Design of optical field of vision imaging for defect detection of paper and transparent film

-

摘要:

为实现包装盒纸质基底层和透明膜层缺陷的同步检测,开展了对纸和膜缺陷的同步成像研究。首先,分别建立了标准球面积分光场、椭球面积分光场和弧面积分光场模型,并利用COMSOL Multiphysics 5.6对3类光场进行射线仿真,对比分析了球面积分光场下射线角度均匀性及辐照均匀性,通过正交仿真优化椭球面积分光场参数;其次,在椭球面积分光场环境、亮场前打光环境、暗场前打光环境下对包装盒成像。与此同时,对包装盒的油污、抵触、开口、泡皱、破损5项常见缺陷依次进行物理检测和机器视觉检测,验证缺陷成像的有效性。试验结果表明,在椭球面积分光场下成像,图像对纸质基底层缺陷特征、透明膜层缺陷特征均有较好的呈现效果,图像上油污、抵触、开口、泡皱、破损的物理检出率分别为96.2%、92.5%、100%、95%、92%,异常检出率分别为98.6%、97.5%、100%、100%、98.4%,缺陷类别检出率分别为97.6%、96%、100%、97%、96%。研究结果表明,椭球面积分光场光路角度和辐照强度均匀,覆透明膜包装盒的缺陷特征呈现清晰,满足工业生产的检测要求。

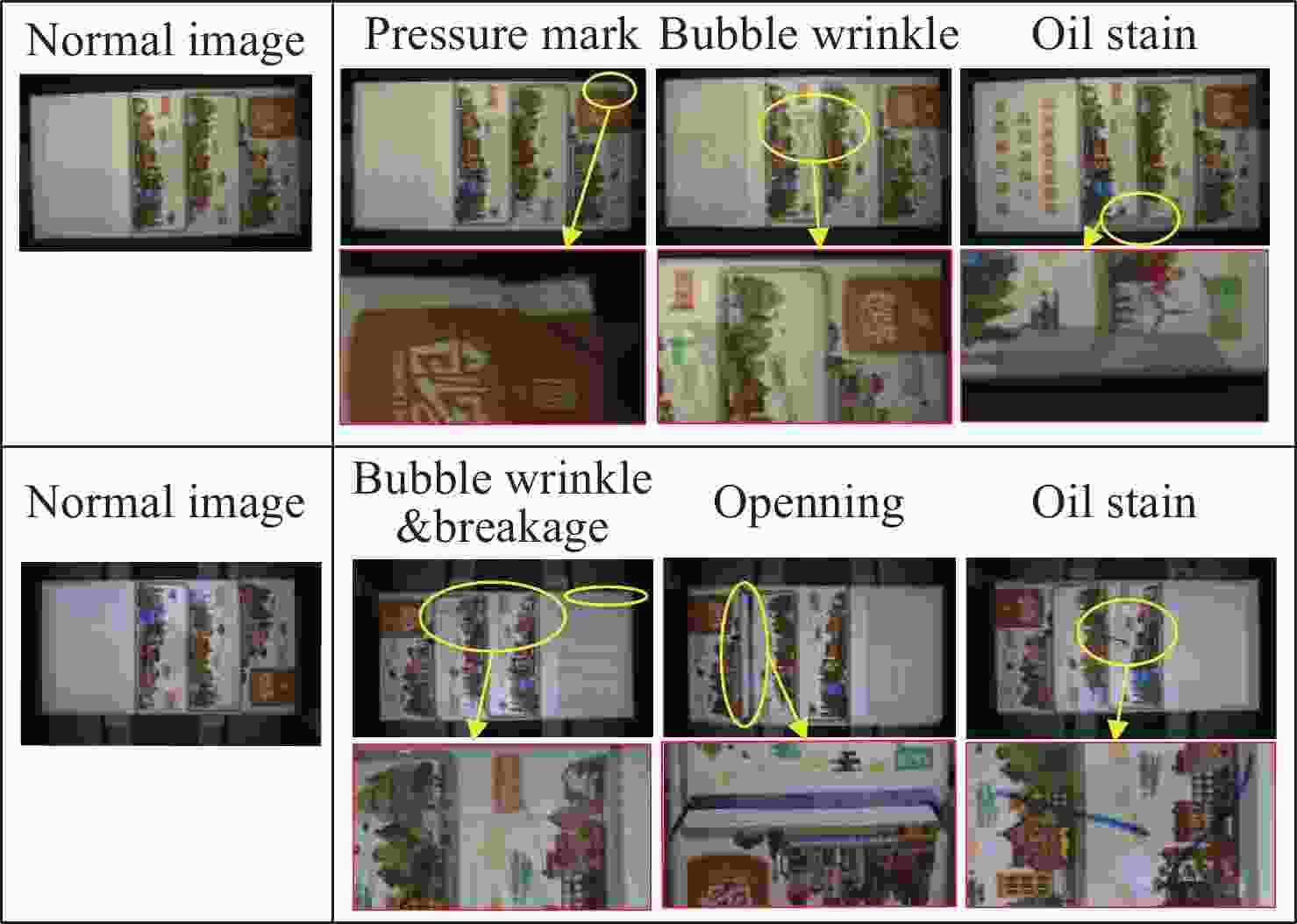

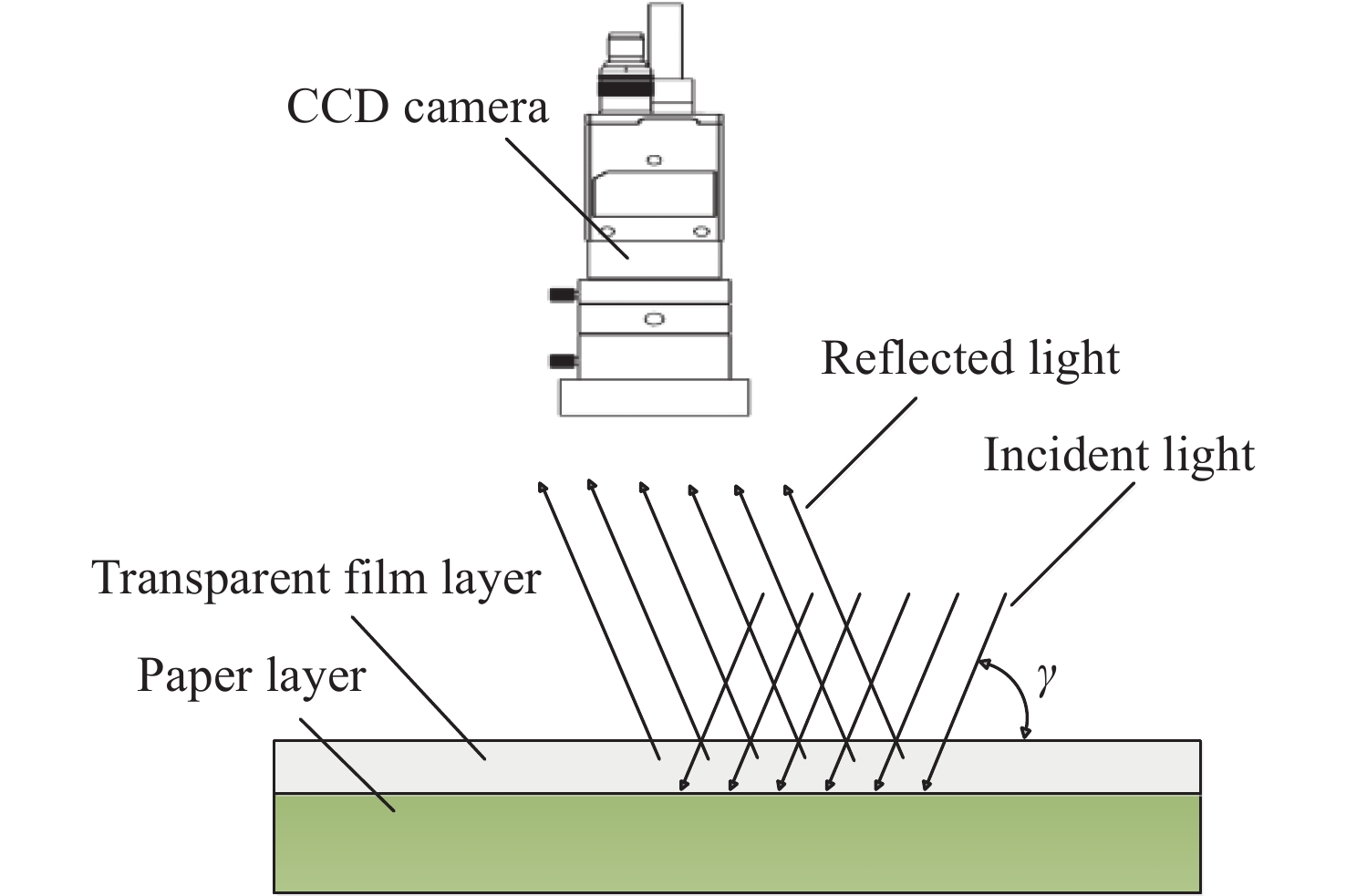

Abstract:To achieve synchronous detection of defects in the paper and transparent film layers of packaging boxes, we studied the synchronous imaging of the paper and film defect. Firstly, we established models for a standard sphere integral light field, an ellipsoidal integral light field, and an arc integral light field. We then simulated three different light fields using COMSOL Multiphysics 5.6 and compared their ray angle uniformity and irradiation uniformity. The parameters of ellipsoidal area integral light field are optimized by orthogonal simulation. Secondly, the packaging box was imaged using the ellipsoidal integral light field, the bright and dark field forward lighting. Physical detection and machine vision were used to detect five common defects in the packaging box, including oil stains, pressure marks, openings, bubble wrinkles, and breakages, to verify the effectiveness of defect imaging. The results show that the images can clearly present defect characteristics in the paper base and transparent film layers under ellipsoidal integral light field. The physical detection rates for oil stains, pressure marks, openings, bubble wrinkles, and breakages were 96.2%, 92.5%, 100%, 95%, and 92%, respectively. Anomaly detection rates were 98.6%, 97.5%, 100%, 100%, 98.4%, respectively. Detection rates of defects were 97.6%, 96%, 100%, 97%, and 96%, respectively. This study indicates that the consistent optical path angle and irradiation intensity result in a uniform ellipsoidal integral light field. Consequently, transparent film imaging of the packaging box shows clear defect characteristics that satisfy the standards for industrial detection application.

-

表 1 3种光场主要参数

Table 1. Main parameters of the three types of integrated light fields

光场类型 光罩尺寸A

×B×H/mm半径R或R1×R2×R3/mm 投射口距

离S/mm辐照面

距离C/mm标准球面积分光场 180×180×130 85 35 20 椭球面积

分光场1180×180×110 85×65×65 35 20 椭球面积

分光场2180×180×110 65×85×65 35 20 弧面积

分光场180×130×130 85 35 20 表 2 因素水平表

Table 2. Coding table of experimental factors and levels

水平 因素 半径比(R1/R2) 投射口距离S/(mm) 辐照面距离C/( mm) 1 1.1 30 5 0 1.3 35 17.5 -1 1.5 40 30 表 3 试验方案与结果

Table 3. Experimental scheme and results

序号 因素 辐照比Q/% R1/R2 S/(mm) C/( mm) 1 1.3 40 30 80 2 1.1 35 5 76 3 1.5 35 5 74 4 1.3 35 17.5 92 5 1.1 30 17.5 76 6 1.3 30 30 82 7 1.5 35 30 70 8 1.3 35 17.5 90 9 1.3 35 17.5 90 10 1.5 40 17.5 70 11 1.3 30 5 86 12 1.3 40 5 84 13 1.3 35 17.5 92 14 1.3 35 17.5 92 15 1.1 40 17.5 74 16 1.1 35 30 72 17 1.5 30 17.5 72 表 4 方差分析

Table 4. Variance analysis

变异来源 平方和 自由度 均方 F P 模型 1104.73 9 122.75 126.36 < 0.0001*** R1:R2 18.00 1 18.00 18.53 0.0035*** S 8.00 1 8.00 8.24 0.0240** C 32.00 1 32.00 32.94 0.0007*** 残差 6.80 7 0.9714 失拟 2.00 3 0.6667 0.5556 0.6716 误差 4.80 4 1.20 总和 1111.53 16 注:**表示影响显著(P<0.05),***表示影响极显著(P<0.01) 表 5 缺陷检出数量统计

Table 5. Statistics on detected defects

缺陷类别 缺陷数量 椭球面积分光场环境 亮场前打光环境 暗场前打光环境 缺陷检出数量 缺陷检出率/% 缺陷检出数量 缺陷检出率/% 缺陷检出数量 缺陷检出率/% 油污 213 205 96.2 206 96.7 138 64.8 抵触 80 74 92.5 76 95 54 67.5 开口 50 50 100 50 100 38 76 泡皱 98 93 95 64 65 93 95 破损 125 115 92 74 59 116 92.8 表 6 图像缺陷的机器视觉检测结果

Table 6. Machine Vision detection results of image defects

缺陷

类别缺陷

数量椭球面积分光场环境 亮场前打光环境 暗场前打光环境 异常检

出数量异常检

出率/%类别检出

数量类别

检出率/%异常检

出数量异常检

出率/%类别检出

数量类别

检出率/%异常检

出数量异常检

出率/%类别检出

数量类别

检出率/%油污 213 210 98.6 208 97.6 210 98.6 210 98.6 140 65.7 140 65.7 抵触 80 78 97.5 75 96 79 98.7 78 97.5 60 75 62 77.5 开口 50 50 100 50 100 50 100 50 100 38 76 40 80 泡皱 98 98 100 95 97 70 71.4 67 68 95 97 95 97 破损 125 123 98.4 120 96 82 65.5 80 64 120 96 122 97.6 -

[1] 姜涛, 张桂林, 高俊鹏. 面向机器视觉检测的缸体横孔照明[J]. 中国光学,2020,13(6):1285-1292. doi: 10.37188/CO.2020-0054JIANG T, ZHANG G L, GAO J P. Illumination of a cylinder block transverse hole for machine vision inspection[J]. Chinese Optics, 2020, 13(6): 1285-1292. (in Chinese). doi: 10.37188/CO.2020-0054 [2] 梁霄, 李家炜, 赵小龙, 等. 基于深度学习的红外目标成像液位检测方法[J]. 光学学报,2021,41(21):2110001. doi: 10.3788/AOS202141.2110001LIANG X, LI J W, ZHAO X L, et al. Infrared target imaging liquid level detection method based on deep learning[J]. Acta Optica Sinica, 2021, 41(21): 2110001. (in Chinese). doi: 10.3788/AOS202141.2110001 [3] 赵鹏鹏, 李庶中, 李迅, 等. 融合视觉显著性和局部熵的红外弱小目标检测[J]. 中国光学,2022,15(2):267-275. doi: 10.37188/CO.2021-0170ZHAO P P, LI SH ZH, LI X, et al. Infrared dim small target detection based on visual saliency and local entropy[J]. Chinese Optics, 2022, 15(2): 267-275. (in Chinese). doi: 10.37188/CO.2021-0170 [4] 王荣昌, 王峰, 任帅军, 等. 基于双流融合网络的单兵伪装偏振成像检测[J]. 光学学报,2022,42(9):0915001.WANG R CH, WANG F, REN SH J, et al. Polarization imaging detection of individual camouflage based on two-stream fusion network[J]. Acta Optica Sinica, 2022, 42(9): 0915001. (in Chinese). [5] 金鹏, 黄浩, 刘检华, 等. 多传感器信息融合的铁路扣件缺陷检测方法[J]. 机械工程学报,2021,57(20):38-46. doi: 10.3901/JME.2021.20.038JIN P, HUANG H, LIU J H, et al. Fault detection method of railway fastener combined with multi-sensor information[J]. Journal of Mechanical Engineering, 2021, 57(20): 38-46. (in Chinese). doi: 10.3901/JME.2021.20.038 [6] 余佳杰, 周建平, 薛瑞雷, 等. 基于结构光视觉和光照模型的焊缝表面质量检测[J]. 中国激光,2022,49(16):1602019.YU J J, ZHOU J P, XUE R L, et al. Weld surface quality detection based on structured light and illumination model[J]. Chinese Journal of Lasers, 2022, 49(16): 1602019. (in Chinese). [7] 田萱, 王子亚, 王建新. 基于语义分割的食品标签文本检测[J]. 农业机械学报,2020,51(8):336-343. doi: 10.6041/j.issn.1000-1298.2020.08.037TIAN X, WANG Z Y, WANG J X. Text detection of food labels based on semantic segmentation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(8): 336-343. (in Chinese). doi: 10.6041/j.issn.1000-1298.2020.08.037 [8] 郜明. 基于机器视觉的抽纸软包装缺陷检测算法研究[D]. 成都: 四川大学, 2021.GAO M. Research on defect detection algorithm of flexible packaging tissue paper on machine vision[D]. Chengdu: Sichuan University, 2021. (in Chinese). [9] 赵宝水. 基于机器视觉的药品包装检测关键技术的研究[D]. 锦州: 辽宁工业大学, 2021.ZHAO B SH. Research on the key technology of drug packaging detection based on machine vision[D]. Jinzhou: Liaoning University of Technology, 2021. (in Chinese). [10] 陈雪纯, 方宇伦, 杜世昌, 等. 基于深度学习的包装缺陷快速检测方法[J]. 机械设计与研究,2021,37(6):165-169,178. doi: 10.13952/j.cnki.jofmdr.2021.0237CHEN X CH, FANG Y L, DU SH CH, et al. Rapid packaging defect detection method based on deep learning[J]. Machine Design and Research, 2021, 37(6): 165-169,178. (in Chinese). doi: 10.13952/j.cnki.jofmdr.2021.0237 [11] 陈其浩, 孙林, 张倩. 基于改进U2-Net的透明件划痕检测方法[J]. 科学技术与工程,2022,22(2):620-627. doi: 10.3969/j.issn.1671-1815.2022.02.025CHEN Q H, SUN L, ZHANG Q. Scratch detection method of transparent parts based on improved U2-Net[J]. Science Technology and Engineering, 2022, 22(2): 620-627. (in Chinese). doi: 10.3969/j.issn.1671-1815.2022.02.025 [12] JIN ZH X, ZHONG F Y, ZHANG Q, et al. Visual detection of tobacco packaging film based on apparent features[J]. International Journal of Advanced Robotic Systems, 2021, 18(3): 1-14. [13] XU Y CH, NAGAHARA H, SHIMADA A, et al. TransCut2: transparent object segmentation from a light-field image[J]. IEEE Transactions on Computational Imaging, 2019, 5(3): 465-477. doi: 10.1109/TCI.2019.2893820 [14] MADESSA A H, DONG J Y, DONG X H, et al. Leveraging an instance segmentation method for detection of transparent materials[C]. 2019 IEEE Conference on SmartWorld, Ubiquitous Intelligence and Computing, Advanced and Trusted Computing, Scalable Computing and Communications, Cloud and Big Data Computing, Internet of People and Smart City Innovation, IEEE, 2019: 406-412. [15] WANG J J, LI R F, MO X T, et al. Web film inspection system[J]. Optik, 2009, 120(13): 630-635. doi: 10.1016/j.ijleo.2008.01.001 [16] REN ZH H, FANG F ZH, YAN N, et al. State of the art in defect detection based on machine vision[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2022, 9(2): 661-691. doi: 10.1007/s40684-021-00343-6 [17] LEE D J, SCHOENBERGER R, ARCHIBALD J, et al. Development of a machine vision system for automatic date grading using digital reflective near-infrared imaging[J]. Journal of Food Engineering, 2008, 86(3): 388-398. doi: 10.1016/j.jfoodeng.2007.10.021 [18] AL-MALLAHI A, KATAOKA T, OKAMOTO H, et al. Detection of potato tubers using an ultraviolet imaging-based machine vision system[J]. Biosystems Engineering, 2010, 105(2): 257-265. doi: 10.1016/j.biosystemseng.2009.11.004 [19] MERY D, LILLO I, LOEBEL H, et al. Automated fish bone detection using X-ray imaging[J]. Journal of Food Engineering, 2011, 105(3): 485-492. doi: 10.1016/j.jfoodeng.2011.03.007 [20] LI Y L, WANG SH J, TIAN Q, et al. A survey of recent advances in visual feature detection[J]. Neurocomputing, 2015, 149: 736-751. doi: 10.1016/j.neucom.2014.08.003 [21] MORENO I, AVENDAÑO-ALEJO M, TZONCHEV R I. Designing light-emitting diode arrays for uniform near-field irradiance[J]. Applied Optics, 2006, 45(10): 2265-2272. doi: 10.1364/AO.45.002265 [22] LIU Y J, KONG J Y, WANG X D, et al. Research on image acquisition of automatic surface vision inspection systems for steel sheet[C]. 2010 3rd International Conference on Advanced Computer Theory and Engineering (ICACTE), IEEE, 2009: 189-192. [23] 赵文宏, 彭超, 陈红星. 基于形态学玻璃屏幕表面划痕检测方法研究[J]. 浙江工业大学学报,2016,44(3):279-282. doi: 10.3969/j.issn.1006-4303.2016.03.009ZHAO W H, PENG CH, CHEN H X. Study on scratch inspection methods of glass screen surface based on morphology[J]. Journal of Zhejiang University of Technology, 2016, 44(3): 279-282. (in Chinese). doi: 10.3969/j.issn.1006-4303.2016.03.009 [24] 刘重阳. 基于计算机视觉的透明材料缺陷检测系统研究[D]. 哈尔滨: 哈尔滨理工大学, 2020.LIU CH Y. Research on defect detection system of transparent materials based on computer vision[D]. Harbin: Harbin University of Science and Technology, 2020. (in Chinese). [25] 苑玮琦, 毕天宇. 玻璃质量在线视觉检测系统光源的设计[J]. 应用光学,2015,36(3):369-375. doi: 10.5768/JAO201536.0301006YUAN W Q, BI T Y. Illuminating source design of online visual inspection system for glass defects[J]. Journal of Applied Optics, 2015, 36(3): 369-375. (in Chinese). doi: 10.5768/JAO201536.0301006 [26] MEZIANE R, MEGUELLATI S, MESSAGIER M. Precision inspection of transparent component quality[J]. The International Journal of Advanced Manufacturing Technology, 2023, 125(3-4): 1731-1741. doi: 10.1007/s00170-022-10774-3 [27] 张以谟. 应用光学[M]. 4版. 北京: 电子工业出版社, 2015.ZHANG Y M. Applied Optics[M]. 4th ed. Beijing: Publishing House of Electronics Industry, 2015. (in Chinese) -

下载:

下载: