Large-scale splicing focal plane error distribution based on optical-structural-thermal integration analysis

-

摘要:

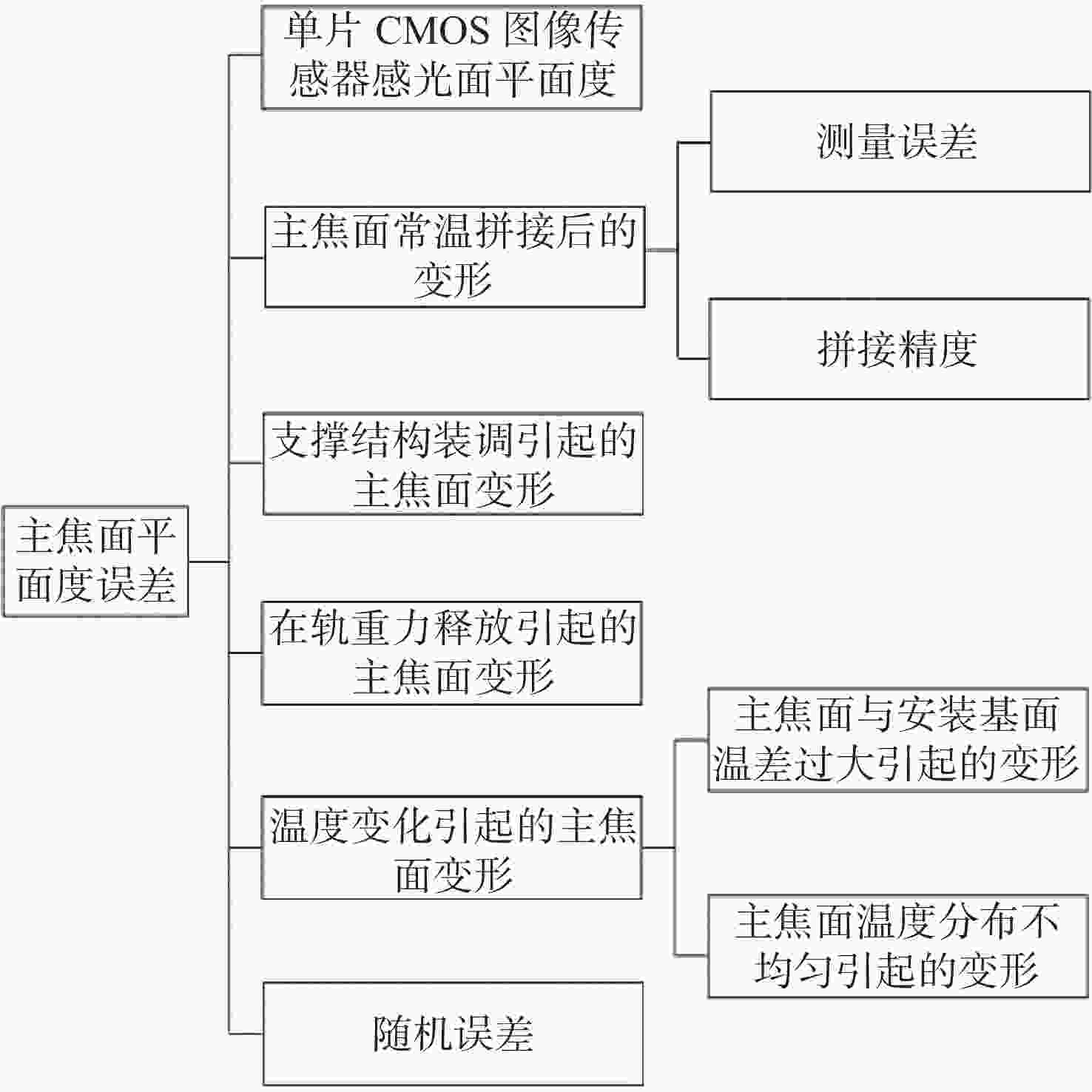

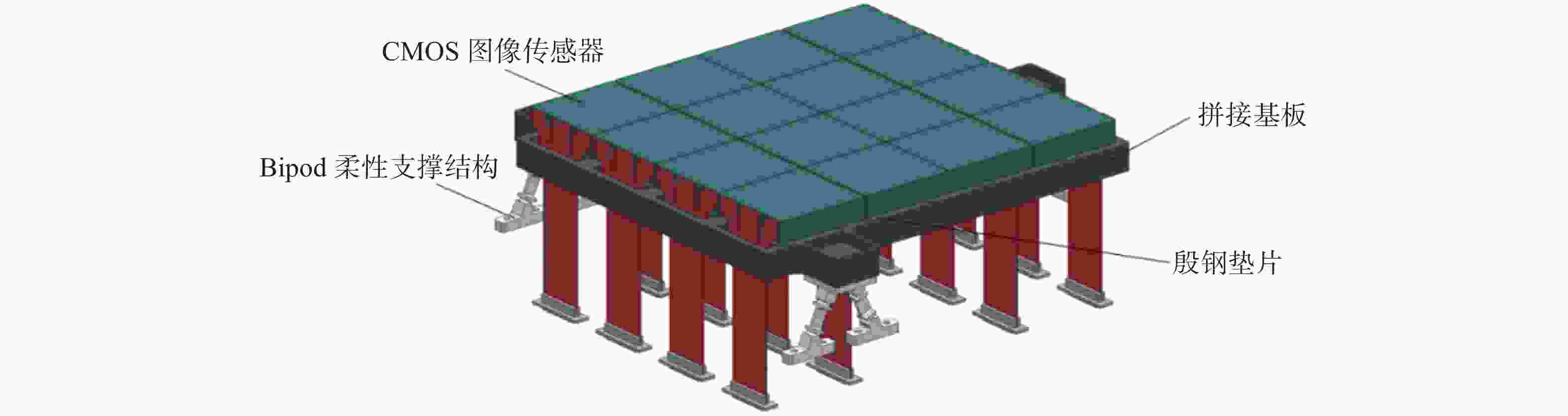

随着空间天文、态势感知、环境监测等领域的要求越来越高,空间望远镜正在向着大视场、大口径的方向发展。大规模焦面拼接技术是大视场空间望远镜的关键技术,其主焦面平面度误差(

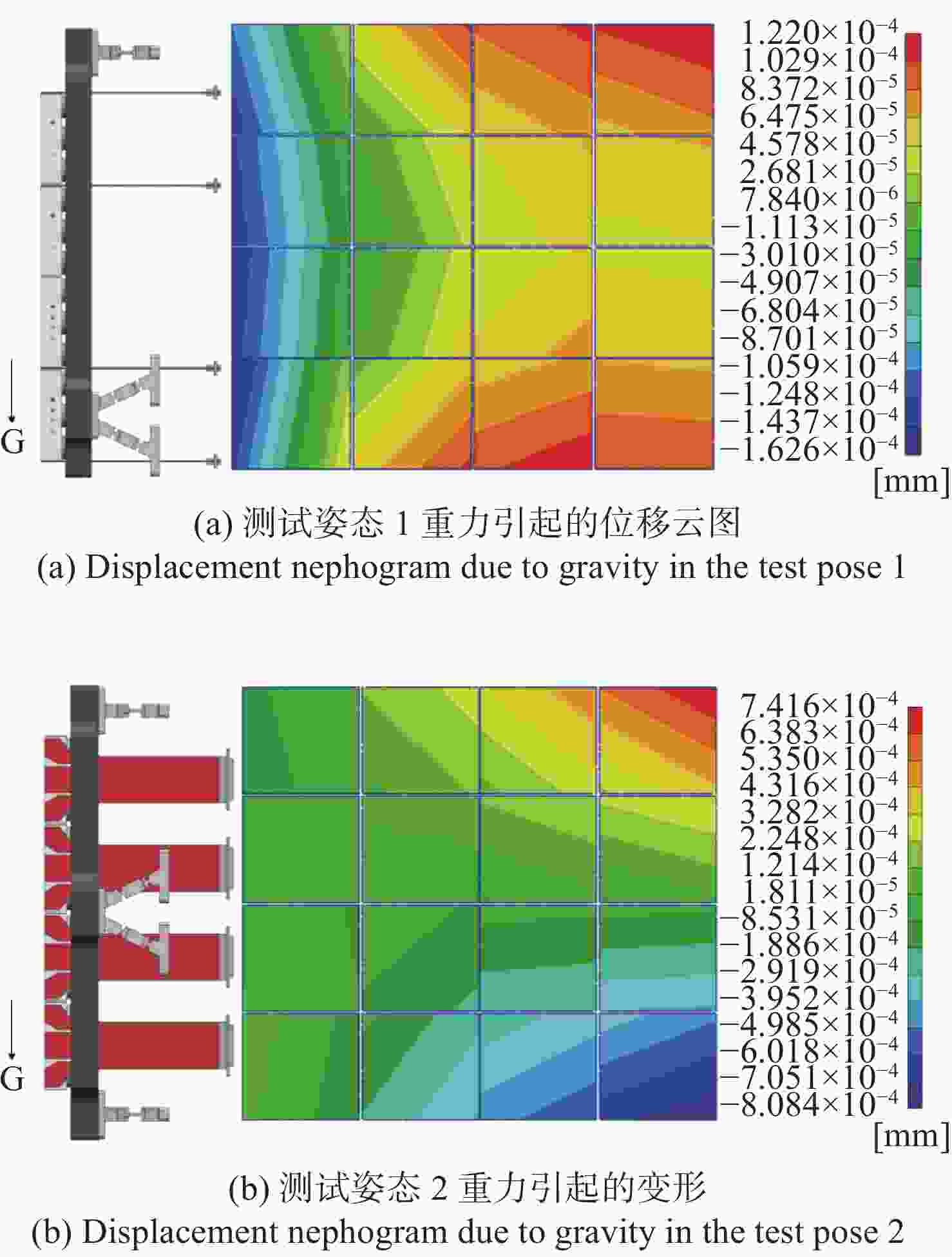

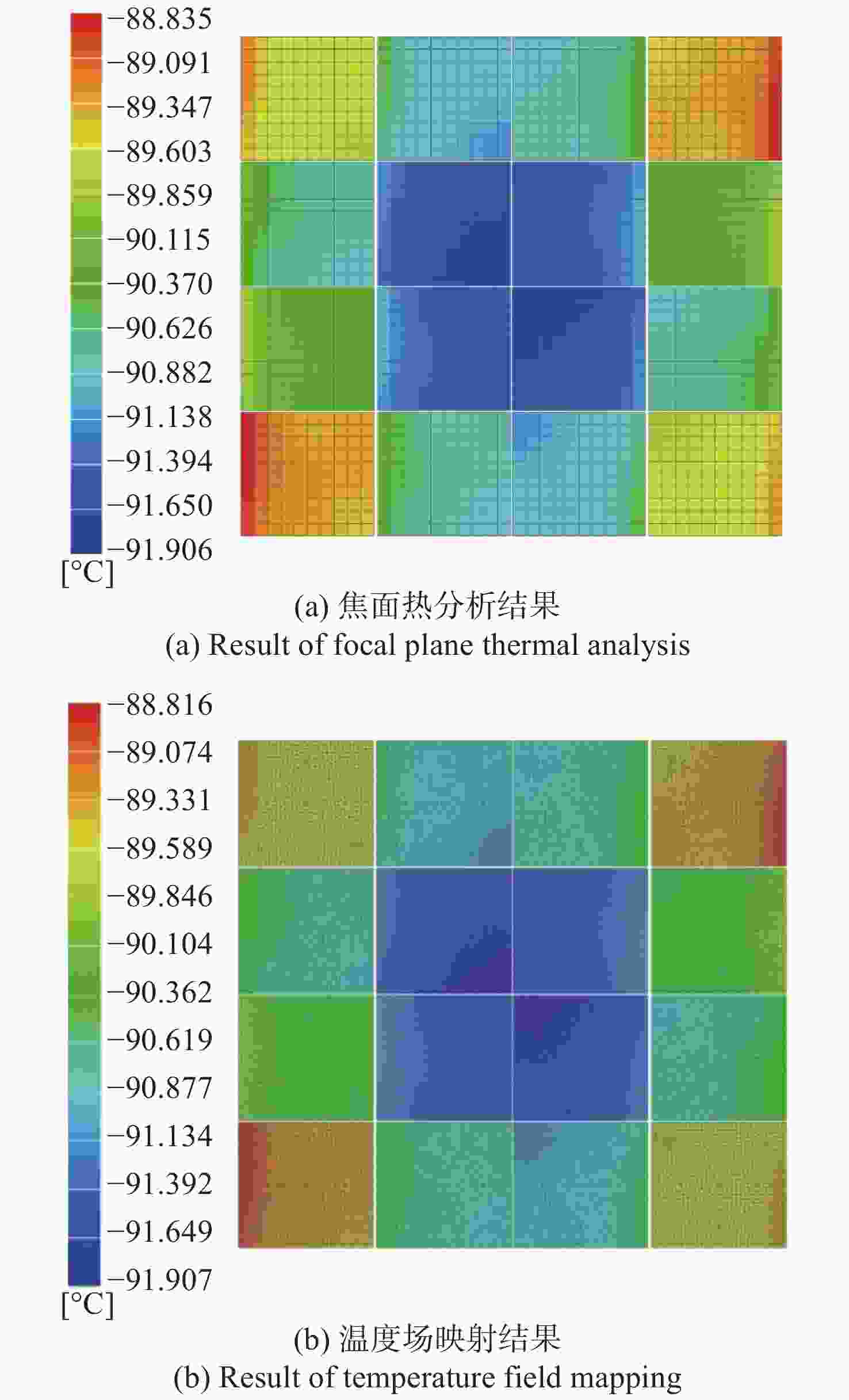

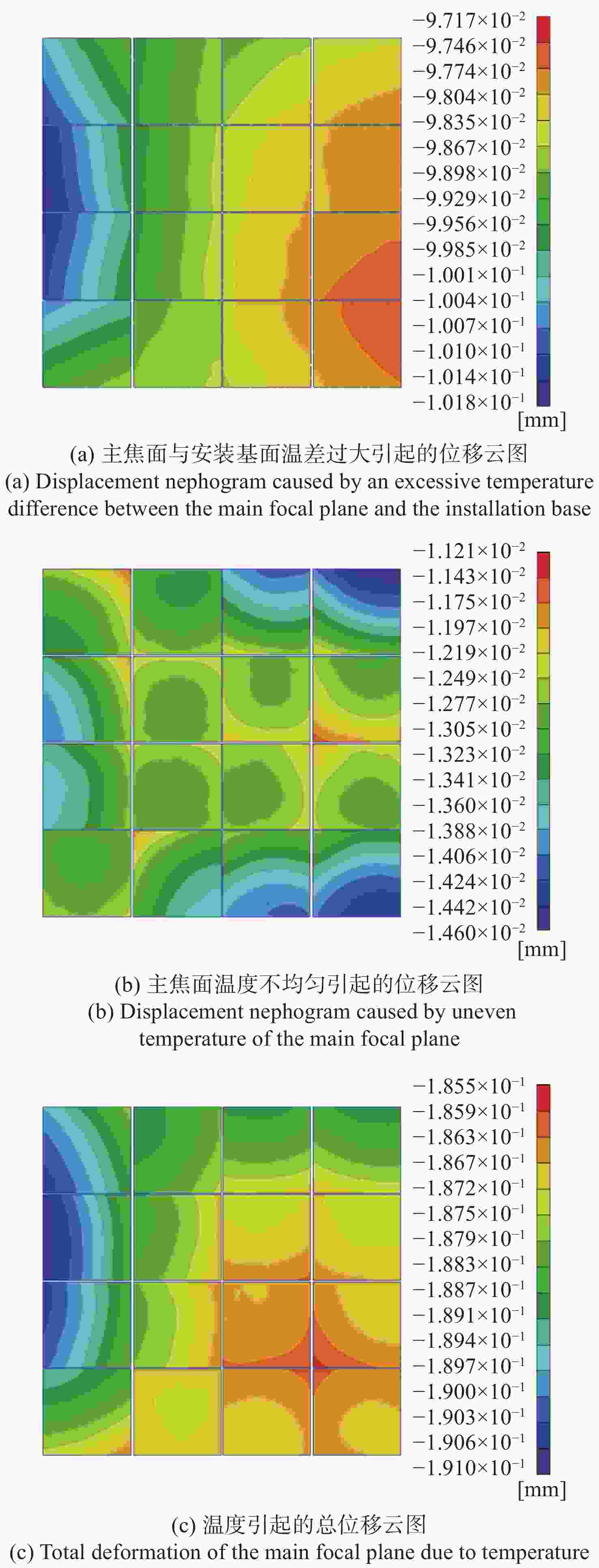

P -V 值)分配方法一般都是基于经验的直接赋值法,容易出现误差分配不合理的问题。本文提出一种拼接焦面误差分配方法,通过光机热集成分析对重要参数误差进行精确分配。以16片互补金属氧化物半导体 (CMOS)图像传感器4×4机械直接拼接焦面为例,建立了拼接焦面误差树,通过光机热集成分析方法分析了重力和温度等重要参数对拼接焦面平面度的影响,最终给出误差分配结果。分析结果表明:两种不同姿态下重力造成的平面度误差分别为0.28 μm、1.55 μm,温度造成的平面度总误差为5.5 μm,留30%余量后,确定重力和温度引起的平面度误差分配值分别为2 μm和7.2 μm。Abstract:As the requirements of space astronomy, situational awareness, environmental monitoring and other fields grow higher, space telescopes are developing toward large fields of view and large apertures. Large-scale focal plane stitching technology is the key technology of large-field space telescopes. The allocation method of the main focal plane flatness error (

P -V value) is generally a direct assignment method based on experience, which is prone to unreasonable error allocation.In this paper, a method of splicing focal plane error allocation is proposed, which can accurately allocate important parameter errors through optical-structural-thermal integration analysis. Taking 4×4 mechanical direct splicing focal plane with 16 pieces of Complementary Metal Oxide Semiconductor(CMOS) image sensor as an example, an error tree of splicing focal planes is established. The influence of important parameters such as gravity and temperature on the flatness of splicing focal plane is analyzed by the method of optical-structural-thermal integration analysis. The error distribution result is finally given. The analysis shows that the flatness errors caused by gravity under two different attitudes are 0.28 μm and 1.55 μm respectively, and the total flatness error caused by temperature is 5.5 μm. After leaving a 30% margin, the assigned values of the flatness error caused by gravity and temperature are determined to be 2 μm and 7.2 μm, respectively. -

表 1 误差分配结果

Table 1. Results of the error distribution

误差项 范围/μm 仿真结果/μm 单片CMOS图像传感器感光面平面度 ≤20 − 主焦面常温拼接后的变形:

(a) 测量误差;

(b) 拼接精度≤8.5 − 支撑结构装调引起的主焦面变形 ≤2 − 在轨重力释放引起的主焦面变形 ≤2 1.55 温度引起的主焦面变形:

(a) 主焦面与安装基面温差过大;

(b) 主焦面温度分布不均匀≤7.2 5.5 随机误差 ≤0.5 − 合计 ≤40.2 − -

[1] 方成, 顾伯忠, 袁祥岩, 等. 2.5 m大视场高分辨率望远镜[J]. 中国科学:物理学 力学 天文学,2019,49(5):059603.FANG CH, GU B ZH, YUAN X Y, et al. 2.5 m wide-field and high-resolution telescope[J]. Scientia Sinica Physica,Mechanica &Astronomica, 2019, 49(5): 059603. (in Chinese) [2] 李宗轩, 金光, 张雷, 等. 3.5m口径空间望远镜单块式主镜技术展望[J]. 中国光学,2014,7(4):532-541.LI Z X, JIN G, ZHANG L, et al. Overview and outlook of monolithic primary mirror of spaceborne telescope with 3.5 m aperture[J]. Chinese Optics, 2014, 7(4): 532-541. (in Chinese) [3] 曹小涛, 孙天宇, 赵运隆, 等. 空间大口径望远镜稳像系统发展现状及趋势[J]. 中国光学,2014,7(5):739-748.CAO X T, SUN T Y, ZHAO Y L, et al. Current status and development tendency of image stabilization system of large aperture space telescope[J]. Chinese Optics, 2014, 7(5): 739-748. (in Chinese) [4] SAKO T, SEKIGUCHI T, SASAKI M, et al. MOA-cam3: a wide-field mosaic CCD camera for a gravitational microlensing survey in New Zealand[J]. Experimental Astronomy, 2008, 22(1): 51-66. [5] OLIVIER S S, SEPPALA L, GILMORE K, et al. LSST camera optics[J]. Proceedings of SPIE, 2006, 6273: 62730Y. doi: 10.1117/12.673235 [6] OBUCHI Y, KOMIYAMA Y, KAMATA Y, et al. Hyper Suprime-Cam: implementation and performance of the cryogenic Dewar[J]. Proceedings of SPIE, 2012, 8446: 84466Q. doi: 10.1117/12.926961 [7] KOMIYAMA Y, OBUCHI Y, NAKAYA H, et al. Hyper Suprime-Cam: camera Dewar design[J]. Publications of the Astronomical Society of Japan, 2018, 70(SP1): S2. [8] RASMUSSEN A P, HALE L, KIM P, et al. Focal plane metrology for the LSST camera[J]. Proceedings of SPIE, 2006, 6273: 62732U. doi: 10.1117/12.673210 [9] TAKACS P Z, O'CONNOR P, RADEKA V, et al. LSST detector module and raft assembly metrology concepts[J]. Proceedings of SPIE, 2006, 6273: 62733Q. doi: 10.1117/12.673399 [10] ROBBINS M S, BASTABLE M, BATES A, et al. Performance of the e2v 1.2 GPix cryogenic camera for the J-PAS 2.5m survey telescope[J]. Proceedings of SPIE, 2016, 9908: 990811. doi: 10.1117/12.2234626 [11] TAYLOR K, MARÍN-FRANCH A, LAPORTE R, et al. JPCAM: a 1.2 GPIXEL camera for the J-PAS survey[J]. Journal of Astronomical Instrumentation, 2014, 3(1): 1350010. doi: 10.1142/S2251171713500104 [12] PRATLONG J, WANG S Y, LEHNER M, et al. A 9 megapixel large-area back-thinned CMOS sensor with high sensitivity and high frame-rate for the TAOS II program[J]. Proceedings of SPIE, 2016, 9915: 991514. [13] WANG S Y, GEARY J C, AMATO S M, et al. High speed wide field CMOS camera for transneptunian automatic occultation survey[J]. Proceedings of SPIE, 2014, 9147: 914772. [14] 温敬阳. 光机热集成分析方法与技术研究[D]. 西安: 西安电子科技大学, 2008.WEN J Y. Research on methods and techniques of optomechanical integrated analysis[D]. Xi’an: Xidian University, 2008. (in Chinese) [15] 王增伟, 赵知诚, 杨溢, 等. 基于刚体运动完备方程的光机热集成分析方法[J/OL]. 红外与激光工程, (2021-11-11). http://kns.cnki.net/kcms/detail/12.1261.TN.20211110.1706.004.html.WANG Z W, ZHAO ZH CH, YANG Y, et al. . Thermal-structural-optical integrated analysis method based on the complete equations of rigid body motion[J/OL]. Infrared and Laser Engineering, (2021-11-11). http://kns.cnki.net/kcms/detail/12.1261.TN.20211110.1706.004.html. (in Chinese) [16] 赵晓东, 王晶. 米级口径经纬仪保护窗口镜面变形分析[J]. 中国光学,2018,11(4):654-661. doi: 10.3788/co.20181104.0654ZHAO X D, WANG J. Analysis of the mirror deformation of one-meter theodolite protective window[J]. Chinese Optics, 2018, 11(4): 654-661. (in Chinese) doi: 10.3788/co.20181104.0654 [17] 张丽敏, 王富国, 安其昌, 等. Bipod柔性结构在小型反射镜支撑中的应用[J]. 光学 精密工程,2015,23(2):438-443. doi: 10.3788/OPE.20152302.0438ZHANG L M, WANG F G, AN Q CH, et al. Application of Bipod to supporting Structure of minitype reflector[J]. Optics and Precision Engineering, 2015, 23(2): 438-443. (in Chinese) doi: 10.3788/OPE.20152302.0438 [18] 明名, 王建立, 张景旭, 等. 大口径望远镜光学系统的误差分配与分析[J]. 光学 精密工程,2009,17(1):104-108.MING M, WANG J L, ZHANG J X, et al. Error budget and analysis for optical system in large telescope[J]. Optics and Precision Engineering, 2009, 17(1): 104-108. (in Chinese) -

下载:

下载: