Integrated optimization design of mirror semi-active support system based on Warping Harness

-

摘要:

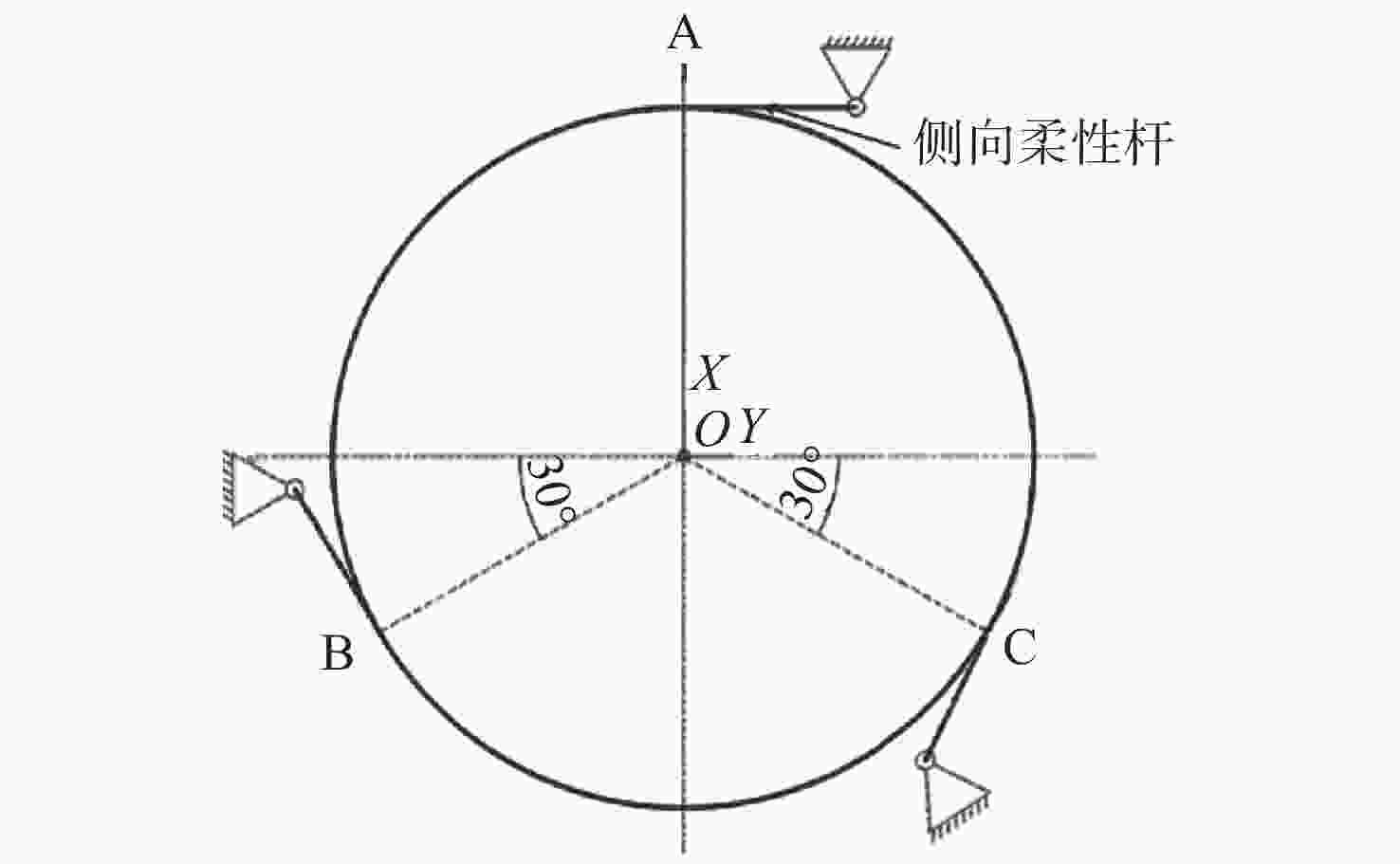

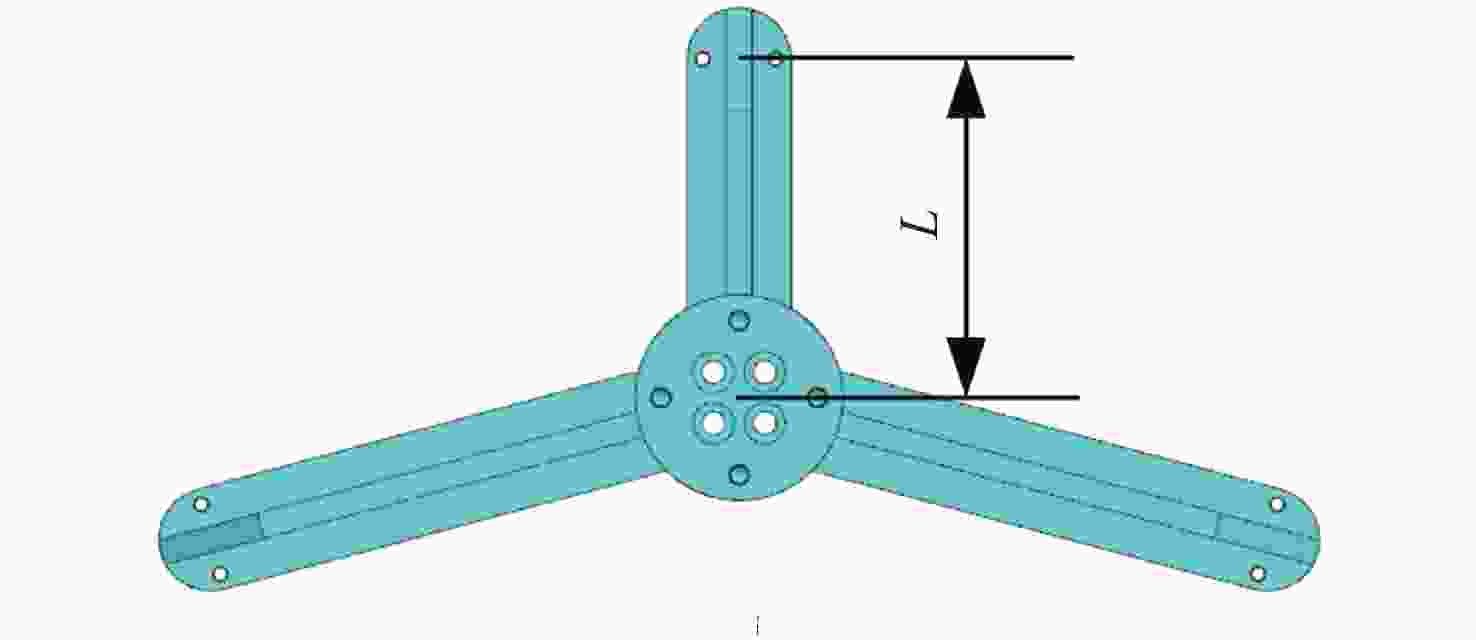

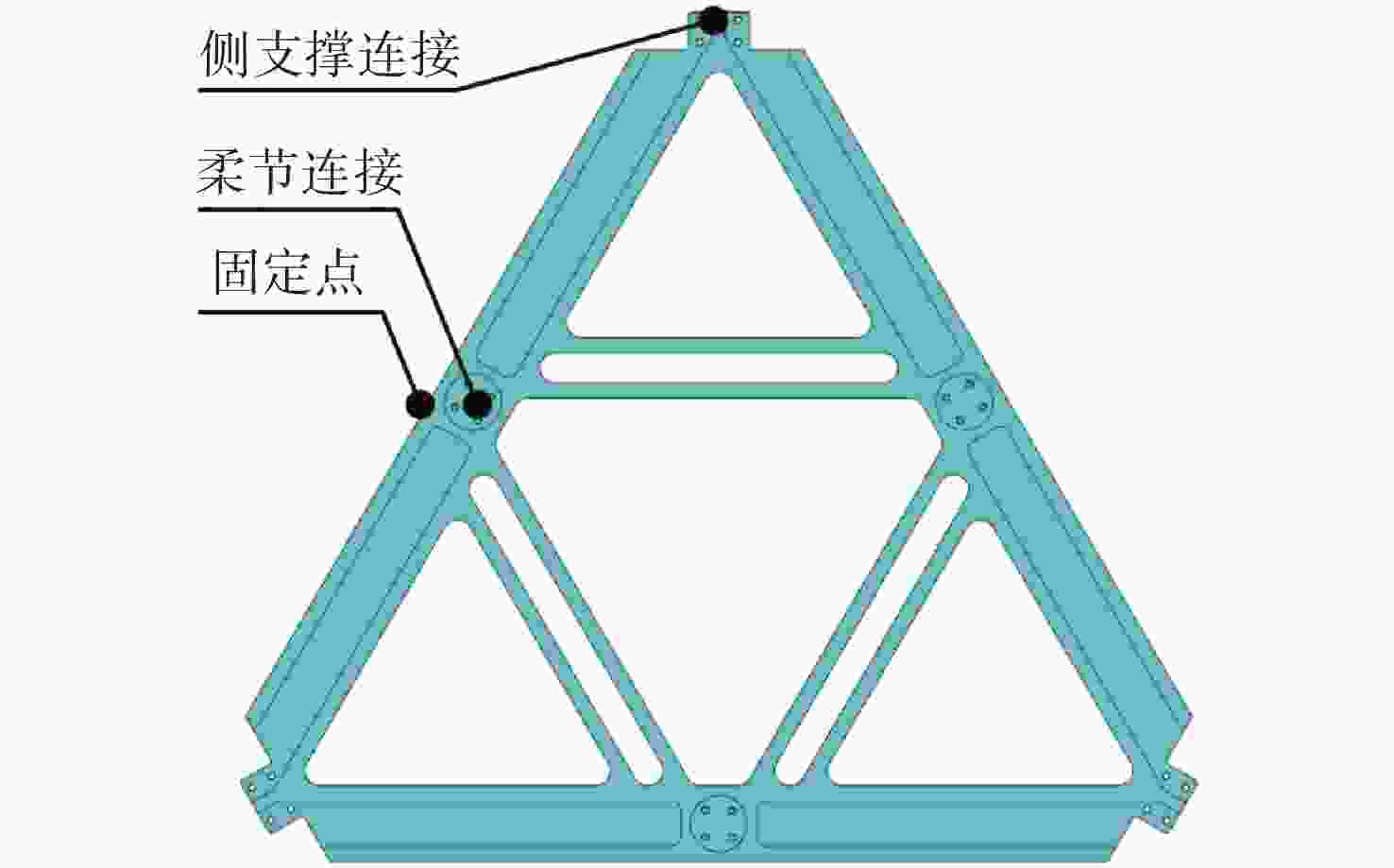

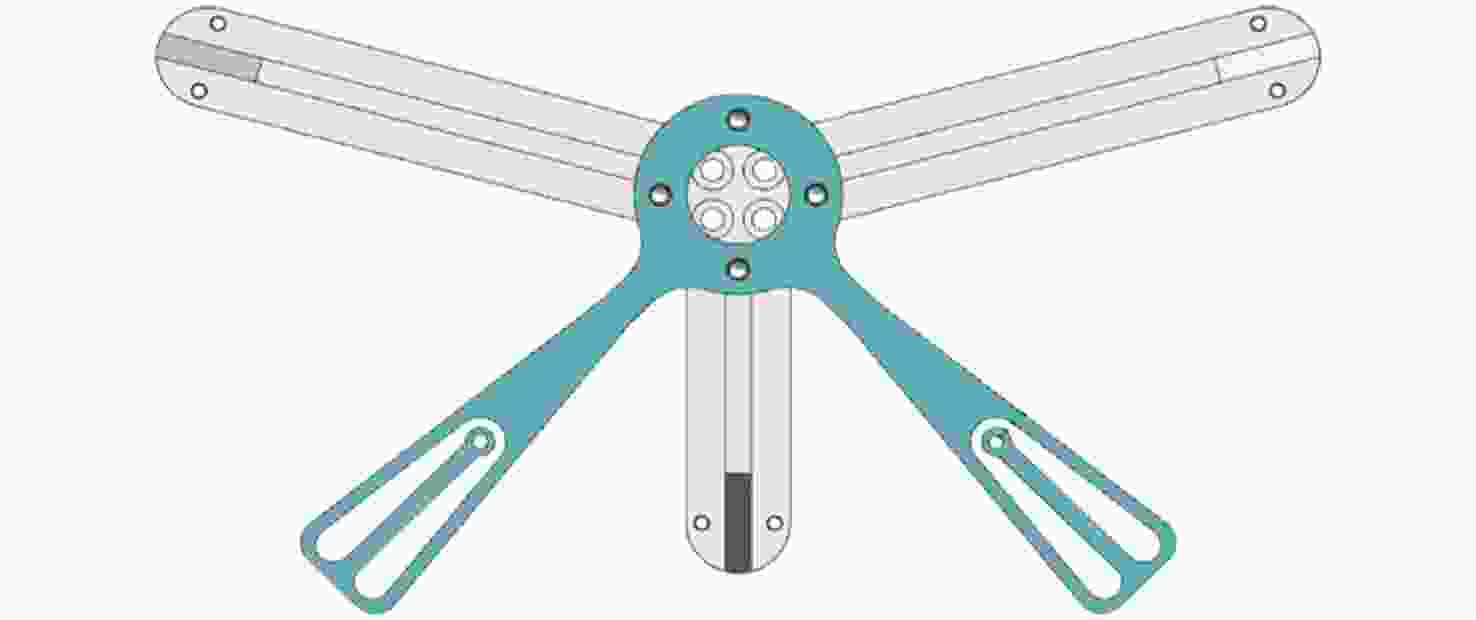

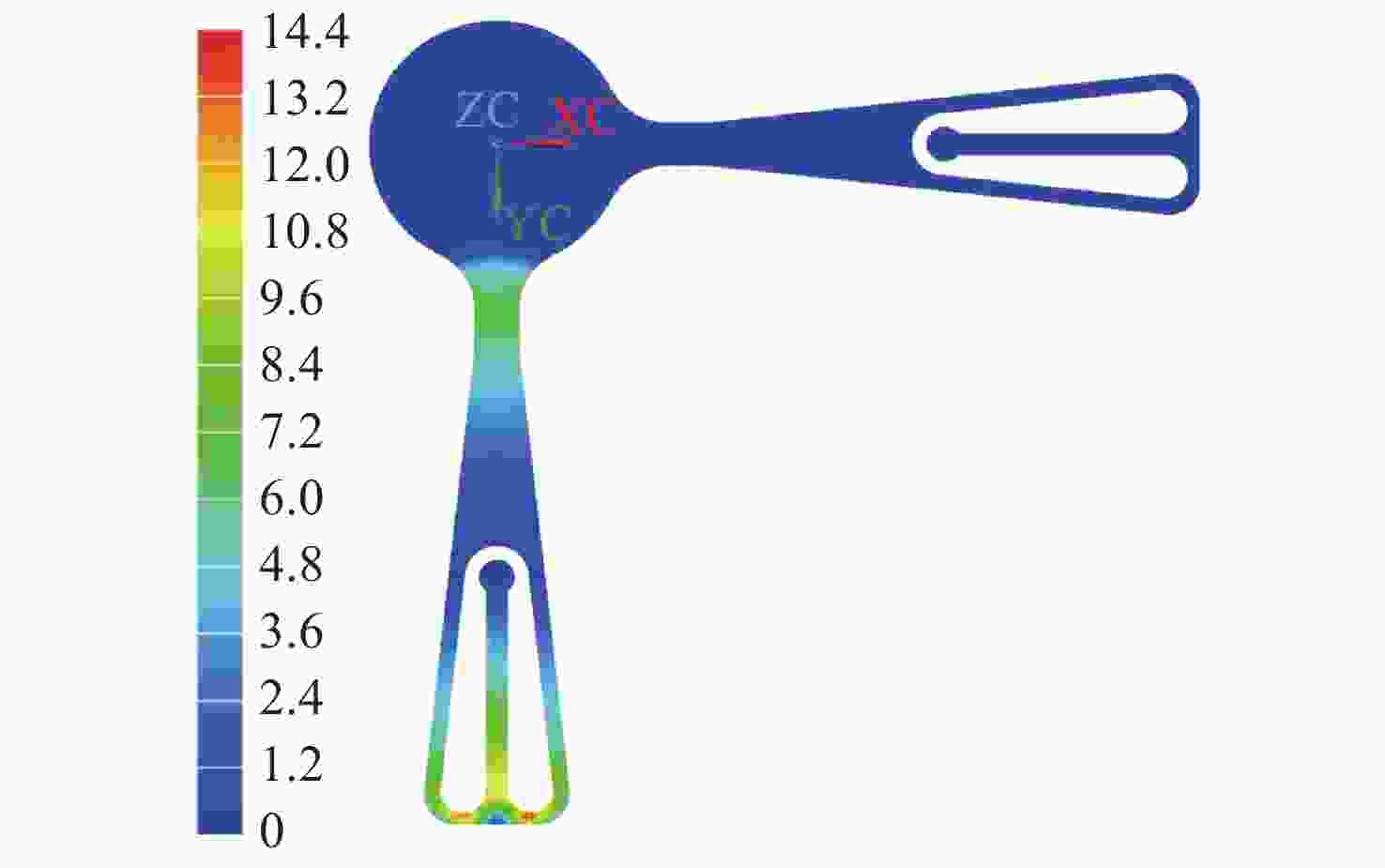

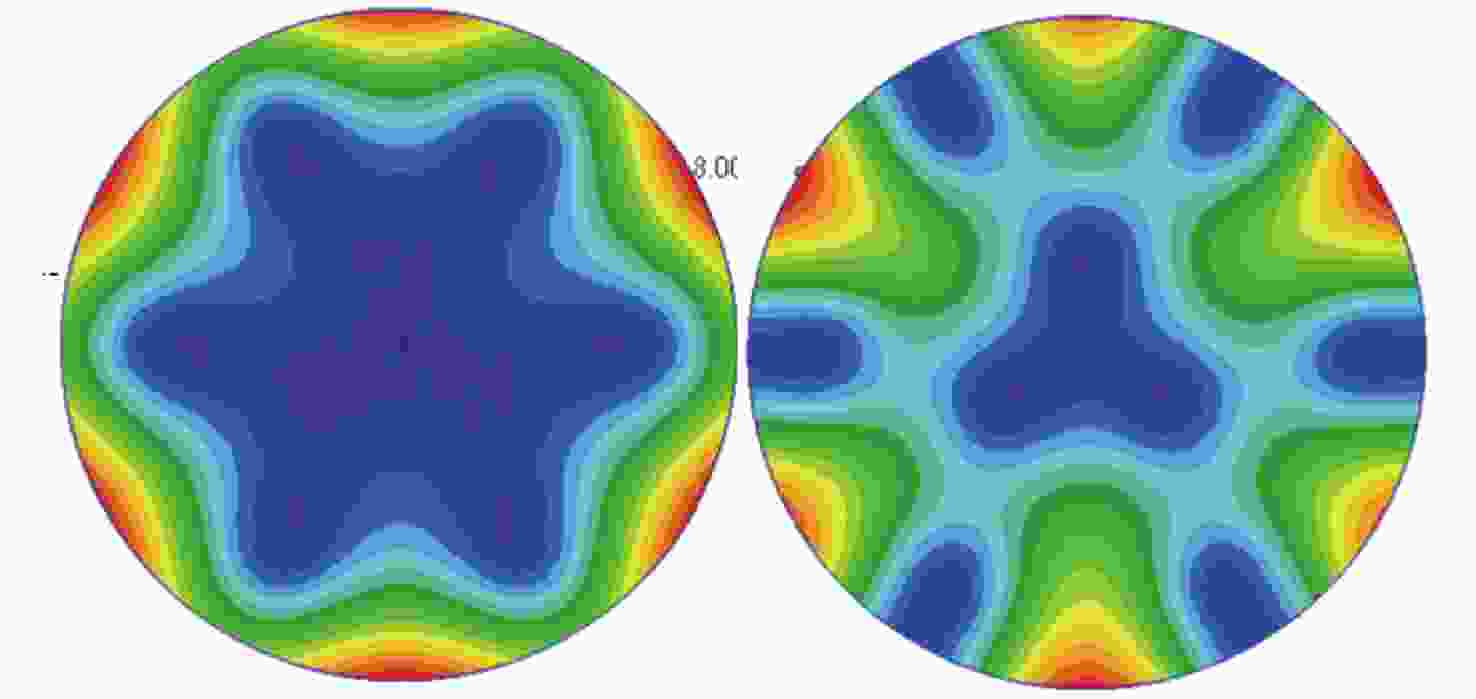

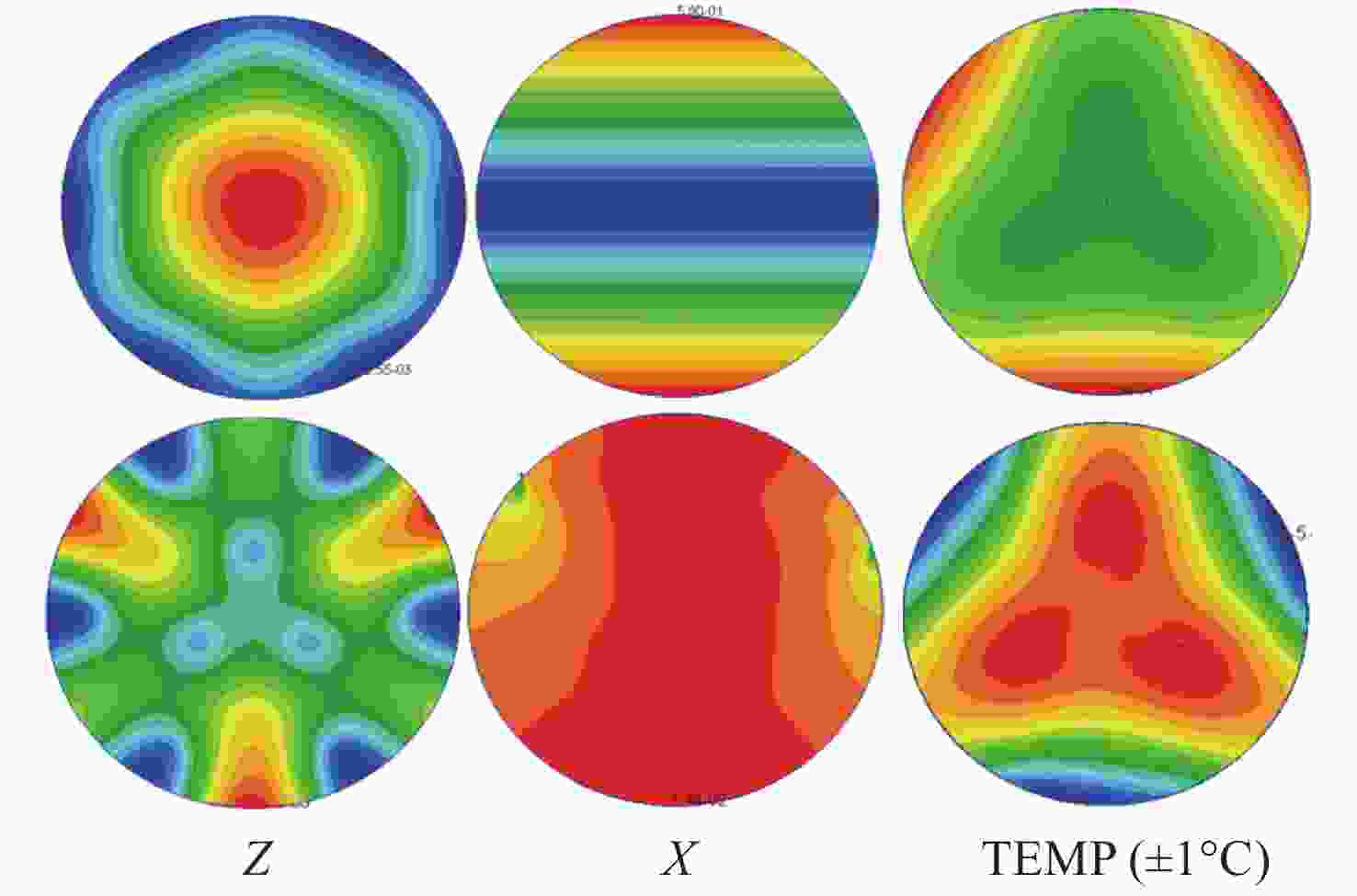

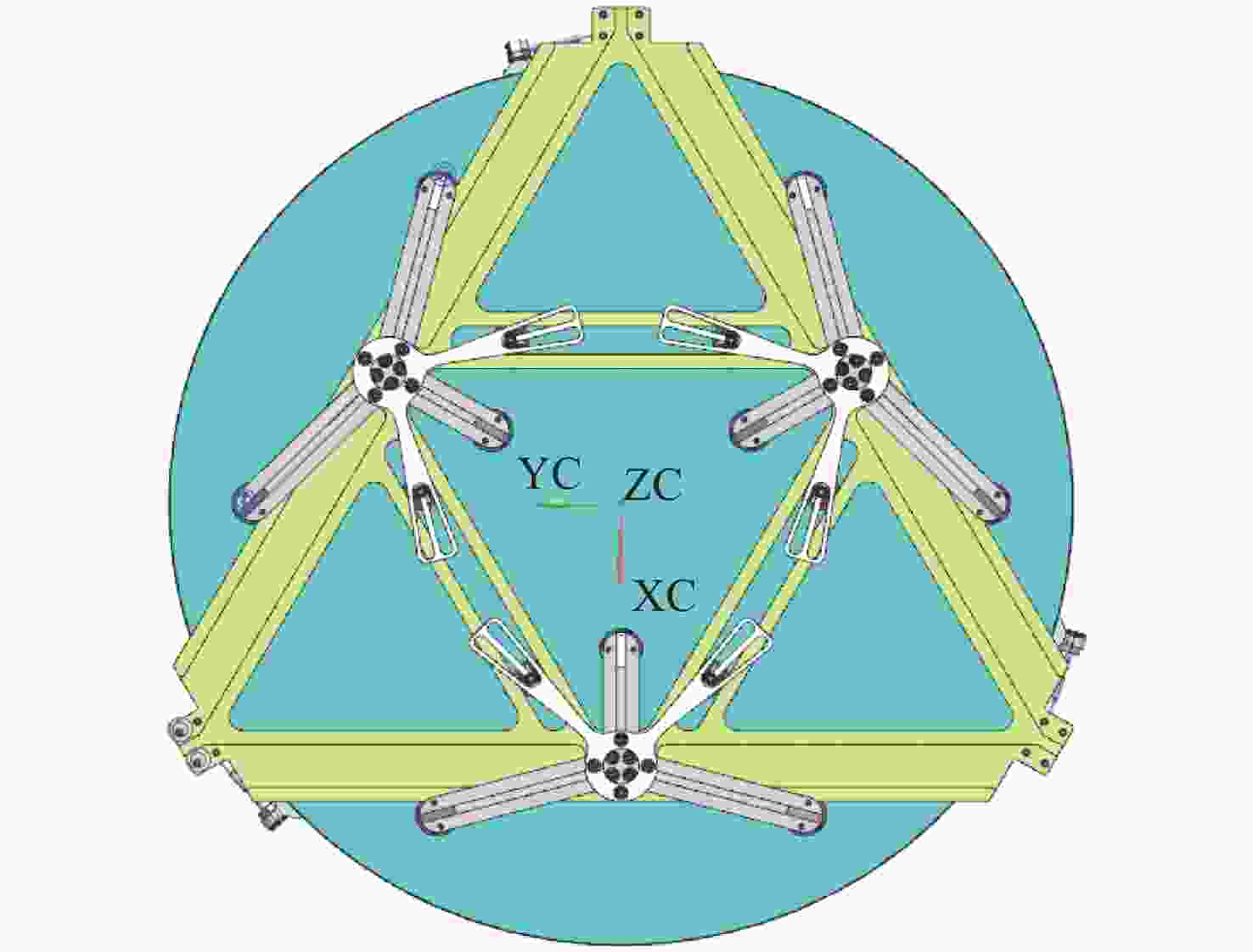

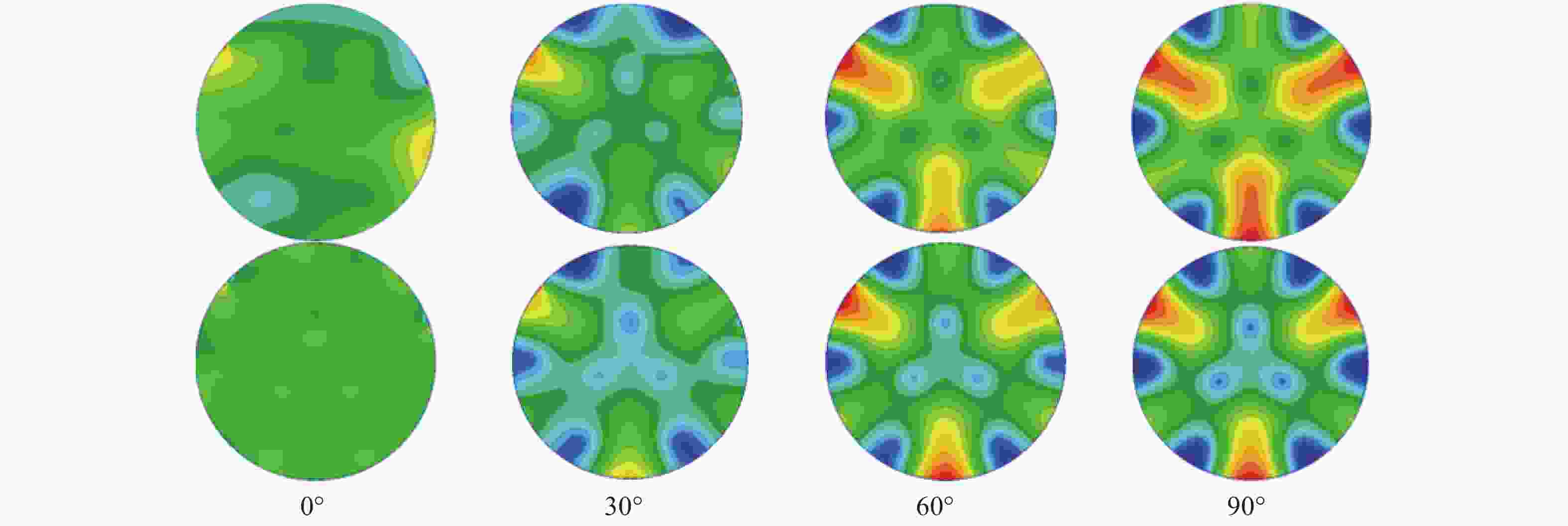

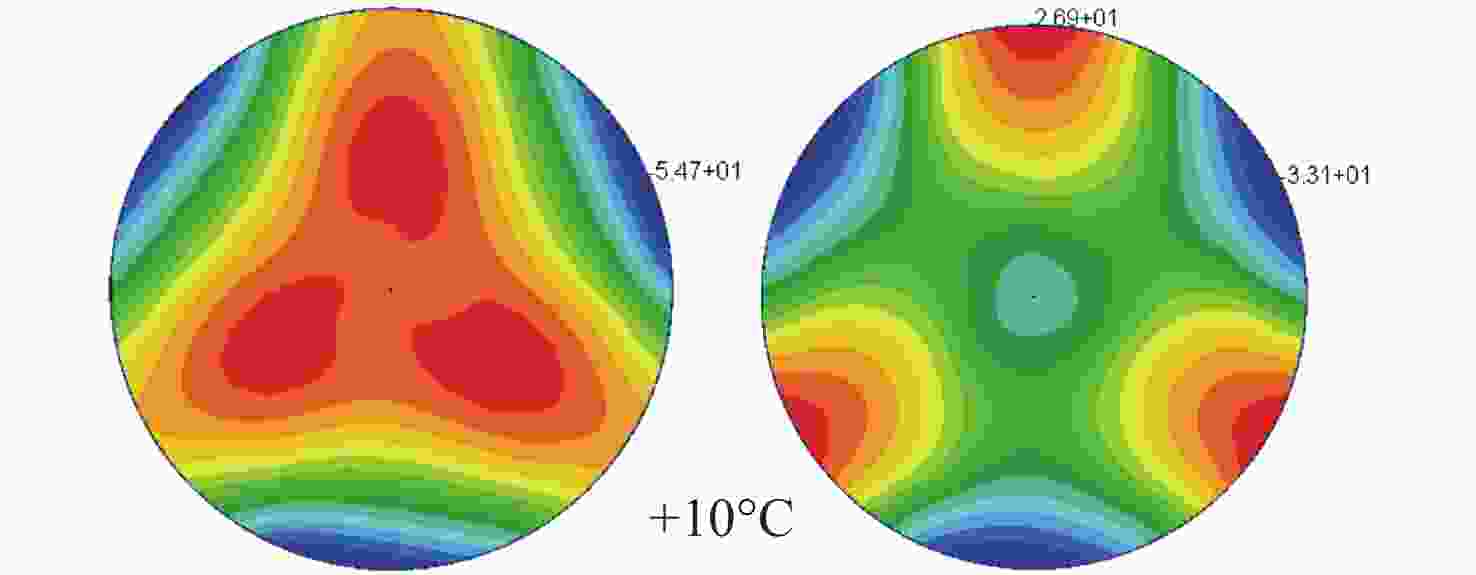

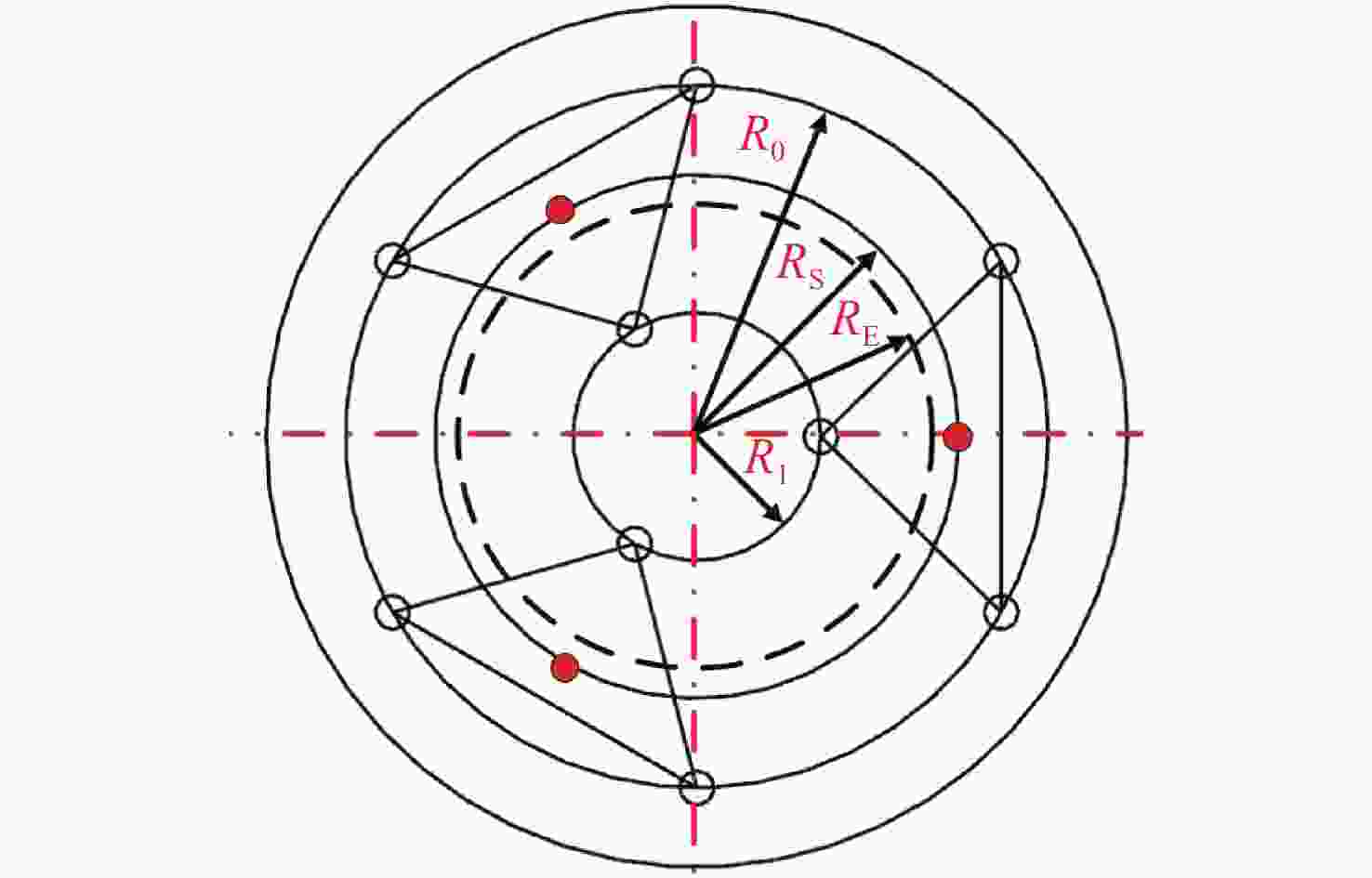

基于半主动光学技术的半主动支撑,通过力矩促动器(Warping Harness, WH)弹簧叶片将校正力转换为校正力矩,对由重力、温度等误差源引入的镜面低阶像差进行校正。针对利用传统经验设计反射镜时存在的设计缺陷,提出一种反射镜支撑系统优化设计新方法,即结合结构尺寸优化和经验设计的镜面支撑系统综合设计优化方法,并建立一套基于WH 的半主动镜面支撑系统。首先,按照经验公式设计了支撑系统初始结构;设计了一款L形镂空式WH弹簧叶片,并对其开展了非线性分析及疲劳分析,确定叶片厚度为2 mm、寿命为1.2×106次。然后,通过优化镜面支撑点位置、三角板柔节位置、支撑系统柔性件关键尺寸参数,将光轴竖直及水平状态下镜面RMS值由119 nm和106 nm分别降至13.3 nm和4.8 nm;1 °C温差状态下镜面面形差由2.8 nm降至1.9 nm;一阶谐振频率由80 Hz提升至130 Hz。最后,采用提出的方法对半主动支撑系统的校正能力进行验证。结果表明:本套半主动支撑系统对镜面离焦、初级像散、初级慧差、初级球差的校正率最高可达99%,且校正后各像差幅值均小于1 nm;室温自重状态下对镜面面形RMS值校正率最高可达46.5%;温升10°C情况下的校正率为31.28%。

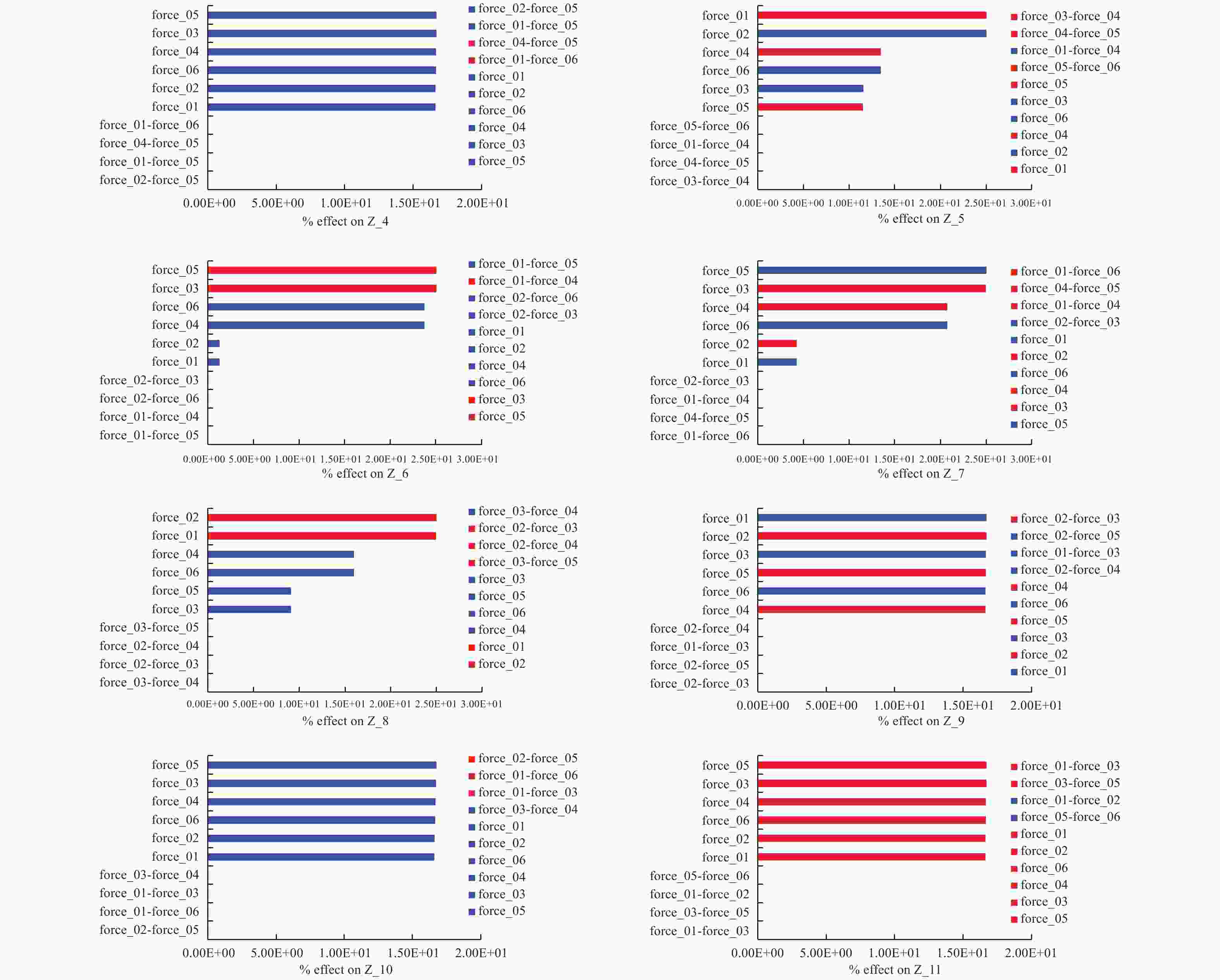

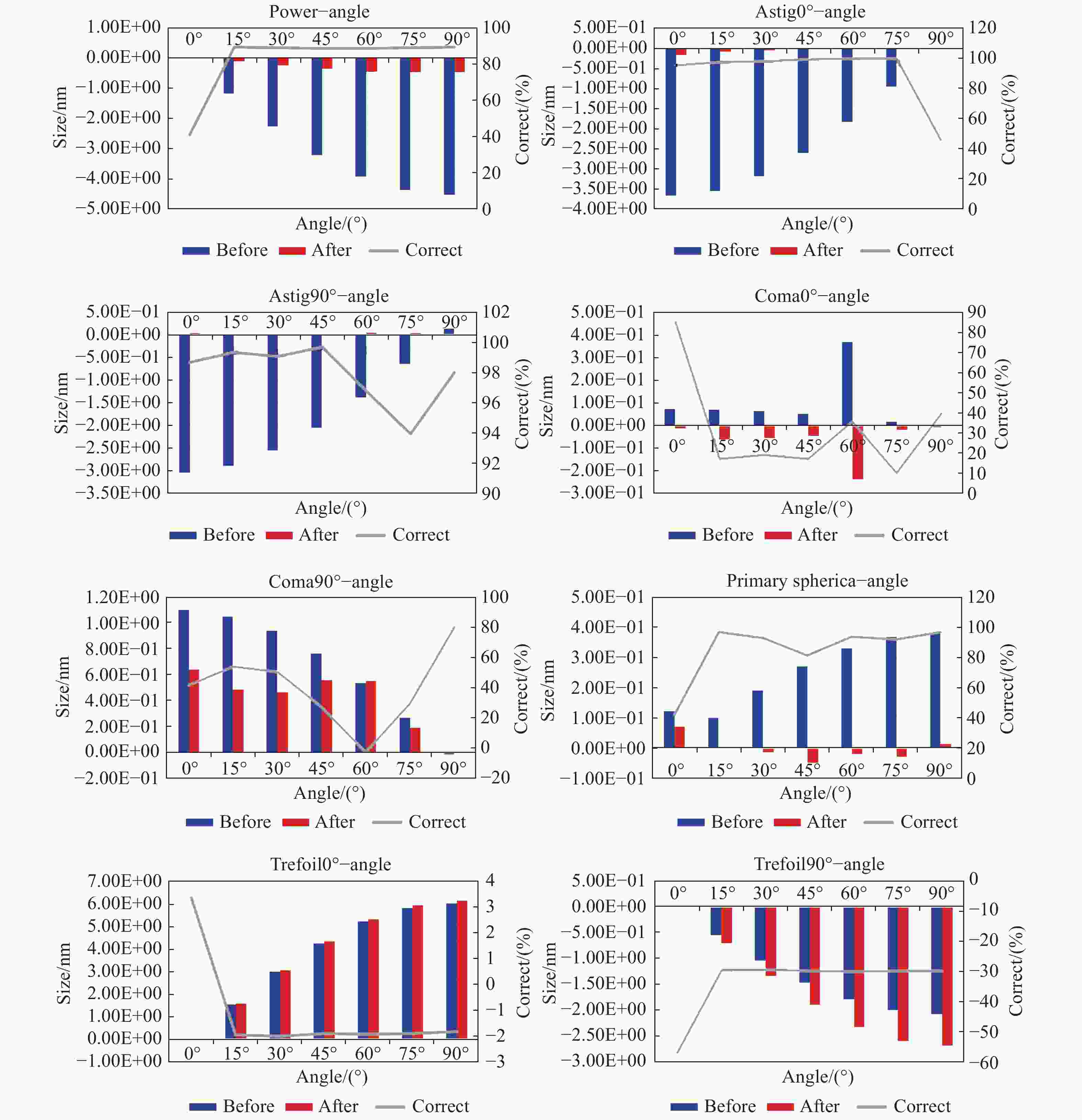

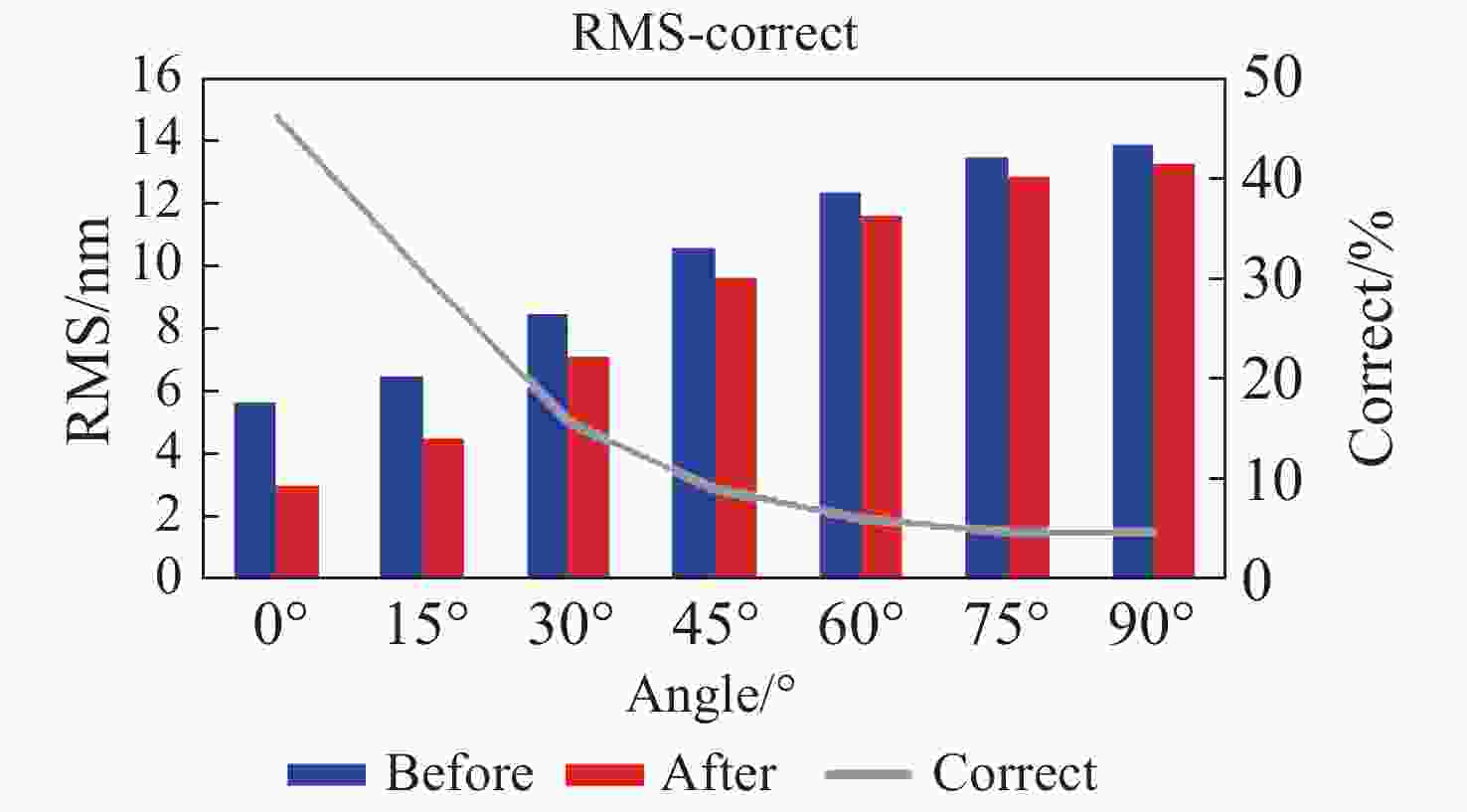

Abstract:The semi-active support is based on the semi-active optical technology, and the correction force is converted into a correction torque through a Warping Harness(WH) spring blade to correct the mirror low-order aberration introduced by error sources such as gravity and temperature. Aiming at the defects of traditional empirical design of mirrors, a new optimal design method for a mirror support system is proposed, that is, a comprehensive design optimization method of mirror support system based on structural size optimization combined with empirical design, and a set of semi-active mirror support systems based on WH is established. Firstly, the initial structure of the support system is designed according to the empirical formula; an L-shaped hollow WH spring blade is designed, and the nonlinear analysis and fatigue analysis are carried out to determine that the blade thickness is 2 mm and the service life is 1.2×106 times. Then, the RMS value of the mirror surface in the vertical and horizontal states of the optical axis was reduced from 119 nm and 106 nm to 13.3 nm and 4.8 nm by optimizing the position of the mirror support point, the position of the triangular plate flexure joint, and the key dimension parameters of the support system’s flexible parts; under the state of 1 °C temperature difference, the specular aberration is reduced from 2.8 nm to 1.9 nm; the first-order resonance frequency is increased from 80 Hz to 130 Hz. Finally, this method is used to verify the correction ability of the semi-active support system. The results show that the correction rate of the semi-active support system for mirror defocus, primary astigmatism, primary coma and primary spherical aberration can reach up to 99%. The amplitude of each aberration is less than 1 nm; the correction rate of the RMS value of the mirror’s surface shape can reach up to 46.5% under it′s own weight state at room temperature, and the correction rate is 31.28%.

-

Key words:

- support system /

- integration optimization /

- semi-active optics /

- Warping Harness /

- low-order aberrations

-

表 1 镜面参数

Table 1. Primary mirror parameters

参数 指标 口径d/mm 500.00 焦距f/mm 6000.00 密度(g/cm-3) 2.53 弹性模量GPa 91.00 泊松比 0.24 热膨胀系数(10−6/K) 0.05 表 2 各柔性件截面积计算结果

Table 2. Calculation results of the cross-sectional area of each flexible part

类别 F/N L/mm Amin/mm2 轴向柔性杆 12 48 0.0014 三角板柔节 50 28 0.0011 侧向柔性杆 58 42 0.0020 表 3 支撑点位置优化结果

Table 3. Optimization results of the support point position

项目 参数 R1/mm 68.3 R0/mm 206.5 PV/nm 52.7 RMS/nm 12.0 表 4 支撑柔性件结构尺寸最优解

Table 4. The optimal solution for the structural size of the supporting flexible parts

项目 参数 H/mm 2.9 Rz/mm 1.4 Rc/mm 0.5 RMSx/nm 4.8 RMSz/nm 13.3 RMSt/nm 1.9 表 5 柔性杆轴及侧向解耦结果

Table 5. Flexible rod axis and lateral decoupling results

项目 参数 R轴/mm 1.4 R侧/mm 0.50 S轴轴/mm 0.00030 S轴侧/mm 0.067 S侧/mm 0.014 满足耦合 满足 表 6 30 °C时镜面面形校正前后对比

Table 6. Comparison of mirror surface shapes before and after correction at 30°C

Temp_30°C Before/nm After/nm correct RMS 19.2 13.2 31.28% Power −13.8 −0.382 97.23% Astig0° −0.588 −0.0783 86.68% Astig90° 0.0998 0.0680 31.86% Coma0° −0.0211 −0.0268 −27.01% Coma90° −0.00346 −0.0466 −1246.82% Primary spherical −2.43 −0.981 59.63% Trefoil0° −12.8 −12.4 3.13% Trefoil90° −1.43 −3.45 −141.26% 表 7 镜室组件前四阶谐振频率

Table 7. The first four-order resonance frequencies of the mirror chamber assembly

阶数 1 2 3 4 频率/Hz 130.5 132.7 199.7 203.3 -

[1] 范文强, 王志臣, 陈宝刚, 等. 地基大口径拼接镜面主动控制技术综述[J]. 中国光学,2020,13(6):1194-1208. doi: 10.37188/CO.2020-0032FAN W Q, WANG ZH CH, CHEN B G, et al. Review of the active control technology of large aperture ground telescopes with segmented mirrors[J]. Chinese Optics, 2020, 13(6): 1194-1208. (in Chinese) doi: 10.37188/CO.2020-0032 [2] 王富国, 吴小霞, 邵亮, 等. 国外大型地基望远镜主镜支撑综述[J]. 激光与红外,2012,42(3):237-243. doi: 10.3969/j.issn.1001-5078.2012.03.001WANG F G, WU X X, SHAO L, et al. Review of foreign ground-based telescope primary mirror support[J]. Laser &Infrared, 2012, 42(3): 237-243. (in Chinese) doi: 10.3969/j.issn.1001-5078.2012.03.001 [3] KAMPHUES F, CHEN L, ZHANG D, et al. Warping harness actuator for the thirty meter telescope primary mirror segments[J]. Proceedings of SPIE, 2020, 11451: 1145150. [4] 王克军.天基大口径反射镜轻量化设计及复合支撑技术研究[D]. 中国科学院研究生院(长春光学精密机械与物理研究所), 2016.WANG K J. Research on the lightweight design and compound support of the large-aperture mirror for space-based telescope[D]. Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, 2016. (in Chinese) [5] 宫雪非, 陈迅, 陈哲. 拼接子镜力矩促动器布局的优化设计[J]. 光学 精密工程,2019,27(2):363-371. doi: 10.3788/OPE.20192702.0363GONG X F, CHEN X, CHEN ZH. Layout optimization of warping harness for segmented-mirror telescope[J]. Optics and Precision Engineering, 2019, 27(2): 363-371. (in Chinese) doi: 10.3788/OPE.20192702.0363 [6] 徐加慧, 夏立新, 陈诚. 基于有限元法的主镜底支撑的优化分析[J]. 机械设计与制造,2004(3):67-69. doi: 10.3969/j.issn.1001-3997.2004.03.034XU J H, XIA L X, CHEN CH. Optimization analysis for the underside support of the primary mirror by the finite element method[J]. Machinery Design &Manufacture, 2004(3): 67-69. (in Chinese) doi: 10.3969/j.issn.1001-3997.2004.03.034 [7] 王从敬. 1 m口径光电经纬仪主镜及其支撑结构研究[D]. 长春: 中国科学院大学(中国科学院长春光学精密机械与物理研究所), 2021, doi: 10.27522/d.cnki.gkcgs.2021.000044.WANG C J. Research on the primary mirror and supporting structure of photoelectric theodolite with 1m aperture[D]. Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, 2021, doi: 10.27522/d.cnki.gkcgs.2021.000044. (in Chinese) [8] 原帅. 2米碳化硅主镜在光机系统中精确定位方法研究[D]. 长春: 中国科学院大学(中国科学院长春光学精密机械与物理研究所), 2018.YUAN SH. Research of precise positioning method of 2-m SiC primary mirror in opto-mechanical system[D]. Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, 2018. (in Chinese) [9] 约德. 光机系统设计[M]. 3版. 周海宪, 程云芳, 译. 北京: 机械工业出版社, 2008: 480-481.YODER JR P R. Opto-Mechanical Systems Design[M]. 3rd ed. ZHOU H X, CHENG Y F, trans. Beijing: China Machine Press, 2008: 480-481. (in Chinese) [10] 吴松航, 董吉洪, 徐抒岩, 等. 快速反射镜椭圆弧柔性铰链多目标优化设计[J]. 红外与激光工程,2021,50(4):20200286. doi: 10.3788/IRLA20200286WU S H, DONG J H, XU SH Y, et al. Multi-objective optimal design of elliptic flexible hinge in fast steering mirror[J]. Infrared and Laser Engineering, 2021, 50(4): 20200286. (in Chinese) doi: 10.3788/IRLA20200286 [11] 韩琳楚. 基于TMT三镜的半主动光学面形校正技术研究[D]. 长春: 中国科学院长春光学精密机械与物理研究所, 2017.HAN L CH. Study on correction of semi-active optics technology for large optical flat mirror based on TMT tertiary mirror[D]. Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Science, China, 2017. (in Chinese) [12] 曲慧东, 魏加立, 董得义, 等. 长条形空间反射镜组件轻量化结构设计[J]. 红外与激光工程,2021,50(6):20200404. doi: 10.3788/IRLA20200404QU H D, WEI J L, DONG D Y, et al. Lightweight structural design of rectangular space mirror assembly[J]. Infrared and Laser Engineering, 2021, 50(6): 20200404. (in Chinese) doi: 10.3788/IRLA20200404 [13] 刘奉昌, 李威, 赵伟国, 等. 临近空间望远镜次镜优化设计[J]. 红外与激光工程,2021,50(2):20200178. doi: 10.3788/IRLA20200178LIU F CH, LI W, ZHAO W G, et al. Optimization design of secondary mirror for near space telescope[J]. Infrared and Laser Engineering, 2021, 50(2): 20200178. (in Chinese) doi: 10.3788/IRLA20200178 [14] 胡海飞, 关英俊, 赵思宏, 等. 大口径反射镜分析驱动设计与优化[J]. 系统仿真学报,2013,25(5):990-994.HU H F, GUAN Y J, ZHAO S H et al. Analysis led design and optimization for large aperture mirror[J]. Journal of System Simulation, 2013, 25(5): 990-994. (in Chinese) [15] 胡海飞, 罗霄, 辛宏伟, 等. 超大口径光学制造均力支撑布局优化[J]. 光学学报,2014,34(4):0422003. doi: 10.3788/AOS201434.0422003HU H F, LUO X, XIN H W, et al. Layout optimization of equal-force supports for ultra-large optical fabrication[J]. Acta Optica Sinica, 2014, 34(4): 0422003. (in Chinese) doi: 10.3788/AOS201434.0422003 [16] 吴松航, 董吉洪, 徐抒岩, 等. 拼接式望远镜主镜主动支撑技术综述[J]. 激光与光电子学进展,2021,58(3):0300006.WU S H, DONG J H, XU SH Y, et al. Overview of active support technology for main mirror of segmented telescopes[J]. Laser &Optoelectronics Progress, 2021, 58(3): 0300006. (in Chinese) -

下载:

下载: