图

Figure 18. Displacement field distribution results of the deformation area without displacement compensation. (a) The column direction displacement field in the deformed reference image; (b) two-dimensional cloud map of the displacement field in the column direction; (c) surface plot of the column direction displacement field; (d) the row direction displacement field in the deformed reference image; (e) two-dimensional cloud map of the displacement field in the row direction; (f) surface plot of the row direction displacement field

图 19 位移补偿后变形区位移场分布结果。(a)列方向位移场变形参考图像中显示;(b)列方向位移场二维云图;(c)列方向位移场三维曲面图;(d)行方向位移场变形参考图像中显示;(e)行方向位移场二维云图;(f)行方向位移场三维曲面图

Figure 19. Displacement field distribution results of the deformation area with displacement compensation. (a) The column direction displacement field in the deformed reference image; (b) two-dimensional cloud map of the displacement field in the column direction; (c) surface plot of column direction displacement field; (d) the row direction displacement field in the deformed reference image; (e) two-dimensional cloud map of displacement field in the row direction; (f) surface plot of row direction displacement field

-

[1] 程凯, 霍德鸿. 微切削技术基础与应用[M]. 丁辉, 译. 北京: 机械工业出版社, 2015.CHENG K, HUO D H. Micro-Cutting Fundamentals and Applications[M]. DING H, trans. Beijing: Machinery Industry Press, 2015. (in Chinese) [2] CHAMBERS D. Digital Image Correlation: Advanced Methods and Applications[M]. New York: Nova Science Publishers, Inc, 2017. [3] LIN M T, SCIAMMARELLA C, ESPINOSA H D, et al. . Advancements in Optical Methods & Digital Image Correlation in Experimental Mechanics, Volume 3[M]. Cham: Society for Experimental Mechanics, Inc, 2020. [4] 胡悦, 王永红, 鲍思源, 等. 高温下数字图像相关散斑最优成像探究[J]. 中国光学,2018,11(5):728-735. doi: 10.3788/co.20181105.0728HU Y, WANG Y H, BAO S Y, et al. Optimal imaging of digital image correlation speckle under high temperature[J]. Chinese Optics, 2018, 11(5): 728-735. (in Chinese) doi: 10.3788/co.20181105.0728 [5] 胡慧然, 但西佐, 赵琪涵, 等. 数字图像相关中的散斑区域自动提取研究[J]. 中国光学,2019,12(6):1329-1337. doi: 10.3788/co.20191206.1329HU H R, DAN X Z, ZHAO Q H, et al. Automatic extraction of speckle area in digital image correlation[J]. Chinese Optics, 2019, 12(6): 1329-1337. (in Chinese) doi: 10.3788/co.20191206.1329 [6] 张贵阳, 霍炬, 杨明, 等. 多相机网络联合约束优化的高精度三维变形全场测量[J]. 光学 精密工程,2021,29(7):1653-1666. doi: 10.37188/OPE.20212907.1653ZHANG G Y, HUO J, YANG M, et al. High-precision and full-field measurement of 3D deformation based on multi-camera network joint constraint optimization[J]. Optics and Precision Engineering, 2021, 29(7): 1653-1666. (in Chinese) doi: 10.37188/OPE.20212907.1653 [7] 王立忠, 赵建博, 谈杰, 等. 高强钢薄板高温焊接变形的视觉测量[J]. 光学 精密工程,2020,28(2):283-295.WANG L ZH, ZHAO J B, TAN J, et al. Visual measurement of high-temperature welding deformation for high-strength steel sheet[J]. Optics and Precision Engineering, 2020, 28(2): 283-295. (in Chinese) [8] 陈小琦, 张可, 聂广超, 等. 基于切削原位成像法的45钢塑性本构参数辨识[J]. 航空制造技术,2021,64(13):90-95.CHEN X Q, ZHANG K, NIE G CH, et al. Identification of plastic constitutive parameters of 45 steel based on in-situ imaging of cutting process[J]. Aeronautical Manufacturing Technology, 2021, 64(13): 90-95. (in Chinese) [9] 张东. 基于切削原位成像的加工应力应变场预报研究[D]. 武汉: 华中科技大学, 2019.ZHANG D. In situ imaging of cutting process and prediction of strain/stress fields[D]. Wuhan: Huazhong University of Science and Technology, 2019. (in Chinese) [10] HARZALLAH M, POTTIER T, GILBLAS R, et al. A coupled in-situ measurement of temperature and kinematic fields in Ti-6Al-4V serrated chip formation at micro-scale[J]. International Journal of Machine Tools and Manufacture, 2018, 130-131: 20-35. doi: 10.1016/j.ijmachtools.2018.03.003 [11] 郭振民. 多晶体金属微切削动态过程在位分析[D]. 长春: 长春理工大学, 2021.GUO ZH M. In situ analysis of dynamic process of polycrystalline metal micro cutting[D]. Changchun: Changchun University of Science and Technology, 2021. (in Chinese) [12] YANG J, BHATTACHARYA K. Augmented Lagrangian digital image correlation[J]. Experimental Mechanics, 2019, 59(2): 187-205. doi: 10.1007/s11340-018-00457-0 [13] 周栋. 晶圆定位视觉检测系统设计[D]. 沈阳: 沈阳工业大学, 2019.ZHOU D. Design of wafer positioning visual inspection system[D]. Shenyang: Shenyang University of Technology, 2019. (in Chinese) [14] 吕福超. 基于傅里叶变换轮廓术的地表沉降监测技术研究[D]. 西安: 西安科技大学, 2017.LV F CH. Research on monitoring technology of ground settlement based on Fourier transform profilometry[D]. Xi’an: Xi’an University of Science and Technology, 2017. (in Chinese) -

下载:

下载: