-

摘要:

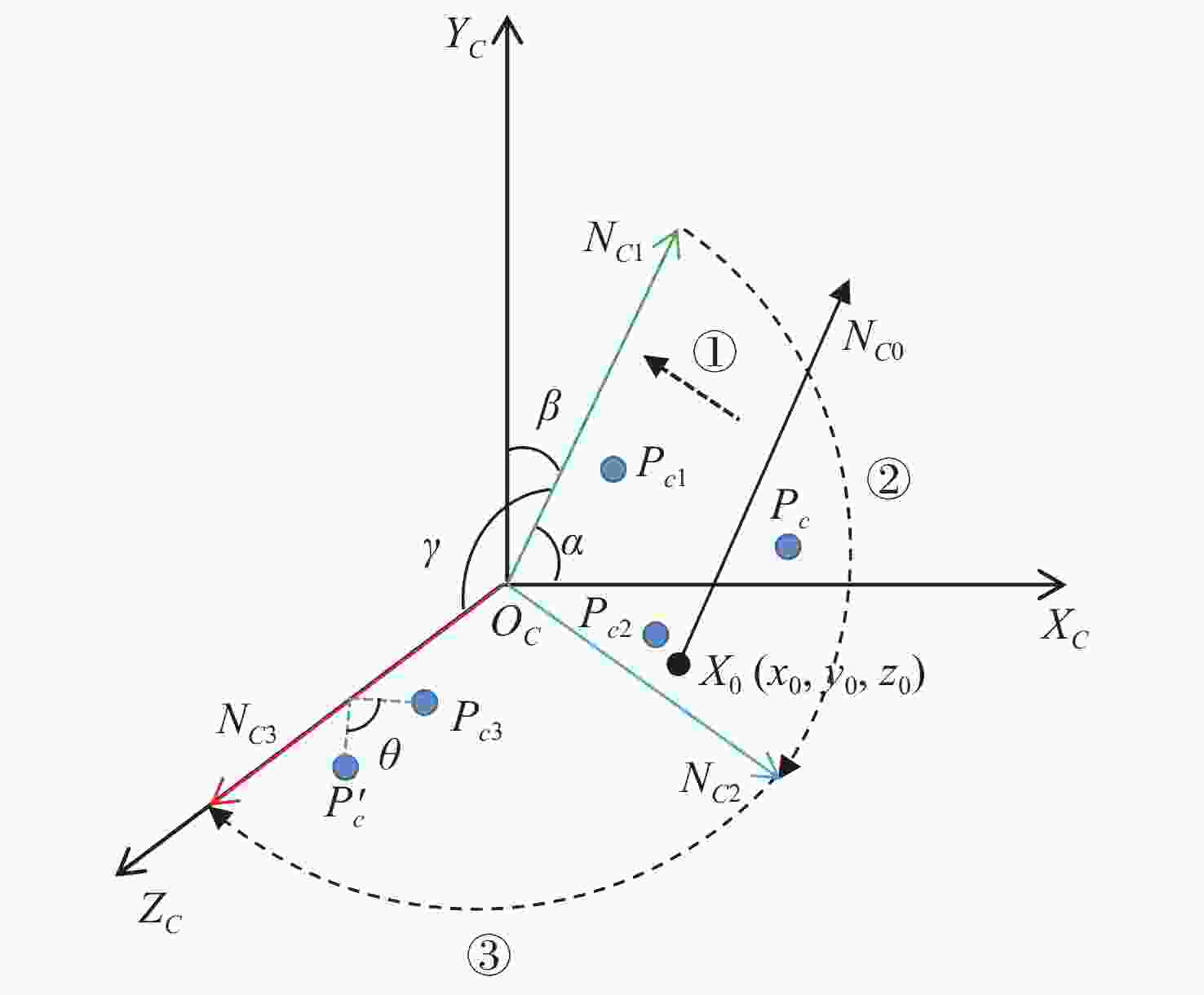

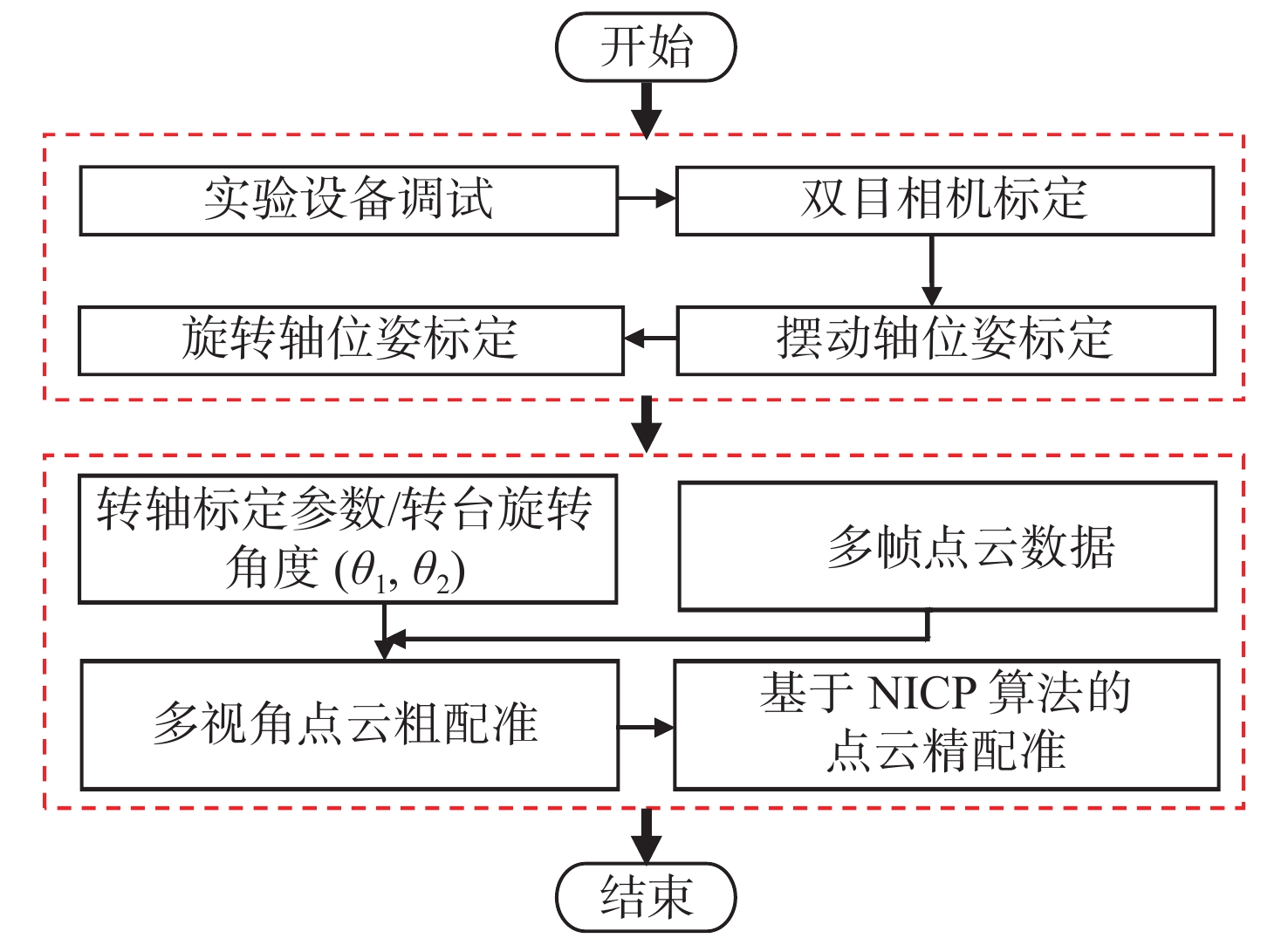

小尺寸零件的表面积小、结构复杂,传统标志点拼接方法需要在零件表面人工粘贴标志点,导致表面的测量数据缺失出现孔洞。基于特征的点云拼接方法要求零件表面具有易区分的几何或距离特征,不适用于包含重复性特征的回转体零件。本文提出一种基于机械拼接的无标志点扫描测量方法,不需要粘贴标志点,不依赖于零件表面特征。首先,采用基于摄影测量的相机标定方法得到相机的高精度内外参数,重建标定板上靶点的高精度三维坐标,接着通过跟踪编码靶点的位置建立转台不同转角对应的旋转矩阵,进而解算出转轴方向向量和轴上定点坐标,实现转轴和相机的同步标定。在完成两个转轴位姿精确标定的基础上,利用转台转角构建旋转拼接矩阵,实现多视角点云粗配准。最后,基于法向迭代最近点算法(Normal Iterative Closest Point, NICP)完成点云的精配准。实验结果表明:使用靶点跟踪法标定后的两转轴夹角误差较传统的标准球拟合法低0.023°,标定后测量标准球的整体平均尺寸误差小于0.012 mm;在小尺寸零件自动化测量时,机械拼接方法在精配准后的点云拼接效果与标志点拼接方法相近,且拼接稳定性更高。机械拼接方法适用于无法粘贴标记点的小尺寸零件三维形貌测量场景。

Abstract:Small-size parts have a small surface area and complex structure. The traditional mark splicing method needs to manually paste marks on the surface of parts, resulting in missing the measurement data of the surface and becoming holes. The feature splicing method requires the surface of parts to have easily distinguishable geometric or distance features, which are not suitable for rotating parts containing repetitive features. We propose a scanning measurement method without marks based on mechanical splicing, which does not need to paste marks or depend on the surface features of parts. Firstly, the camera calibration method based on photogrammetry is used to reconstruct the high-precision three-dimensional coordinates of the target on the calibration board. By tracking the position of the coded target, the rotation matrix corresponding to different angles of the turntable is established, and the direction vector of the rotation axis and the fixed point coordinates on the axis are solved. Then the synchronous calibration of the rotation axis and the camera is completed. Secondly, based on the accurate calibration of poses of two rotation axes, the rotation mosaic matrix is constructed by using the turntable angle to realize the rough registration of multi-view point clouds. Finally, based on the Normal Iterative Closest Point (NICP) algorithm, the fine registration of the point clouds is completed. Experimental results show that the angle error between the two rotation axes calibrated by the target tracking method is 0.023° lower than that of the traditional standard ball fitting method. After calibration, the average size error of the standard ball is less than 0.012 mm. In the automatic measurement of small-size parts, the point cloud splicing effect of the mechanical splicing method after fine registration is similar to that of the mark splicing method, and the splicing stability is higher. The mechanical splicing method is suitable for the 3D topography measurement of small-size parts where the marks cannot be pasted.

-

Key words:

- structured light /

- mechanical splicing /

- small-size parts /

- axis calibration /

- NICP algorithm

-

表 1 相机标定内参数

Table 1. Camera calibration internal parameters

内参数 左相机 右相机 f/pixel 4666.2300 4666.5600 $ {x}_{0}/{\mathrm{pixel }}$ 47.6090 −14.4401 $ {y}_{0}/{\mathrm{pixel}} $ 10.2786 −14.5546 $ {K}_{1} $ −3.4003×10−9 −4.1734×10−9 $ {K}_{2} $ 1.1598×10−15 1.8279×10−15 $ {K}_{3} $ 1.8523×10−22 −2.2075×10−23 $ {P}_{1} $ −7.4732×10−8 1.5797×10−8 $ {P}_{2} $ 1.0306×10−8 −2.0569×10−9 $ {b}_{1} $ 1.2749×10−4 2.4643×10−6 $ {b}_{2} $ −2.2662×10−5 3.9066×10−5 表 2 相机标定外参数

Table 2. Camera calibration external parameters

相机编号 ${{\boldsymbol{R}}_C}$ ${{\boldsymbol{T}}_C}$ 左相机 1 0 0 0 0 1 0 0 0 0 1 0 右相机 0.8992 −0.0098 0.4374 176.2110 0.0063 0.9999 0.0094 −0.1690 −0.4374 −0.0057 0.8992 −40.5125 表 3 标准球拟合法与本文方法的性能对比

Table 3. Comparison between standard ball fitting method and the proposed method

实验

编号标准球拟合法[22] 本文方法 夹角/

(°)点积 夹角误差/

(°)夹角/

(°)点积 夹角误差/

(°)1 89.938 0.001078 0.062 89.962 0.000666 0.038 2 89.923 0.001341 0.077 89.949 0.000883 0.051 3 89.934 0.001145 0.066 89.962 0.000658 0.038 4 89.939 0.001072 0.061 89.955 0.000786 0.045 5 89.940 0.001048 0.060 89.961 0.000686 0.039 6 89.929 0.001245 0.071 89.965 0.000604 0.035 7 89.938 0.001079 0.062 89.952 0.000838 0.048 8 89.938 0.001085 0.062 89.947 0.000922 0.053 9 89.939 0.001058 0.061 89.965 0.000606 0.035 10 89.940 0.001048 0.060 89.967 0.000583 0.033 平均 89.936 0.001120 0.064 89.959 0.000723 0.041 -

[1] 吕虹毓, 李茂月, 蔡东辰, 等. 光栅投影在机三维形貌检测技术研究进展[J]. 中国光学(中英文),2023,16(3):500-513.LV H Y, LI M Y, CAI D CH, et al. Research progress of grating projection on machine 3D topography inspection technology[J]. Chinese Optics, 2023, 16(3): 500-513. (in Chinese) [2] HELLE R H, LEMU H G. A case study on use of 3D scanning for reverse engineering and quality control[J]. Materials Today:Proceedings, 2021, 45: 5255-5262. doi: 10.1016/j.matpr.2021.01.828 [3] YANG X X, ZHU SH SH. Application of 3D laser scanner in digitization of movable cultural relics[C]. 2021 IEEE International Conference on Power Electronics, Computer Applications, Shenyang, IEEE, 2021: 550-553. [4] 李茂月, 刘泽隆, 赵伟翔, 等. 面结构光在机检测的叶片反光抑制技术[J]. 中国光学,2022,15(3):464-475. doi: 10.37188/CO.2021-0194LI M Y, LIU Z L, ZHAO W X, et al. Blade reflection suppression technology based on surface structured light on-machine detection[J]. Chinese Optics, 2022, 15(3): 464-475. (in Chinese) doi: 10.37188/CO.2021-0194 [5] MEZA J, CONTRERAS-ORTIZ S H, PEREZ L A R, et al. Three-dimensional multimodal medical imaging system based on freehand ultrasound and structured light[J]. Optical Engineering, 2021, 60(5): 054106. [6] 王永红, 张倩, 胡寅, 等. 显微条纹投影小视场三维表面成像技术综述[J]. 中国光学,2021,14(3):447-457. doi: 10.37188/CO.2020-0199WANG Y H, ZHANG Q, HU Y, et al. 3D small-field surface imaging based on microscopic fringe projection profilometry: a review[J]. Chinese Optics, 2021, 14(3): 447-457. (in Chinese) doi: 10.37188/CO.2020-0199 [7] 任明阳, 王立忠, 赵建博, 等. 复杂曲面零件面结构光扫描视点规划[J]. 中国光学(中英文),2023,16(1):113-126.REN M Y, WANG L ZH, ZHAO J B, et al. Viewpoint planning of surface structured light scanning for complex surface parts[J]. Chinese Optics, 2023, 16(1): 113-126. (in Chinese) [8] 杨鹏程, 杨朝, 孟杰, 等. 基于法向量和面状指数特征的文物点云棱界配准方法[J]. 中国光学(中英文),2023,16(3):654-662. doi: 10.37188/CO.2022-0156YANG P CH, YANG ZH, MENG J, et al. Aligning method for point cloud prism boundaries of cultural relics based on normal vector and faceted index features[J]. Chinese Optics, 2023, 16(3): 654-662. (in Chinese) doi: 10.37188/CO.2022-0156 [9] 马国庆, 刘丽, 于正林, 等. 大型复杂曲面三维形貌测量及应用研究进展[J]. 中国光学,2019,12(2):214-228. doi: 10.3788/co.20191202.0214MA G Q, LIU L, YU ZH L, et al. Application and development of three-dimensional profile measurement for large and complex surface[J]. Chinese Optics, 2019, 12(2): 214-228. (in Chinese) doi: 10.3788/co.20191202.0214 [10] LIN X B, ZHOU Y W, LIN CH. Study on 3D data mosaic method of point cloud data in reverse engineering[C]. 2021 Asia-Pacific Conference on Communications Technology and Computer Science, IEEE, 2021: 143-147. [11] QIN L, CHEN X, GONG X. An improved 3D reconstruction method for weak texture objects combined with calibration and ICP registration[C]. 2023 IEEE 6th International Conference on Industrial Cyber-Physical Systems, IEEE, 2023: 1-5. [12] XIANG J, FAN W Q, LIU P, et al. Point cloud alignment method based on improved ISS-ICP algorithm[C]. 2022 5th International Conference on Information Communication and Signal Processing, IEEE, 2022: 249-253. [13] LI J L, CHEN B R, YUAN M, et al. Matching algorithm for 3D point cloud recognition and registration based on multi-statistics histogram descriptors[J]. Sensors, 2022, 22(2): 417. doi: 10.3390/s22020417 [14] ZOU Z S, WANG R, ZOU J L, et al. Robust descriptor for key-point detection and matching in color images with radial distortion[J]. Journal of Electronic Imaging, 2022, 31(2): 023038. [15] 何成刚, 郑衡, 丁克, 等. 基于机械臂辅助的多视角三维点云拼接算法研究[J]. 激光与光电子学进展,2023,60(20):2015001.HE CH G, ZHENG H, DING K, et al. Research on multi-view 3D point cloud stitching algorithm based on robot arm assistance[J]. Laser & Optoelectronics Progress, 2023, 60(20): 2015001. (in Chinese) [16] SILVA M Z, BRITO T, LIMA J L, et al. Industrial robotic arm in machining process aimed to 3D objects reconstruction[C]. 2021 22nd IEEE International Conference on Industrial Technology, IEEE, 2021: 1100-1105. [17] CAI X Q, ZHONG K J, FU Y J, et al. Calibration method for the rotating axis in panoramic 3D shape measurement based on a turntable[J]. Measurement Science and Technology, 2021, 32(3): 035004. doi: 10.1088/1361-6501/abcb7e [18] YE J, XIA G S, LIU F, et al. 3D reconstruction of line-structured light based on binocular vision calibration rotary axis[J]. Applied Optics, 2020, 59(27): 8272-8278. doi: 10.1364/AO.403356 [19] 胡民政, 习俊通. 面向结构光三维测量的两轴转台标定[J]. 上海交通大学学报,2010,44(4):506-511. doi: 10.16183/j.cnki.jsjtu.2010.04.014HU M ZH, XI J T. Two-axis turntable calibration in three-dimensional structured light measurement system[J]. Journal of Shanghai Jiaotong University, 2010, 44(4): 506-511. (in Chinese) doi: 10.16183/j.cnki.jsjtu.2010.04.014 [20] YE Y P, SONG ZH. An accurate 3D point cloud registration approach for the turntable-based 3D scanning system[C]. 2015 IEEE International Conference on Information and Automation, IEEE, 2015: 982-986. [21] 李杨, 许志闻, 宋展, 等. 面向全自动三维扫描系统的多视角三维数据自动配准技术[J]. 吉林大学学报(理学版),2014,52(2):319-325. doi: 10.13413/j.cnki.jdxblxb.2014.02.31LI Y, XU ZH W, SONG ZH, et al. Automated multi-view 3D data registration for fully-automated 3D scanning system[J]. Journal of Jilin University (Science Edition), 2014, 52(2): 319-325. (in Chinese) doi: 10.13413/j.cnki.jdxblxb.2014.02.31 [22] LI W L, WU A, LI Z CH, et al. A new calibration method between an optical sensor and a rotating platform in turbine blade inspection[J]. Measurement Science and Technology, 2017, 28(3): 035009. doi: 10.1088/1361-6501/aa50df [23] 吕海东, 任永潮, 戴士杰, 等. 基于2D靶标的摄像机与转台中心轴同步标定方法[J]. 传感器与微系统,2019,38(7):23-27. doi: 10.13873/j.1000-9787(2019)07-0023-05LV H D, REN Y CH, DAI SH J, et al. Synchronization calibration method of camera and turntable center axis based on 2D target[J]. Transducer and Microsystem Technologies, 2019, 38(7): 23-27. (in Chinese) doi: 10.13873/j.1000-9787(2019)07-0023-05 [24] PANG X F, LAU R W H, SONG ZH, et al. A tool-free calibration method for turntable-based 3D scanning systems[J]. IEEE Computer Graphics and Applications, 2016, 36(1): 52-61. doi: 10.1109/MCG.2014.83 [25] 陈仁虹, 梁晋, 叶美图, 等. 柔性复合薄膜成形极限曲线的视觉测定方法[J]. 中国光学,2022,15(1):22-33.CHEN R H, LIANG J, YE M T, et al. Visual method for measuring forming limit curve of pliable composite film[J]. Chinese Optics, 2022, 15(1): 22-33. (in Chinese) [26] 任明阳, 王立忠, 付白强, 等. 高温数字图像相关法变形测量中玻璃介质误差校正[J]. 中国光学,2022,15(2):327-338.REN M Y, WANG L ZH, FU B Q, et al. Error correction of glass mediums in high-temperature digital image correlation deformation measurement[J]. Chinese Optics, 2022, 15(2): 327-338. (in Chinese) [27] ZHANG D H, LIANG J, GUO C, et al. Exploitation of photogrammetry measurement system[J]. Optical Engineering, 2010, 49(3): 037005-16. [28] HU H, LIANG J, XIAO Z Z, et al. A four-camera videogrammetric system for 3-D motion measurement of deformable object[J]. Optics and Lasers in Engineering, 2012, 50(5): 800-811. [29] ZHU K, GONG L, GU D J, et al. An analytic calibration method for turntable-based 3D scanning system[C]. 2019 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, IEEE, 2019: 495-500. [30] SERAFIN J, GRISETTI G. NICP: Dense normal based point cloud registration[C]. 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems, IEEE, 2015: 742-749. -

下载:

下载: