-

摘要:

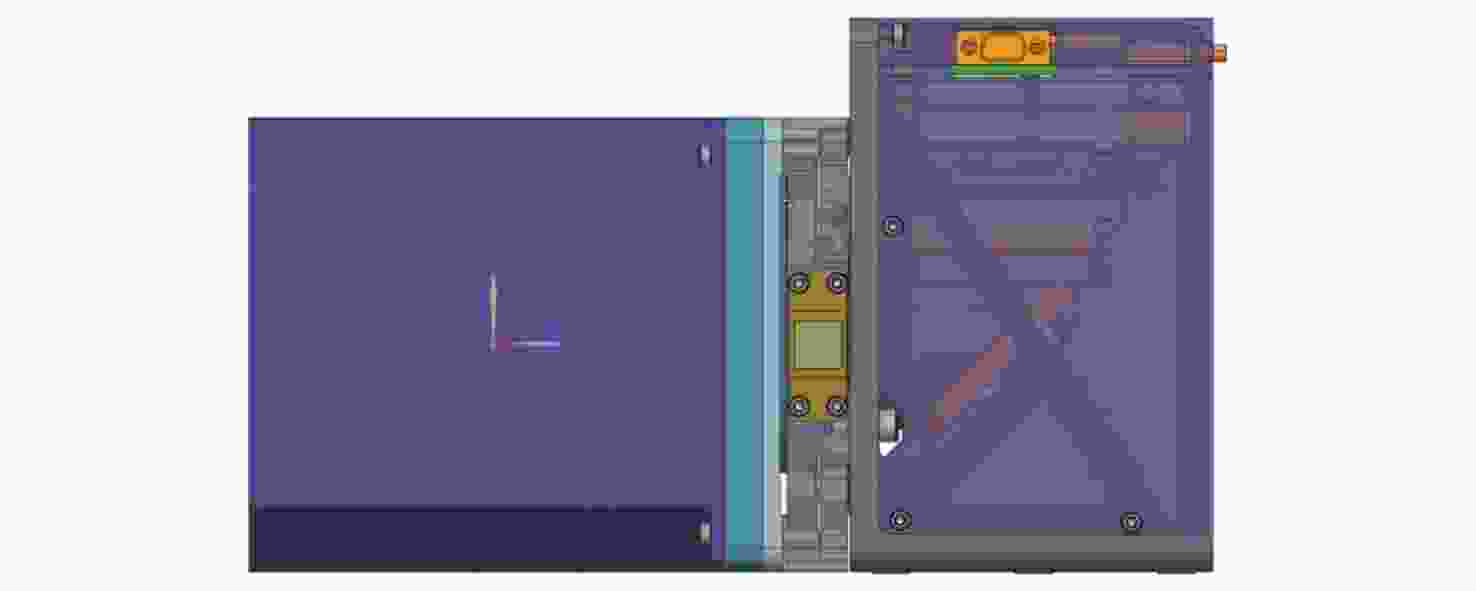

为了满足精准高效快速部署航天遥感器对轻小型空间相机的迫切需求,对满足轻小型相机成像的光学系统形式及成像体制进行了详细对比分析,确定了RC+补偿组的光学系统形式,采用小F数+微小像元的成像体制。对比美国鸽子相机的详细参数,设计了500 km轨道高度上可实现3.48 m分辨率的轻小型全铝高分相机。详细介绍了相机的总体结构、光学系统、光机结构、成像电子学及热控设计结果,得到F5.6的RC+补偿组光学设计结果。采用RSA-6061微晶铝合金做为相机反射镜的结构材料,配合一体化硬铝合金高刚性结构。静力学(重力变形和温度变形)仿真分析结果满足光学设计公差要求。动力学仿真分析结果表明:一阶模态为302.92 Hz,具有足够高的动态刚度和安全裕度。成像电子学采用3.2 μm大面阵9 K×7 K探测器低噪声小型化设计。相机热控由卫星平台保证20 °C±4 °C的温度水平。集成测试结果表明:(1)相机中心视场波像差RMS为

λ /15.6,5个视场系统波像差均优于λ /12.3,可以确保相机近衍射极限高质量成像。实测奈奎斯特频率处的光学传递函数为0.217;(2)相机三方向正弦振动最大处放大1.17倍,整机一阶模态为295 Hz,与仿真结果的偏差为2.61%,相机结构刚度大,力学稳定性好;1×10−4 Pa,16 °C、20 °C、24 °C三个温度工况下成像清晰,可分辨奈奎斯特频率处对应的分辨率板图像;(3)对2 km外目标成像效果良好,图像清晰且灰度层次分明,阴影边界锐利。本文所设计轻小型全铝高分相机在500 km轨道高度上实现了3.48 m分辨率,15 km×15 km幅宽,整机重量为2 kg,结构刚度和强度试验结果满足航天发射场景需要,可以为轻小型甚高分辨率空间相机设计提供理论指导和工程借鉴。Abstract:In order to meet the urgent need of developing lightweight and compact space cameras quickly, effectively, and rapidly, a detailed comparative analysis is conducted, including optical system forms and imaging systems. The optical system form of RC+ compensation group is determined, and the imaging system of small F#+micropixel is adopted. Compared with the detailed parameters of the DOVE camera, a lightweight all-aluminum high-resolution camera with a resolution of 3.48 m at an orbital altitude of 500 km is designed. The overall design results of the camera, its optical and optomechanical structures, imaging electronics, and thermal control are described in detail. The optical design results of the RC+ compensation group of F5.6 are obtained. Using RSA-6061 microcrystalline aluminum alloy as the structural material of the mirror, coupled with an integrated high-rigidity hard aluminum alloy structure, the static (gravity and temperature deformation) simulation analysis results meet the optical design tolerance requirements. The dynamic simulation analysis results show that the first order mode is 302.92 Hz, which has a sufficiently high dynamic stiffness and safety redundancy. The imaging electronics using a 3.2 μm large area array 9 K×7 K detector is designed for low noise miniaturization. Thermal control is provided by the satellite platform at a temperature level of 20 °C± 4 °C for the camera. Integration test results show that: (1) The RMS wave aberration of the central field of view is

λ /15.6, and the wavefront aberration of the five fields of view is better thanλ /12.3, which ensure high-quality imaging near the diffraction limit of the camera. The measured optical transfer function at Nyquist frequency is 0.217; (2) The maximum sinusoidal vibration of the camera in three directions is amplified 1.17 times, and the first-order mode of the camera is 295 Hz, with a deviation of 2.61% from the simulation result. The structural stiffness is high and the mechanical stability is good. Under vacuum environment of 10−4 Pa and three different temperatures of 16 °C, 20 °C and 24 °C, the image is clear and can distinguish the corresponding resolution plate image at Nyquist frequency; (3) The image of 2 km outfield target is good, as well as clear and distinct grayscale image with sharp shadow boundaries. The all-aluminum high-resolution camera is achieved 3.48 m resolution at a track height of 500 km,width of 15 km×15 km and a total weight of 2 kg. The structural rigidity and strength test results meet the requirements of space launch scenarios, and these can provide theoretical guidance and engineering reference for the design of lightweight and higher-resolution space cameras.-

Key words:

- lightweight and compact size /

- high rigidity /

- dynamic stiffness /

- low noise

-

表 1 典型轻小结构光学系统型式特点对比

Table 1. Comparison of types and characteristics for common optical systems

光学系统型式 结构特点 同轴RC+补偿组 结构尺寸小且简单、重量轻,视场大于1°,畸变小,像质较优良,装调难度适中,光学长度约为焦距的0.4~0.2倍 同轴三反TMC 结构尺寸小、重量较轻,视场约为1°~3°,畸变较小,像质优良,装调难度大,光学长度约为焦距的0.4~0.2倍 离轴三反Rug-TMA 结构较大、重量较轻,视场为3°,畸变较大,像质优良,装调难度大,光学长度约为焦距的0.33~0.27倍 表 2 轻小型全铝高分相机光学设计结果

Table 2. Optical design results of all-aluminum high resolution camera with lightweight and compact size

指标 波段范围

/nm像元分辨率GSD/m 光学焦距

/mmF# 成像幅宽

/km视场 参数 450~800 3.48 460 5.6 15×15

(@500 km)Φ2.5° 表 3 光学系统稳定性公差

Table 3. Stability tolerances of the optical system

指标 X向偏心

(μm)Y向偏心

(μm)Z向位置

公差(μm)绕X轴

倾角(″)绕Y轴

倾角(″)绕Z轴

倾角(″)主镜 ±1.5 ±1.5 ±2 ±1 ±1 ±5 次镜 ±1 ±1 ±4 ±2 ±2 ±20 三镜 ±5 ±5 ±10 ±3 ±3 ±20 透镜1 ±5 ±5 ±10 ±2.5 ±2.5 ±20 透镜2 ±6 ±6 ±10 ±3 ±3 ±20 透镜3 ±10 ±10 ±15 ±3.5 ±3.5 ±20 表 4 相机静力学和动力学分析结果

Table 4. Static and dynamic analysis results of the camera

整机仿真 X向(nm) Y向(nm) Z向(nm) 主镜 重力

变形面型(RMS) 5.222 5.222 1.939 角位移 0.151″ 0.151″ 0.009″ 温度变形 1.396 次镜 重力

变形面型(RMS) 1.557 1.587 0.036 角位移 0.578″ 0.601″ 0.012″ 温度变形 0.741 整机模态 302.92 Hz(一阶) 表 5 对日定向低温工况各组件温度

Table 5. Each component's temperature under low temperature on the behavior of sun-tracking

序号 组件名称 温度/°C 1 主镜组件 20.4 2 次镜组件 20.1 3 补偿镜筒 20.7 4 尾罩 16.9~21.1 表 6 相机力学振动试验条件

Table 6. Mechanical vibration test conditions of the camera

正弦振动 名称 频率范围(Hz) 试验量级 正弦X/Y/Z 5~8 4.08 mm(O-P) 8~100 1.05 g 扫描率 4.0 oct/min 随机振动 名称 频率范围(Hz) 功率谱密度 总均方根加速度值 X/Y/Z 20~150 +3 dB/oct 5.02 g 150~600 0.01 g2/Hz 600~1100 0.02 g2/Hz 1100~2000 −6 dB/oct 表 7 相机波像差测试结果

Table 7. Wavefront aberration results of the camera

视场 波像差(RMS) 中心视场 λ/15.6 左视场 λ/14 右视场 λ/12.9 上视场 λ/12.3 中下视场 λ/14.7 -

[1] 王丰璞, 李新南, 徐晨, 等. 大型光学红外望远镜拼接非球面子镜反衍补偿检测光路设计[J]. 中国光学(中英文),2021,14(5):1184-1193. doi: 10.37188/CO.2020-0218WANG F P, LI X N, XU CH, et al. Optical testing path design for LOT aspheric segmented mirrors with reflective-diffractive compensation[J]. Chinese Optics, 2021, 14(5): 1184-1193. (in Chinese) doi: 10.37188/CO.2020-0218 [2] 赵宇, 苏成志, 赵贵军, 等. Φ500mm超轻量化SiC反射镜结构优化设计[J]. 中国光学(中英文),2020,13(6):1352-1361. doi: 10.37188/CO.2019-0201ZHAO Y, SU CH ZH, ZHAO G J, et al. Structural optimization for the design of an ultra-lightweight SiC mirror with a diameter of 500 mm[J]. Chinese Optics, 2020, 13(6): 1352-1361. (in Chinese) doi: 10.37188/CO.2019-0201 [3] 曹明辉, 辛宏伟, 陈长征, 等. 微小型空间相机碳纤维整体式主框架轻量化设计[J]. 仪器仪表学报,2022,43(2):54-61.CAO M H, XIN H W, CHEN CH ZH, et al. A lightweight design of carbon fiber integrated main frame for the micro space camera[J]. Chinese Journal of Scientific Instrument, 2022, 43(2): 54-61. (in Chinese) [4] 刘永健, 张飞, 谢婷, 等. 基于伴随仿真的偏振复用超构透镜[J]. 中国光学(中英文),2021,14(4):754-763. doi: 10.37188/CO.2021-0035LIU Y J, ZHANG F, XIE T, et al. Polarization-multiplexed metalens enabled by adjoint optimization[J]. Chinese Optics, 2021, 14(4): 754-763. (in Chinese) doi: 10.37188/CO.2021-0035 [5] 孔德成, 刘伟, 颜昌翔, 等. 空间卫星相机安装固定基频性能优化设计[J]. 计算机仿真,2019,36(6):98-102.KONG D CH, LIU W, YAN CH X, et al. Optimization design of fundamental frequency on space satellite camera installation[J]. Computer Simulation, 2019, 36(6): 98-102. (in Chinese) [6] XIE Y J, MAO X L, LI J P, et al. Optical design and fabrication of an all-aluminum unobscured two-mirror freeform imaging telescope[J]. Applied Optics, 2020, 59(3): 833-840. doi: 10.1364/AO.379324 [7] 王上, 张星祥, 朱俊青. 空间相机全铝合金光机结构的设计与分析[J]. 红外技术,2022,44(4):364-370.WANG SH, ZHANG X X, ZHU J Q. Design and analysis of all aluminum alloy optical mechanical structure of space cameras[J]. Infrared Technology, 2022, 44(4): 364-370. (in Chinese) [8] RISSE S, GEBHARDT A, DAMM C, et al. Novel TMA telescope based on ultra precise metal mirrors[J]. Proceedings of SPIE, 2008, 7010: 701016. doi: 10.1117/12.789824 [9] JUNAID M. The development of a hardware-in-the-loop platform for the attitude determination and control testing of a small satellite[J]. Byte Españ a, 2015, 1(4): 78-80. [10] HAND E. Startup liftoff[J]. Science, 2015, 348(6231): 172-177. doi: 10.1126/science.348.6231.172 [11] 龚燃, 姜代洋. 2022年国外民商用对地观测卫星发展综述[J]. 国际太空,2023(2):26-33.GONG R, JIANG D Y. Overview of the development of foreign civil and commercial earth observation satellites in 2022[J]. Space International, 2023(2): 26-33. (in Chinese) [12] 伍雁雄, 王丽萍. 小型化宽谱段星敏感器光学系统设计[J]. 应用光学,2021,42(5):782-789. doi: 10.5768/JAO202142.0501004WU Y X, WANG L P. Optical system of star sensor with miniaturization and wide spectral band[J]. Journal of Applied Optics, 2021, 42(5): 782-789. (in Chinese) doi: 10.5768/JAO202142.0501004 [13] 金光, 张亮, 胡福生. 大 F数高分辨率空间望远镜光学系统[J]. 光学 精密工程,2007,15(2):155-159.JIN G, ZHANG L, HU F SH. Investigation on space optical system of high F number and high resolution[J]. Optics and Precision Engineering, 2007, 15(2): 155-159. (in Chinese) [14] 张刘, 郑潇逸, 张帆, 等. 大容差多柔性透镜组结构优化设计[J]. 吉林大学学报(工学版),2021,51(2):478-485.ZHANG L, ZHENG X Y, ZHANG F, et al. Structural optimization design of large tolerance and multi-flexibility lens subassembly[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(2): 478-485. (in Chinese) [15] 周鹏骥, 王晓东, 董吉洪, 等. 天问一号高分相机成像噪声分析与抑制[J]. 光学 精密工程,2022,30(2):217-226. doi: 10.37188/OPE.20223002.0217ZHOU P J, WANG X D, DONG J H, et al. Imaging noise analyzing and suppressing for Tianwen-1 high-resolution camera[J]. Optics and Precision Engineering, 2022, 30(2): 217-226. (in Chinese) doi: 10.37188/OPE.20223002.0217 [16] 温中凯, 张庆君, 李爽, 等. 空间光电跟瞄系统多光轴平行性标校研究[J]. 中国光学(中英文),2021,14(3):625-633. doi: 10.37188/CO.2020-0133WEN ZH K, ZHANG Q J, LI SH, et al. Multi-optical axis parallelism calibration of space photoelectric tracking and aiming system[J]. Chinese Optics, 2021, 14(3): 625-633. (in Chinese) doi: 10.37188/CO.2020-0133 [17] 李寒霜, 李博, 李昊晨, 等. 基于一种透镜材料的宽谱段紫外成像仪光学设计[J]. 中国光学(中英文),2022,15(1):65-71. doi: 10.37188/CO.2021-0127LI H SH, LI B, LI H CH, et al. Optical design of a wide-spectrum ultraviolet imager based on a single material[J]. Chinese Optics, 2022, 15(1): 65-71. (in Chinese) doi: 10.37188/CO.2021-0127 -

下载:

下载: