Design and experiment of high-resolution detection imaging system with ultra-thin and ultra-short object-image distance

-

摘要:

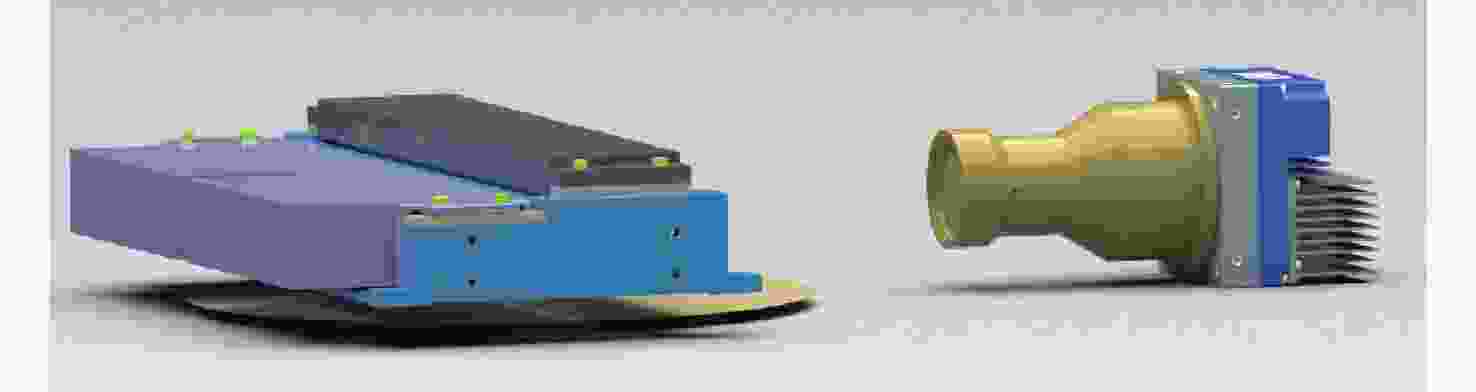

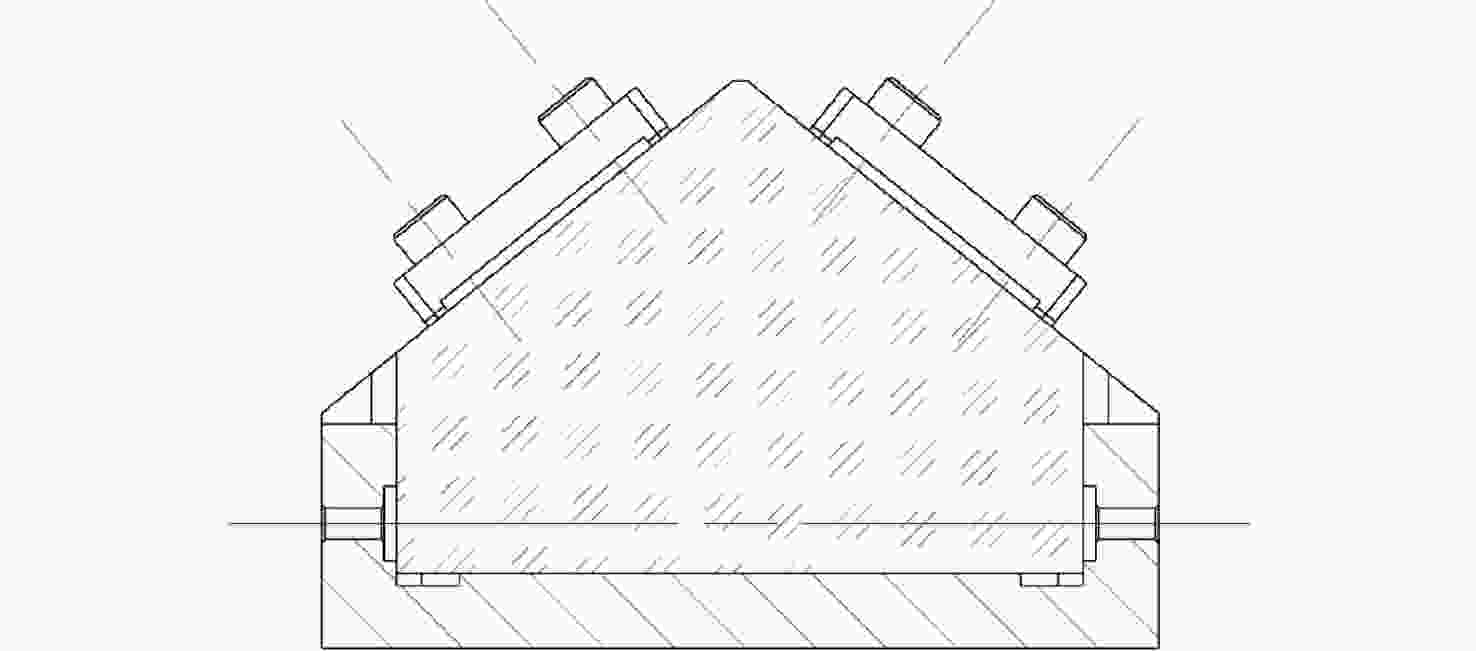

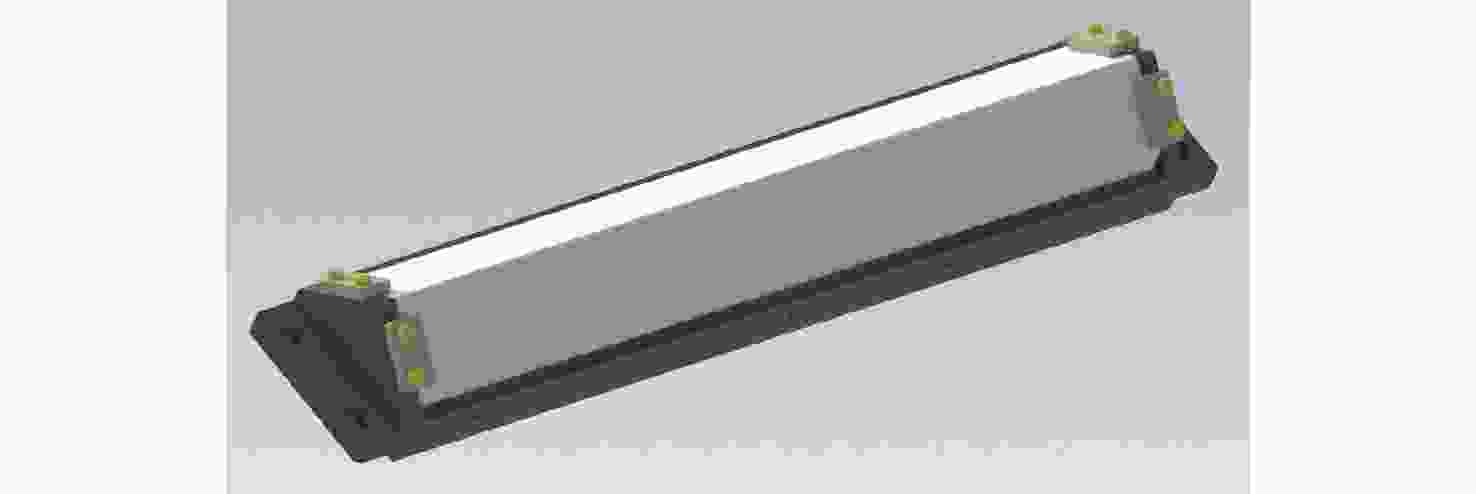

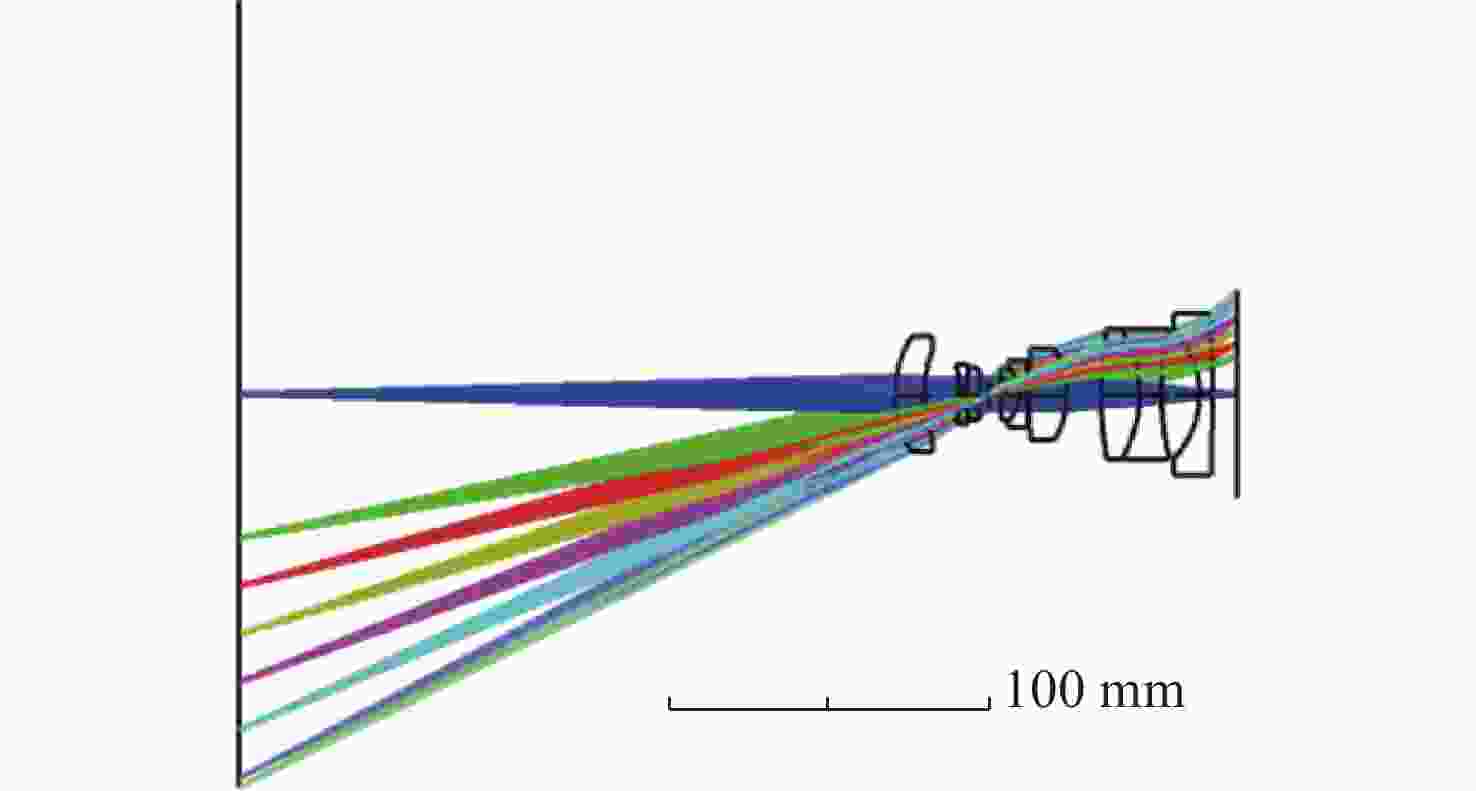

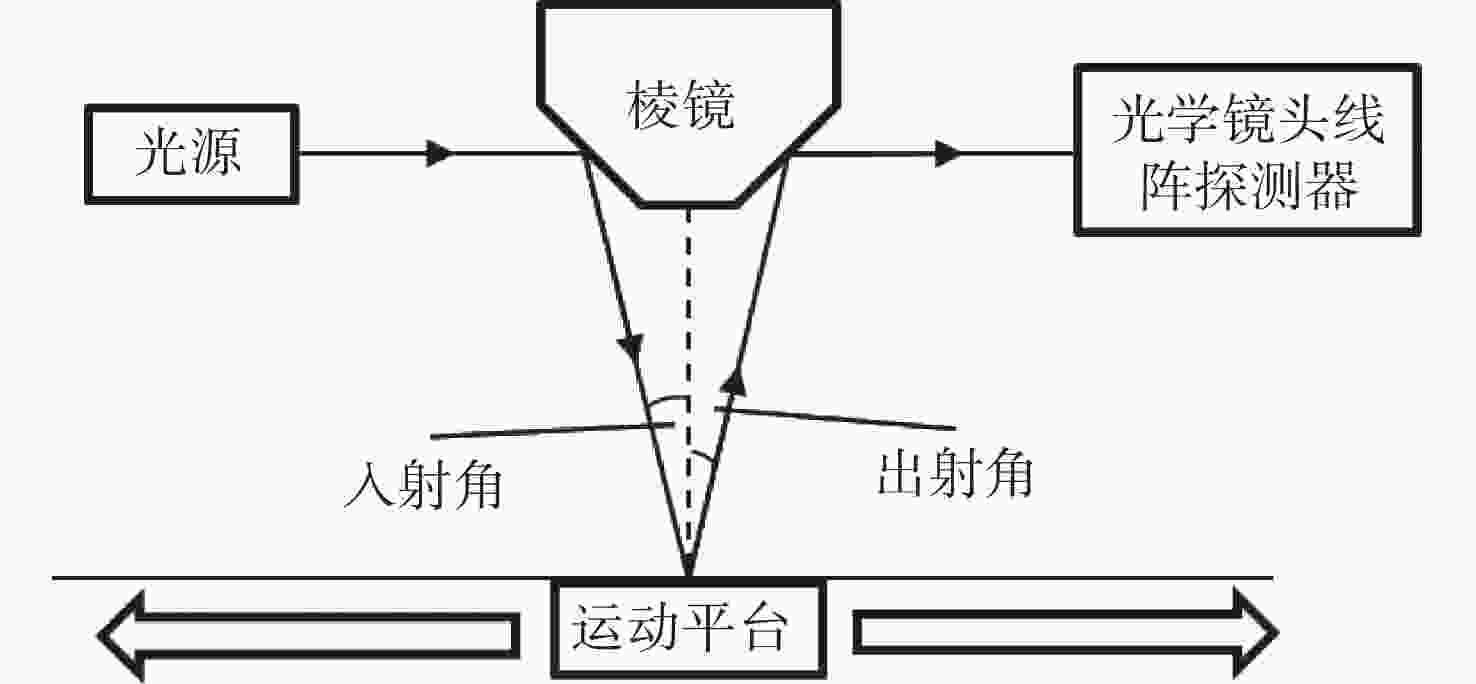

为缩短12寸晶圆检测成像系统的轴向和径向尺寸,提出一种小角度棱镜折转光路与超短物像距镜头相结合的解决方法。设计优于1/12

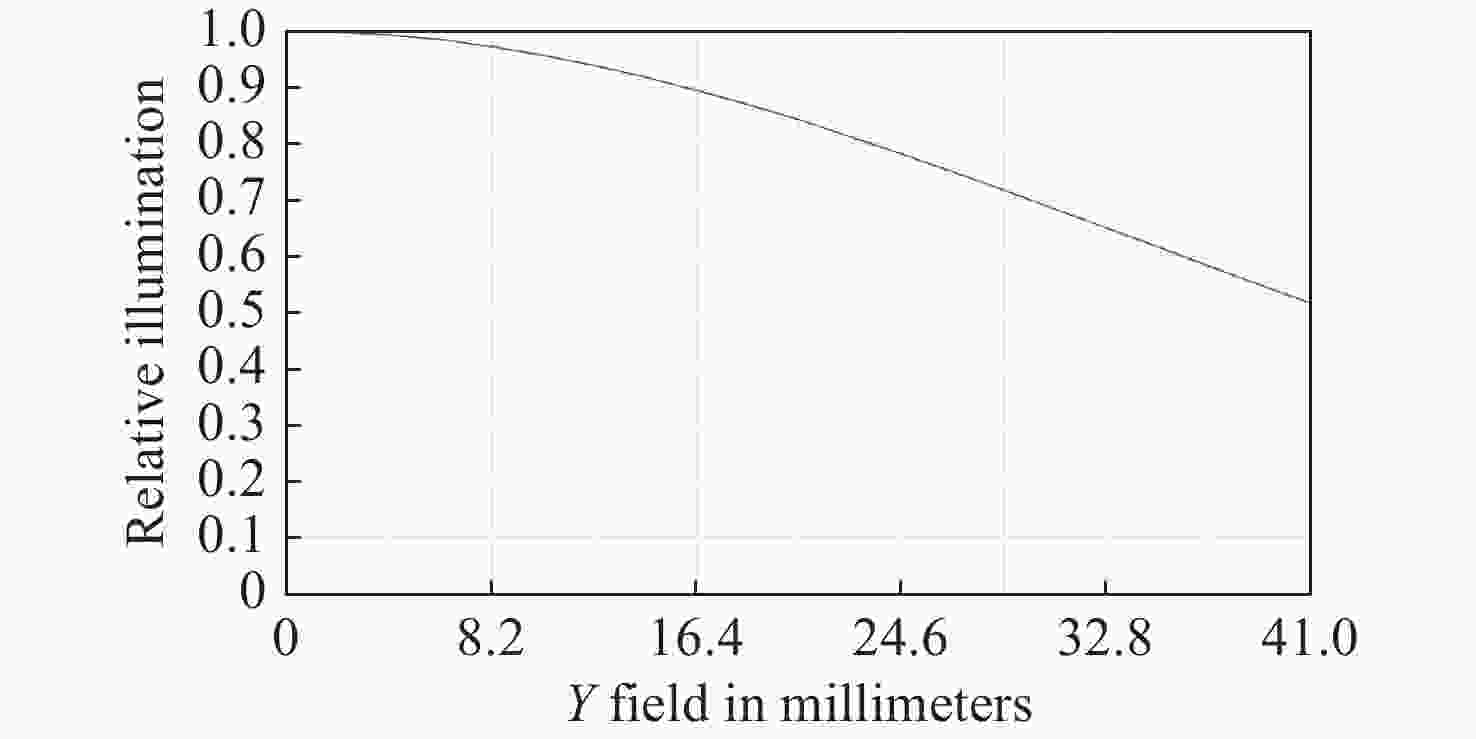

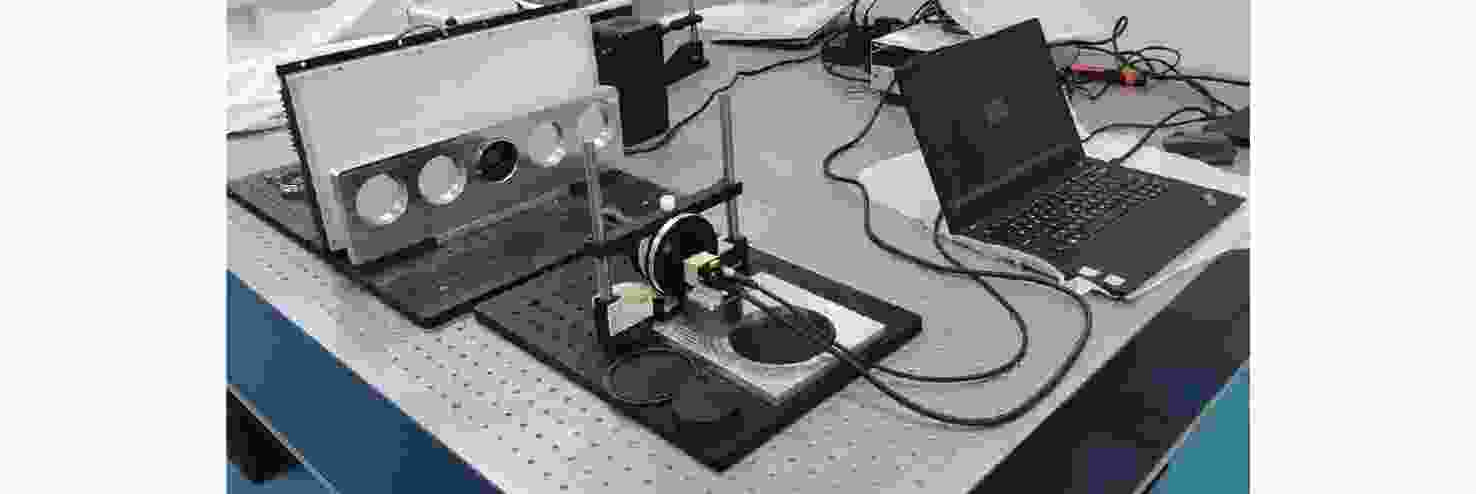

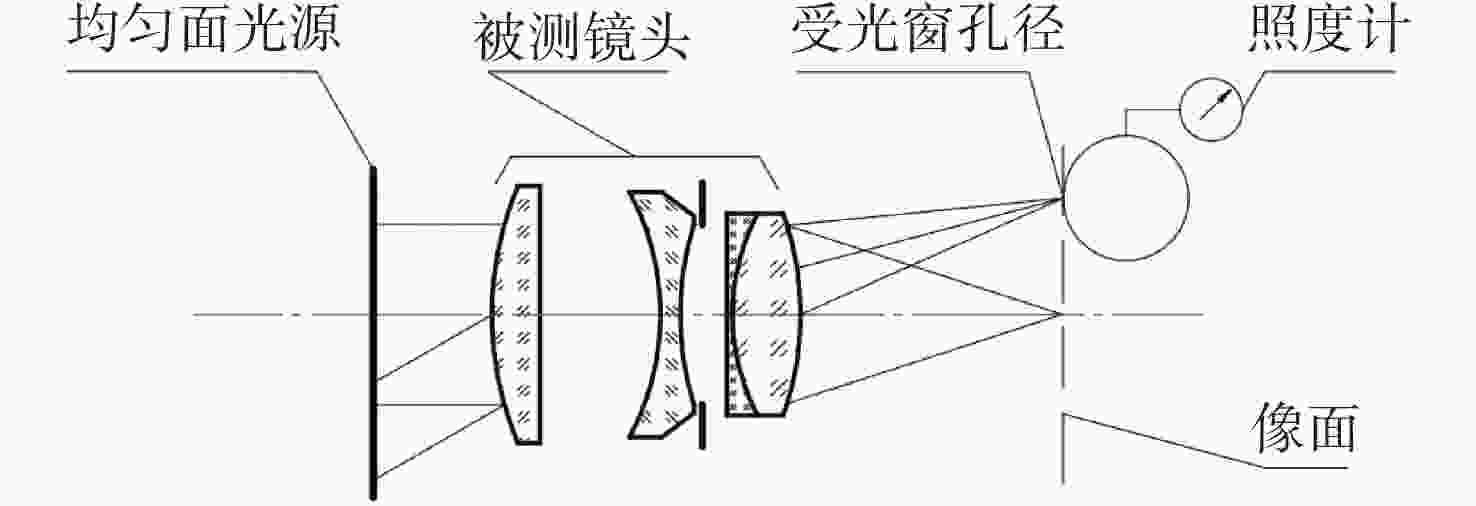

λ (λ =632.8 nm)面形精度的小角度棱镜折转光路,实现照明系统与成像镜头的水平布置,径向尺寸仅为80 mm,在保证不影响系统成像质量的前提下,极大地降低了整个系统的径向尺寸,同时也实现了12°的小角度明场照明。设计放大倍率为0.264的对称混合型光学系统,采用纯球面系统获得较大成像视场,像高为81.92 mm,物像距仅为392.5 mm,极大地降低了整个系统轴向尺寸。设计结果表明,整个成像系统全视场平均光学传递函数优于0.4@100l p/mm,相对畸变优于0.03%,像面照度均匀性全视场优于50%。实际测试结果表明:全视场实际成像分辨率优于18.88 μm,达到了系统极限分辨率;全视场像面照度均匀性为43.3%,满足均匀性优于40%的研制要求。研究结果表明本文提出的超薄超短物像距高分辨率检测成像系统合理、有效,解决了12寸晶圆检测成像系统空间尺寸压缩的难题,并降低了研制成本,为后续近距离大尺寸物体检测成像系统的研制提供参考依据。Abstract:To shorten the axial and radial dimensions of the 12-inch wafer detection imaging system, a solution combining the small angle prism refraction path and the ultra-short object-image distance lens is proposed. A small angle prism with shape accuracy better than 1/12

λ (λ =632.8 nm) is designed to convert the optical path and realize the horizontal arrangement between the lighting system and the imaging lens. The radial size is only 80 mm, which greatly reduces the radial size of the whole system without affecting the imaging quality. At the same time, a small angle of 12° bright field lighting is realized. A symmetrical hybrid optical system with magnification of 0.264 is designed. A pure spherical system is used to obtain a large imaging field of view. The image height is 81.92 mm, and the object-image distance is only 392.5 mm, which greatly reduces the axial size of the whole system. The design results show that the average optical transfer function of the whole imaging system is better than 0.4@100 lp/mm, the relative distortion is better than 0.03%, and the uniformity of the image surface illuminance is better than 50%. The actual test results show that the actual imaging resolution is better than 18.88 μm, which reaches the ultimate resolution of the system. The uniformity of illumination of image surface is 43.3%, which meets the development requirement of uniformity better than 40%. The research results show that the ultra-thin and ultra-short object-image distance imaging system is reasonable and effective, which solves the problem of space size compression of the 12-inch wafer detection imaging system and reduces the development cost. It provides a reference for the development of the imaging system for detecting large objects in short distance. -

表 1 几种棱镜材料参数

Table 1. The material parameters of prism

材料

名称密度ρ

103 kg/m3弹性模量E/

GPa泊松比μ 线膨胀系数

10−6/K微晶玻璃 2.53 91 0.24 0.05 熔石英 2.19 72 0.17 0.5 K9 2.52 79.2 0.21 8.3 表 2 设计参数

Table 2. Designed parameters

棱镜参数 数值 棱镜尺寸 330 mm×55 mm×40 mm 镜厚比 8.25∶1 棱镜夹角 102° 表 3 不同照度下的相面照度值

Table 3. Image surface illuminance values under different illuminations

不同照度下测试 焦面位置不同像高时像面照度值(lx) −41 mm 0 41 mm 1 14.9 34.2 14.9 2 17.5 39.9 17.5 3 16.3 36.7 15.8 4 17.7 40.0 17.4 5 13.5 30.6 13.3 6 12.3 28.5 12.3 7 9.9 23.2 9.9 8 14.5 33.3 14.4 9 16.0 36.6 16.0 10 8.9 20.7 8.8 -

[1] 卢荣胜, 吴昂, 张腾达, 等. 自动光学(视觉)检测技术及其在缺陷检测中的应用综述[J]. 光学学报,2018,38(8):0815002. doi: 10.3788/AOS201838.0815002LU R SH, WU A, ZHANG T D, et al. Review on automated optical (visual) inspection and its applications in defect detection[J]. Acta Optica Sinica, 2018, 38(8): 0815002. (in Chinese). doi: 10.3788/AOS201838.0815002 [2] 胡跃明, 谭颖. 自动光学检测在中国的应用现状和发展[J]. 微计算机信息,2006,22(4):143-146.HU Y M, TAN Y. State and development of automatic optical inspection applications in China[J]. Microcomputer Information, 2006, 22(4): 143-146. (in Chinese). [3] 潘珍英. 工业自动光学检测中的照明系统设计[D]. 厦门: 厦门大学, 2007.PAN ZH Y. The design of illumination system in industrial automatic optical inspection[D]. Xiamen: Xiamen University, 2007. (in Chinese). [4] 李明泽, 侯溪, 赵文川, 等. 非球面光学表面缺陷检测技术现状和发展趋势(特邀)[J]. 红外与激光工程,2022,51(9):20220457.LI M Z, HOU X, ZHAO W CH, et al. Current situation and development trend of aspheric optical surface defect detection technology (invited)[J]. Infrared and Laser Engineering, 2022, 51(9): 20220457. (in Chinese). [5] 周辉, 熊显名. 提高AOI检测设备对准精度的研究[J]. 自动化与仪器仪表,2022(7):1-4,14.ZHOU H, XIONG X M. Study on improving the alignment accuracy of AOI testing equipment[J]. Automation & Instrumentation, 2022(7): 1-4,14. (in Chinese). [6] LU R SH, SHI Y Q, LI Q, et al. AOI techniques for surface defect inspection[J]. Applied Mechanics and Materials, 2010, 36: 297-302. doi: 10.4028/www.scientific.net/AMM.36.297 [7] 李晨. 基于机器视觉的不同属性表面中微弱缺陷的检测技术研究[D]. 杭州: 浙江大学, 2018.LI CH. Detection technology of weak defects on the surfaces with different property based on machine vision[D]. Hangzhou: Zhejiang University, 2018. (in Chinese). [8] 刘韬, 胡玥, 董健, 等. 激光主动照明光学系统设计[J]. 中国光学,2016,9(3):342-348. doi: 10.3788/co.20160903.0342LIU T, HU Y, DONG J, et al. Design of laser active illumination optical system[J]. Chinese Optics, 2016, 9(3): 342-348. (in Chinese). doi: 10.3788/co.20160903.0342 [9] 陈世炜. 基于明暗场成像的多扫描方式图案化晶圆检测技术研究[D]. 杭州: 浙江大学, 2021.CHEN SH W. Research on patterned wafer inspection technology with multi-sean mode based on bright and dark field imaging[D]. Hangzhou: Zhejiang University, 2021. (in Chinese). [10] 陈宇轩, 仇中军, 汤骏杰. 线扫描视觉检测系统机械-成像综合误差建模[J]. 红外与激光工程,2022,51(12):20220282.CHEN Y X, QIU ZH J, TANG J J. Mechanical-imaging comprehensive error modeling in line scan vision detection systems[J]. Infrared and Laser Engineering, 2022, 51(12): 20220282. (in Chinese). [11] 樊星皓. 星载高分成像与高光谱采集双路共口径光学系统的设计与研究[D]. 长春: 中国科学院大学(中国科学院长春光学精密机械与物理研究所), 2022.FAN X H. Design and research on the dual-channel co-aperture optical system for spaceborne high-resolution imaging and hyperspectral acquisition[D]. Changchun: University of Chinese Academy of Sciences (Changchun Institute of Optics, Fine Mechanicsand Physics, Chinese Academy of Sciences), 2022. (in Chinese). [12] 张美君. 航空相机反射镜支撑结构优化设计及环境适应性分析[D]. 长春: 中国科学院大学(中国科学院长春光学精密机械与物理研究所), 2022.ZHANG M J. Optimal design and environmental adaptability analysis for mounting mirror in an aerial camera[D]. Changchun: University of Chinese Academy of Sciences (Changchun Institute of Optics, Fine Mechanicsand Physics, Chinese Academy of Sciences), 2022. (in Chinese). [13] 柴世豪, 郭晨霞, 李建鑫. 轮廓测量系统中摄像机的光学畸变校正方法[J]. 电子测量技术,2021,44(21):158-162. doi: 10.19651/j.cnki.emt.2107306CHAI SH H, GUO CH X, LI J X. Optical distortion correction method for cameras in contour measuring system[J]. Electronic Measurement Technology, 2021, 44(21): 158-162. (in Chinese). doi: 10.19651/j.cnki.emt.2107306 [14] 秦子长, 任成明, 戚允升, 等. 小型高分辨率空间相机光学系统低误差敏感度设计[J]. 红外与激光工程,2022,51(10):20220365.QIN Z CH, REN CH M, QI Y SH, et al. Low error-sensitive design of small-sized high-resolution space camera optical system[J]. Infrared and Laser Engineering, 2022, 51(10): 20220365. (in Chinese). [15] 左超, 陈钱. 分辨率、超分辨率与空间带宽积拓展-从计算光学成像角度的一些思考[J]. 中国光学(中英文),2022,15(6):1105-1166.ZUO CH, CHEN Q. Resolution, super-resolution and spatial bandwidth product expansion-some thoughts from the perspective of computational optical imaging[J]. Chinese Optics, 2022, 15(6): 1105-1166. (in Chinese). [16] 国家机械工业局. JB/T 8248.3-1999 照相镜头渐晕系数及像面照度均匀度测量方法[S]. 北京: 机械工业出版社, 2004.State Administration of Machinery Industry. JB/T 8248.3-1999 Method for measuring the coefficient of vignetting and uniformity of image plane illuminance[S]. Beijing: China Machine Press, 2004. (in Chinese). -

下载:

下载: