-

摘要:

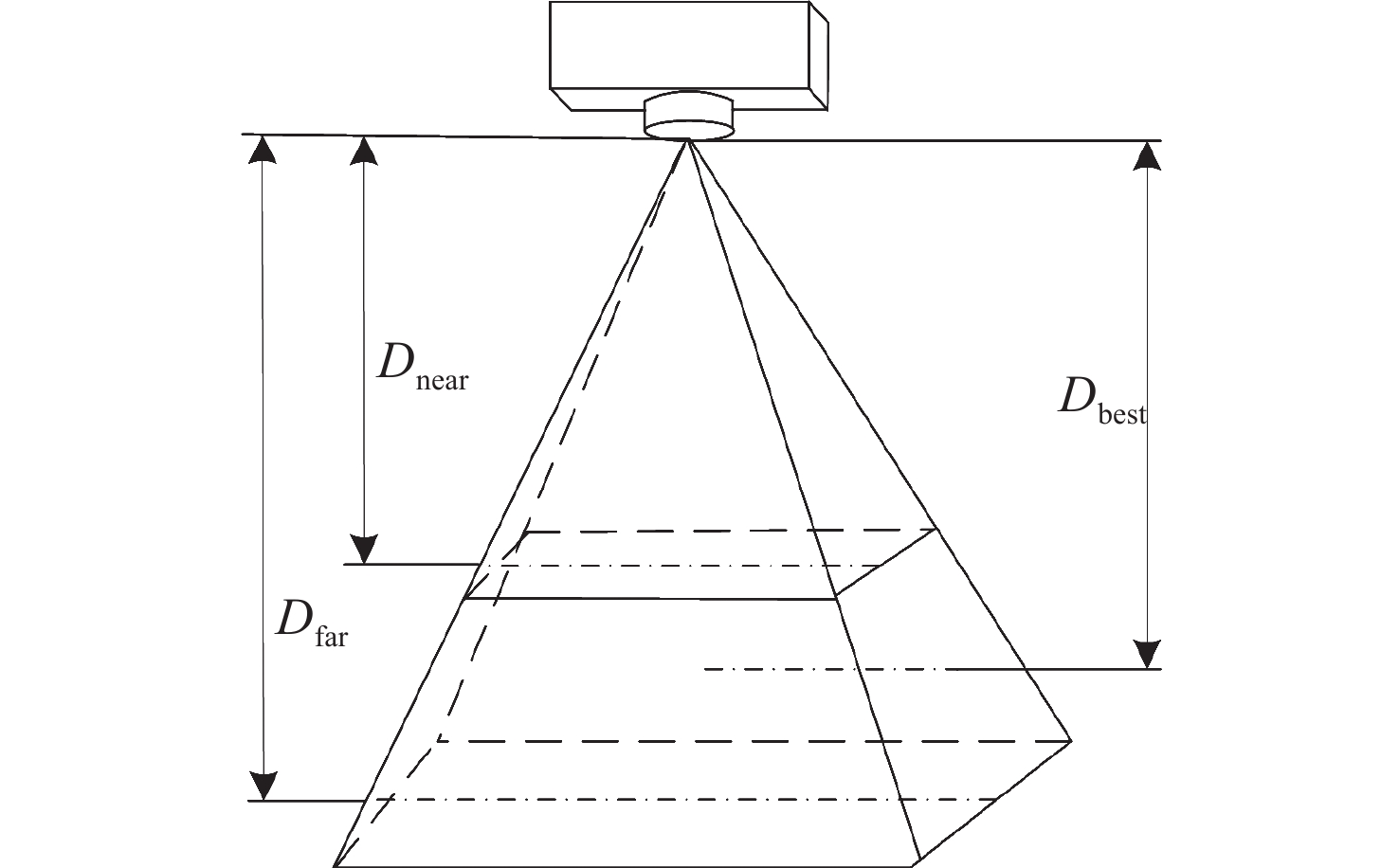

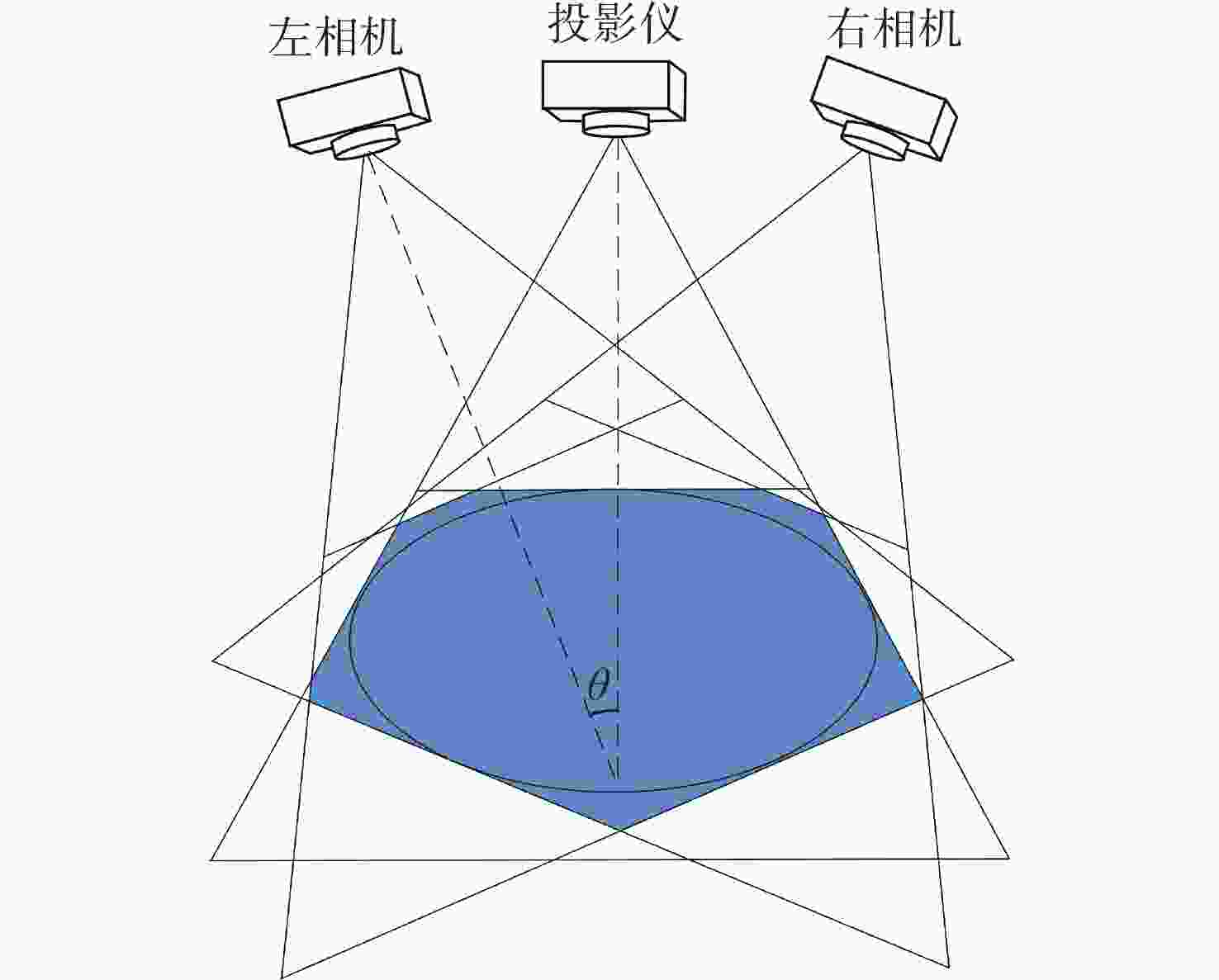

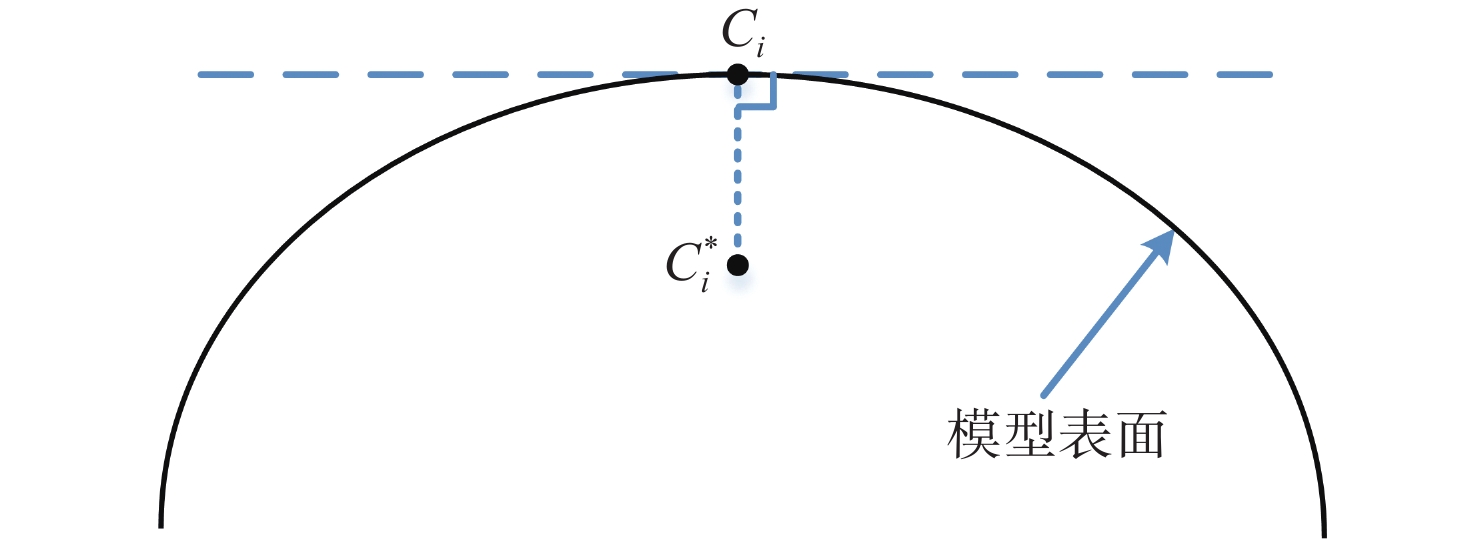

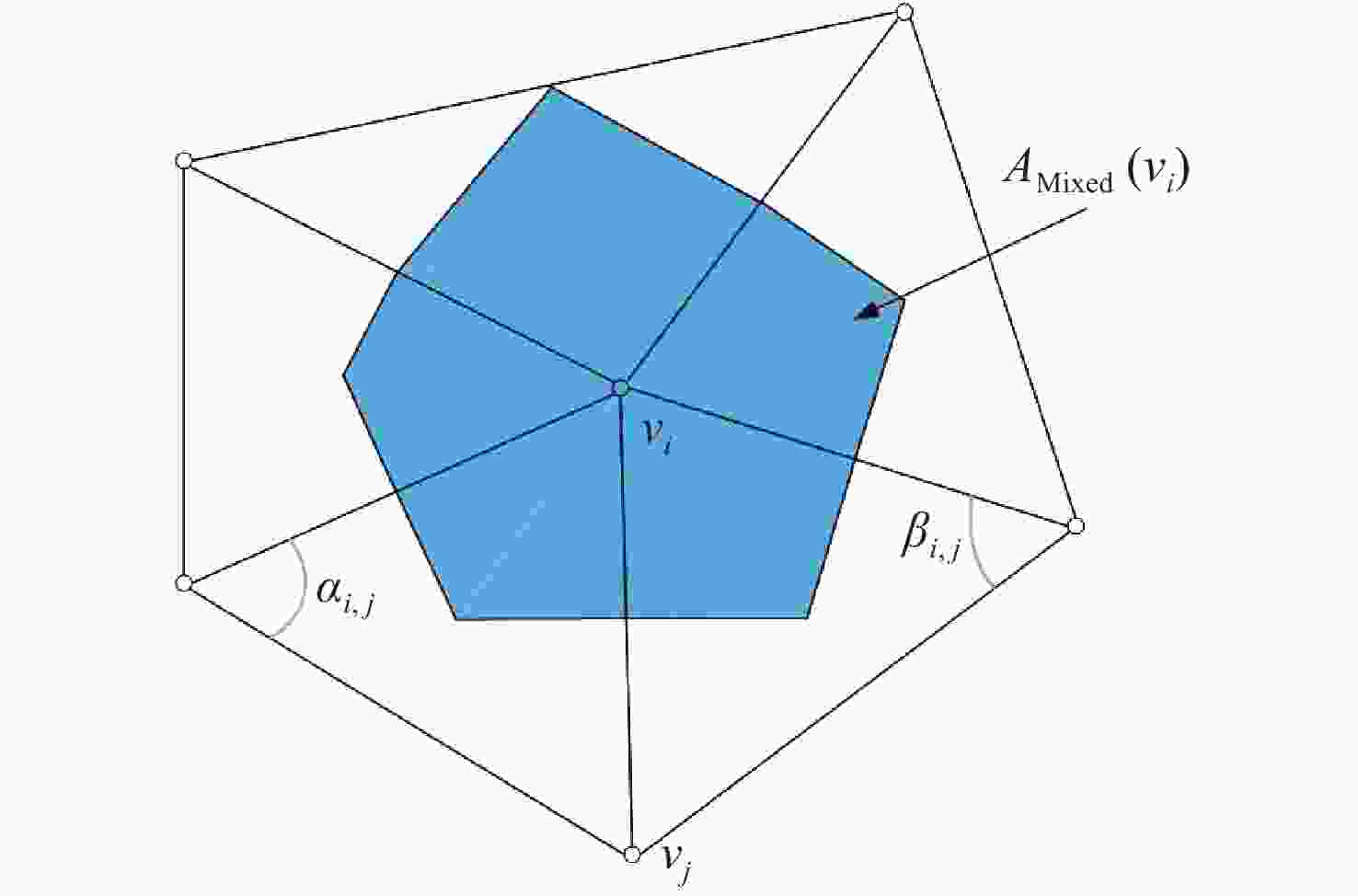

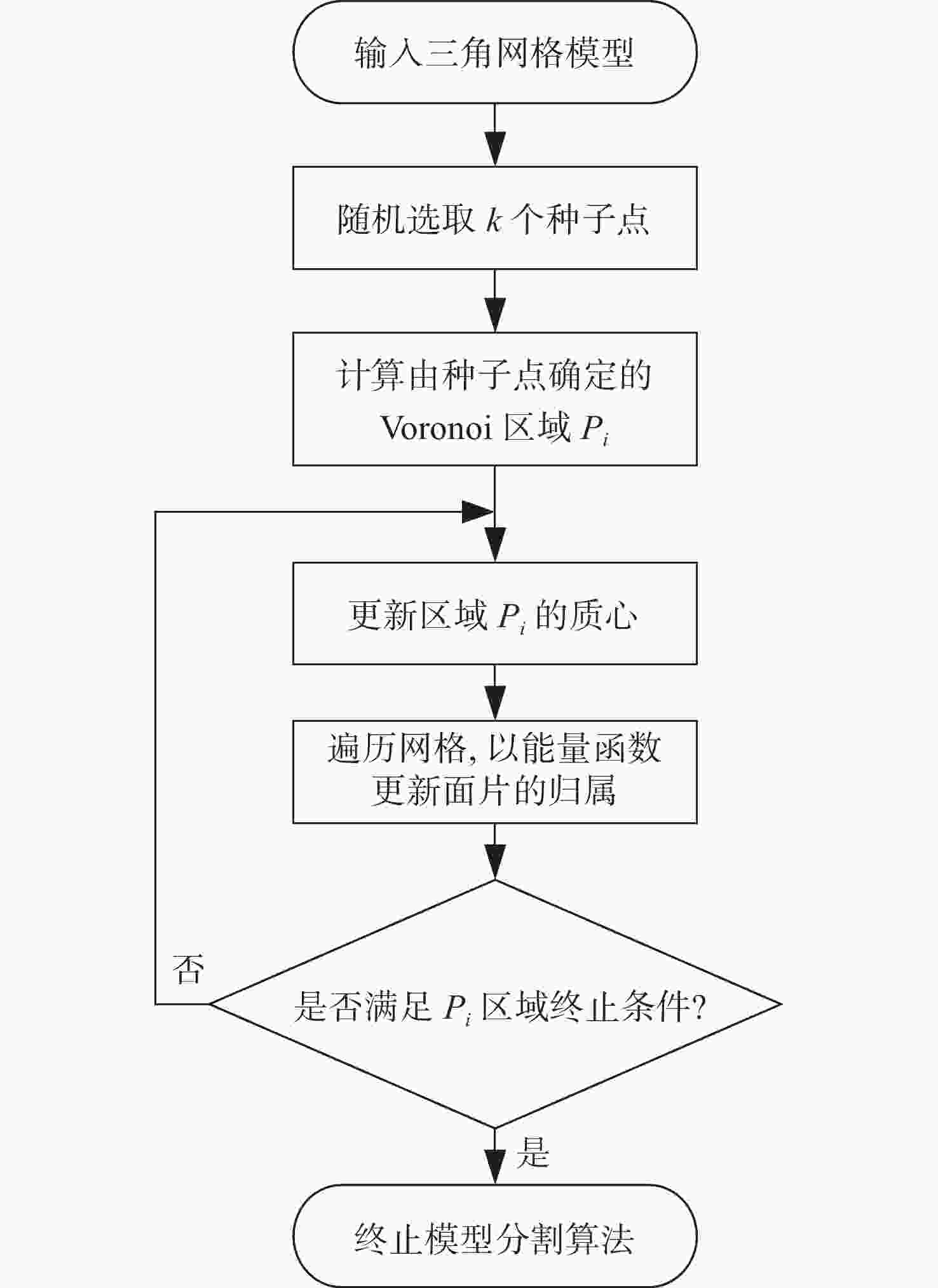

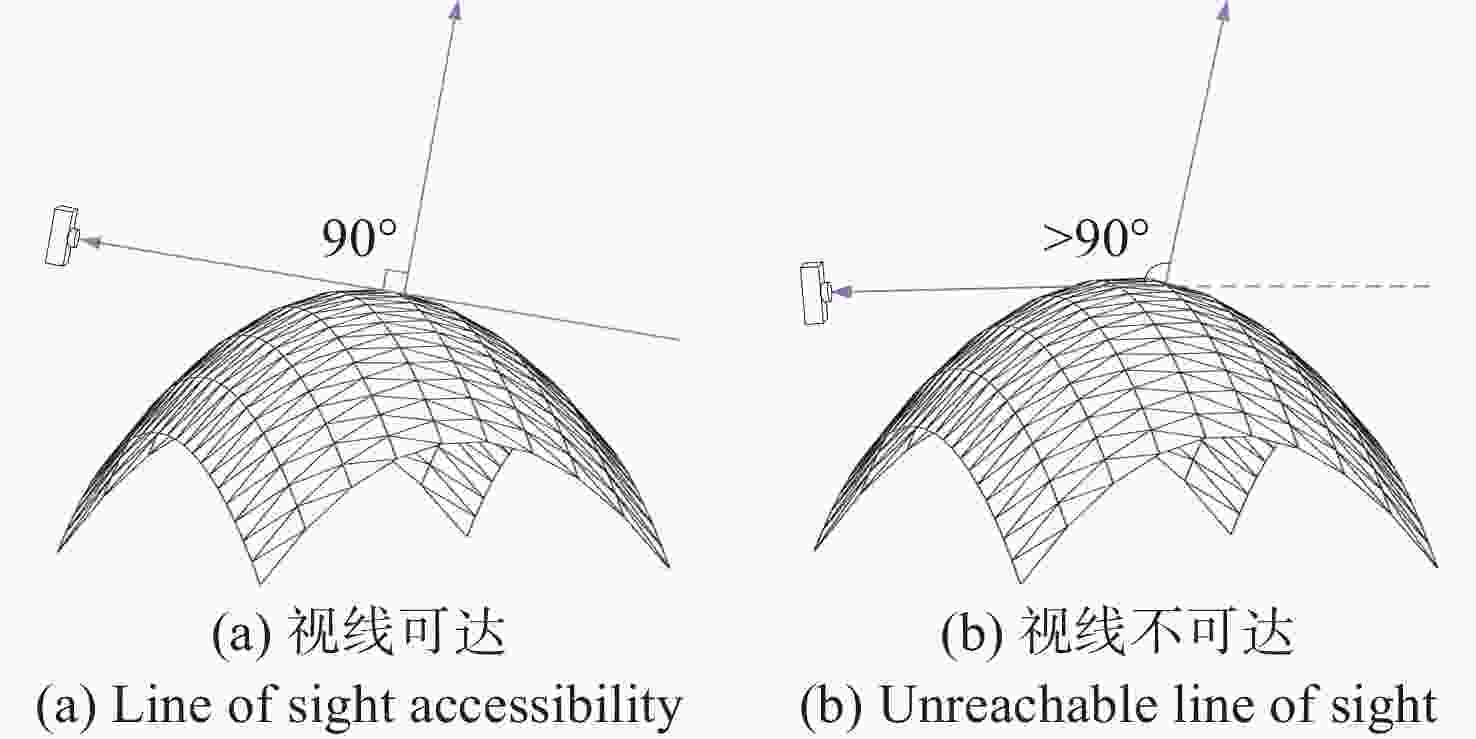

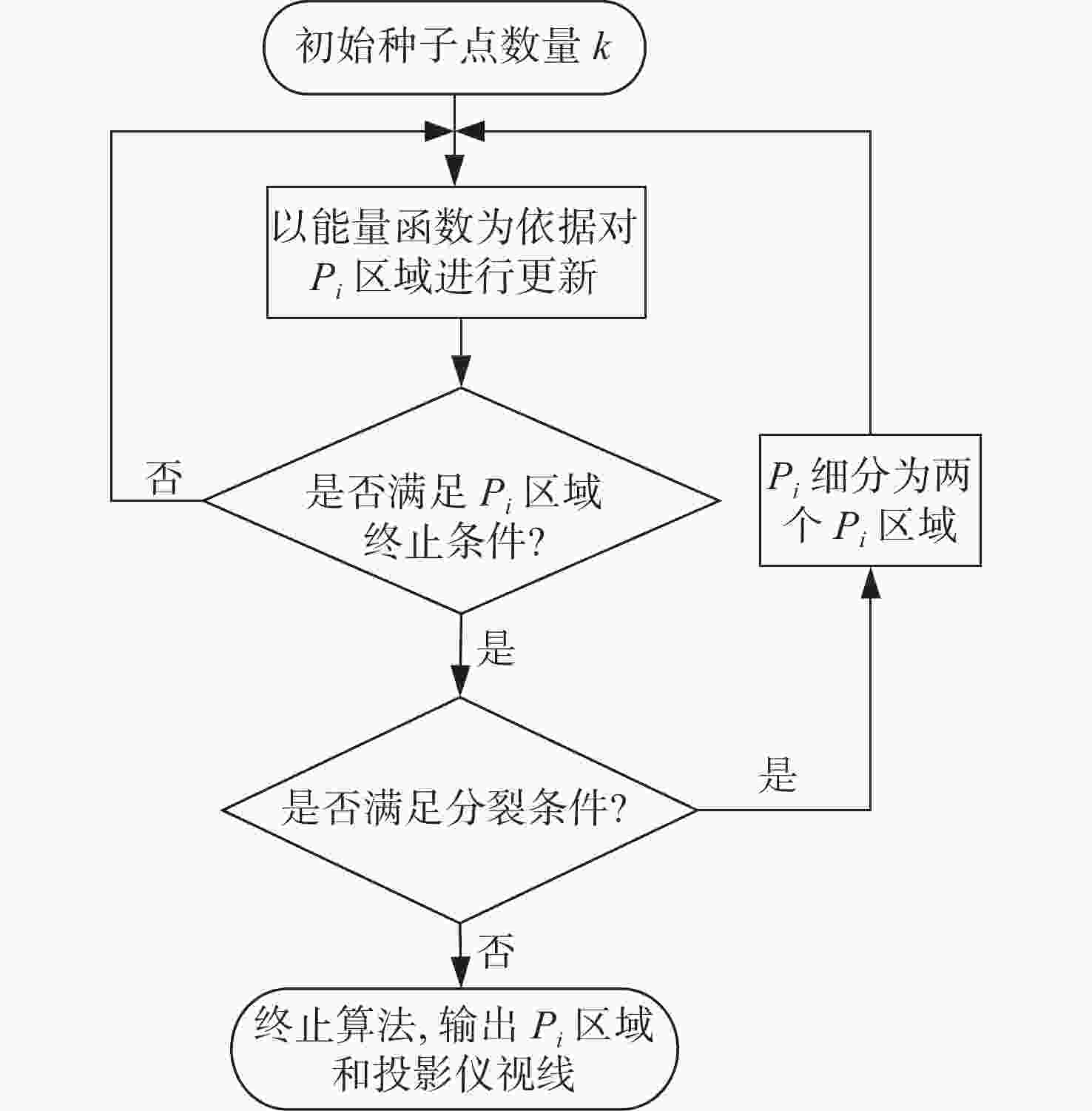

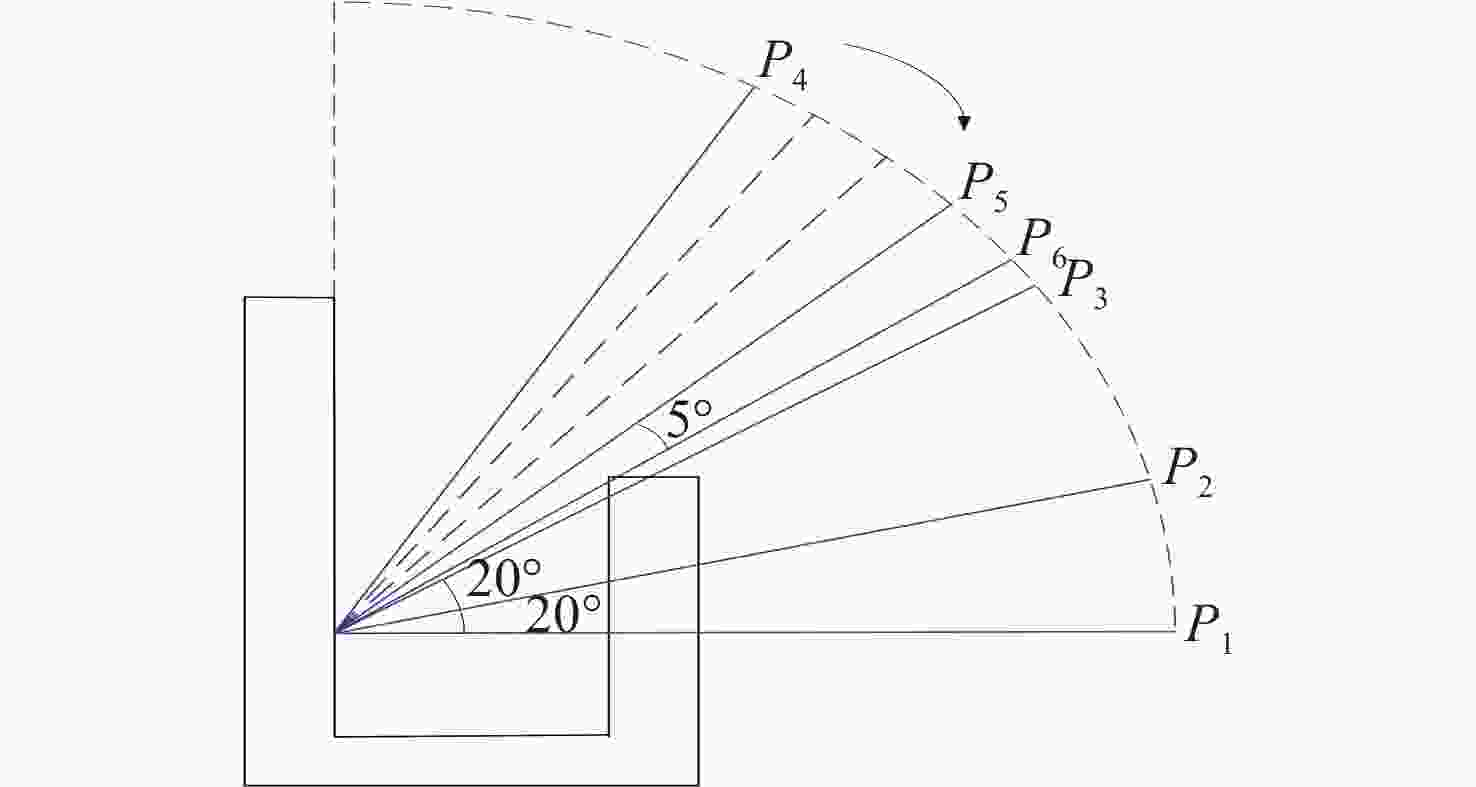

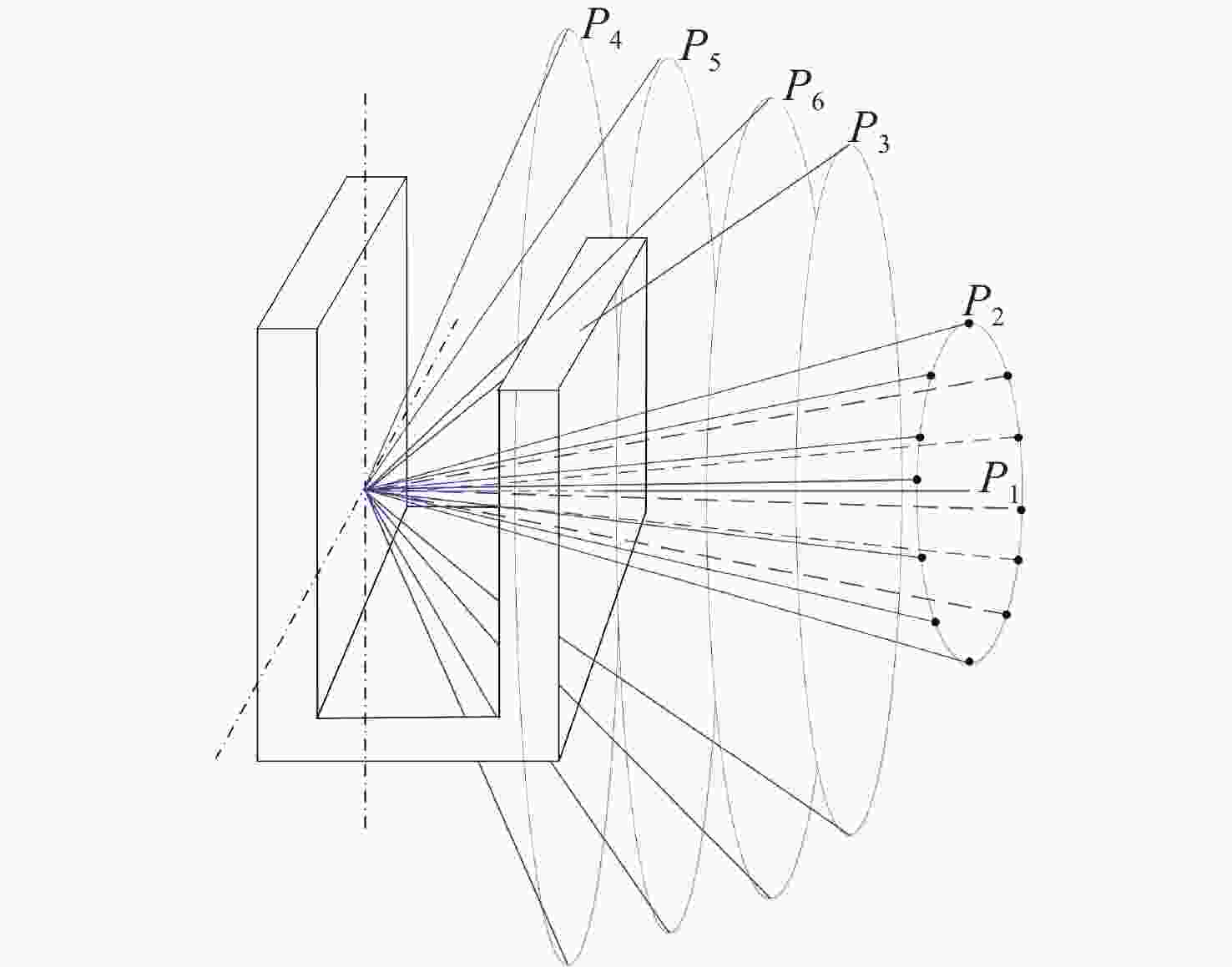

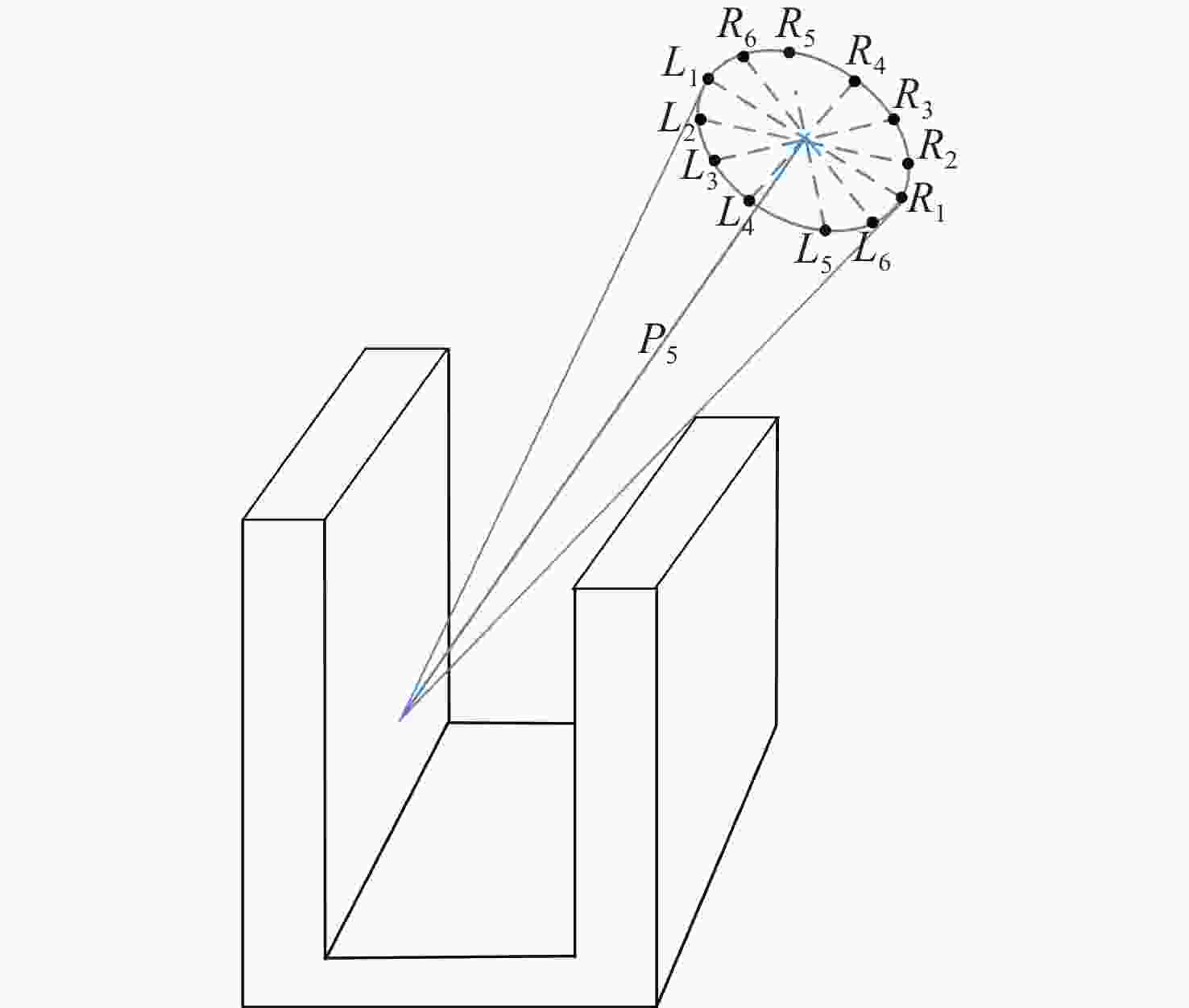

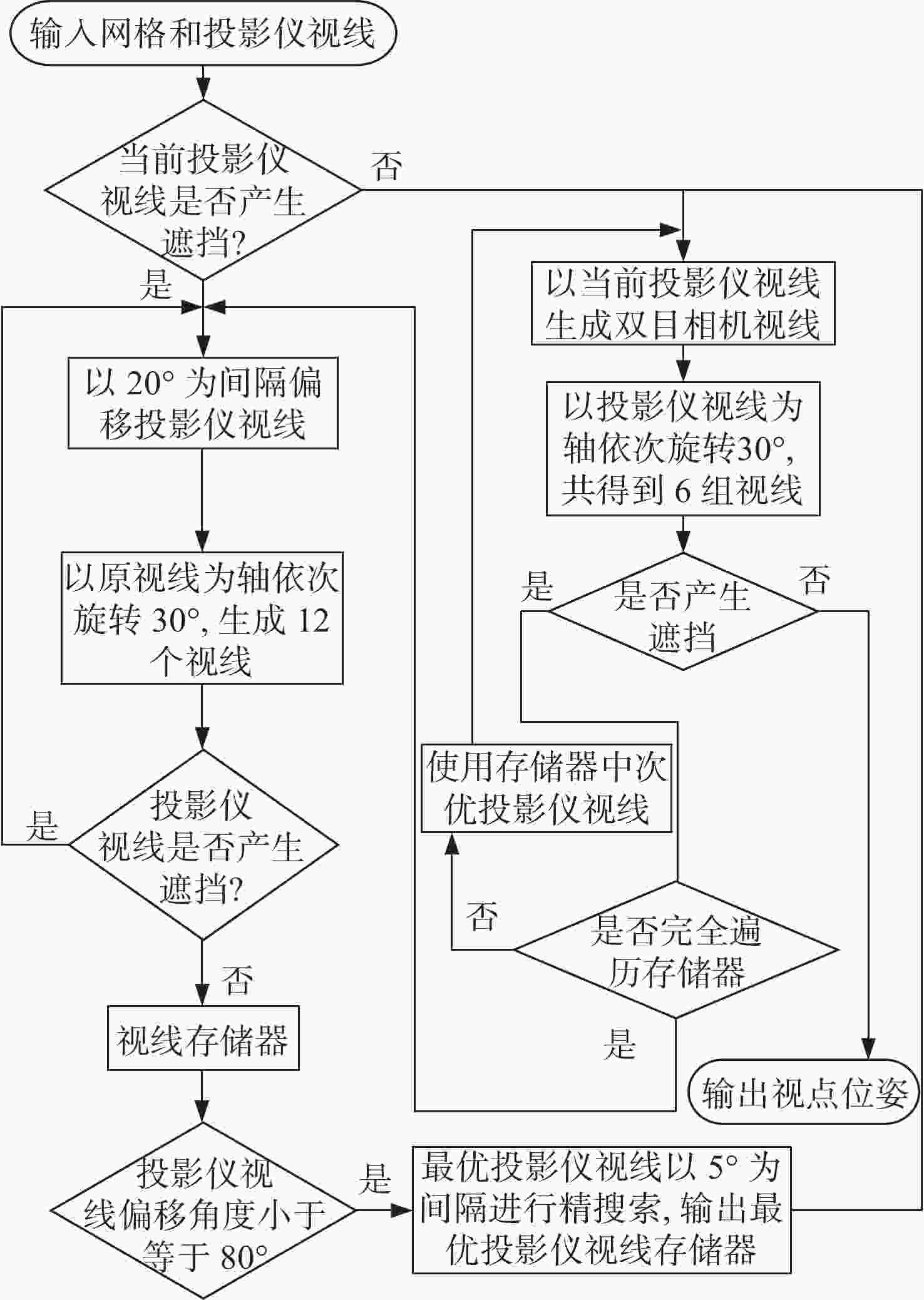

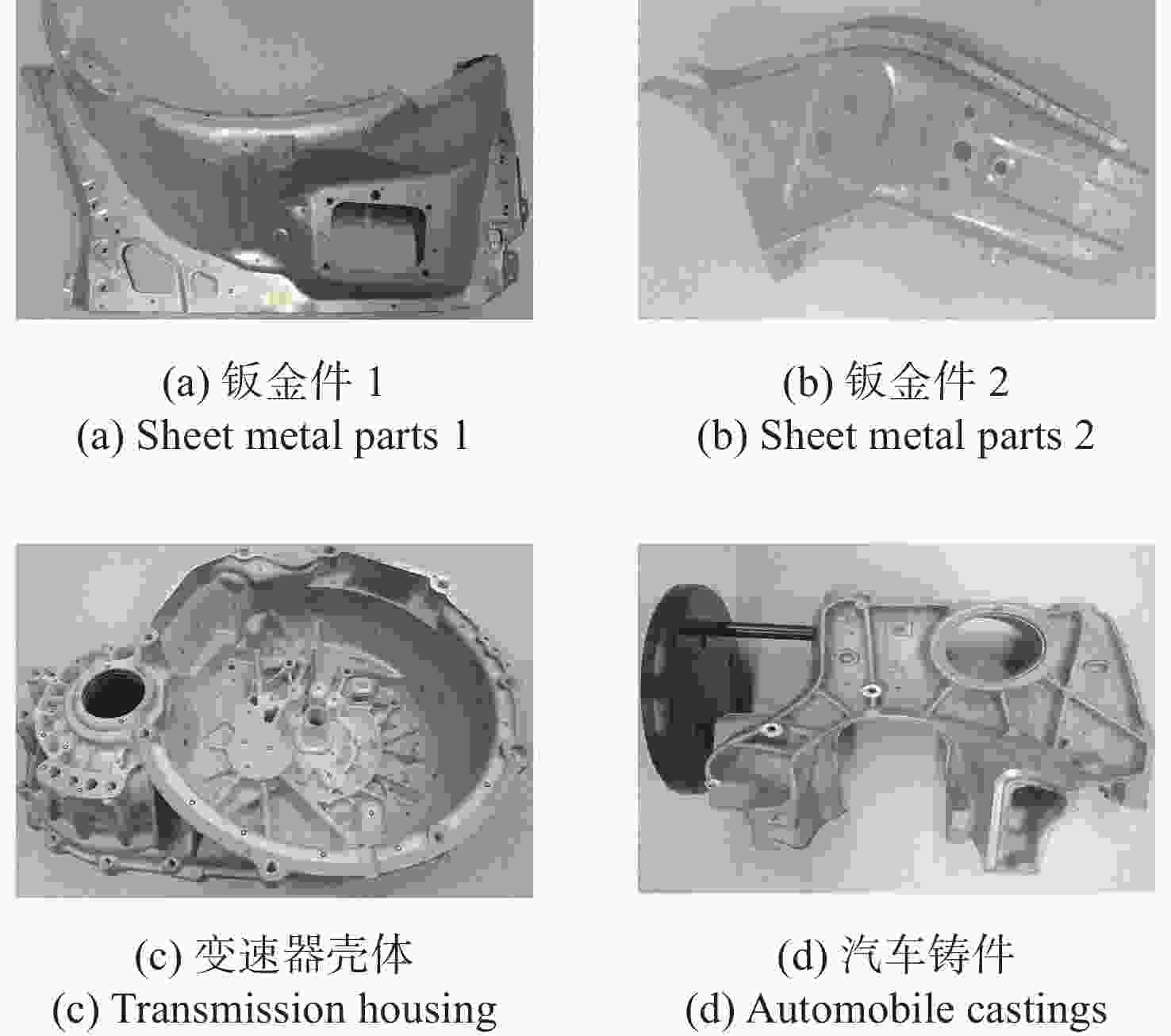

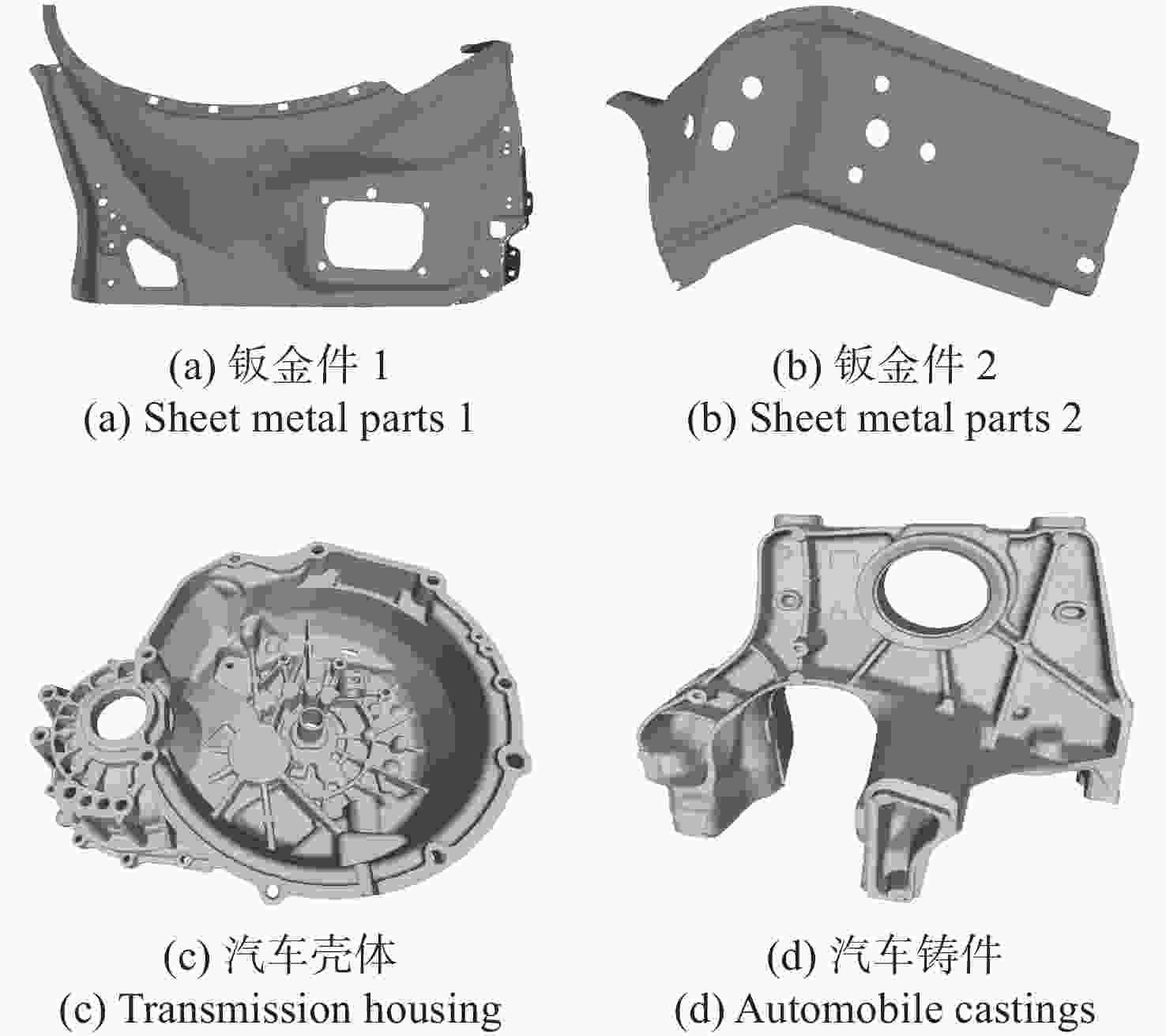

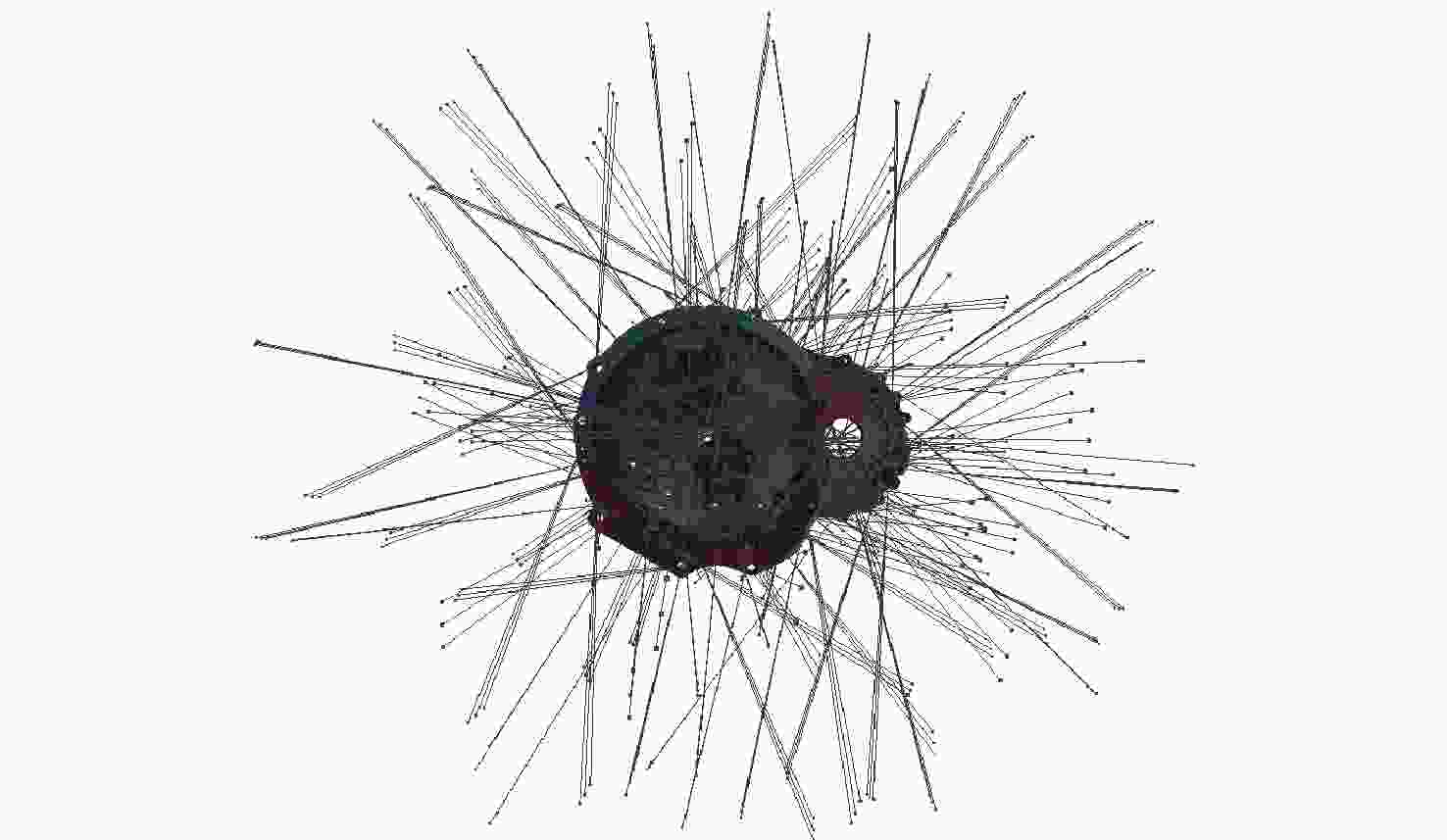

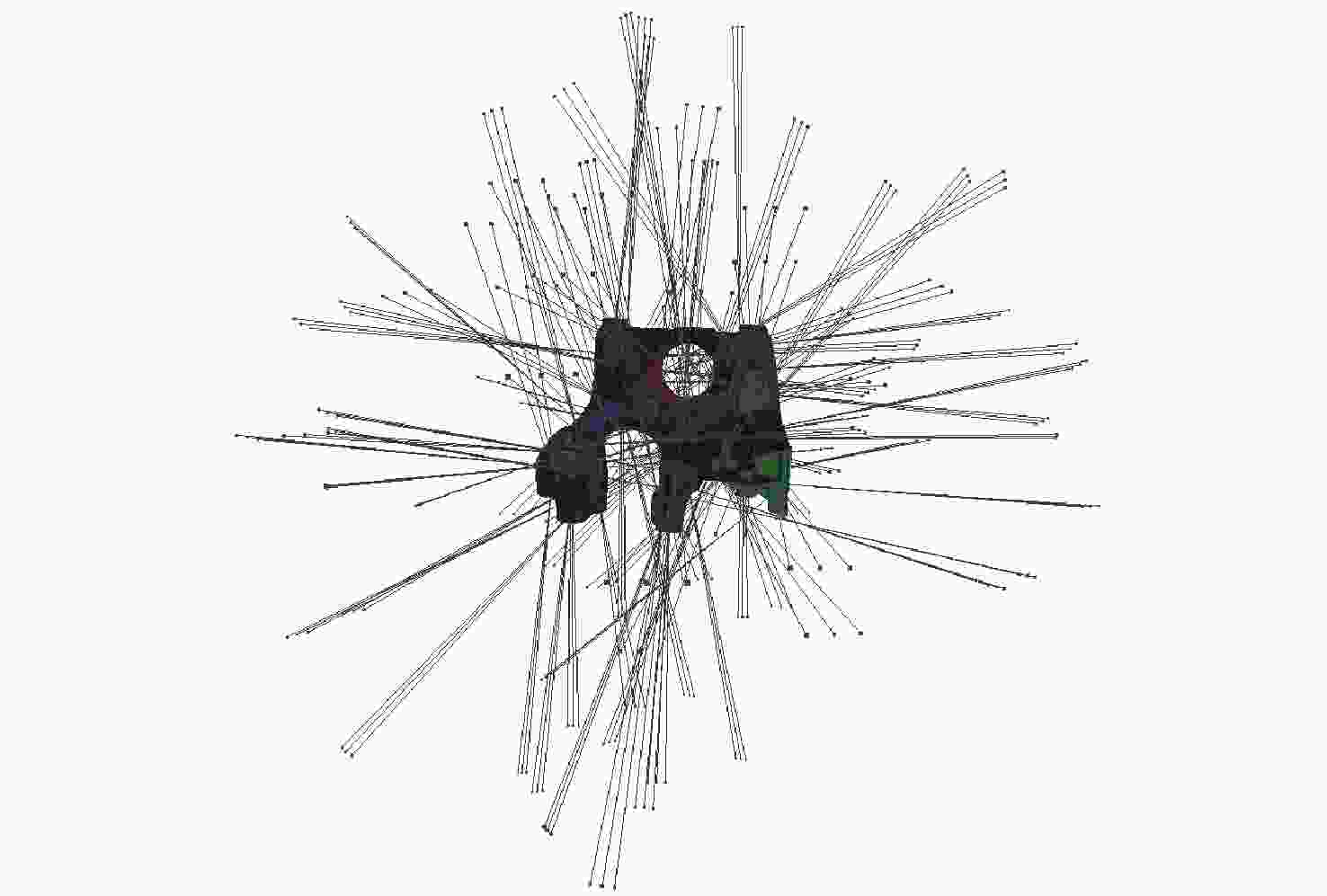

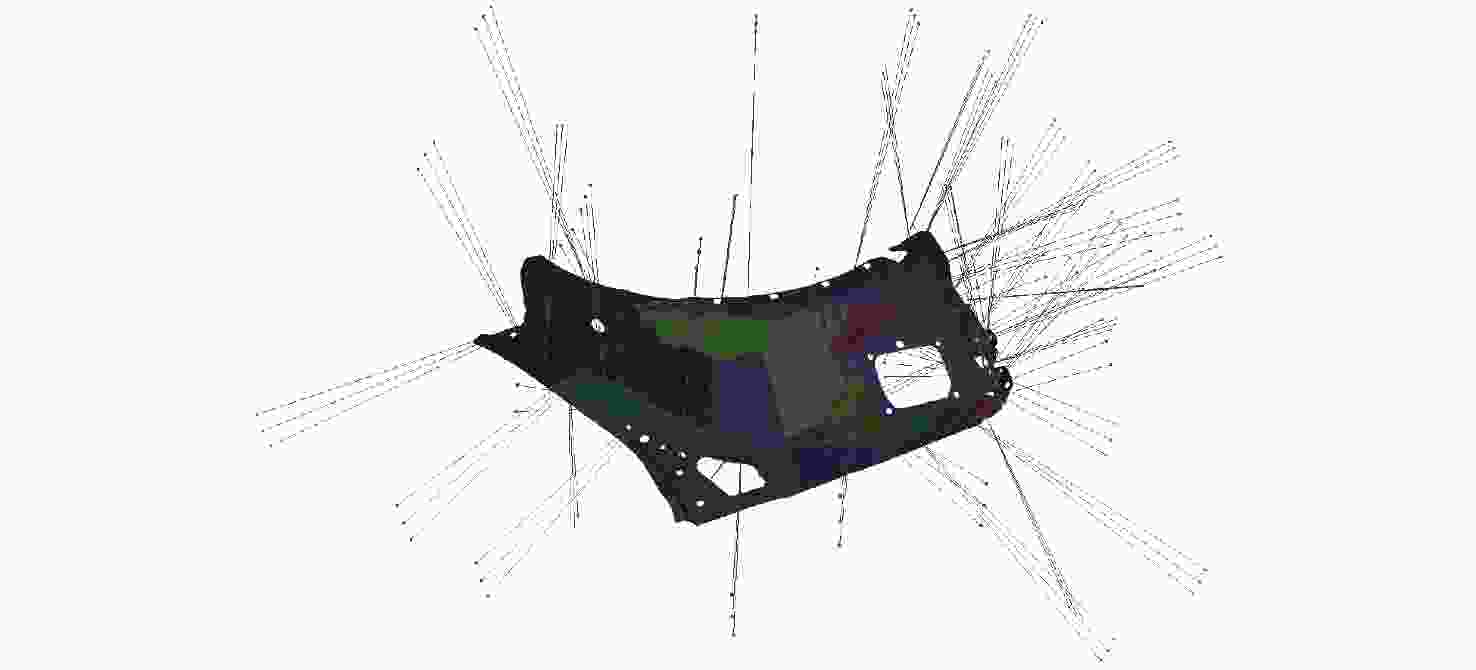

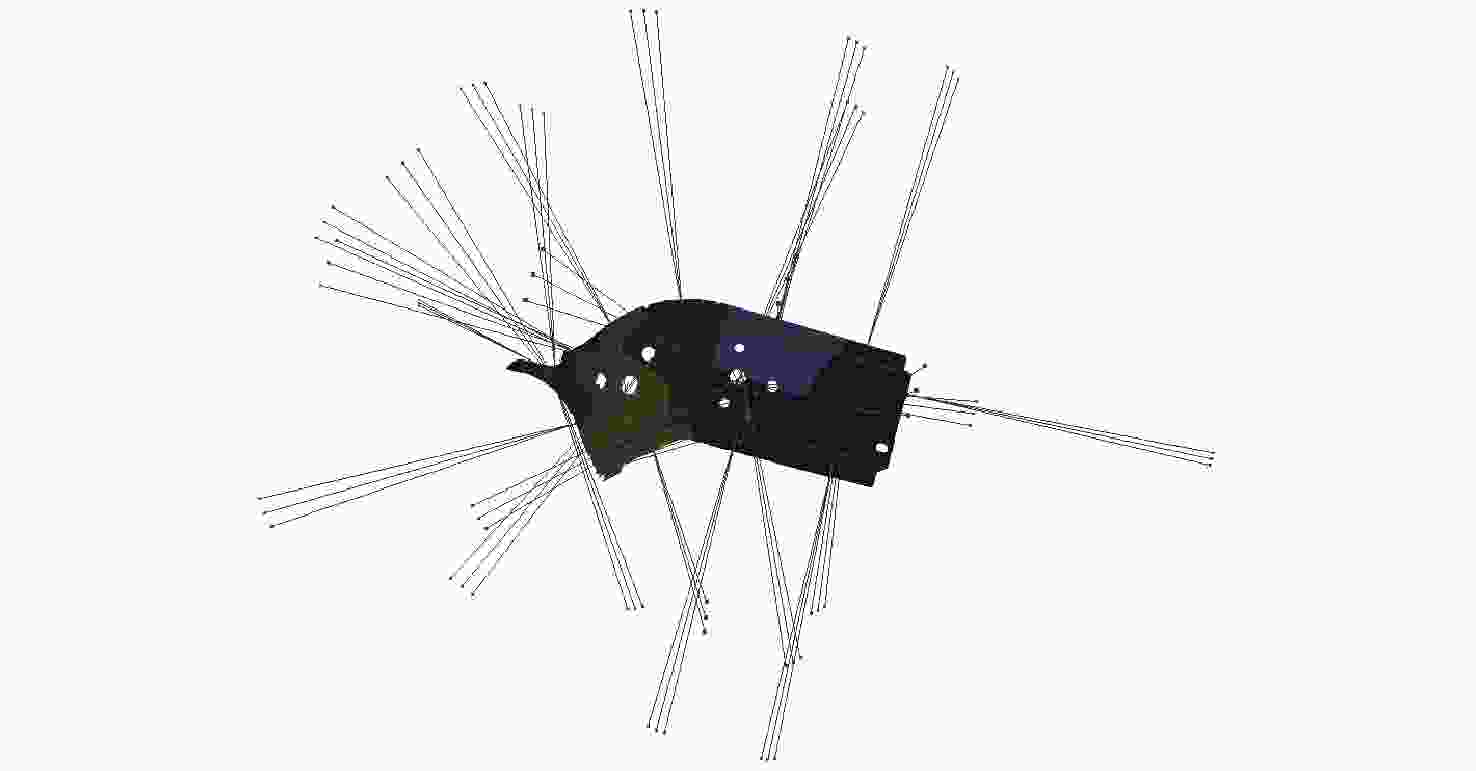

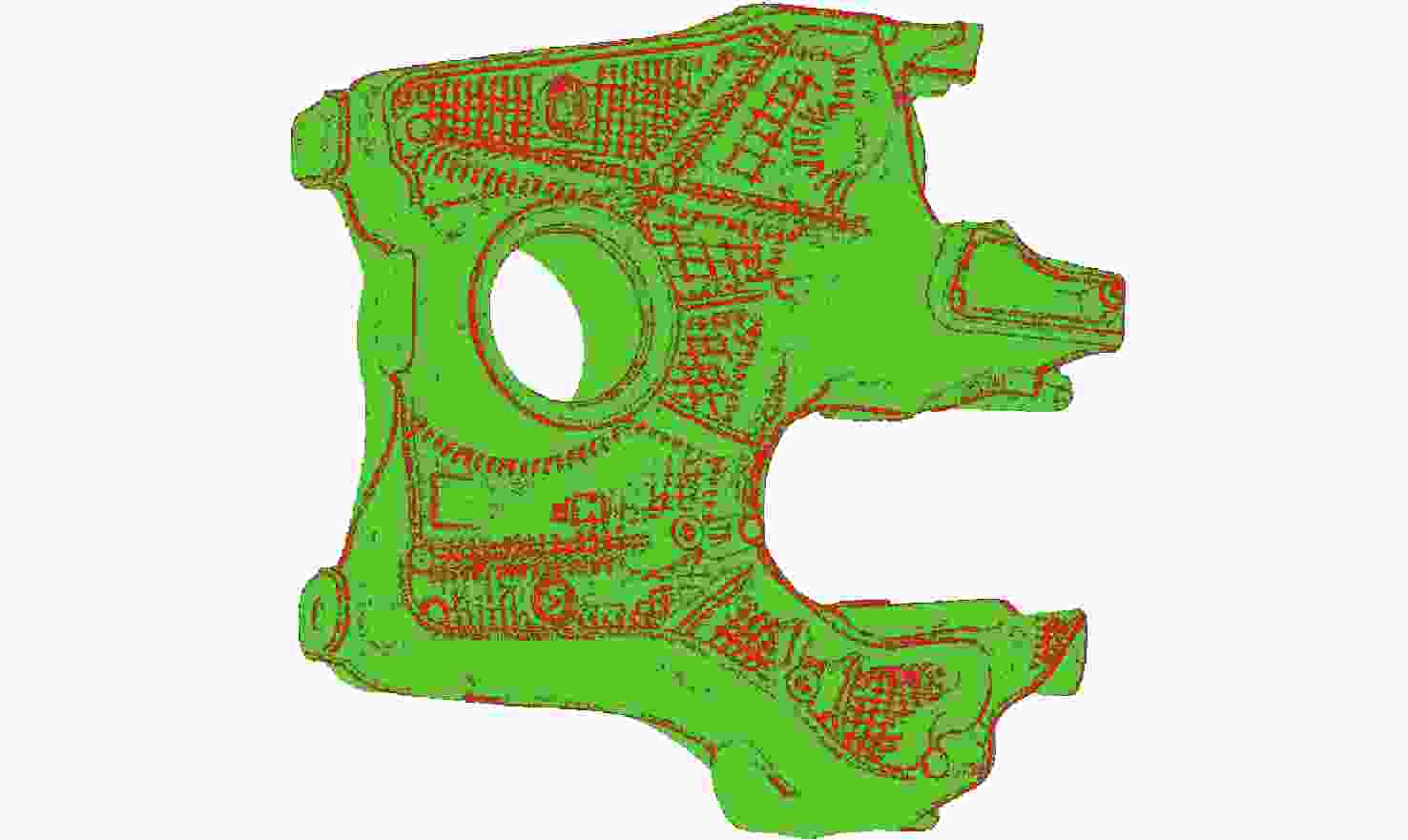

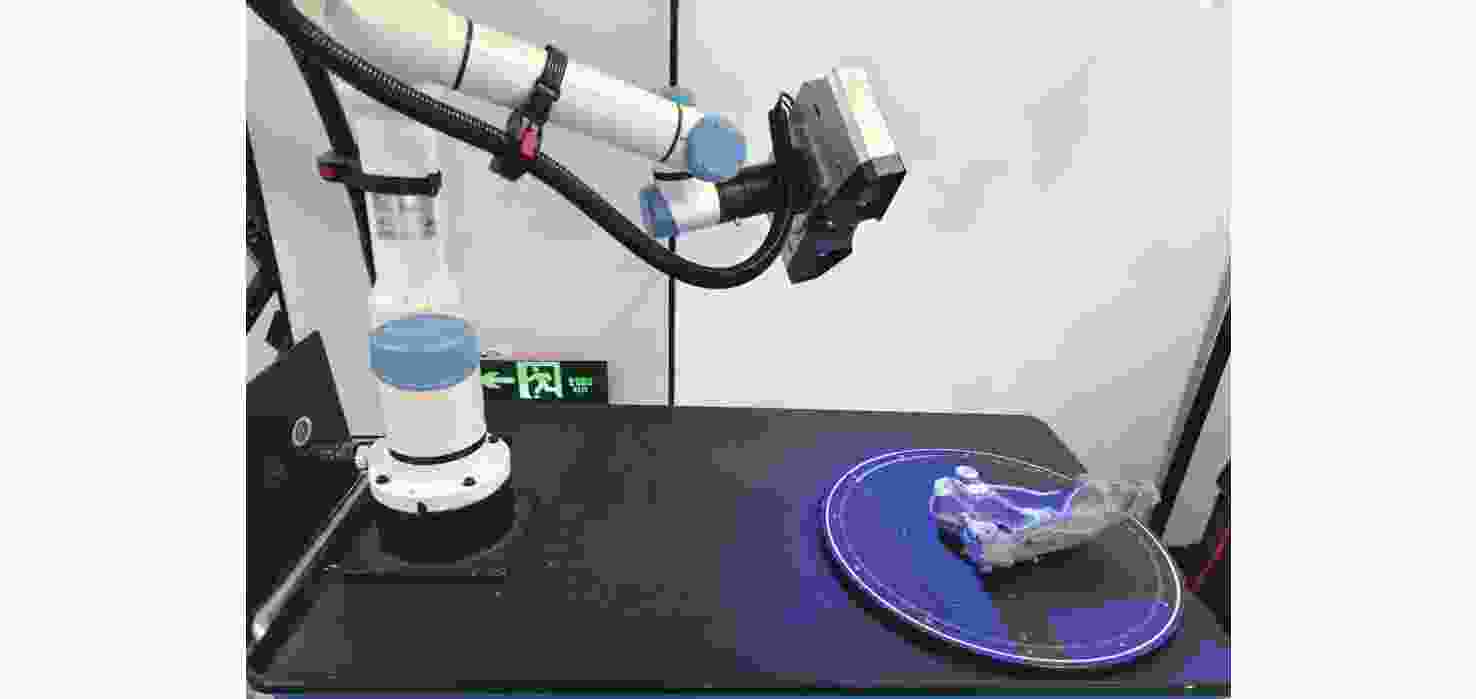

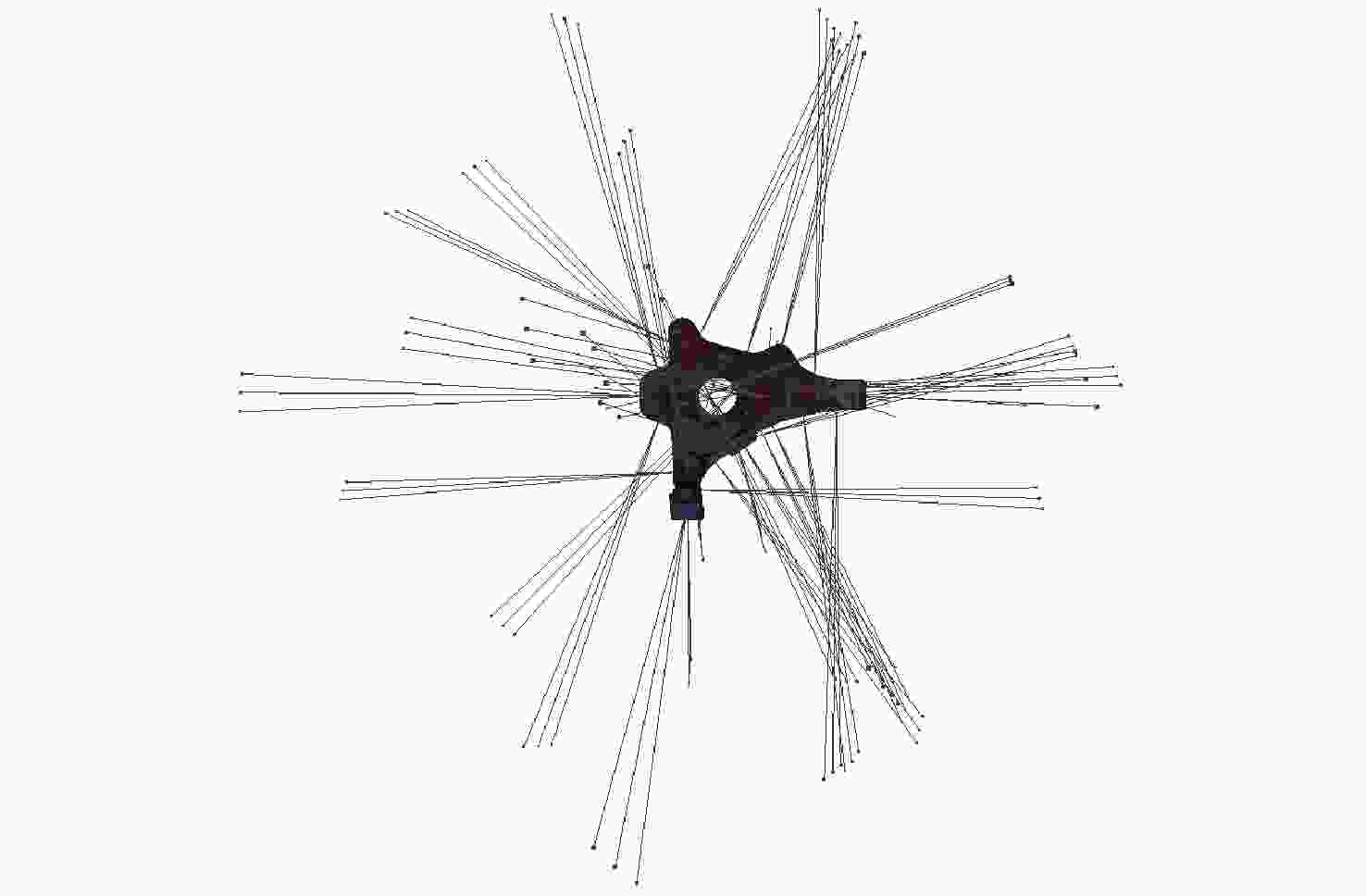

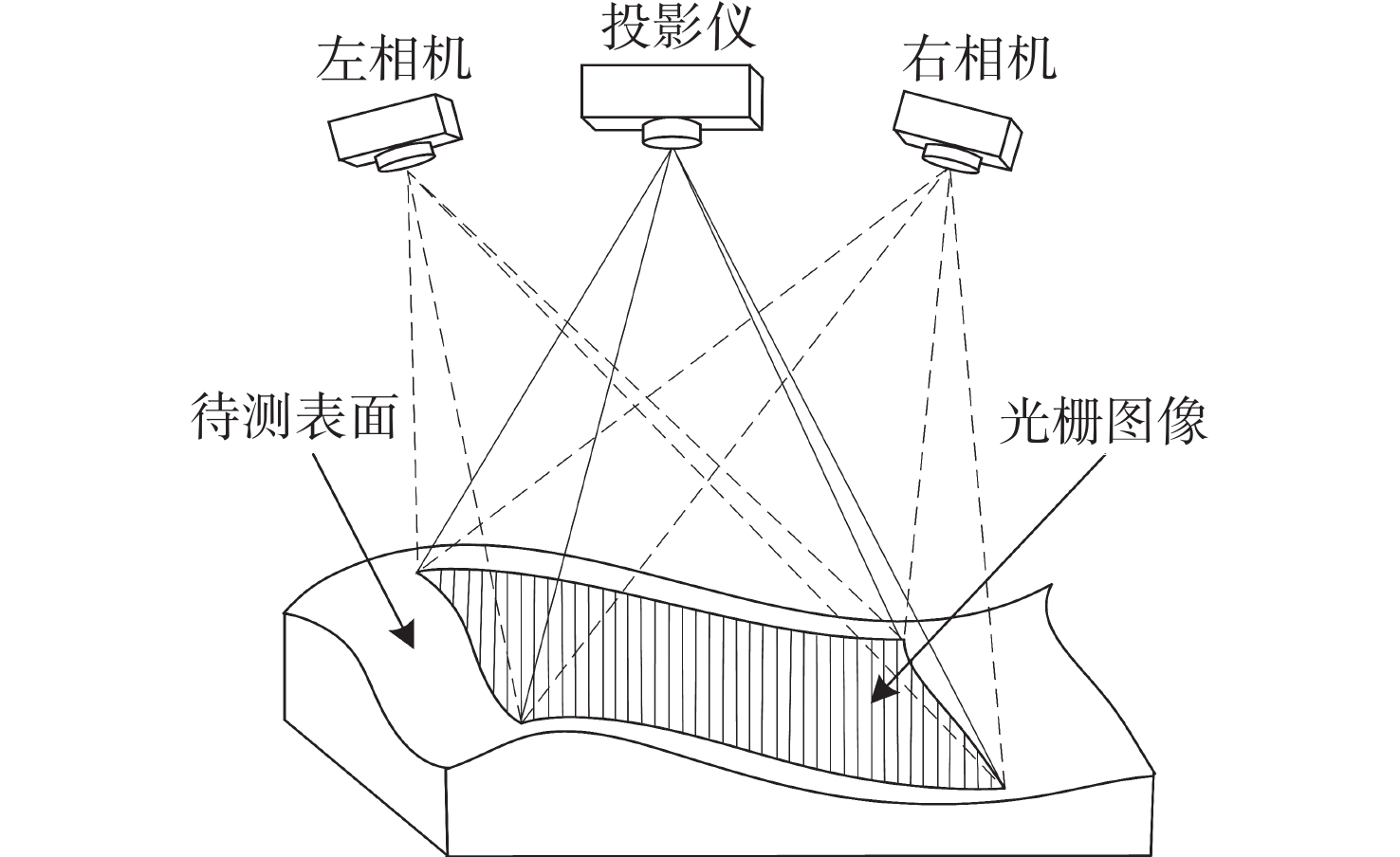

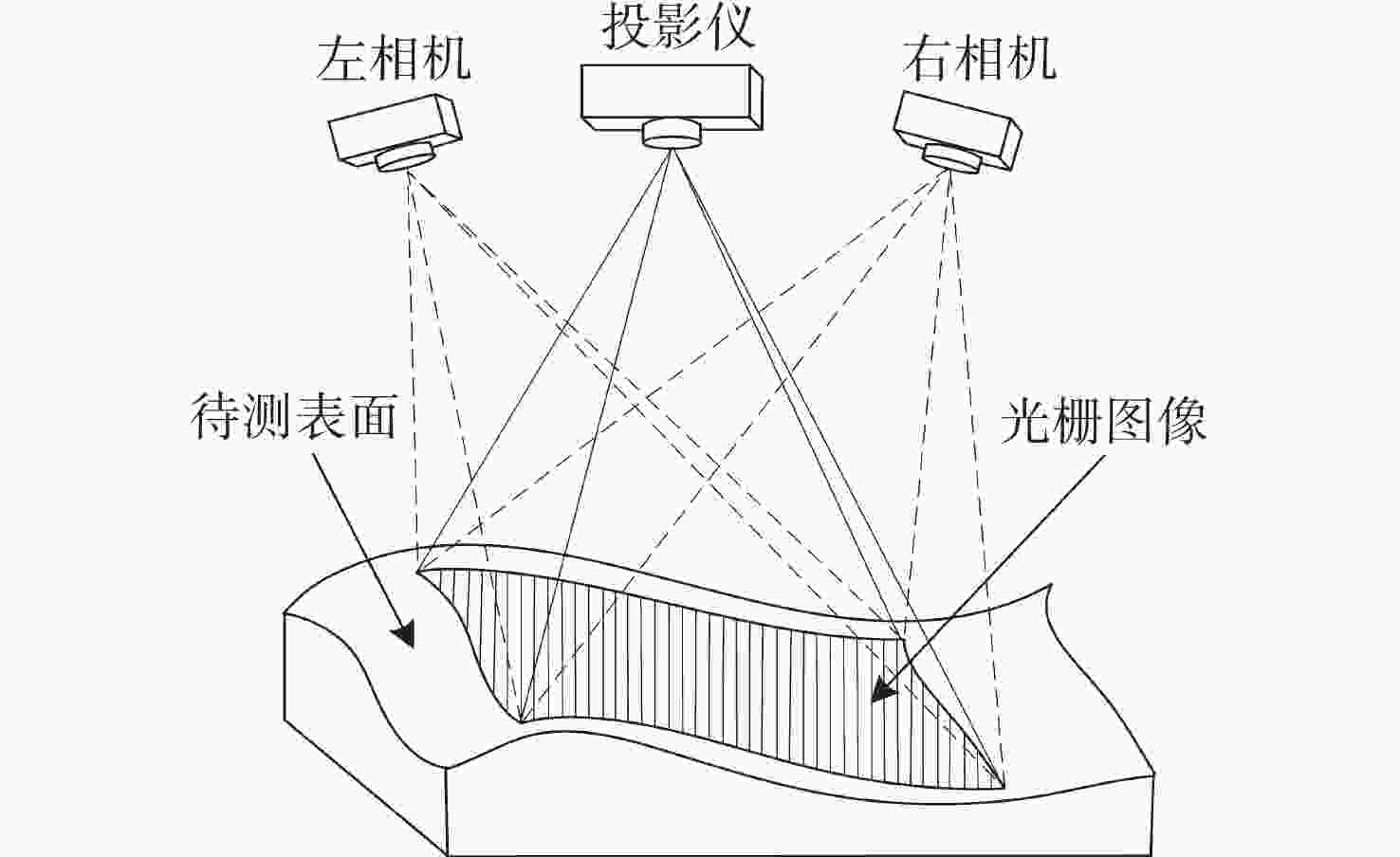

当进行扫描重建时,示教扫描繁琐且通用性差,目前视点规划的重点依然是自动获取覆盖模型的最少视点集。为了实现对不同复杂程度零部件的自动化三维扫描重建,本文对视点规划过程中可能发生的视点冗余、视点遮挡、双目重建约束等问题进行研究。首先,针对现有视点规划难以对模型进行完整扫描的问题,通过分析面结构光扫描特性,对Lloyd’s算法进行改进,提出使用欧式距离和法向量偏差的能量函数对模型进行Voronoi划分,生成初始扫描视点。接着,针对视点冗余问题,提出了对初始扫描视点进行分裂的迭代算法。最后,针对生成的视点容易产生遮挡的问题,提出了一种视线去遮挡策略,并以提高模型覆盖率为目的,提出了使用追扫视点的方法。实验结果表明:在最佳视点数量下,对于汽车铸件和壳体的覆盖率达到了94%以上,对于简单曲面汽车钣金的覆盖率达到了99.5%以上,并实现了汽车转向节的自动规划扫描,满足视点自动规划的覆盖率和效率以及对不同复杂程度零件的适应性要求。

Abstract:Teaching scans are cumbersome and have poor versatility when performing scan reconstruction. Viewpoint planning has continued to focus on automatically obtaining the minimum set of viewpoints covering the model. To realize automated 3D scanning and reconstruction of parts with different complexity levels, we study issues such as viewpoint redundancy, viewpoint occlusion, and binocular reconstruction constraints that may occur during viewpoint planning. First, given the difficulty of completely scaning the model with existing viewpoint planning, Lloyd's algorithm is improved by analyzing the characteristics of surface structured light scanning and the energy function of Euclidean distance and normal vector deviation is applied to perform Voronoi partitioning of the model to generate an initial scanning viewpoint. Then, to address the viewpoint redundancy problem, an iterative algorithm for splitting the initial scanning viewpoints is proposed. Finally, given the problem that the generated viewpoints are prone to occlusion, a line-of-sight de-occlusion strategy is proposed. Moreover, to improve the model coverage, a method of using panning viewpoints is proposed. The experimental results show that under the optimal number of viewpoints, the coverage rate of automobile castings and shells reaches more than 94%, and that of the simple curved automobile sheet metal reaches more than 99.5%, and automatic planning and scanning of the automotive steering knuckle is realized. Planning scanning meets the coverage and efficiency requirements of automatic viewpoint planning and the adaptability requirements for parts with different complexity levels.

-

表 1 汽车壳体扫描结果

Table 1. Scanning results of automobile transmission housing

$ \alpha $权值 视点

数量处理

耗时/s覆盖率 追加视点

数量处理

耗时/s覆盖率

(追扫)0.1 77 167.69 91.64 20 14.53 93.41 0.1 77 157.28 91.11 20 14.40 93.41 0.1 79 183.77 92.07 18 11.19 93.53 0.15 158 324.06 94.17 43 22.62 95.39 0.15 156 363.92 94.90 41 23.07 95.80 0.15 161 290.06 94.17 39 17.81 95.33 0.2 237 481.22 95.60 75 47.89 96.33 0.2 245 538.25 95.90 72 27.67 96.53 0.2 237 476.17 95.60 66 43.08 96.41 表 2 汽车铸件扫描结果

Table 2. Scanning results of automobile castings

$ \alpha $权值 视点

数量处理

耗时/s覆盖率 追加视点

数量处理

耗时/s覆盖率

(追扫)0.1 49 180.83 93.39 14 13.86 94.68 0.1 44 157.02 91.60 14 17.63 94.19 0.1 50 175.53 92.05 14 11.62 94.88 0.15 110 342.40 94.76 33 20.21 96.39 0.15 100 309.02 95.67 32 20.05 97.21 0.15 110 319.99 94.80 35 23.27 96.46 0.2 166 392.54 96.97 50 36.33 97.84 0.2 181 504.09 96.83 57 36.74 97.80 0.2 173 466.90 96.90 58 40.29 98.04 表 3 钣金1扫描结果

Table 3. Scanning results of sheet metal 1

$ \alpha $权值 视点

数量处理

耗时/s覆盖率 追加视点

数量处理

耗时/s覆盖率

(追扫)0.0075 49 31.36 98.41 5 0.55 98.41 0.0075 49 33.48 98.66 6 0.53 98.66 0.0075 43 36.05 96.37 5 0.45 96.37 0.01 51 35.97 99.52 5 0.50 99.52 0.01 56 41.36 99.52 2 0.18 99.53 0.01 53 33.11 99.52 5 0.67 99.53 0.0125 63 42.03 99.67 4 0.38 99.67 0.0125 62 39.45 99.34 6 0.49 99.34 0.0125 63 46.74 99.67 4 0.37 99.67 表 4 钣金2扫描结果

Table 4. Scanning results of sheet metal 2

$ \alpha $权值 视点

数量处理

耗时/s覆盖率 追加视点

数量处理

耗时/s覆盖率

(追扫)0.01 23 29.95 97.95 5 4.42 97.97 0.01 22 24.20 97.94 3 2.18 97.94 0.01 28 29.81 99.68 5 3.27 99.69 0.0125 30 32.50 99.93 7 3.32 99.94 0.0125 30 38.59 99.92 6 2.44 99.94 0.0125 30 35.12 99.93 7 3.41 99.94 0.015 29 33.77 99.93 7 3.39 99.94 0.015 34 35.44 99.92 9 3.44 99.95 0.015 29 33.21 99.93 7 3.40 99.94 -

[1] SHEN Y J, REN J J, HUANG N D, et al. Surface form inspection with contact coordinate measurement: a review[J]. International Journal of Extreme Manufacturing, 2023, 5(2): 022006. doi: 10.1088/2631-7990/acc76e [2] 吕虹毓, 李茂月, 蔡东辰, 等. 光栅投影在机三维形貌检测技术研究进展[J]. 中国光学(中英文),2023,16(3):500-513. doi: 10.37188/CO.2022-0083LV H Y, LI M Y, CAI D CH, et al. Research progress of grating projection on machine 3D topography inspection technology[J]. Chinese Optics, 2023, 16(3): 500-513. (in Chinese). doi: 10.37188/CO.2022-0083 [3] GOSPODNETIĆ P, MOSBACH D, RAUHUT M, et al. Viewpoint placement for inspection planning[J]. Machine Vision and Applications, 2022, 33(1): 2. doi: 10.1007/s00138-021-01252-z [4] PEUZIN-JUBERT M, POLETTE A, NOZAIS D, et al. Survey on the view planning problem for reverse engineering and automated control applications[J]. Computer-Aided Design, 2021, 141: 103094. doi: 10.1016/j.cad.2021.103094 [5] WU Q, ZOU W, XU D. Viewpoint planning for freeform surface inspection using plane structured light scanners[J]. International Journal of Automation and Computing, 2016, 13(1): 42-52. doi: 10.1007/s11633-015-0916-8 [6] 罗晨, 邵佳丰, 王伟, 等. 考虑镜面反射和阴影的复杂曲面测量视点规划[J/OL]. 机械工程学报, 2023: 1-12. https://kns-cnki-net.webvpn.xju.edu.cn:8040/kcms/detail/11.2187.TH.20230927.1545.002.html.LUO CH, SHAO J F, WANG W, et al. View planning for complex surface measurement considering specular reflections and shadows[J/OL]. Journal of Me0 Chinese). [7] 任明阳, 王立忠, 赵建博, 等. 复杂曲面零件面结构光扫描视点规划[J]. 中国光学(中英文),2023,16(1):113-126. doi: 10.37188/CO.2022-0026REN M Y, WANG L ZH, ZHAO J B, et al. Viewpoint planning of surface structured light scanning for complex surface parts[J]. Chinese Optics, 2023, 16(1): 113-126. (in Chinese). doi: 10.37188/CO.2022-0026 [8] 韩沛文. 面结构光自动化三维测量中视点生成与路径规划关键技术研究[D]. 华中科技大学, 2018.HAN P W. Research on key technique of viewpoint generation and path planning for automated surface structured-light 3D measurement[D]. Wuhan: Huazhong University of Science and Technology, 2018. (in Chinese). [9] SCOTT W R. Model-based view planning[J]. Machine Vision and Applications, 2009, 20(1): 47-69. doi: 10.1007/s00138-007-0110-2 [10] STADERINI V, GLÜCK T, SCHNEIDER P, et al. Surface sampling for optimal viewpoint generation[C]//2023 IEEE 13th International Conference on Pattern Recognition Systems (ICPRS), IEEE, 2023: 1-7. [11] MOSBACH D, GOSPODNETIĆ P, RAUHUT M, et al. Feature-driven viewpoint placement for model-based surface inspection[J]. Machine Vision and Applications, 2021, 32(1): 8. doi: 10.1007/s00138-020-01116-y [12] 李茂月, 蔡东辰, 赵伟翔, 等. 航空叶片形貌高精度结构光扫描视点规划[J]. 中国光学(中英文),2023,16(4):802-815. doi: 10.37188/CO.2022-0221LI M Y, CAI D CH, ZHAO W X, et al. High precision structural light scanning viewpoint planning for aircraft blade morphology[J]. Chinese Optics, 2023, 16(4): 802-815. (in Chinese). doi: 10.37188/CO.2022-0221 [13] 刘洪鹏, 赵文政, 刘银华, 等. 测量不确定度约束下的结构光检测视点规划方法[J]. 计算机集成制造系统,2022,28(4):1079-1086.LIU H P, ZHAO W ZH, LIU Y H, et al. View planning of structured light for free-form surfaces with control of measurement uncertainty[J]. Computer Integrated Manufacturing Systems, 2022, 28(4): 1079-1086. (in Chinese). [14] KRUECKEMEIER S, ANDERL R, SCHLEICH B. File format selection for efficient digital process chains in additive manufacturing[J]. Proceedings of the Design Society, 2023, 3: 1875-1884. doi: 10.1017/pds.2023.188 [15] LU J Y, LAZAR E A, RYCROFT C H. An extension to VORO++ for multithreaded computation of Voronoi cells[J]. Computer Physics Communications, 2023, 291: 108832. doi: 10.1016/j.cpc.2023.108832 [16] KANUNGO T, MOUNT D M, NETANYAHU N S, et al. An efficient k-means clustering algorithm: Analysis and implementation[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2002, 24(7): 881-892. doi: 10.1109/TPAMI.2002.1017616 [17] MEYER M, DESBRUN M, SCHRÖDER P, et al. Discrete differential-geometry operators for triangulated 2-manifolds[C]//Visualization and mathematics III, Springer, 2003: 35-57. [18] LIU Y H, ZHAO W ZH, LIU H P, et al. Coverage path planning for robotic quality inspection with control on measurement uncertainty[J]. IEEE/ASME Transactions on Mechatronics, 2022, 27(5): 3482-3493. doi: 10.1109/TMECH.2022.3142756 [19] PAN J, CHITTA S, MANOCHA D. FCL: a general purpose library for collision and proximity queries[C]//2012 IEEE International Conference on Robotics and Automation, IEEE, 2012: 3859-3866. [20] 徐建宁, 王立忠, 梁晋, 等. 三维测量中面结构光视点简化与机械臂路径优化方法[J/OL]. 计算机集成制造系统, 2023: 1-22. https://doi.org/10.13196/j.cims.2023.0332.XU J N, WANG L ZH, LIANG J, et al. Viewpoint simplification of surface structured light and path optimization of manipulator in 3D measurement[J/OL]. Computer Integrated Manufacturing Systems, 2023: 1-22. https://doi.org/10.13196/j.cims.2023.0332. (in Chinese). -

下载:

下载: