Development of high-precision beam splitter for inter-satellite communication system

-

摘要:

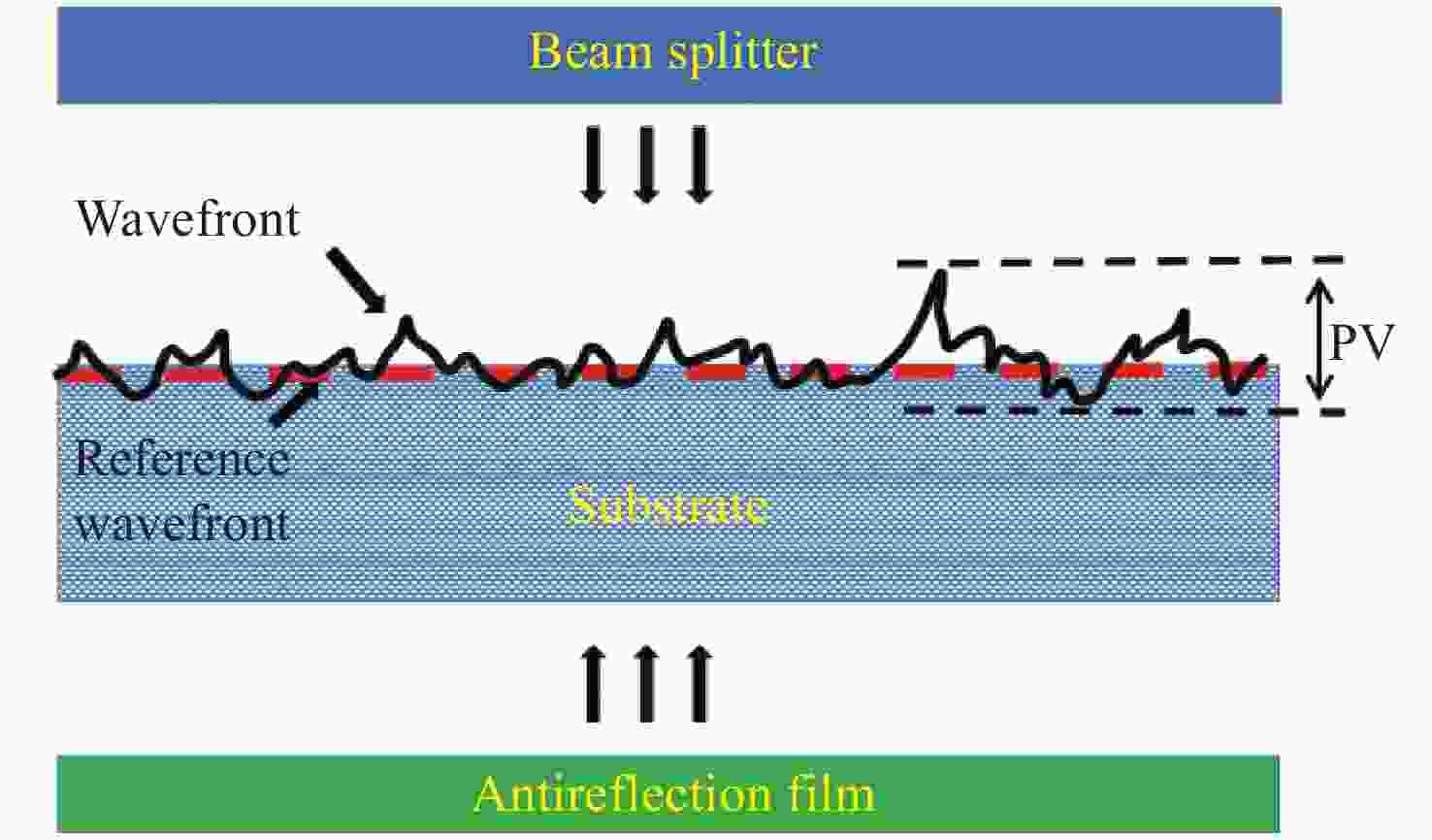

随着星间通信系统的迅速发展,数据传输的精度要求不断提高。分光镜作为系统的核心元件,其光谱特性和面形精度直接影响整个系统的传输精度。本文基于薄膜干涉理论,选取Ta2O5与SiO2作为高低折射率膜层材料进行膜系设计,采用电子束蒸发的方式在石英基板上制备高精度分光镜。同时根据膜层应力补偿原理建立面形修正模型,修正分光镜面形。光谱分析仪检测结果显示,分光镜在入射角度为21.5°~23.5°内,1563 nm透过率大于98%,1540 nm反射率大于99%。激光干涉仪检测结果显示,分光镜反射面形精度RMS由

λ /10修正至λ /90(λ =632.8 nm),透过面形精度RMS为λ /90。Abstract:With the rapid development of inter-satellite communication systems, the requirements for data transmission accuracy are constantly increasing. As the core component, the spectral characteristics and surface shape accuracy of the beam splitter directly affect the transmission accuracy of the whole system. According to the interference theory of thin film, Ta2O5 and SiO2 were selected as the high and low refractive index film materials for the design of the film system, and electron beam evaporation was used to prepare a high-precision beam splitter on a quartz substrate. At the same time, a surface shape correction model was established based on the principle of film stress compensation to control the surface shape. Through the detection of a spectral analyzer, it can be seen that the transmittance of beam splitter is greater than 98% at 1563 nm and the reflectance is greater than 99% at 1540 nm within the incidence range of 21.5° to 23.5°. The surface shape was measured by laser interferometer, it can be seen that the reflective surface shape accuracy RMS is corrected from

λ /10 toλ /90 (λ =632.8 nm), and the transmissive optical surface shape accuracy RMS isλ /90.-

Key words:

- inter-satellite communication /

- beam splitter /

- stress compensation /

- surface accuracy

-

表 1 材料沉积工艺参数

Table 1. Material deposition process parameters

材料 沉积速率/(nm·s−1) 起始真空度/(×10−4 Pa) 沉积温度/(°C) Ta2O5 0.4 7 220 SiO2 0.6 7 220 表 2 不同离子源工艺参数对应的样片

$\Delta $ PowerTable 2.

$\Delta $ power of the sample corresponding to different process parameters of ion source编号 电压/V 束流/mA 面形图 ∆power(λ) 基底 沉积后 1 1 100 950

0.148 5 2 1 000 920

0.160 2 3 950 900

0.182 1 表 3 离子源工艺参数

Table 3. Process parameters of ion source

材料 电压/

V束流/

mA气体 O2/

Sccm气体 Ar/

SccmTa2O5 1 100 950 50 8 SiO2(直控) 1 100 950 50 8 SiO2(背反) 950 900 50 8 SiO2(晶控) 950 900 50 8 表 4 样品沉积分光膜的面形结果

Table 4. Surface shape results of sample deposited beam splitter

类别 编号 1# 2# 3# 4# 基底 面形图

PV(λ) 0.074 6 0.076 1 0.077 4 0.072 3 RMS(λ) 0.008 7 0.009 2 0.009 7 0.008 3 Power(λ) 0.007 3 0.008 1 0.008 4 0.007 8 沉积后 面形

PV(λ) 0.516 7 0.528 9 0.531 6 0.515 3 RMS(λ) 0.111 8 0.111 6 0.111 4 0.111 9 Power(λ) −0.385 9 −0.383 9 −0.382 7 −0.3854 表 5 样品Power改变量与A值随沉积SiO2膜层厚度变化的数据

Table 5. Data on the variation of sample Power and A-values with different thicknesses of deposited SiO2 film

SiO2厚度(nm) ∆Power(λ) A(∆λ/100 nm SiO2) 3 500 0.155 1 0.004 43 5 000 0.228 0 0.004 56 6 500 0.308 8 0.004 75 8 000 0.394 4 0.004 93 9 500 0.488 3 0.005 14 表 6 修正前后样品的面形参数

Table 6. Surface parameters of samples before and after correction

类别 面形图 PV(λ) RMS(λ) Power(λ) 修正前

0.531 6 0.111 4 −0.382 7 修正后

0.121 9 0.016 2 −0.042 9 表 7 修正前后的面形参数与面形图

Table 7. Surface parameters and surface profile before and after correction

类别 面形图 PV(λ) RMS(λ) Power(λ) 基底

0.0723 0.0083 0.0078 修正前( 反射面形)

0.5153 0.1119 −0.3854 修正后(反射面形)

0.0888 0.0107 −0.0153 修正前(透过面形)

0.0694 0.0097 0.0136 修正后(透过面形)

0.0783 0.0103 0.0141 -

[1] 刘旭光, 钱志升, 周继航, 等. “星链”卫星系统及国内卫星互联网星座发展思考[J]. 通信技术,2022,55(2):197-204. doi: 10.3969/j.issn.1002-0802.2022.02.010LIU X G, QIAN ZH SH, ZHOU J H, et al. Thinking on the development of “starlink” satellite system and domestic satellite internet constellation[J]. Communications Technology, 2022, 55(2): 197-204. (in Chinese). doi: 10.3969/j.issn.1002-0802.2022.02.010 [2] 李锐, 林宝军, 刘迎春, 等. 激光星间链路发展综述: 现状、趋势、展望[J]. 红外与激光工程,2023,52(3):20220393. doi: 10.3788/IRLA20220393LI R, LIN B J, LIU Y CH, et al. Review on laser intersatellite link: current status, trends, and prospects[J]. Infrared and Laser Engineering, 2023, 52(3): 20220393. (in Chinese). doi: 10.3788/IRLA20220393 [3] 王燕, 陈培永, 宋义伟, 等. 国外空间激光通信技术的发展现状与趋势[J]. 飞控与探测,2019,2(1):8-16.WANG Y, CHEN P Y, SONG Y W, et al. Progress on the development and trend of overseas space laser communication technology[J]. Flight Control & Detection, 2019, 2(1): 8-16. (in Chinese). [4] 高铎瑞, 李天伦, 孙悦, 等. 空间激光通信最新进展与发展趋势[J]. 中国光学,2018,11(6):901-913. doi: 10.3788/co.20181106.0901GAO D R, LI T L, SUN Y, et al. Latest developments and trends of space laser communication[J]. Chinese Optics, 2018, 11(6): 901-913. (in Chinese). doi: 10.3788/co.20181106.0901 [5] 夏方园, 汪勃, 张国亭, 等. 激光星间链路终端技术发展与展望[J]. 光学技术,2023,49(2):175-183.XIA F Y, WANG B, ZHANG G T, et al. Recent development and prospective of inter-satellite laser links terminal technology[J]. Optical Technique, 2023, 49(2): 175-183. (in Chinese). [6] 樊彦峥. 大口径镜面高反射膜制备及面形控制技术[D]. 西安: 西安工业大学, 2021.FAN Y ZH. Deposition and surface shape control technology of large-aperture mirror high-reflection film[D]. Xi’an: Xi’an Technological University, 2021. (in Chinese). [7] 高伟饶, 董科研, 江伦. 单波长激光通信终端的隔离度[J]. 中国光学(中英文), 2023, 16(5): 1137-1148.GAO W R, DONG K Y, JIANG L. Isolation of single wavelength laser communication terminals[J]. Chinese Optics, 2023, 16(5): 1137-1148. [8] 李波, 王超, 闫涛, 等. 多层高反膜的应力研究[J]. 真空与低温,2023,29(2):146-152. doi: 10.3969/j.issn.1006-7086.2023.02.007LI B, WANG CH, YAN T, et al. Stress study of multi-layer high reflection films[J]. Vacuum and Cryogenics, 2023, 29(2): 146-152. (in Chinese). doi: 10.3969/j.issn.1006-7086.2023.02.007 [9] 李阳, 徐均琪, 刘政, 等. 残余应力对介质高反膜面型影响的研究[J]. 真空科学与技术学报,2021,41(5):484-490. doi: 10.13922/j.cnki.cjvst.202009001LI Y, XU J Q, LIU ZH, et al. Study on the influence of residual stress on dielectric high reflection films[J]. Chinese Journal of Vacuum Science and Technology, 2021, 41(5): 484-490. (in Chinese). doi: 10.13922/j.cnki.cjvst.202009001 [10] 白金林, 姜玉刚, 王利栓, 等. 超低面形宽带高反射薄膜设计及制备技术研究[J]. 红外与激光工程,2021,50(2):20200413. doi: 10.3788/IRLA20200413BAI J L, JIANG Y G, WANG L SH, et al. Research on the design and preparation of ultra-low plane wide-band high reflection film[J]. Infrared and Laser Engineering, 2021, 50(2): 20200413. (in Chinese). doi: 10.3788/IRLA20200413 [11] OHRING M. Materials Science of Thin Films[M]. 2nd ed. San Diego: Academic Press, 2001: 436-439. [12] 王凯旋, 陈刚, 刘定权, 等. 绿光波段60 pm超窄带滤光片的研制[J]. 中国光学,2022,15(1):119-131.WANG K X, CHEN G, LIU D Q, et al. Fabrication of an ultra-narrow band-pass filter with 60 pm bandwidth in green light band[J]. Chinese Optics, 2022, 15(1): 119-131. (in Chinese). [13] 田晓习. 光学薄膜技术中的基片与薄膜热力学匹配问题研究[D]. 成都: 中国科学院大学(中国科学院光电技术研究所), 2020.TIAN X X. Study on thermodynamic matching between substrate and films in optical thin film technology[D]. Chengdu: University of Chinese Academy of Sciences (Institute of Optics and Electronics, Chinese Academy of Science), 2020. (in Chinese). [14] STONEY G G. The tension of metallic films deposited by electrolysis[J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 1909, 82(553): 172-175. [15] GRIGORIEV F V, SULIMOV V B, TIKHONRAVOV A V. Atomistic simulation of stresses in growing silicon dioxide films[J]. Coatings, 2020, 10(3): 220. doi: 10.3390/coatings10030220 [16] 潘永刚, 林兆文, 王奔, 等. 深紫外大口径非球面反射膜的均匀性研究[J]. 中国光学(中英文),2022,15(4):740-746. doi: 10.37188/CO.2022-0005PAN Y G, LIN ZH W, WANG B, et al. Film thickness uniformity of deep ultraviolet large aperture aspheric mirror[J]. Chinese Optics, 2022, 15(4): 740-746. (in Chinese). doi: 10.37188/CO.2022-0005 -

下载:

下载: