Development and algorithm research of optical alignment system for a high precision flip chip bonder

-

摘要:

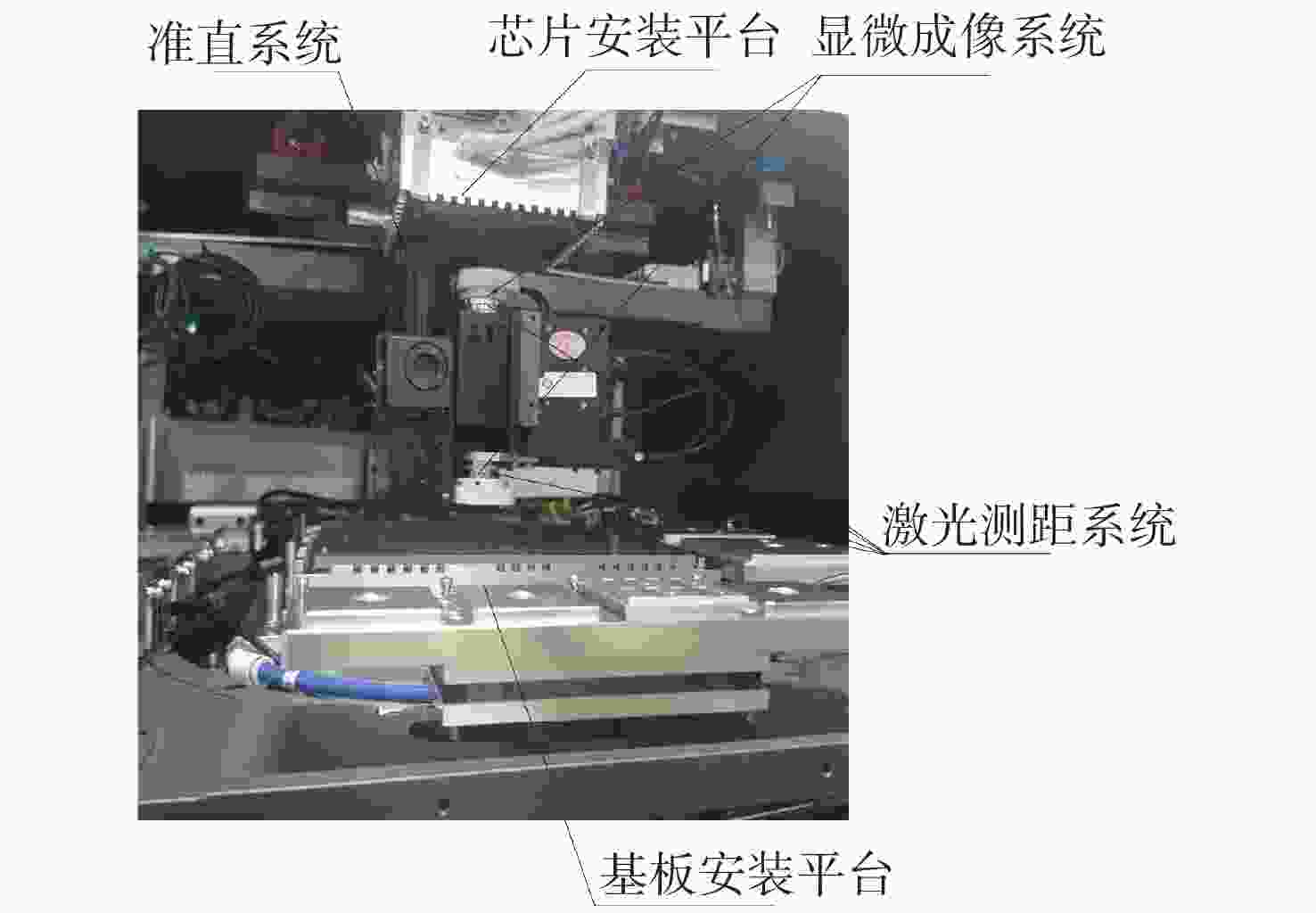

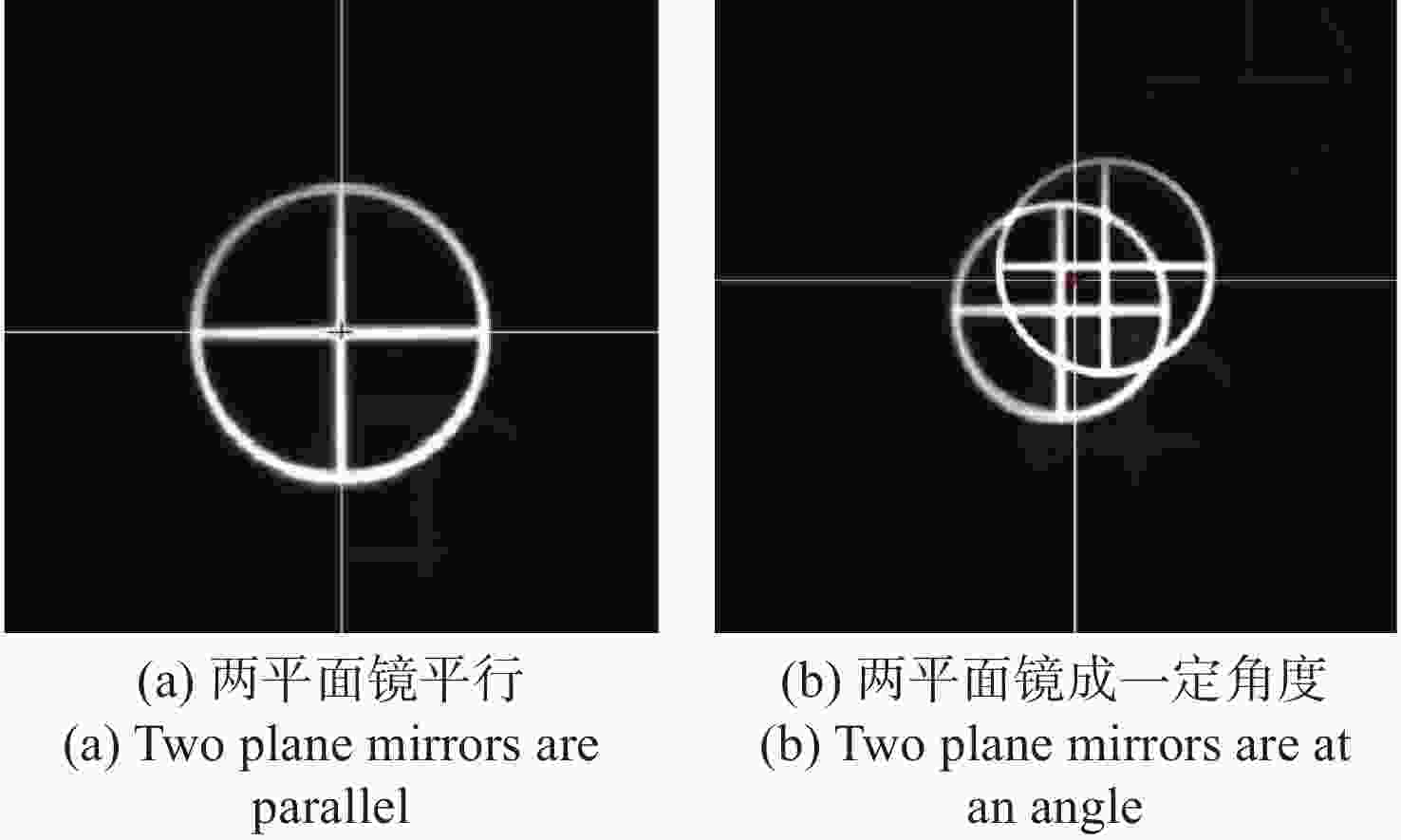

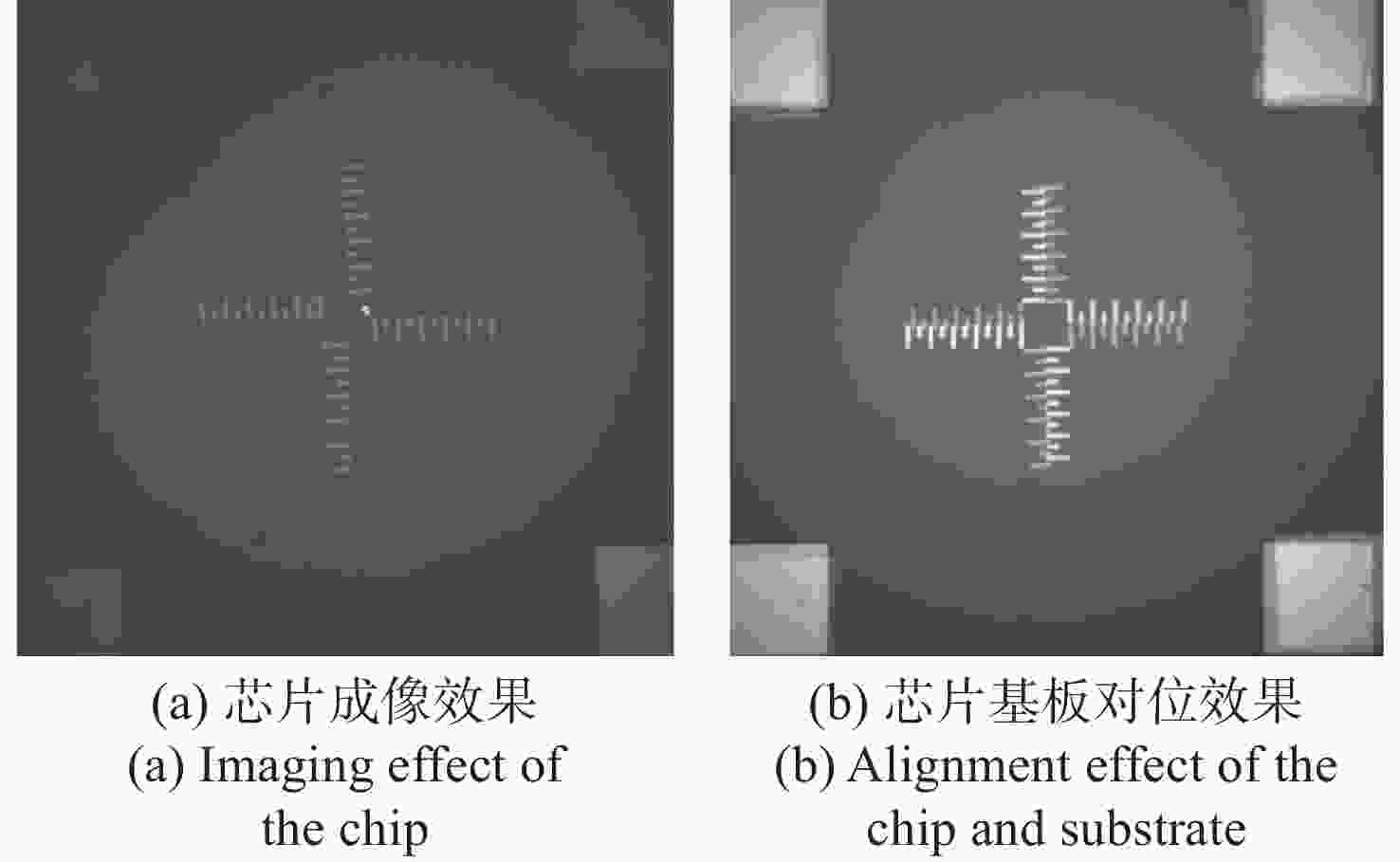

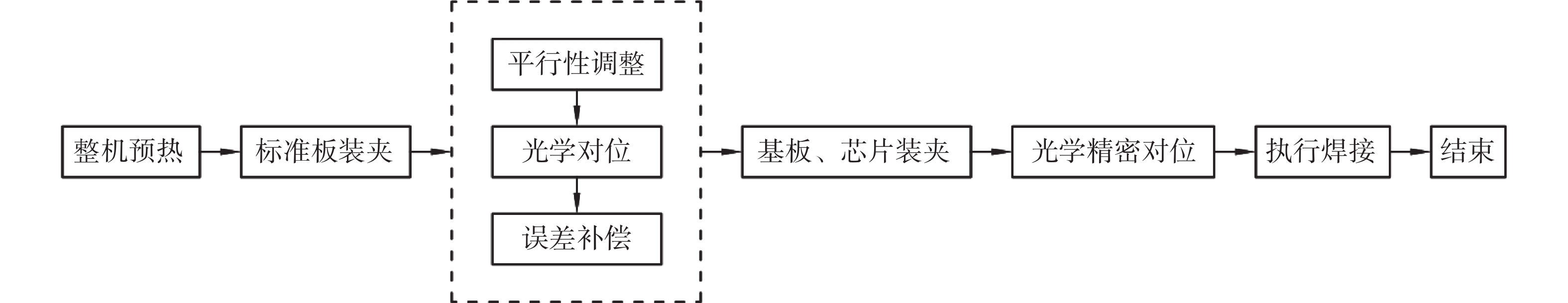

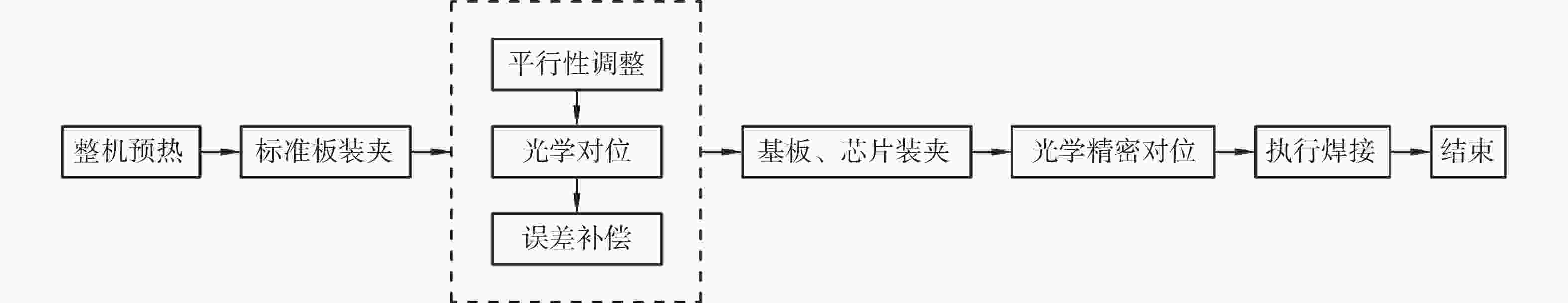

针对国内红外焦平面倒装焊机对高精度光学对位系统的迫切需求,对光学对位系统进行了设计及验证,并对该系统用到的平行调整、光学对位及坐标系误差补偿算法进行研究。文章首先对倒装焊接光学对位工艺进行分析;然后对平行性调整及光学对位算法进行介绍,并根据光学对位系统测试流程,提出更加合理的误差补偿算法;最后,以上述算法为理论依据,设计光学对位系统,其包括准直系统、显微成像系统和激光测距三部分。所设计的光学系统可实现平行性粗调,特征点识别及平行性精调功能。试验结果表明,准直系统准直效果较好,显微成像系统分辨率高,成像质量较好,激光测距系统的测距精度为0.084 μm。设计的高精度光学对位系统解决了国内红外焦平面倒装焊机对高精度光学对位系统的迫切需求,已经在国内某型号的倒装焊机中得到应用,对于提高国产高端集成电路的自主研发和生产能力具有非常重要的意义。

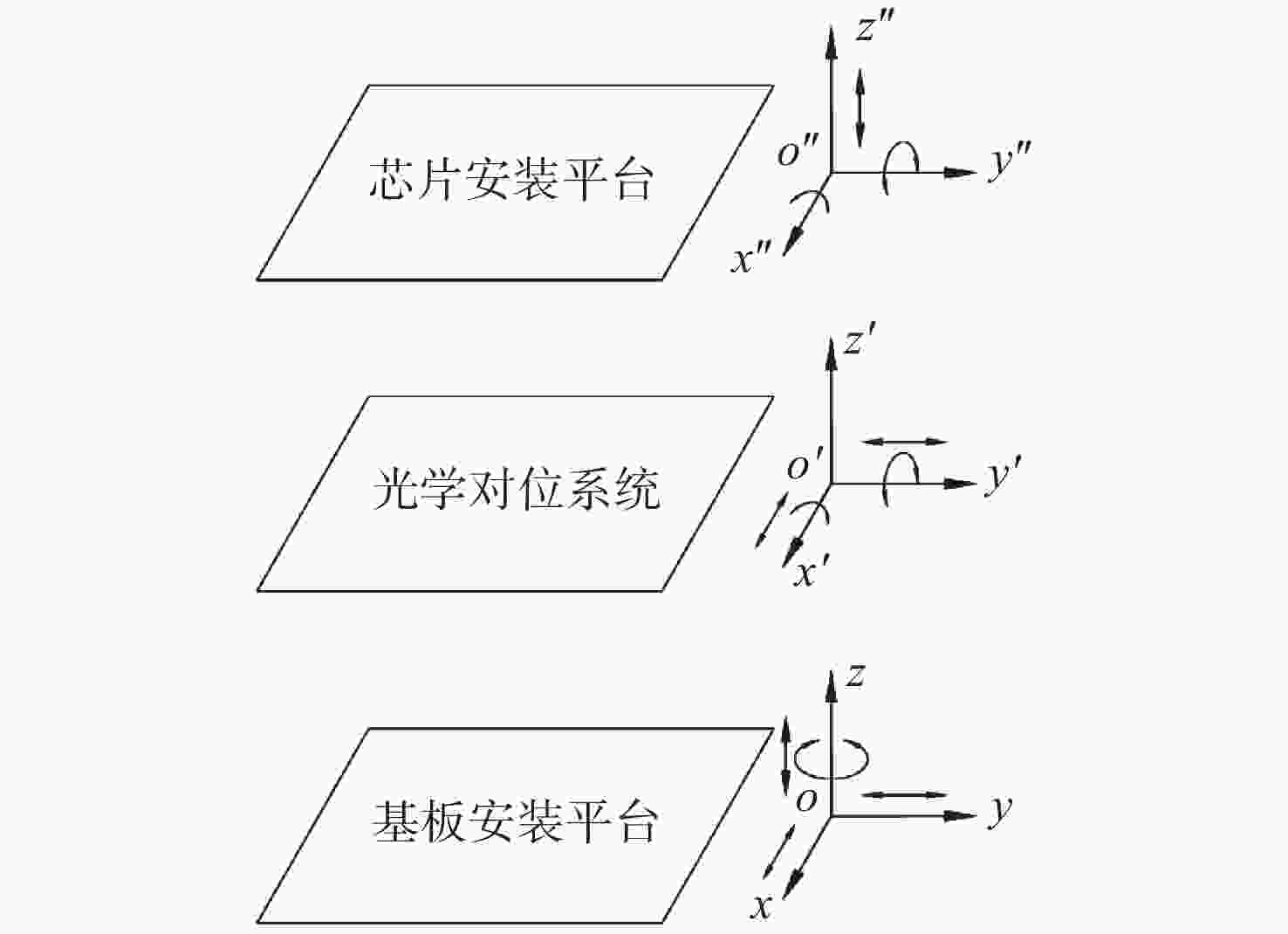

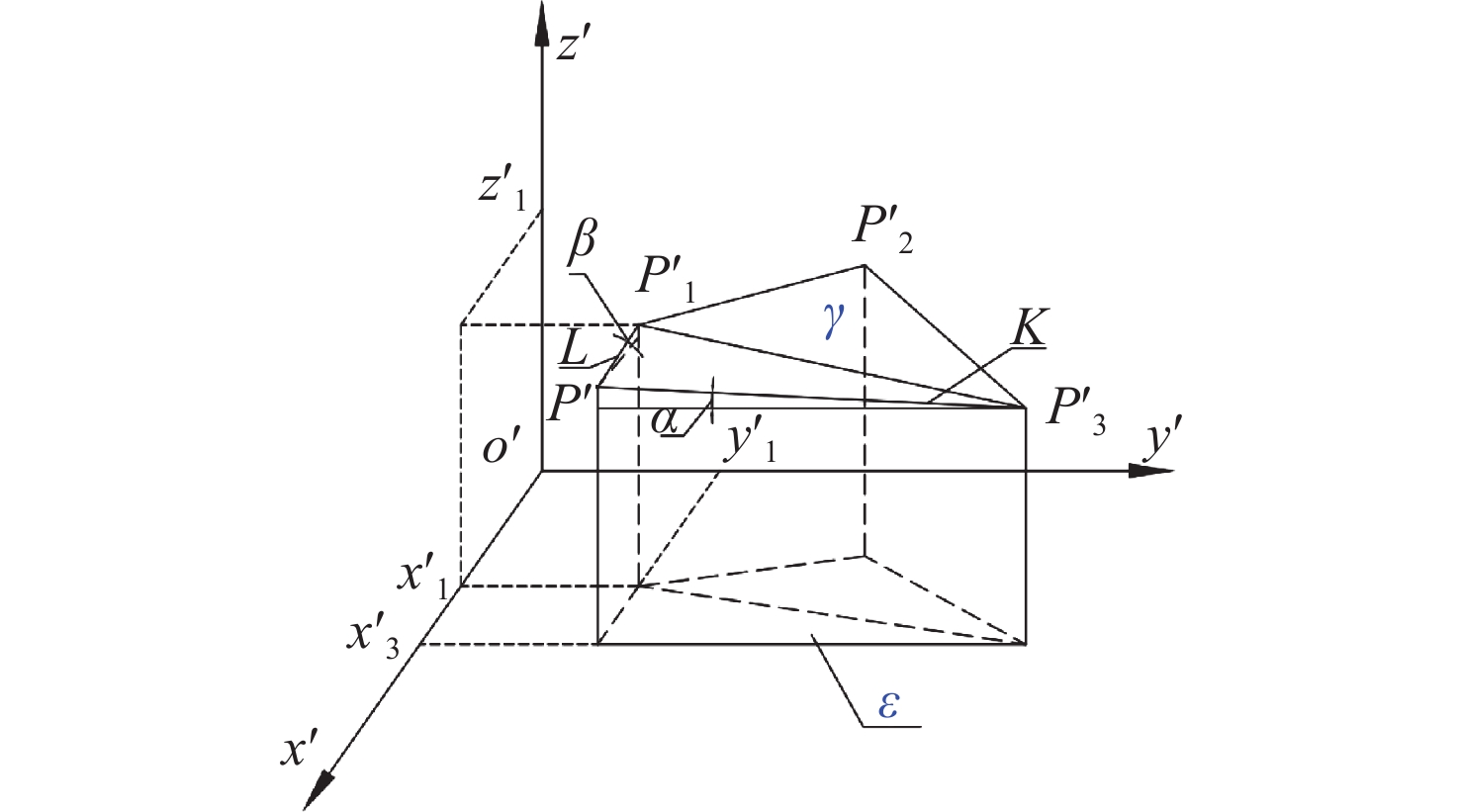

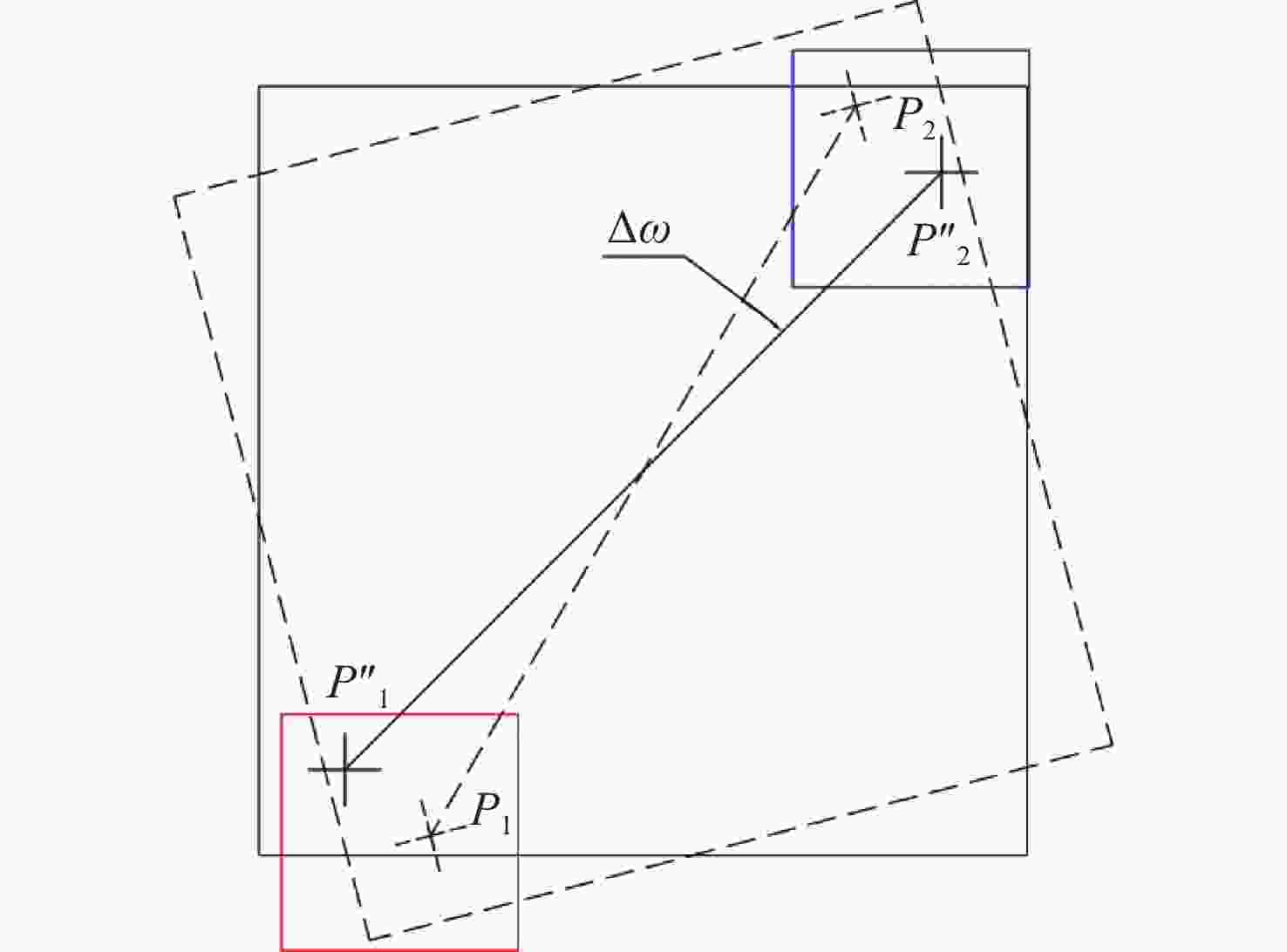

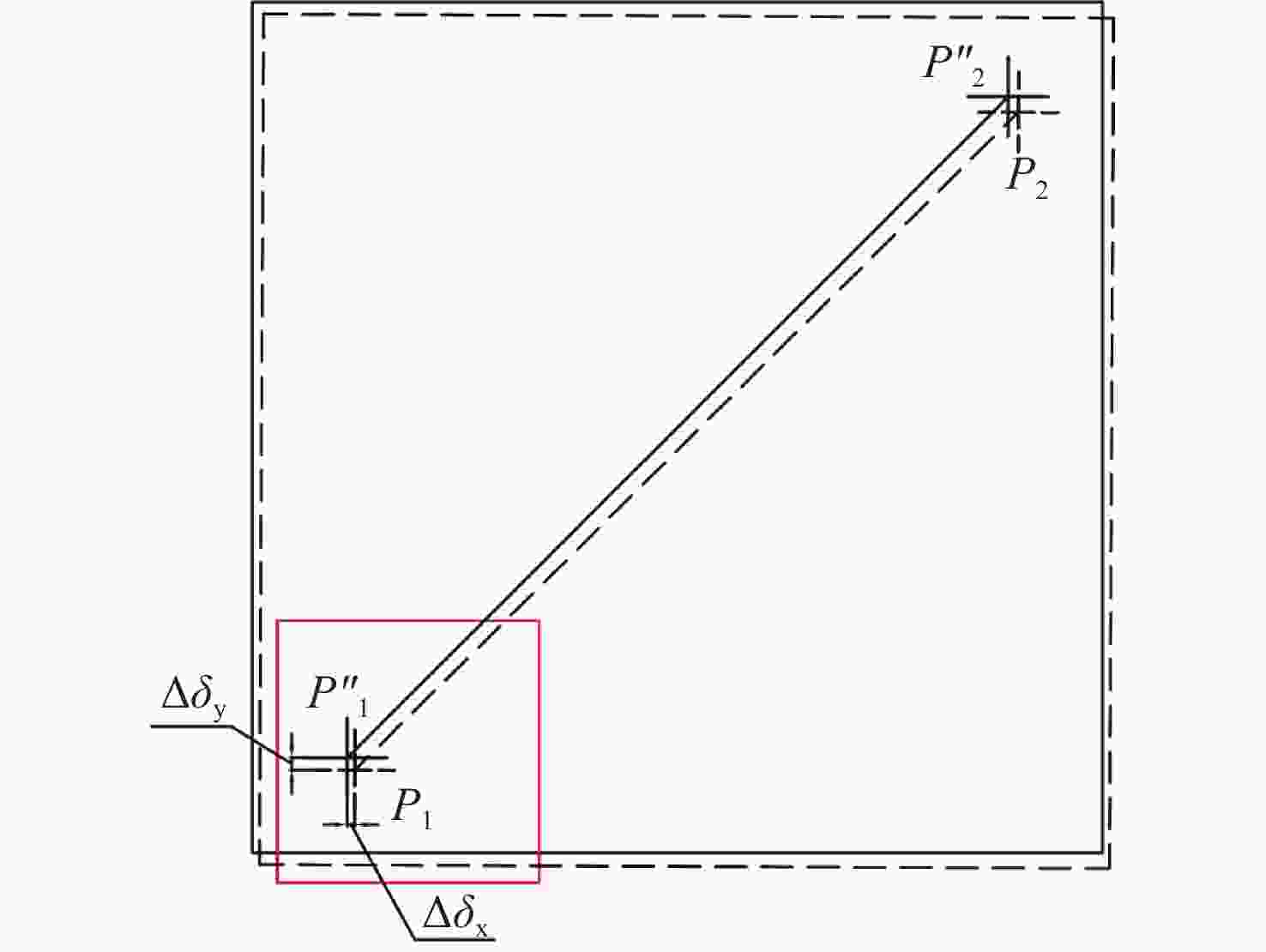

Abstract:Aiming at the urgent demand of high-precision optical alignment systems for a domestic infrared focal plane flip chip bonder, an optical alignment system was designed and verified, and the parallel adjustment, optical alignment and coordinate system error compensation algorithms applied to the system were researched. Firstly, this paper analysed the optical alignment process of a flip chip bonder, then introduced the parallelism adjustment and optical alignment algorithm, and proposed a more reasonable error compensation algorithm according to the test process of the optical alignment system. Finally, based on the above calculation algorithm, the optical alignment system was designed including three parts: a collimation system, a microscopic imaging system and a laser ranging system. The functions of parallel coarse adjustment, feature point recognition and parallel fine adjustment were realized. The experimental results show that the collimation system has a good collimation effect, the microscopic imaging system has high resolution and good imaging quality, and the ranging accuracy of the laser ranging system is 0.084 μm. The designed high-precision optical alignment system solves the urgent need of a domestic infrared focal plane flip chip bonder for high-precision optical alignment systems. It has been applied in a certain types of flip chip bonders, and has very important social significance for improving the independent research and development and production capacity of domestic high-end large-scale integrated circuits.

-

表 1 激光测距结果

Table 1. Results of laser ranging

位置参数(μm) 激光探测器参数 第1次 第2次 第3次 第4次 第5次 第6次 0 1.396 1.433 1.417 1.425 1.415 1.402 2 1.622 1.638 1.643 1.639 1.615 1.645 4 1.813 1.858 1.826 1.844 1.832 1.822 6 2.123 2.206 2.143 2.189 2.168 2.202 8 2.615 2.704 2.687 2.712 2.667 2.711 10 3.247 3.345 3.316 3.335 3.356 3.268 12 3.858 3.941 3.854 3.903 3.884 3.862 14 4.234 4.404 4.302 4.297 4.483 4.333 16 4.654 4.699 4.684 4.725 4.655 4.708 18 4.613 4.621 4.59 4.625 4.592 4.564 20 4.221 4.585 4.339 4.502 4.458 4.48 22 3.778 3.786 3.623 3.682 3.698 3.631 24 2.402 2.516 2.529 2.515 2.564 2.488 26 1.115 1.116 1.252 1.212 1.203 1.415 聚焦点(μm) 15.55 15.56 15.61 15.57 15.58 15.63 -

[1] 丁瑞军, 杨建荣, 何力, 等. 碲镉汞红外焦平面器件技术进展[J]. 红外与激光工程,2020,49(1):0103010.DING R J, YANG J R, HE L, et al. Development of technologies for HgCdTe IRFPA[J]. Infrared and Laser Engineering, 2020, 49(1): 0103010. (in Chinese) [2] 沈宏海, 黄猛, 李嘉全, 等. 国外先进航空光电载荷的进展与关键技术分析[J]. 中国光学,2012,5(1):20-29.SHEN H H, HUANG M, LI J Q, et al. Recent progress in aerial electro-optic payloads and their key technologies[J]. Chinese Optics, 2012, 5(1): 20-29. (in Chinese) [3] CAULFIELD J, CURZAN J. Small pixel infrared sensor technology[J]. Proceedings of SPIE, 2017, 10177: 1017725. doi: 10.1117/12.2264824 [4] 周立庆, 宁提, 张敏, 等. 10μm像元间距1024×1024中波红外探测器研制进展[J]. 激光与红外,2019,49(8):915-920.ZHOU L Q, NING T, ZHANG M, et al. Developments of 10 μm pixel pitch 1024×1024 MW infrared detectors[J]. Laser &Infrared, 2019, 49(8): 915-920. (in Chinese) [5] 吕宝林, 佟首峰, 徐伟, 等. 基于配准的机载红外非均匀性校正技术应用[J]. 中国光学,2020,13(5):1124-1137. doi: 10.37188/CO.2020-0109LV B L, TONG SH F, XU W, et al. Non-uniformity correction of airborne infrared detection system based on inter-frame registration[J]. Chinese Optics, 2020, 13(5): 1124-1137. (in Chinese) doi: 10.37188/CO.2020-0109 [6] 徐飞, 潘其坤, 陈飞, 等. 中红外Fe2+: ZnSe激光器研究进展[J]. 中国光学,2021,14(3):458-469. doi: 10.37188/CO.2020-0180XU F, PAN Q K, CHEN F, et al. Development progress of Fe2+: ZnSe lasers[J]. Chinese Optics, 2021, 14(3): 458-469. (in Chinese) doi: 10.37188/CO.2020-0180 [7] 狄希远. 高精度倒装焊机的研制[J]. 电子工艺技术,2020,41(4):226-229.DI X Y. Development of high precision flip chip bonder[J]. Electronics Process Technology, 2020, 41(4): 226-229. (in Chinese) [8] 耿红艳, 周州, 宋国峰, 等. 红外探测器倒装互连技术进展[J]. 红外与激光工程,2014,43(3):722-726. doi: 10.3969/j.issn.1007-2276.2014.03.010GENG H Y, ZHOU ZH, SONG G F, et al. Flip chip bonding technology for IR detectors[J]. Infrared and Laser Engineering, 2014, 43(3): 722-726. (in Chinese) doi: 10.3969/j.issn.1007-2276.2014.03.010 [9] NG F C, ABAS M A. Underfill flow in flip-chip encapsulation process: a review[J]. Journal of Electronic Packaging, 2022, 144(1): 010803. doi: 10.1115/1.4050697 [10] BAISHYA K, HARVEY D M, ZHANG G M, et al. Investigation into how the floor plan layout of a manufactured PCB influences flip-chip susceptibility to vibration[J]. IEEE Transactions on Components,Packaging and Manufacturing Technology, 2020, 10(5): 741-748. doi: 10.1109/TCPMT.2020.2987334 [11] 王晓奎. 倒装焊接设备精密对位系统的精度设计[D]. 西安: 西安电子科技大学, 2013.WANG X K. Accuracy design for the pricision alignment system of flip chip bonding[D]. Xi’an: Xidian University, 2013. (in Chinese) [12] 邱彪, 常青青, 黄美发. 倒装芯片键合机键合误差分析[J]. 机床与液压,2016,44(1):20-23. doi: 10.3969/j.issn.1001-3881.2016.01.006QIU B, CHANG Q Q, HUANG M F. Bonding error analysis of flip chip bonding machine[J]. Machine Tool &Hydraulics, 2016, 44(1): 20-23. (in Chinese) doi: 10.3969/j.issn.1001-3881.2016.01.006 [13] 张彩云, 郎鹏, 王晓奎, 等. 倒装焊机视觉定位系统[J]. 电子工艺技术,2012,33(1):41-44,59. doi: 10.3969/j.issn.1001-3474.2012.01.012ZHANG C Y, LANG P, WANG X K, et al. Vision positioning system of flip chip bonder[J]. Electronics Process Technology, 2012, 33(1): 41-44,59. (in Chinese) doi: 10.3969/j.issn.1001-3474.2012.01.012 [14] 金忠, 谢锋, 何迎辉, 等. 倒装焊接在压力敏感芯片封装工艺中的研究[J]. 电子与封装,2012,12(9):10-13. doi: 10.3969/j.issn.1681-1070.2012.09.003JIN ZH, XIE F, HE Y H, et al. Research of flip-chip bonding in the pressure sensitive Chip’s encapsulation processing[J]. Electronics &Packaging, 2012, 12(9): 10-13. (in Chinese) doi: 10.3969/j.issn.1681-1070.2012.09.003 [15] 刘文波, 刘斌, 凡陈玲, 等. 高德红外640×512中波红外探测器的规模化生产[J]. 红外,2021,42(2):8-14.LIU L B, LIU B, FAN CH L, et al. Large-scale production of 640×512 middle-wavelength infrared detectors from guide infrared company limited[J]. Infrared, 2021, 42(2): 8-14. (in Chinese) [16] 张雅丽, 余卿, 尚文键, 等. 斜照明式彩色共聚焦测量系统设计及其实验研究[J]. 中国光学,2022,15(3):514-524. doi: 10.37188/CO.2021-0181ZHANG Y L, YU Q, SHANG W J, et al. Chromatic confocal measurement system and its experimental study based on inclined illumination[J]. Chinese Optics, 2022, 15(3): 514-524. (in Chinese) doi: 10.37188/CO.2021-0181 -

下载:

下载: