-

摘要:

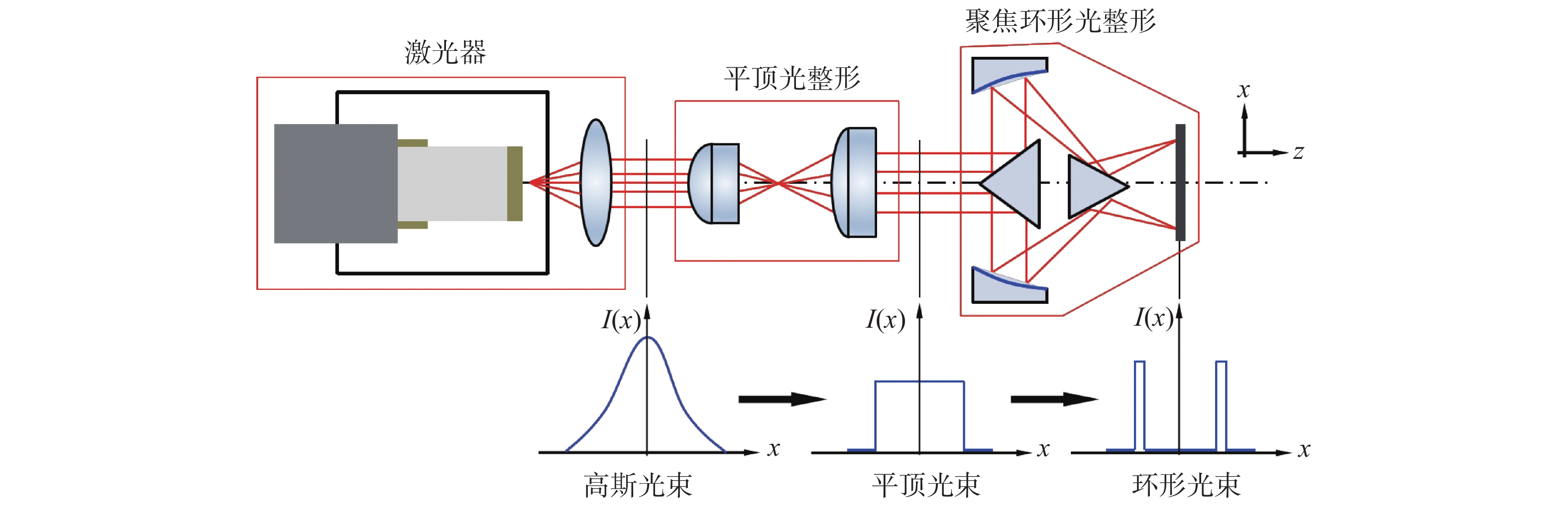

为了产生半径可自由调控的聚焦环形激光且确保离焦后光束强度仍均匀,本文提出一种透射-反射式组合的环形光光学系统设计方法。对于透射式系统,基于等能量分割原理,建立入射光与出射光投射高度的映射函数,优化透镜的各项参数,将入射的高斯光先整形成平顶圆形光,实现光束强度均匀化。反射式系统通过调整焦面环形光直径调控范围、工作距离等参数,结合几何光线追迹原理,计算圆锥反射镜、抛物柱面镜及动镜的各项参数,将平顶圆形光再整形成环形光。实验结果表明:当动镜半顶角为16°时,所设计系统能够实现聚焦环形光半径在15~30 mm范围的自由调控,尺寸误差不超过0.05 mm,离焦后强度均匀度达到84%。该设计方法无需更换系统镜片即可兼顾强度均匀性和尺寸自由度,可操作性好,产生的环形光加工精度和效率更高。

Abstract:We present a method for designing a transmissive-reflective combined optical system to generate a focused ring-shaped laser beam. The design aims to achieve a freely adjustable radius for the focused ring-shaped laser beam and ensure uniform beam intensity even after defocusing. Based on the principle of equal energy splitting, the transmissive system establishes mapping functions for the input and output light projection height. It optimizes the lens parameters to shape the incident Gaussian light into a flat-topped circular shape, thus achieving uniformity of beam intensity. On the other hand, the reflective system uses the adjustable diameter range of the focal plane ring-shaped light and working distance parameters. By applying the principle of geometric ray tracing, it calculates the parameters of the conical reflecting mirror, parabolic cylindrical mirror, and dynamic mirror, then the flat-topped circular light is transformed into a ring-shaped light. The experimental results show that when the half-apex angle of the dynamic mirror is 16°, the designed system can achieve a freely adjustable radius for the focused ring-shaped laser beam from 15 mm to 30 mm with a size error not more than 0.05 mm, and the intensity uniformity after defocusing reaches 84%. The design method can achieve both uniformity of intensity and freedom of size adjustment without replacing the system lens. It has good operability and yields higher precision and efficiency in the processing of ring-shaped light.

-

Key words:

- optical system /

- ring-shaped laser /

- radius control /

- defocus uniformity

-

表 1 初始条件

Table 1. Initial condition

入瞳半径

d/mm波长

λ/nmD

/mmS

/mm工作距离

/mm均匀度

/%数值 12 632.8 30 15 150~170 >80% 表 2 透镜参数

Table 2. Lens parameters

有效直径/mm 材料 厚度/mm 曲率半径/mm Conic A4 A6 A8 A10 面型1 27 PMMA 15 5 −1.914 1.047×10−4 −3.943×10−7 1.167×10−9 −1.609×10−12 面型2 36 PMMA 12 17.877 −0.959 −1.983×10−4 3.056×10−8 −4.444×10−11 7.283×10−14 表 3 反射镜及面上特征点参数

Table 3. Parameters of characteristic points on the mirror and surface

α(°) Q F f/mm K θ(°) L/mm ΔZ/mm 材料 数值 45 (18,−114.04) (−50,−22.04) 160 (70,−180.04) 16 27.2 4.5 7075-T6 -

[1] SUGIOKA K, CHENG Y. A tutorial on optics for ultrafast laser materials processing: basic microprocessing system to beam shaping and advanced focusing methods[J]. Advanced Optical Technologies, 2012, 1(5): 353-364. doi: 10.1515/aot-2012-0033 [2] 吴顺华, 刘国军, 王贞福, 等. 低温808 nm高效率半导体激光器[J]. 发光学报,2022,43(5):786-795. doi: 10.37188/CJL.20220025WU SH H, LIU G J, WANG ZH F, et al. Low temperature 808 nm high efficiency semiconductor laser[J]. Chinese Journal of Luminescence, 2022, 43(5): 786-795. (in Chinese) doi: 10.37188/CJL.20220025 [3] 顾勇刚, 牛健, 杨坚, 等. 激光在医疗领域中的应用[J]. 中国光学(中英文),2023,16(2):283-295. doi: 10.37188/CO.2023-0017GU Y G, NIU J, YANG J, et al. Application of laser in the medical field[J]. Chinese Optics, 2023, 16(2): 283-295. (in Chinese) doi: 10.37188/CO.2023-0017 [4] 韩赛一, 田思聪, 徐汉阳, 等. 高速1 550 nm垂直腔面发射激光器研究进展[J]. 发光学报,2022,43(5):736-744. doi: 10.37188/CJL.20220048HAN S Y, TIAN S C, XU H Y, et al. Research progress of high-speed 1550 nm vertical cavity surface emitting laser[J]. Chinese Journal of Luminescence, 2022, 43(5): 736-744. (in Chinese) doi: 10.37188/CJL.20220048 [5] 刘小亮, 孙少华, 孟祥厅, 等. 激光诱导击穿光谱法测定稀土矿区土壤中钐含量[J]. 中国光学(中英文),2022,15(4):712-721. doi: 10.37188/CO.2022-0042LIU X L, SUN SH H, MENG X T, et al. Measurement of Sm in rare earth mineral soil using laser-induced Breakdown spectroscopy[J]. Chinese Optics, 2022, 15(4): 712-721. (in Chinese) doi: 10.37188/CO.2022-0042 [6] 高瑀含. 高斯光束整形技术研究[D]. 长春: 长春理工大学, 2012.GAO Y H. Research on Gaussian beam shaping[D]. Changchun: Changchun University of Science and Technology, 2012. (in Chinese) [7] 范祺, 蔡玉强, 贾思楠. 基于RobotStudio的机器人焊接工作站仿真[J]. 华北理工大学学报(自然科学版),2023,45(1):81-88.FAN Q, CAI Y Q, JIA S N. Robot welding workstation simulation based on Robot Studio[J]. Journal of North China University of Science and Technology (Natural Science Edition), 2023, 45(1): 81-88. (in Chinese) [8] 陈银银. 基于激光视觉焊缝跟踪技术的机器人焊接智能产线设计[J]. 科技创新与应用,2023,13(1):120-123.CHEN Y Y. Design of robot welding intelligent production line based on laser vision seam tracking technology[J]. Technology Innovation and Application, 2023, 13(1): 120-123. (in Chinese) [9] SHAMOV E M, EVTIHEEV N N, SHIGANOV I N, et al. Technology and equipment for laser welding of annular pipes junction in fixed position of gas-main pipelines[J]. Journal of Physics:Conference Series, 2018, 1109(1): 012025. [10] 付强, 闫磊, 谭双龙, 等. 轻小型金属基增材制造光学系统[J]. 中国光学(中英文),2022,15(5):1019-1028. doi: 10.37188/CO.2022-0128FU Q, YAN L, TAN SH L, et al. Light-and-small optical systems by metal-based additive manufacturing[J]. Chinese Optics, 2022, 15(5): 1019-1028. (in Chinese) doi: 10.37188/CO.2022-0128 [11] 傅戈雁, 石世宏, 韩学磊. 环形激光光内同轴送丝焊接试验研究[J]. 中国激光,2010,37(8):2080-2085. doi: 10.3788/CJL20103708.2080FU G Y, SHI SH H, HAN X L. Test research of laser welding based on coaxial wire feeding through an annular laser beam[J]. Chinese Journal of Lasers, 2010, 37(8): 2080-2085. (in Chinese) doi: 10.3788/CJL20103708.2080 [12] KOTAR M, FUJISHIMA M, LEVY G N. Advances in the understanding of the annular laser beam wire cladding process[J]. Journal of Materials Processing Technology, 2021, 294: 117105. doi: 10.1016/j.jmatprotec.2021.117105 [13] SHEN ZH X, YU J, SONG ZH ZH, et al. Customized design and efficient fabrication of two freeform aluminum mirrors by single point diamond turning technique[J]. Applied Optics, 2019, 58(9): 2269-2276. doi: 10.1364/AO.58.002269 [14] 王德恩, 杨英, 张鑫, 等. 一种环形光束变换装置及变换方法: 中国, 108931855A[P]. 2018-12-04.WANG D E, YANG Y, ZHANG X, et al.. An annular beam conversion device and conversion method: CN, 108931855A[P]. 2018-12-04. (in Chinese) [15] 田玉元, 张佳琦, 姜潇桐, 等. 轴向位置可调的双中空环形光斑[J]. 中国光学(中英文),2023,16(2):329-338. doi: 10.37188/CO.2022-0036TIAN Y Y, ZHANG J Q, JIANG X T, et al. Double doughnut-shaped focal spots with controllable position in axial direction[J]. Chinese Optics, 2023, 16(2): 329-338. (in Chinese) doi: 10.37188/CO.2022-0036 [16] 史光远. 基于非球面柱透镜的高斯光束整形[D]. 天津: 天津理工大学, 2014.SHI G Y. Gaussian beam shaping based on aspheric cylindrical lenses[D]. Tianjin: Tianjin University of Technology, 2014. (in Chinese) [17] 常颖, 王狮凌. 基于球面-非球面柱透镜的圆光斑高斯光束整形[J]. 激光与光电子学进展,2018,55(6):89-94.CHANG Y, WANG SH L. Gaussian beam shaping of round spot based on spheric-aspheric cylindrical lens[J]. Laser &Optoelectronics Progress, 2018, 55(6): 89-94. (in Chinese) [18] 胡萍, 刘晓萌, 田颖, 等. 直接泵浦中红外Dy: PbGa2S4激光器研究进展[J]. 发光学报,2022,43(12):1905-1914. doi: 10.37188/CJL.20220203HU P, LIU X M, TIAN Y, et al. Research progress of directly pumped mid-infrared Dy: PbGa2S4 lasers[J]. Chinese Journal of Luminescence, 2022, 43(12): 1905-1914. (in Chinese) doi: 10.37188/CJL.20220203 [19] 彭亚蒙, 苏宙平. 用于发散激光光束整形的自由曲面透镜设计[J]. 光学学报,2016,36(5):217-227.PENG Y M, SU ZH P. Design of freeform surface lens for shaping divergent laser beam[J]. Acta Optica Sinica, 2016, 36(5): 217-227. (in Chinese) [20] CHEN B H, WU Q Y, TANG Y H, et al. Design of an optical system for generating annular-focused beams using a conical mirror and a parabolic cylindrical mirror[J]. Optik, 2023, 281: 170625. doi: 10.1016/j.ijleo.2023.170625 [21] CHEN J N, YU Y J, WANG F F. Production of annular flat-topped vortex beams[J]. Chinese Optics Letters, 2011, 9(1): 011402. doi: 10.3788/COL201109.011402 [22] 陈重琳. 利用液晶空间光调制器将激光整形为平顶光束的研究[D]. 武汉: 武汉理工大学, 2016.CHEN ZH L. Investigation on flat-top laser beam shaping using liquid crystal spatial light modulator[D]. Wuhan: Wuhan University of Technology, 2016. (in Chinese) -

下载:

下载: