On-machine detection technology and application progress of high dynamic range fringe structured light

-

摘要:

条纹结构光技术是近年来发展迅速的非接触式测量方法,为机械加工在机检测提供了新的解决方案。由于加工环境光线复杂且金属零件本身具有高反光的特性,造成结构光在机检测的精度降低。将高动态范围(High Dynamic Range,HDR)技术应用于结构光检测中,可抑制高反光的影响,实现金属零件在复杂场景的测量。本文首先介绍了结构光测量原理,总结出HDR结构光在机检测面临的难点;其次,对HDR结构光技术进行了全面综述,以机械加工在机检测为背景,对基于硬件设备的HDR技术和基于条纹算法的HDR技术分别进行了归纳分析;然后,根据在机检测的条件需求,对各类技术进行总结,并比较不同方法的优缺点和在机检测的适用性;最后,结合近年来先进制造技术和精密测量的研究热点,对潜在应用进行分析,提出技术展望。

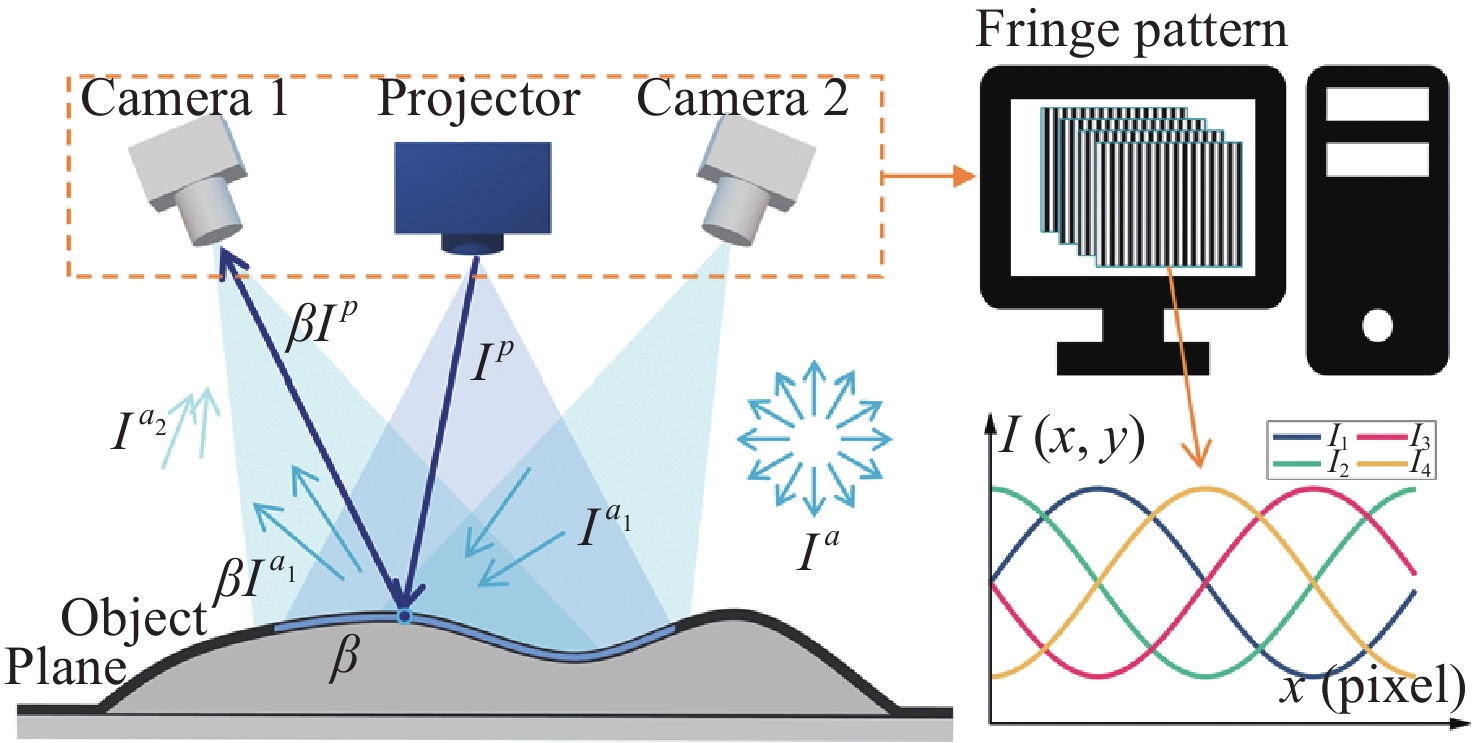

Abstract:Fringe structured light technology is a non-contact measurement method, which has developed rapidly in recent years and provides a new solution for on-machine detection in mechanical processing. However, the accuracy of structured light for on-machine detection is compromised by the convoluted lighting in machining environments and metal parts’ high reflectivity, leading to inaccurate measurements. Applying high dynamic range (HDR) technology to structured light detection can reduce the effect of high reflectivity, achieving the measurement of metal parts in complex scenes. This paper introduces the measurement principle of structured light and summarizes the challenges of on-machine detection for HDR structured light. Subsequently, this paper provides a comprehensive review of HDR structured light technology. In the context of on-machine detection of mechanical processing, the HDR technology based on hardware equipment and the HDR technology based on stripe algorithm are discussed and analyzed, respectively. Following this, different technologies are summarized according to the requirements of on-machine detection. The advantages and disadvantages of various methods are presented, and the applicability of on-machine detection is compared. Finally, the potential applications are analyzed, and the technological prospects will be proposed in combination with the research hotspots of advanced manufacturing technology and precision measurement in recent years.

-

表 1 三维视觉测量技术分类

Table 1. Classification of three-dimensional visual measurement technology

视觉测

量分类是否投

射光源具体分类 特点 被动视

觉测量否 单目视觉测量 基于图像聚焦程度完成三维重建,多用于显微视觉测量中。 双目视觉测量 根据三角测量原理实现三维重建,应用于双目立体摄像头。 多目视觉测量 增加辅助相机,通过光束平差提高测量精度。 主动视

觉测量是 点扫描式 激光器投射光点,根据光标中心坐标和标定数据进行重建,测量效率低。 线扫描式 激光器投射光条代替光点,提高效率,广泛应用于激光扫描仪中。 面扫描式 通过投影仪投射二维结构光,单次投射覆盖区域大,测量效率最高。 表 2 基于硬件设备的HDR技术对比

Table 2. Comparison of HDR technologies based on hardware devices

表 3 基于条纹算法的HDR技术对比

Table 3. Comparison of HDR technologies based on fringe algorithm

表 4 各类HDR测量技术总结

Table 4. Summary of various HDR measurement technologies

HDR技术 优点 缺点 光线条件

适应性系统硬件设备 检测效率 加工在机检测 相机曝光 无需添置额外硬件、无后续其他处理。 选择曝光时间具有一定盲目性,需多次测量合成最优数据。 单次曝光适应性较差,多重曝光适应性好。 简单 差 不适用 偏振滤光片 额外硬件较为简单、无其他复杂算法。 单偏振通道易降低整体图像的SNR,使用多个偏振通道时,需多次调整偏振片角度合成最优数据。 单通道适应性较差,多通道适应性好。 单通道简单,多通道较复杂。 差 不适用 相位偏折术 适用于类镜面物体的测量,测量精度高,无其他复杂算法 空间摆放位置受限制,不适用于金属等反光件。 好 简单 好 适用(镜面、类镜面工件) 光度立体法 利用多照明系统实现视角补盲 建立的反射模型不具有普适性。 好 复杂 好 不适用 调整条纹强度 逐像素调整图像亮度,条纹图像具有较高的SNR 对于场景和反射区域的标定需投射多组条纹确定映射关系,算法的效率需依靠投影仪的帧率决定。 好 简单 好

(配合高速投影)适用(配合高速投影) 颜色信息 算法简单,无其他复杂算法 对于带有颜色和纹理特征的被测物,测量精度会受到影响。 好 简单 好 适用 图案编码、解码 算法简单 增加条纹频率和相移步数,影响了测量的效率,且测量精度较低。 差 简单 差 不适用 智能算法 测量效率高,可以实现动态测量 算法复杂,成本较高,需要高度定制的训练样本。 好 简单 好 适用 -

[1] 李文龙, 李中伟, 毛金城. iPoint3D曲面检测软件开发与工程应用综述[J]. 机械工程学报,2020,56(7):127-150. doi: 10.3901/JME.2020.07.127LI W L, LI ZH W, MAO J CH. The development and application review of iPoint3D software for surface inspection[J]. Journal of Mechanical Engineering, 2020, 56(7): 127-150. (in Chinese) doi: 10.3901/JME.2020.07.127 [2] 李茂月, 刘泽隆, 赵伟翔, 等. 面结构光在机检测的叶片反光抑制技术[J]. 中国光学,2022,15(3):464-475. doi: 10.37188/CO.2021-0194LI M Y, LIU Z L, ZHAO W X, et al. Blade reflection suppression technology based on surface structured light on-machine detection[J]. Chinese Optics, 2022, 15(3): 464-475. (in Chinese) doi: 10.37188/CO.2021-0194 [3] 任明阳, 王立忠, 赵建博, 等. 复杂曲面零件面结构光扫描视点规划[J]. 中国光学(中英文),2023,16(1):113-126. doi: 10.37188/CO.2022-0026REN M Y, WANG L ZH, ZHAO J B, et al. Viewpoint planning of surface structured light scanning for complex surface parts[J]. Chinese Optics, 2023, 16(1): 113-126. (in Chinese) doi: 10.37188/CO.2022-0026 [4] 张宗华, 刘巍, 刘国栋, 等. 三维视觉测量技术及应用进展[J]. 中国图象图形学报,2021,26(6):1483-1502.ZHANG Z H, LIU W, LIU G D, et al. Overview of the development and application of 3D vision measurement technology[J]. Journal of Image and Graphics, 2021, 26(6): 1483-1502. (in Chinese) [5] XU J, ZHANG S. Status, challenges, and future perspectives of fringe projection profilometry[J]. Optics and Lasers in Engineering, 2020, 135: 106193. doi: 10.1016/j.optlaseng.2020.106193 [6] 张宗华, 于瑾, 高楠, 等. 高反光表面三维形貌测量技术[J]. 红外与激光工程,2020,49(3):0303006. doi: 10.3788/IRLA202049.0303006ZHANG Z H, YU J, GAO N, et al. Three-dimensional shape measurement techniques of shiny surfaces[J]. Infrared and Laser Engineering, 2020, 49(3): 0303006. (in Chinese) doi: 10.3788/IRLA202049.0303006 [7] FENG S J, ZHANG L, ZUO CH, et al. High dynamic range 3D measurements with fringe projection profilometry: a review[J]. Measurement Science and Technology, 2018, 29(12): 122001. doi: 10.1088/1361-6501/aae4fb [8] ZHANG P, ZHONG K, LI ZH W, et al. Hybrid-quality-guided phase fusion model for high dynamic range 3D surface measurement by structured light technology[J]. Optics Express, 2022, 30(9): 14600-14614. doi: 10.1364/OE.457305 [9] Zhang S. Rapid and automatic optimal exposure control for digital fringe projection technique[J]. Optics and Lasers in Engineering, 2020, 128: 106029. doi: 10.1016/j.optlaseng.2020.106029 [10] 马泽龙, 高慧斌, 余毅, 等. 采用图像直方图特征函数的高速相机自动曝光方法[J]. 光学 精密工程,2017,25(4):1026-1035. doi: 10.3788/OPE.20172504.1026MA Z L, GAO H B, YU Y, et al. Auto exposure control for high frame rate camera using image histogram feature function[J]. Optics and Precision Engineering, 2017, 25(4): 1026-1035. (in Chinese) doi: 10.3788/OPE.20172504.1026 [11] 雷经发, 陆宗胜, 李永玲, 等. 基于投影栅相位法和多曝光图像融合技术的强反射表面轮廓检测[J]. 光学 精密工程,2022,30(18):2195-2204. doi: 10.37188/OPE.20223018.2195LEI J F, LU Z SH, LI Y L, et al. High reflection surface topography measurement based on fringe projection phase method and multi-exposure image fusion technology[J]. Optics and Precision Engineering, 2022, 30(18): 2195-2204. (in Chinese) doi: 10.37188/OPE.20223018.2195 [12] ZHANG S, YAU S T. High dynamic range scanning technique[J]. Optical Engineering, 2009, 48(3): 033604. doi: 10.1117/1.3099720 [13] SONG ZH, JIANG H L, LIN H B, et al. A high dynamic range structured light means for the 3D measurement of specular surface[J]. Optics and Lasers in Engineering, 2017, 95: 8-16. doi: 10.1016/j.optlaseng.2017.03.008 [14] FENG SH J, ZHANG Y ZH, CHEN Q, et al. General solution for high dynamic range three-dimensional shape measurement using the fringe projection technique[J]. Optics and Lasers in Engineering, 2014, 59: 56-71. doi: 10.1016/j.optlaseng.2014.03.003 [15] CUI H H, LI ZH J, TIAN W, et al. Multiple-exposure adaptive selection algorithm for high dynamic range 3D fringe projection measurement[J]. Proceedings of SPIE, 2019, 11053: 110530M. [16] RAO L, DA F P. High dynamic range 3D shape determination based on automatic exposure selection[J]. Journal of Visual Communication and Image Representation, 2018, 50: 217-226. doi: 10.1016/j.jvcir.2017.12.003 [17] WU K, TAN J, XIA H L, et al. An exposure fusion-based structured light approach for the 3D measurement of a specular surface[J]. IEEE Sensors Journal, 2021, 21(5): 6314-6324. doi: 10.1109/JSEN.2020.3027317 [18] SALAHIEH B, CHEN ZH Y, RODRIGUEZ J J, et al. Multi-polarization fringe projection imaging for high dynamic range objects[J]. Optics Express, 2014, 22(8): 10064-10071. doi: 10.1364/OE.22.010064 [19] 平茜茜, 刘勇, 董欣明, 等. 基于偏振双目视觉的无纹理高反光目标三维重构[J]. 红外与毫米波学报,2017,36(4):432-438.PING X X, LIU Y, DONG X M, et al. 3-D reconstruction of textureless and high-reflective target by polarization and binocular stereo vision[J]. Journal of Infrared and Millimeter Waves, 2017, 36(4): 432-438. (in Chinese) [20] 郝婧蕾, 赵永强, 赵海盟, 等. 偏振多光谱机器视觉的高反光无纹理目标三维重构方法[J]. 测绘学报,2018,47(6):816-824.HAO J L, ZHAO Y Q, ZHAO H M, et al. 3D Reconstruction of High-reflective and Textureless Targets Based on Multispectral Polarization and Machine Vision[J]. Acta Geodaetica et Cartographica Sinica, 2018, 47(6): 816-824. (in Chinese) [21] WANG Y H, ZHANG Q, HU Y, et al. Rapid 3D measurement of high dynamic range surface based on multi-polarization fringe projection[J]. Optical Engineering, 2021, 60(8): 084107. [22] ZHU ZH M, ZHU W T, ZHOU F Q, et al. Three-dimensional measurement of fringe projection based on the camera response function of the polarization system[J]. Optical Engineering, 2021, 60(5): 055105. [23] MAEDA Y, SHIBATA S, HAGEN N, et al. Single shot 3D profilometry by polarization pattern projection[J]. Applied Optics, 2020, 59(6): 1654-1659. doi: 10.1364/AO.382690 [24] XIANG G, ZHU H J, GUO H W. Spatial phase-shifting profilometry by use of polarization for measuring 3D shapes of metal objects[J]. Optics Express, 2021, 29(13): 20981-20994. doi: 10.1364/OE.427407 [25] 王月敏, 张宗华, 高楠. 基于全场条纹反射的镜面物体三维面形测量综述[J]. 光学 精密工程,2018,26(5):1014-1027. doi: 10.3788/OPE.20182605.1014WANG Y M, ZHANG Z H, GAO N. Review on three-dimensional surface measurements of specular objects based on full-field fringe reflection[J]. Optics and Precision Engineering, 2018, 26(5): 1014-1027. (in Chinese) doi: 10.3788/OPE.20182605.1014 [26] ZHUANG Y CH, ZHENG Y M, LIN SH B, et al. Surface shape distortion online measurement method for compact laser cavities based on phase measuring Deflectometry[J]. Photonics, 2022, 9(3): 151. doi: 10.3390/photonics9030151 [27] GAO F, XU Y J, JIANG X Q. Near optical coaxial phase measuring deflectometry for measuring structured specular surfaces[J]. Optics Express, 2022, 30(10): 17554-17566. doi: 10.1364/OE.457198 [28] HAN H, WU SH Q, SONG ZH. Curved LCD based deflectometry method for specular surface measurement[J]. Optics and Lasers in Engineering, 2022, 151: 106909. doi: 10.1016/j.optlaseng.2021.106909 [29] SU P, PARKS R E, WANG L R, et al. Software configurable optical test system: a computerized reverse Hartmann test[J]. Applied Optics, 2010, 49(23): 4404-4412. doi: 10.1364/AO.49.004404 [30] 邵山川, 陶小平, 王孝坤. 基于条纹反射的超精密车削反射镜的在位面形检测[J]. 激光与光电子学进展,2018,55(7):071203.SHAO SH CH, TAO X P, WANG X K. On-machine surface shape measurement of reflective mirrors by ultra-precision turning based on fringe reflection[J]. Laser & Optoelectronics Progress, 2018, 55(7): 071203. (in Chinese) [31] 袁婷. 基于条纹反射法的大口径非球面反射镜面形检测技术研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2016.YUAN T. Study on fringe-reflection optical surface shape measurement technology for large aspheric mirror[D]. Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, CAS, 2016. (in Chinese) [32] OH C J, LOWMAN A E, SMITH G A, et al. Fabrication and testing of 4.2m off-axis aspheric primary mirror of Daniel K. Inouye Solar Telescope[J]. Proceedings of SPIE, 2016, 9912: 99120O. [33] WOODHAM R J. Photometric method for determining surface orientation from multiple images[J]. Optical Engineering, 1980, 19(1): 191139. [34] LU L, QI L, LUO Y S, et al. Three-dimensional reconstruction from single image base on combination of CNN and multi-spectral photometric stereo[J]. Sensors, 2018, 18(3): 764. doi: 10.3390/s18030764 [35] 张颖, 李金龙, 黄趾维, 等. 基于BRDF模型的金属表面反射特性及相变特性研究[J]. 光电技术应用,2017,32(3):32-35. doi: 10.3969/j.issn.1673-1255.2017.03.008ZHANG Y, LI J L, HUANG ZH W, et al. Research on reflection and phase shift characters of metal surface based on BRDF model[J]. Electro-Optic Technology Application, 2017, 32(3): 32-35. (in Chinese) doi: 10.3969/j.issn.1673-1255.2017.03.008 [36] 王金海, 李华, 魏力. 基于C-T模型的光学元件加工表面的光学特性研究[J]. 光学技术,2021,47(2):172-177.WANG J H, LI H, WEI L. Study on optical properties of machining surface of optical element based on C-T model[J]. Optical Technique, 2021, 47(2): 172-177. [37] PEI X H, REN M J, WANG X, et al. Profile measurement of non-Lambertian surfaces by integrating fringe projection profilometry with near-field photometric stereo[J]. Measurement, 2022, 187: 110277. doi: 10.1016/j.measurement.2021.110277 [38] MENG L F, LU L Y, BEDARD N, et al. Single-shot specular surface reconstruction with gonio-plenoptic imaging[C]. IEEE International Conference on Computer Vision, IEEE, 2015: 3433-3441. [39] WADDINGTON C, KOFMAN J. Analysis of measurement sensitivity to illuminance and fringe-pattern gray levels for fringe-pattern projection adaptive to ambient lighting[J]. Optics and Lasers in Engineering, 2010, 48(2): 251-256. doi: 10.1016/j.optlaseng.2009.07.001 [40] LI D, KOFMAN J. Adaptive fringe-pattern projection for image saturation avoidance in 3D surface-shape measurement[J]. Optics Express, 2014, 22(8): 9887-9901. doi: 10.1364/OE.22.009887 [41] JIANG H ZH, ZHAO H J, LI X D. High dynamic range fringe acquisition: a novel 3-D scanning technique for high-reflective surfaces[J]. Optics and Lasers in Engineering, 2012, 50(10): 1484-1493. doi: 10.1016/j.optlaseng.2011.11.021 [42] WANG J H, YANG Y X, ZHOU Y G. 3-D shape reconstruction of non-uniform reflectance surface based on pixel intensity, pixel color and camera exposure time adaptive adjustment[J]. Scientific Reports, 2021, 11(1): 4700. doi: 10.1038/s41598-021-83779-9 [43] SUN J H, ZHANG Q Y. A 3D shape measurement method for high-reflective surface based on accurate adaptive fringe projection[J]. Optics and Lasers in Engineering, 2022, 153: 106994. doi: 10.1016/j.optlaseng.2022.106994 [44] BABAIE G, ABOLBASHARI M, FARAHI F. Dynamics range enhancement in digital fringe projection technique[J]. Precision Engineering, 2015, 39: 243-251. doi: 10.1016/j.precisioneng.2014.06.007 [45] CHEN CH, GAO N, WANG X J, et al. Adaptive pixel-to-pixel projection intensity adjustment for measuring a shiny surface using orthogonal color fringe pattern projection[J]. Measurement Science and Technology, 2018, 29(5): 055203. doi: 10.1088/1361-6501/aab07a [46] 冯维, 徐仕楠, 王恒辉, 等. 逐像素调制的高反光表面三维测量方法[J]. 中国光学,2022,15(3):488-497. doi: 10.37188/CO.2021-0220FENG W, XU SH N, WANG H H, et al. Three-dimensional measurement method of highly reflective surface based on per-pixel modulation[J]. Chinese Optics, 2022, 15(3): 488-497. (in Chinese) doi: 10.37188/CO.2021-0220 [47] 李乾, 薛俊鹏, 张启灿, 等. 利用相机响应曲线实现高反光元件三维面形测量[J]. 光学学报,2022,42(7):0712001. doi: 10.3788/AOS202242.0712001LI Q, XUE J P, ZHANG Q C, et al. Three dimensional shape measurement of high reflective elements using camera response curve[J]. Acta Optica Sinica, 2022, 42(7): 0712001. (in Chinese) doi: 10.3788/AOS202242.0712001 [48] SHAFER S A. Using color to separate reflection components[J]. Color Research & Application, 1985, 10(4): 210-218. [49] WANG J H, YANG Y X. High-speed three-dimensional measurement technique for object surface with a large range of reflectivity variations[J]. Applied Optics, 2018, 57(30): 9172-9182. doi: 10.1364/AO.57.009172 [50] CHUA S Y, LIM C C, ENG S K, et al. Improved high dynamic range for 3D shape measurement based on saturation of the coloured fringe[J]. Pertanika Journal of Science & Technology, 2021, 29(2): 759-770. [51] YIN Y K, CAI Z W, JIANG H, et al. High dynamic range imaging for fringe projection profilometry with single-shot raw data of the color camera[J]. Optics and Lasers in Engineering, 2017, 89: 138-144. doi: 10.1016/j.optlaseng.2016.08.019 [52] ZHENG Y, WANG Y J, SURESH V, et al. Real-time high-dynamic-range fringe acquisition for 3D shape measurement with a RGB camera[J]. Measurement Science and Technology, 2019, 30(7): 075202. doi: 10.1088/1361-6501/ab0ced [53] LIU Y ZH, FU Y J, ZHUAN Y H, et al. High dynamic range real-time 3D measurement based on Fourier transform profilometry[J]. Optics & Laser Technology, 2021, 138: 106833. [54] CHEN Y M, HE Y M, HU E Y. Phase deviation analysis and phase retrieval for partial intensity saturation in phase-shifting projected fringe profilometry[J]. Optics Communications, 2008, 281(11): 3087-3090. doi: 10.1016/j.optcom.2008.01.070 [55] JIANG C F, BELL T, ZHANG S. High dynamic range real-time 3D shape measurement[J]. Optics Express, 2016, 24(7): 7337-7346. doi: 10.1364/OE.24.007337 [56] WANG M M, DU G L, ZHOU C L, et al. Enhanced high dynamic range 3D shape measurement based on generalized phase-shifting algorithm[J]. Optics Communications, 2017, 385: 43-53. doi: 10.1016/j.optcom.2016.10.023 [57] ZUO CH, HUANG L, ZHANG M L, et al. Temporal phase unwrapping algorithms for fringe projection profilometry: A comparative review[J]. Optics and Lasers in Engineering, 2016, 85: 84-103. doi: 10.1016/j.optlaseng.2016.04.022 [58] CHEN B, ZHANG S. High-quality 3D shape measurement using saturated fringe patterns[J]. Optics and Lasers in Engineering, 2016, 87: 83-89. doi: 10.1016/j.optlaseng.2016.04.012 [59] HE Z X, LI P L, ZHAO X Y, et al. Chessboard-like high-frequency patterns for 3D measurement of reflective surface[J]. IEEE Transactions on Instrumentation and Measurement, 2021, 70: 5009712. [60] HU Y, CHEN Q, LIANG Y CH, et al. Microscopic 3D measurement of shiny surfaces based on a multi-frequency phase-shifting scheme[J]. Optics and Lasers in Engineering, 2019, 122: 1-7. doi: 10.1016/j.optlaseng.2019.05.019 [61] 张启灿, 吴周杰. 基于格雷码图案投影的结构光三维成像技术[J]. 红外与激光工程,2020,49(3):0303004. doi: 10.3788/IRLA202049.0303004ZHANG Q C, WU ZH J. Three-dimensional imaging technique based on Gray-coded structured illumination[J]. Infrared and Laser Engineering, 2020, 49(3): 0303004. (in Chinese) doi: 10.3788/IRLA202049.0303004 [62] SONG ZH, CHUNG R, ZHANG X T. An accurate and robust strip-edge-based structured light means for shiny surface micromeasurement in 3-D[J]. IEEE Transactions on Industrial Electronics, 2013, 60(3): 1023-1032. doi: 10.1109/TIE.2012.2188875 [63] LU L L, WU ZH J, ZHANG Q C, et al. High-efficiency dynamic three-dimensional shape measurement based on misaligned Gray-code light[J]. Optics and Lasers in Engineering, 2022, 150: 106873. doi: 10.1016/j.optlaseng.2021.106873 [64] ZUO CH, QIAN J M, FENG SH J, et al. Deep learning in optical metrology: a review[J]. Light:Science & Applications, 2022, 11(1): 39. [65] REYES-FIGUEROA A, FLORES V H, RIVERA M. Deep neural network for fringe pattern filtering and normalization[J]. Applied Optics, 2021, 60(7): 2022-2036. doi: 10.1364/AO.413404 [66] JEON W, JEONG W, SON K, et al. Speckle noise reduction for digital holographic images using multi-scale convolutional neural networks[J]. Optics Letters, 2018, 43(17): 4240-4243. doi: 10.1364/OL.43.004240 [67] ZHANG B W, LIN SH N, LIN J Y, et al. Single-shot high-precision 3D reconstruction with color fringe projection profilometry based BP neural network[J]. Optics Communications, 2022, 517: 128323. doi: 10.1016/j.optcom.2022.128323 [68] NGUYEN H, WANG ZH Y. Accurate 3D shape reconstruction from single structured-light image via fringe-to-fringe network[J]. Photonics, 2021, 8(11): 459. doi: 10.3390/photonics8110459 [69] FENG SH J, ZUO CH, YIN W, et al. Micro deep learning profilometry for high-speed 3D surface imaging[J]. Optics and Lasers in Engineering, 2019, 121: 416-427. doi: 10.1016/j.optlaseng.2019.04.020 [70] LIU Y, BLUNT L, GAO F, et al. High-dynamic-range 3D measurement for E-beam fusion additive manufacturing based on SVM intelligent fringe projection system[J]. Surface Topography:Metrology and Properties, 2021, 9(3): 034002. doi: 10.1088/2051-672X/ac0c62 [71] 彭广泽, 陈文静. 基于卷积神经网络去噪正则化的条纹图修复[J]. 光学学报,2020,40(18):1810002. doi: 10.3788/AOS202040.1810002PENG G Z, CHEN W J. Fringe pattern inpainting based on convolutional neural network denoising regularization[J]. Acta Optica Sinica, 2020, 40(18): 1810002. (in Chinese) doi: 10.3788/AOS202040.1810002 [72] YANG G W, YANG M, ZHOU N, et al. High dynamic range fringe pattern acquisition based on deep neural network[J]. Optics Communications, 2022, 512: 127765. doi: 10.1016/j.optcom.2021.127765 [73] QIAO G, HUANG Y Y, SONG Y P, et al. A single-shot phase retrieval method for phase measuring deflectometry based on deep learning[J]. Optics Communications, 2020, 476: 126303. doi: 10.1016/j.optcom.2020.126303 [74] ZHANG L, CHEN Q, ZUO CH, et al. High-speed high dynamic range 3D shape measurement based on deep learning[J]. Optics and Lasers in Engineering, 2020, 134: 106245. doi: 10.1016/j.optlaseng.2020.106245 [75] HU Y, CHEN Q, TAO T Y, et al. Absolute three-dimensional micro surface profile measurement based on a Greenough-type stereomicroscope[J]. Measurement Science and Technology, 2017, 28(4): 045004. doi: 10.1088/1361-6501/aa5a2d [76] 陈龙, 王文聪, 张峰峰, 等. 基于双目结构光的术中肝脏表面局部亮度饱和分区投影[J]. 光学 精密工程,2021,29(11):2590-2602. doi: 10.37188/OPE.20212911.2590CHEN L, WANG W C, ZHANG F F, et al. Zonal projection based on binocular structured light for localized luminance saturation of intraoperative liver surface[J]. Optics and Precision Engineering, 2021, 29(11): 2590-2602. (in Chinese) doi: 10.37188/OPE.20212911.2590 -

下载:

下载: