-

摘要:

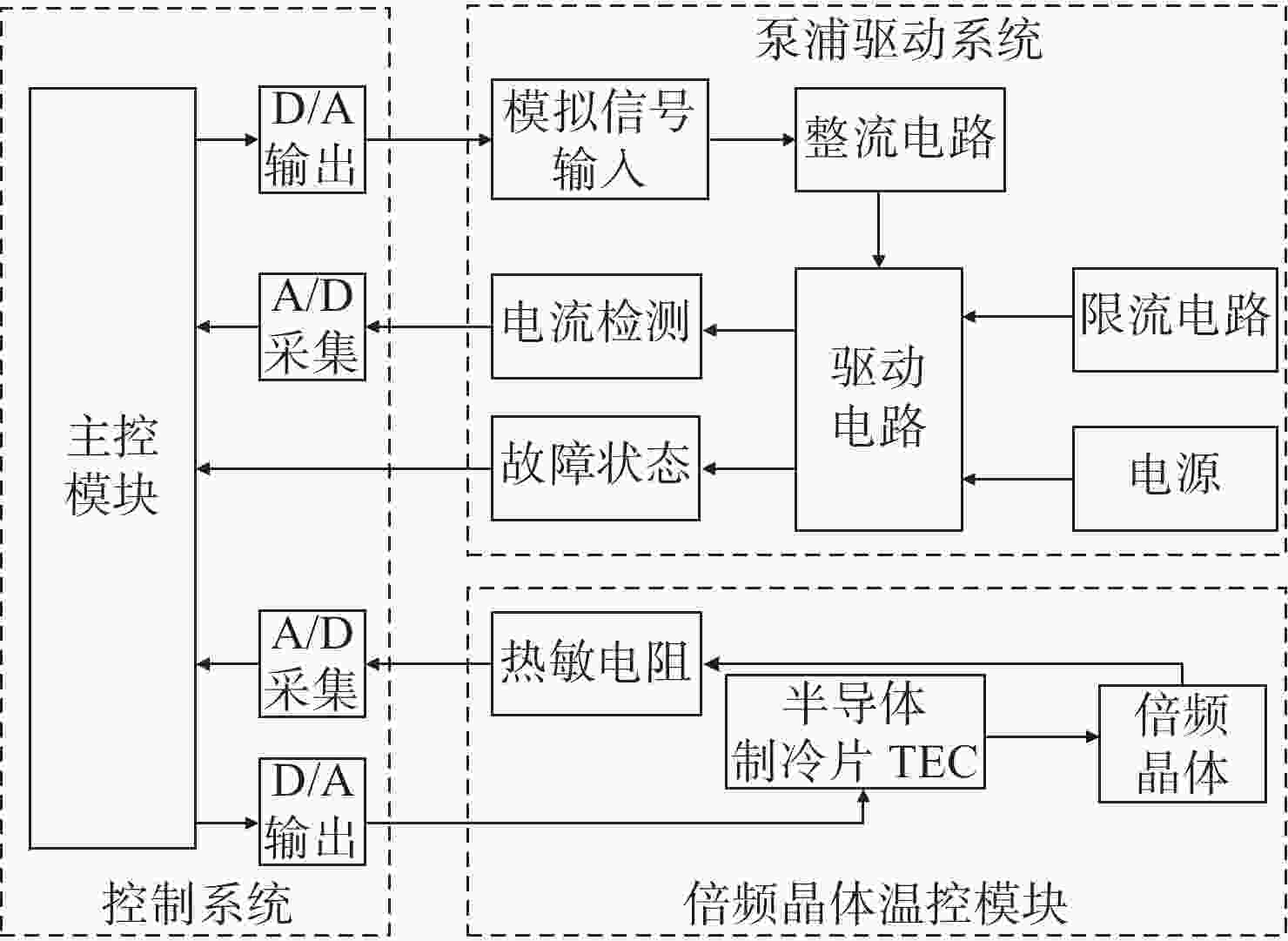

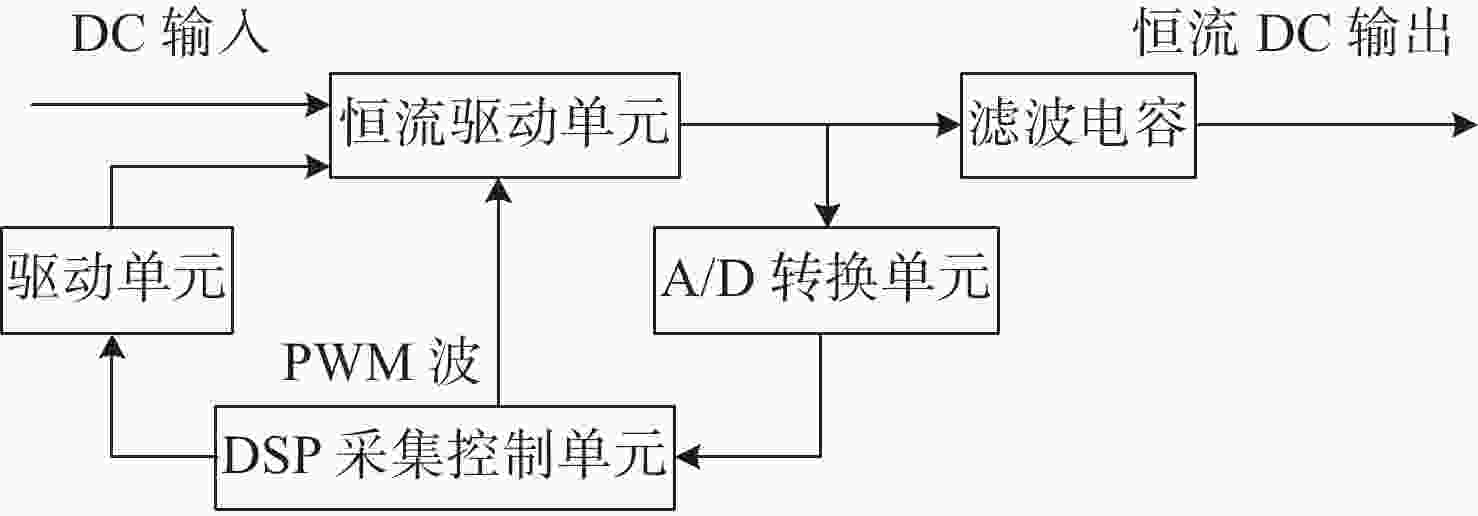

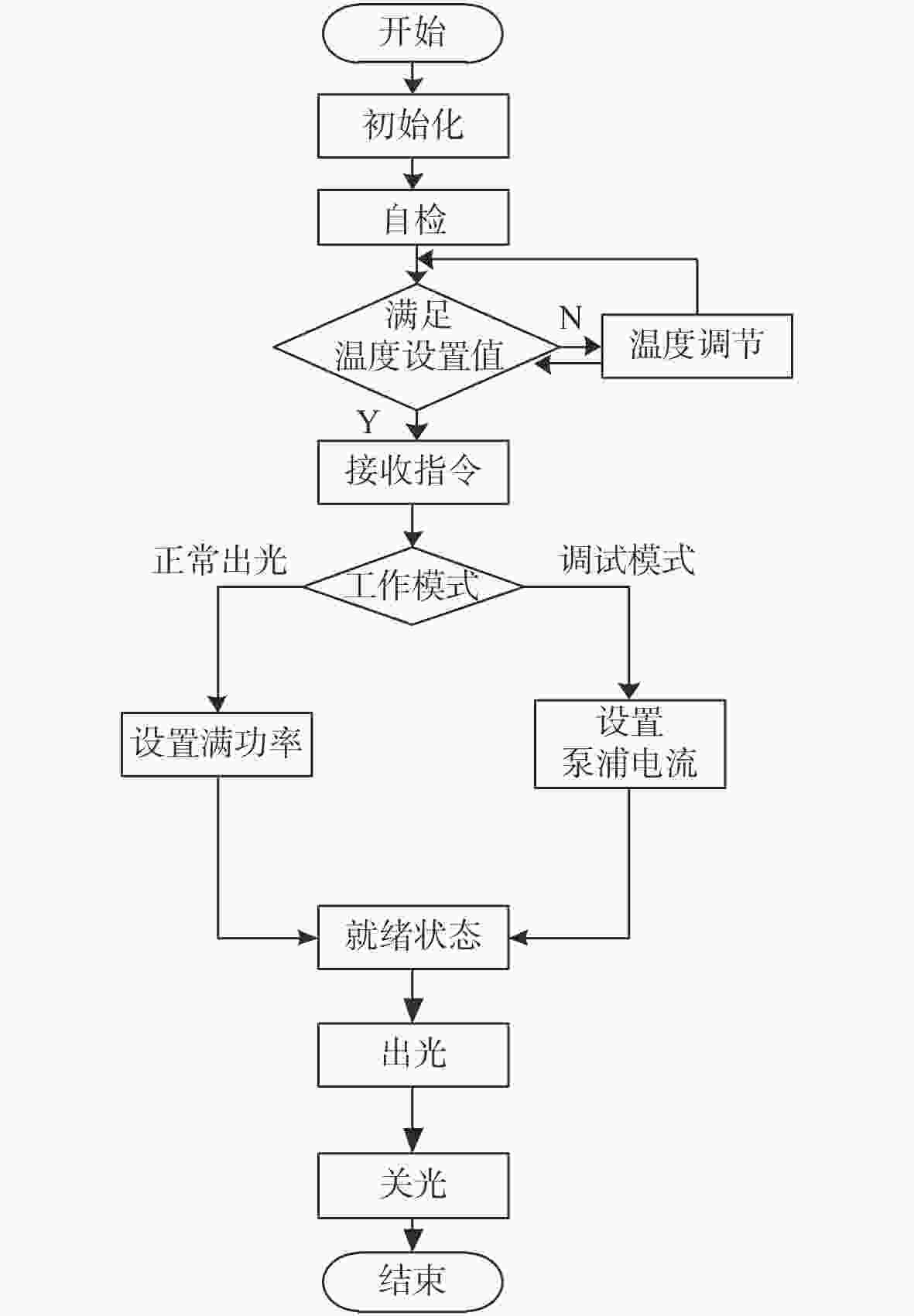

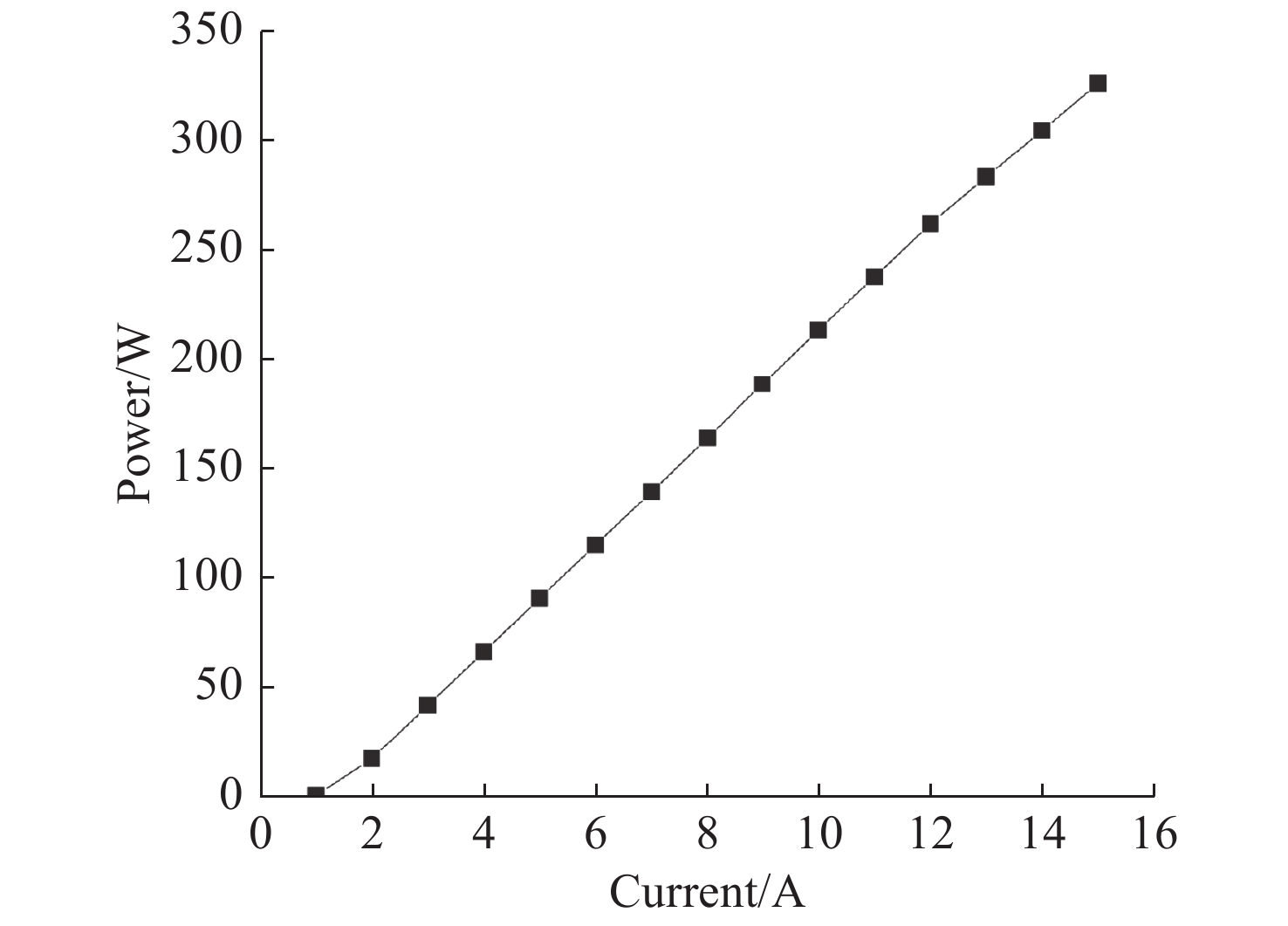

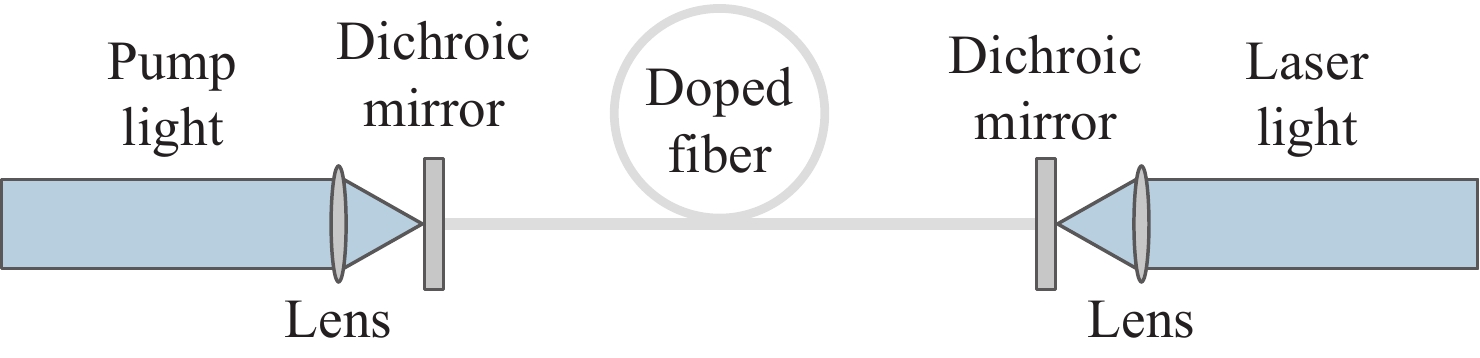

为了实现激光器稳定且安全地输出,设计了一款基于515-nm的大功率激光器控制系统。首先,对该系统的泵浦驱动模块进行研究,利用现场可编程门阵列(FPGA)完成对模块的模拟采样并在数字信号处理(DSP)中完成计算输出,采用数字PID方式完成恒流源的闭环控制;其次,使用半导体制冷器(TEC)实现倍频晶体模块的稳定温度控制,以热敏电阻(NTC)作为反馈实现温度控制;最后,设计了激光器的人机交互系统,实现了对激光器内部状态的实时监测、判断与存储。为了验证控制系统的有效性,选择一款泵浦进行测试。实验结果表明:泵浦驱动模块能够持续稳定地工作,控制系统能够实时监测激光器的内部状态,安全可靠。倍频后的激光器输出中心波长为514.98 nm,功率可达170 W,光功率稳定度为±0.07 dB,并且控制系统的所有器件及设备均100%采用国产化,满足515-nm大功率激光器的系统设计需求。

Abstract:In order to realize the stable and safe output of lasers, a control system based on a 515-nm high-power laser is designed. Firstly, the pump drive module of the system is studied. The analog sampling of the module is completed by Field Programmable Gate Array (FPGA) and the calculation output is completed in Digital Signal Processing (DSP). The closed-loop control of the constant current source is completed by using the digital Proportion-Integral-Derivative (PID) algorithm. Secondly, a Thermo Electric Cooler (TEC) is used to achieve the stable temperature control of the frequency doubling crystal module, and the Negative Temperature Coefficient (NTC) is used as the feedback to realize the temperature control. Finally, the human-computer interaction system of the laser is designed, which realizes the real-time monitoring, judgment and storage of the internal state of the laser. In order to verify the effectiveness of the control system, a pump is selected for testing. The experimental results show that the pump drive module can work continuously and stably, and the control system can monitor the internal state of the laser in real time, which is safe and reliable. The laser output center wavelength after frequency doubling is 514.98 nm, the power can reach 170 W, and the optical power stability is ±0.07 dB. All devices and equipment for the control system are made in China, meeting the system design requirements of 515-nm high-power laser.

-

Key words:

- fiber laser /

- pump drive module /

- laser control system

-

表 1 温度测试结果

Table 1. Results of temperature measurements

(°C) Expected

temperature1st

Measured

temperature2nd

Measured

temperature3rd

Measured

temperatureAverage

temperature|Max

error|40 39.98 40.01 39.99 39.99 0.02 41 41.02 40.99 41.01 41.01 0.02 42 42.03 42.02 41.99 42.01 0.03 43 42.99 42.99 43.01 43.00 0.01 44 44.02 43.97 44.01 44.00 0.03 45 44.99 45.01 45.02 45.01 0.02 46 46.01 45.98 45.99 45.99 0.02 47 47.01 47.03 46.99 47.01 0.03 48 48.01 48.01 47.99 48.00 0.01 49 48.99 48.98 49.01 48.99 0.02 50 50.01 50.03 49.99 50.01 0.03 -

[1] 党文佳, 李哲, 卢娜, 等. 0.9~1.0 μm近红外连续光纤激光器的研究进展[J]. 中国光学,2021,14(2):264-274. doi: 10.37188/CO.2020-0193DANG W J, LI ZH, LU N, et al. Research progress of 0.9~1.0 μm near-infrared continuous-wave fiber lasers[J]. Chinese Optics, 2021, 14(2): 264-274. (in Chinese) doi: 10.37188/CO.2020-0193 [2] 石俊凯, 王国名, 纪荣祎, 等. 结构紧凑的双波长连续波掺铒光纤激光器[J]. 中国光学,2019,12(4):810-819. doi: 10.3788/co.20191204.0810SHI J K, WANG G M, JI R Y, et al. Compact dual-wavelength continuous-wave Er-doped fiber laser[J]. Chinese Optics, 2019, 12(4): 810-819. (in Chinese) doi: 10.3788/co.20191204.0810 [3] 陈柄言, 于永吉, 吴春婷, 等. 窄线宽1 064 nm光纤激光泵浦高效率中红外3.8 μm MgO: PPLN光参量振荡器[J]. 中国光学,2021,14(2):361-367. doi: 10.37188/CO.2020-0169CHEN B Y, YU Y J, WU CH T, et al. High efficiency mid-infrared 3.8 μm MgO: PPLN optical parametric oscillator pumped by narrow linewidth 1 064 nm fiber laser[J]. Chinese Optics, 2021, 14(2): 361-367. (in Chinese) doi: 10.37188/CO.2020-0169 [4] 王烨, 张岩, 秦莉, 等. 高功率半导体激光器列阵封装引入应变的测量[J]. 光学 精密工程,2010,18(9):1951-1958.WANG Y, ZHANG Y, QIN L, et al. Measurement of packaging-induced strain in high power diode laser bar[J]. Optics and Precision Engineering, 2010, 18(9): 1951-1958. (in Chinese) [5] 任乐燕. 非线性晶体温度控制系统的研究[D]. 武汉: 华中科技大学, 2008.REN L Y. Research of temperature control system for nonlinear crystal[D]. Wuhan: Huazhong University of Science and Technology, 2008. (in Chinese) [6] 黄超, 马连英, 朱峰, 等. 陶瓷表面放电光泵浦源放电特性研究[J]. 中国光学,2019,12(6):1321-1328. doi: 10.3788/co.20191206.1321HUANG CH, MA L Y, ZHU F et al. Discharge characteristics of optical pumping source by ceramic surface discharge[J]. Chinese Optics, 2019, 12(6): 1321-1328. (in Chinese) doi: 10.3788/co.20191206.1321 [7] ERICKSON C J, VAN ZIJLL M, DOERMANN G, et al. An ultrahigh stability, low-noise laser current driver with digital control[J]. Review of Scientific Instruments, 2008, 79(7): 072107. [8] 田小建, 尚祖国, 高博, 等. 980 nm高稳定度激光泵浦源控制系统[J]. 光学 精密工程,2015,23(4):982-987. doi: 10.3788/OPE.20152304.0982TIAN X J, SHANG Z G, GAO B, et al. Control system for 980 nm high stability laser pump source[J]. Optics and Precision Engineering, 2015, 23(4): 982-987. (in Chinese) doi: 10.3788/OPE.20152304.0982 [9] 谭改娟, 谢冀江, 张来明, 等. 中波红外激光技术最新进展[J]. 中国光学,2013,6(4):501-512.TAN G J, XIE J J, ZHANG L M, et al. Recent progress in mid-infrared laser technology[J]. Chinese Optics, 2013, 6(4): 501-512. (in Chinese) [10] 王镇锐, 张兴斌, 温世喆, 等. 结合TEC的泵驱两相温控系统的空间应用[J]. 宇航学报,2018,39(10):1176-1184. doi: 10.3873/j.issn.1000-1328.2018.10.014WANG ZH R, ZHANG X B, WEN SH ZH, et al. Space applications of pumped two-phase temperature control system combined with TEC[J]. Journal of Astronautics, 2018, 39(10): 1176-1184. (in Chinese) doi: 10.3873/j.issn.1000-1328.2018.10.014 [11] 张元飞, 樊绍巍, 刘宏, 等. 面向高温的NTC温度检测系统设计优化及标定[J]. 哈尔滨工业大学学报,2018,50(1):18-23. doi: 10.11918/j.issn.0367-6234.201612038ZHANG Y F, FAN SH W, LIU H, et al. Optimal design and calibration of NTC thermistor based temperature measurement system for high temperature application[J]. Journal of Harbin Institute of Technology, 2018, 50(1): 18-23. (in Chinese) doi: 10.11918/j.issn.0367-6234.201612038 -

下载:

下载: