Design of the central support structure of a large aperture mirror with a wide working temperature

-

摘要:

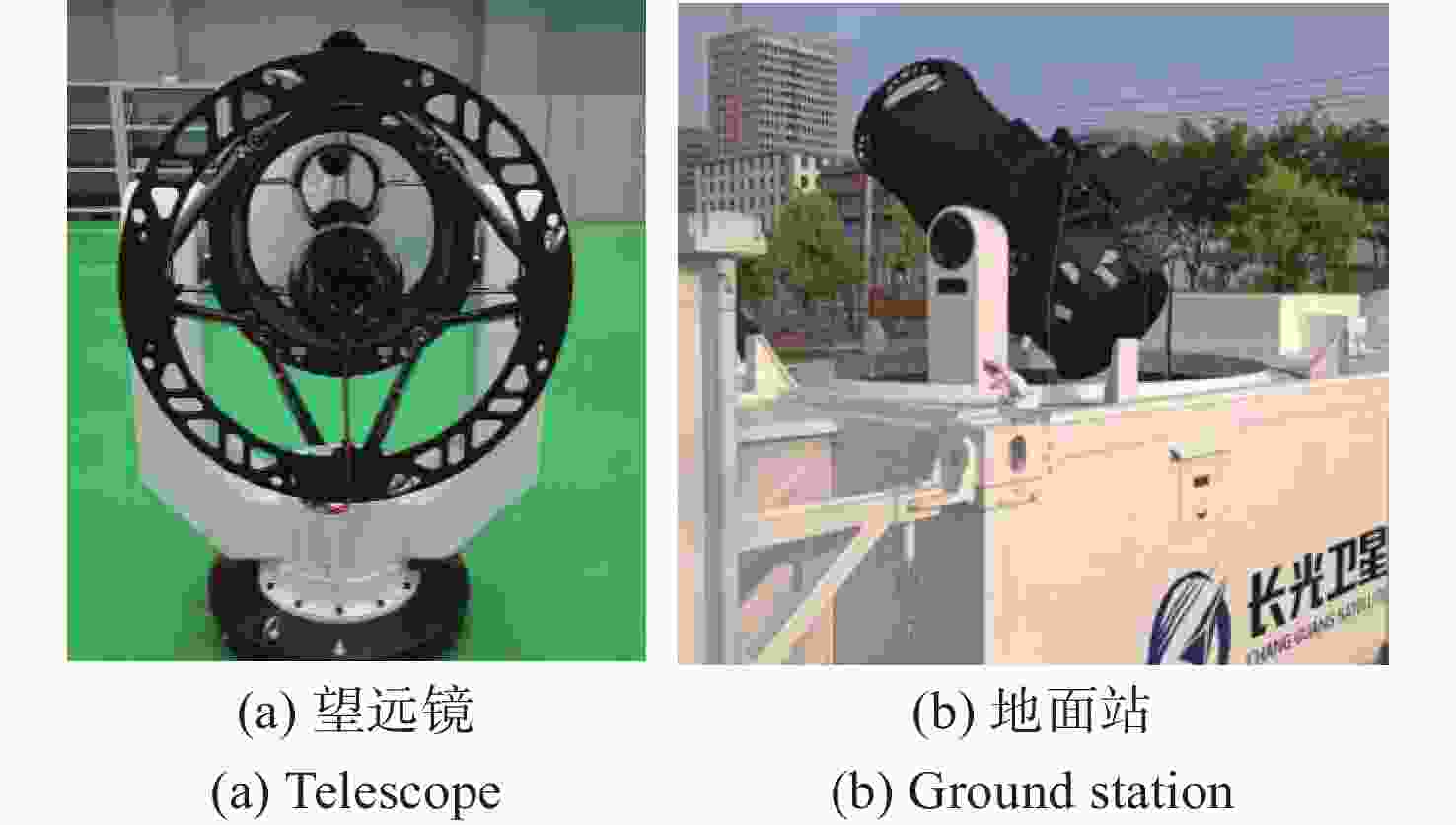

为提升低轨卫星与地面站间激光链路的通信质量,商业地面站内望远镜配备的大口径主镜需适应户外环境中恶劣的温度条件。针对某通光口径

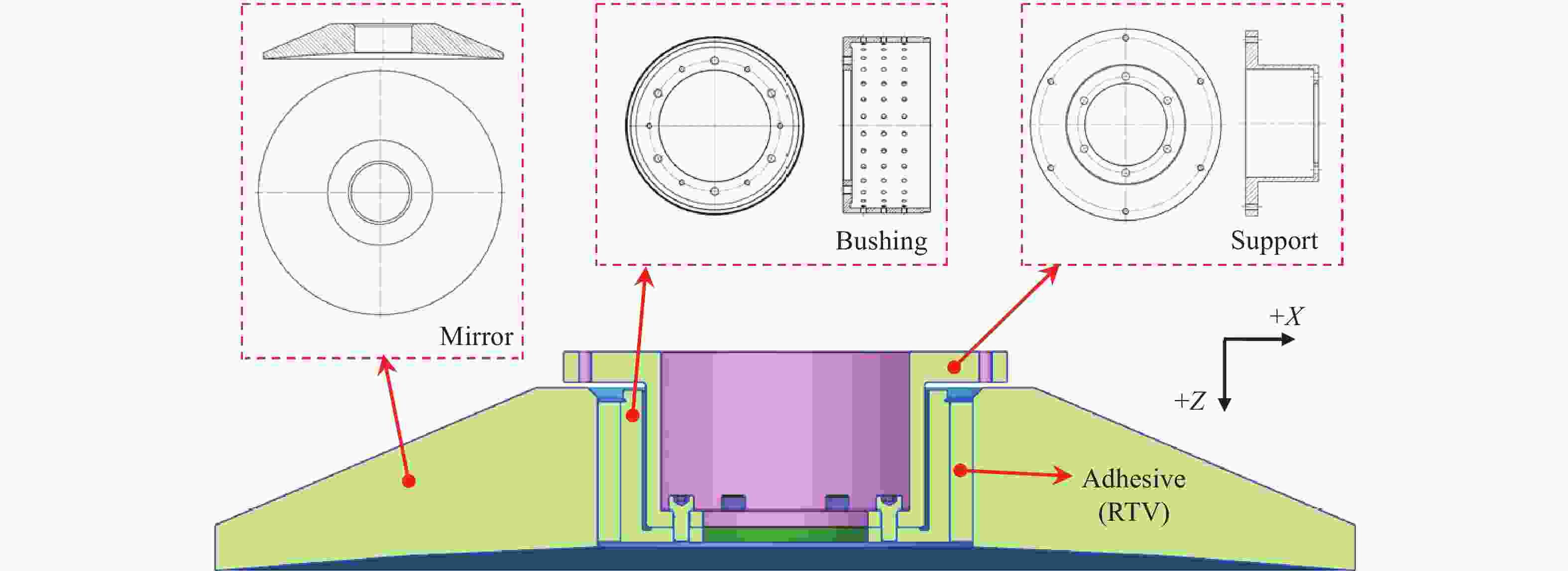

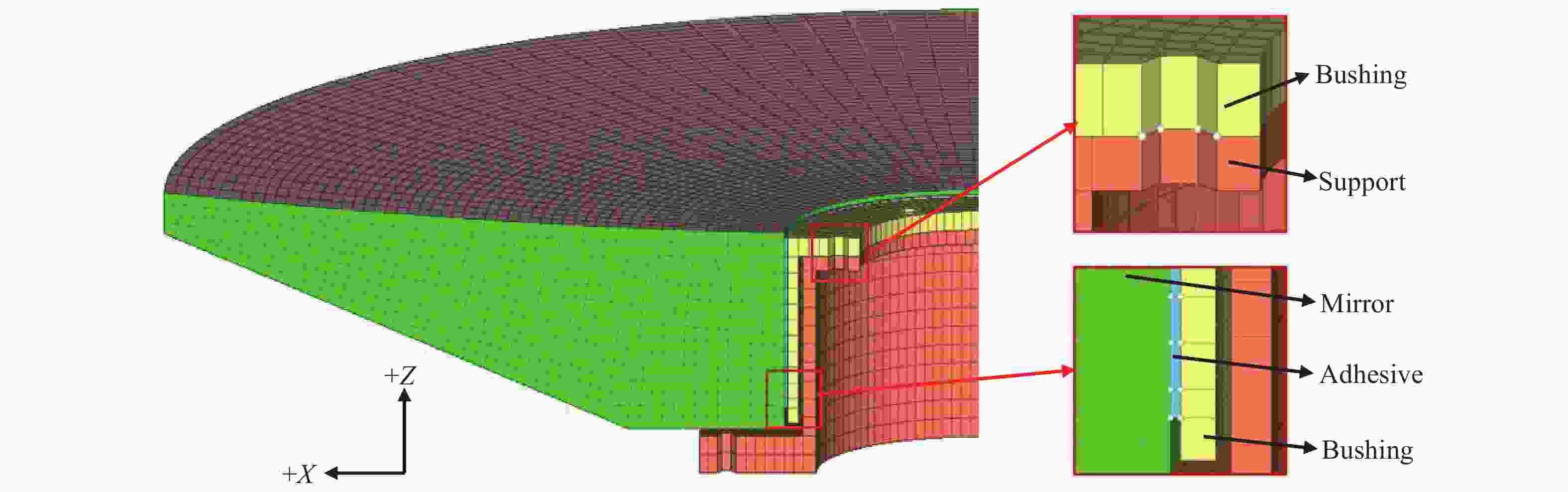

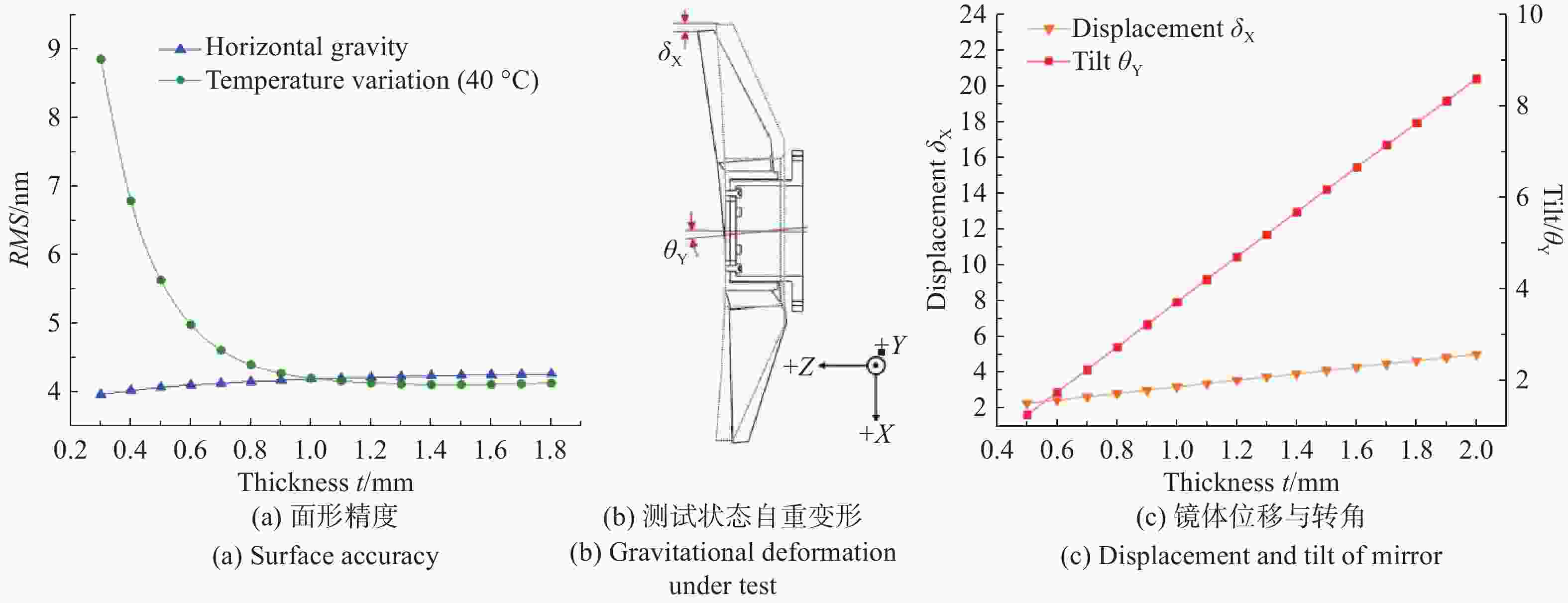

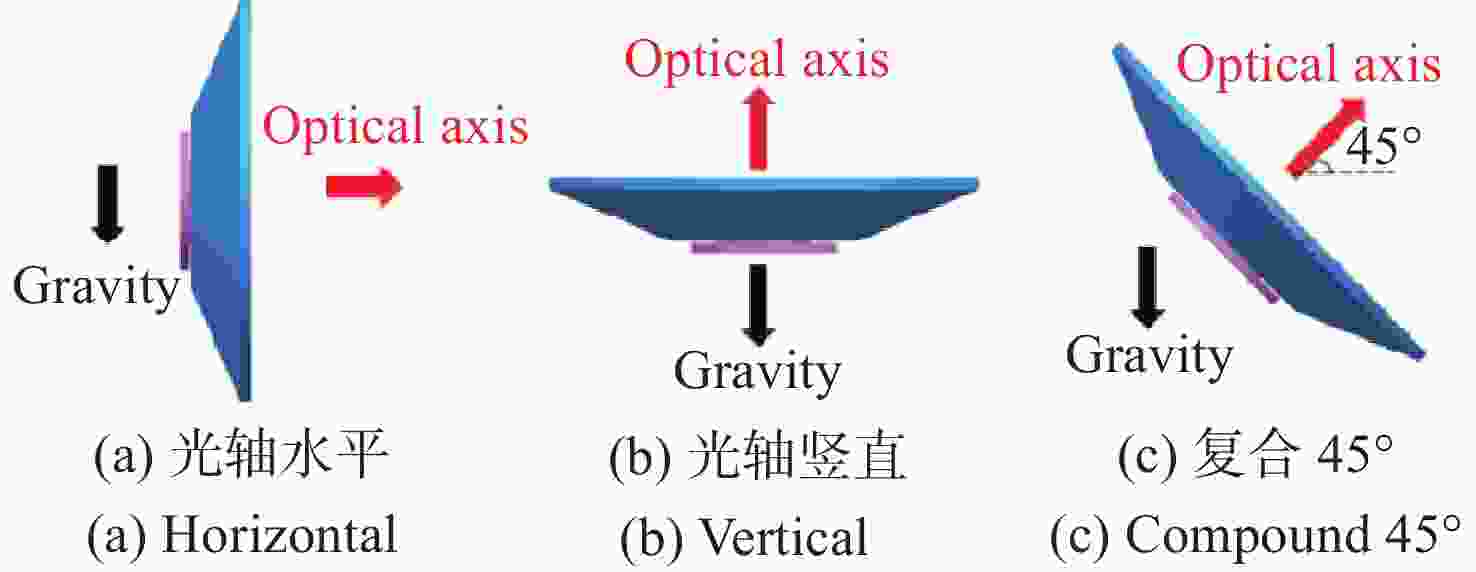

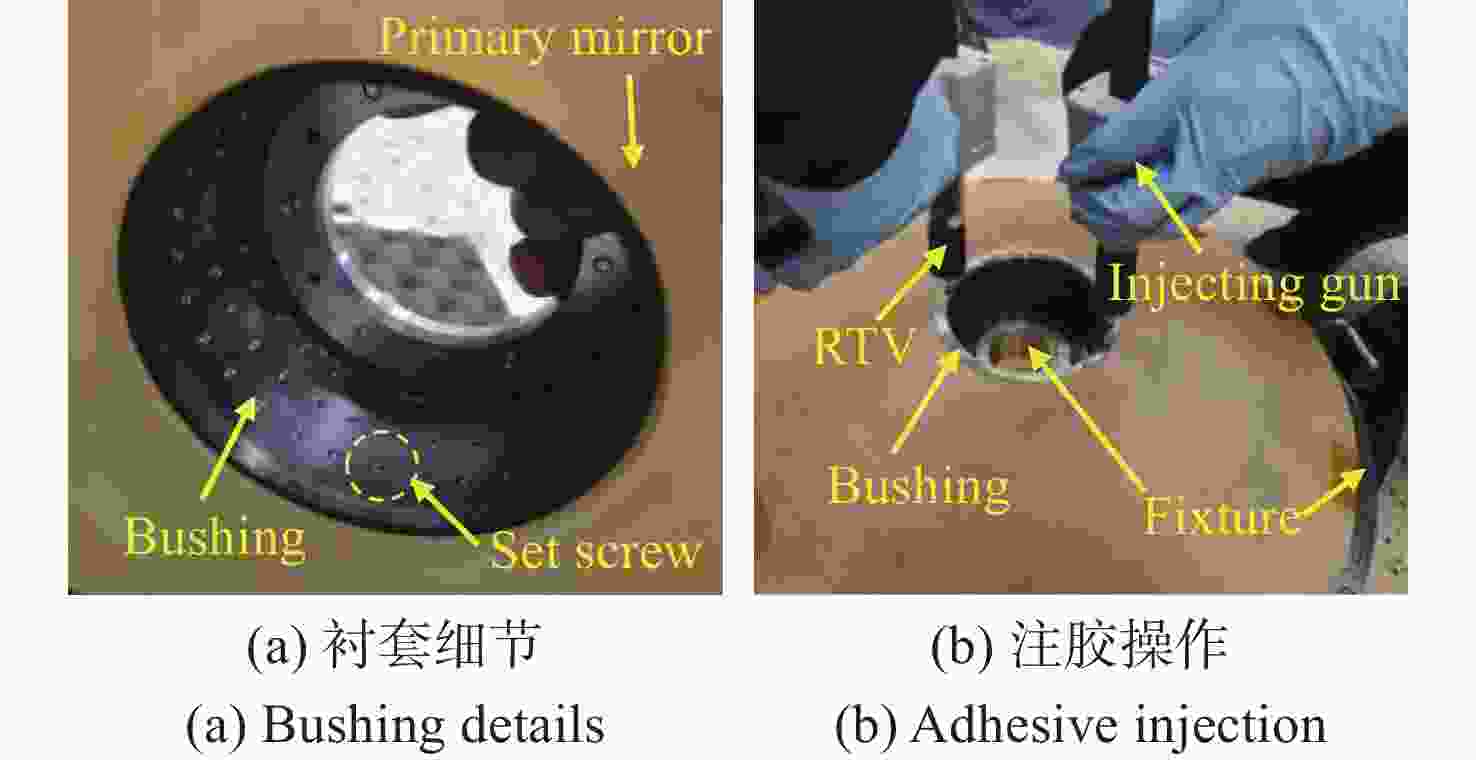

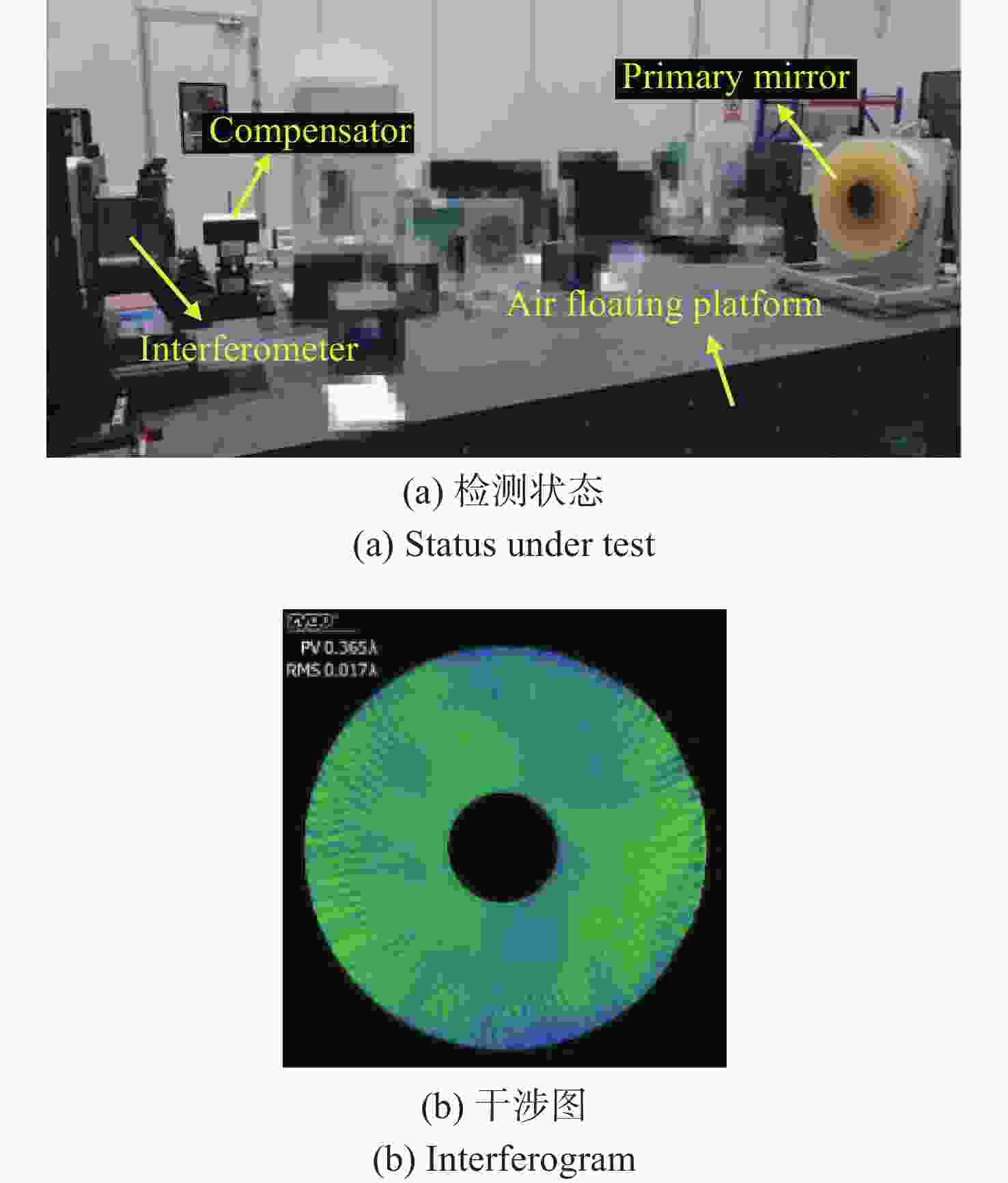

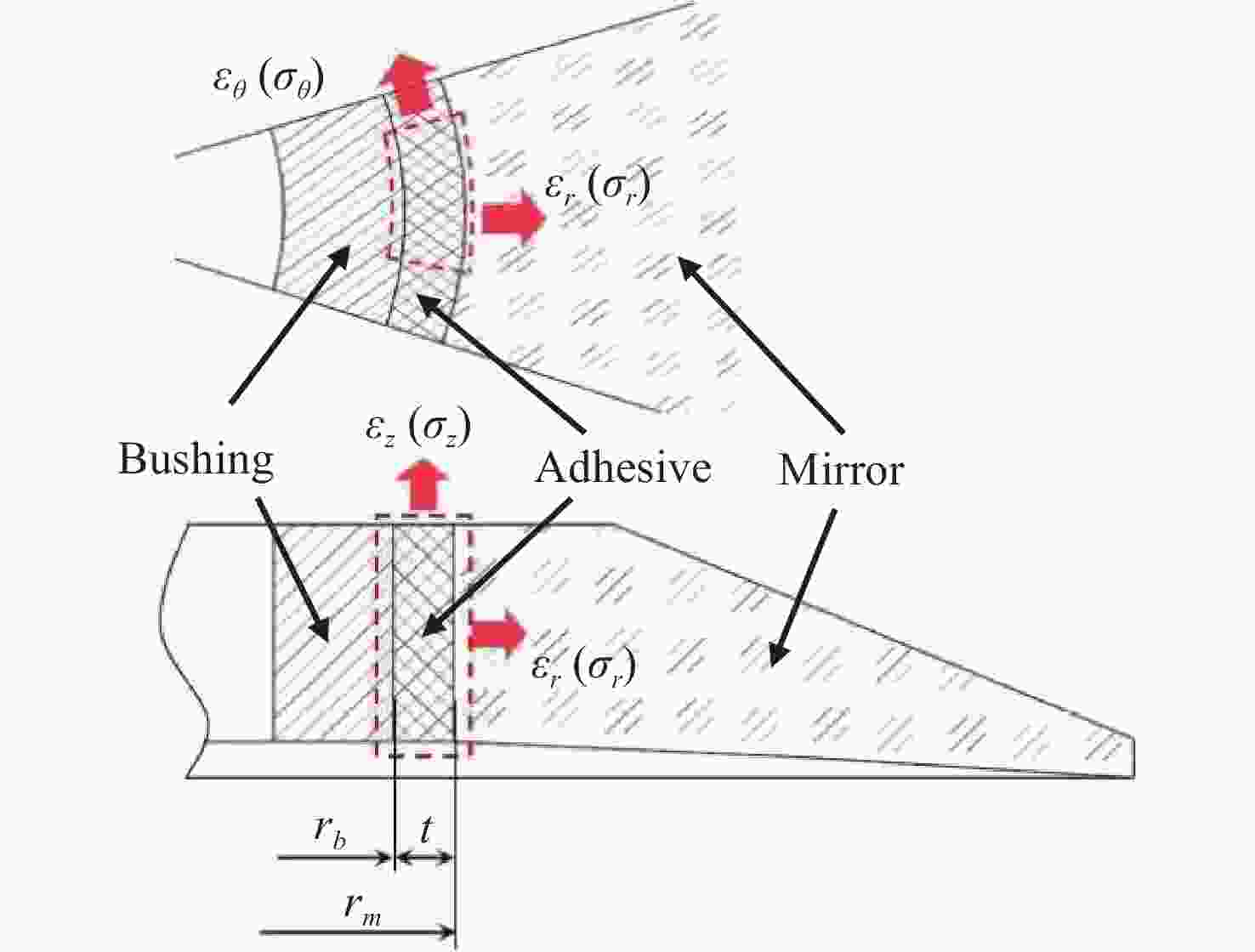

$\Phi $ 500 mm的高精度主镜组件,提出一种使用室温硫化硅橡胶的中心支撑方案。镜体采用微晶材料,衬套和支撑筒均为钛合金材质。1 mm厚的胶层在卸载镜体自身重力的同时,可有效减小组件内部热应力。胶层的厚度和高度可通过仿真优化确定,特制的粘接工装可准确控制胶层形状和厚度,衬套上的通气孔促进了胶层的充分固化。仿真分析表明:主镜在40 °C温度均匀变化工况下的面形精度RMS值为4.199 nm;光轴竖直重力工况下的RMS值为13.748 nm;光轴水平重力工况下的RMS值为4.187 nm,镜体最大倾角和位移分别为4.722″和3.597 μm,组件基频达到53.45 Hz;实测主镜的面形精度为RMS 0.017λ (λ=632.8 nm),经大范围高低温循环试验及真空镀膜后,主镜均可保持高精度面形。文中支撑结构可以显著提升高精度反射镜的温度适应能力,在地面大型光电设备中具有广阔的应用前景。Abstract:In order to improve the communication quality of LEO-OGS laser links, commercial ground station telescopes equipped with large aperture primary mirrors must be able to withstand extreme outdoor temperature. A central support scheme using room-temperature vulcanizing silicone rubber was proposed for a high-precision primary mirror with an optical aperture of 500 mm. The mirror is made of microcrystal material, and both of the bushing and the supporting cylinder are made of titanium alloy. A 1-mm-thick adhesive layer is used, which can effectively reduce the thermal stress inside the assembly during temperature changes while unloading the gravity of the mirror blank. The thickness and height of the adhesive layer are determined by optimization. A specially designed fixture can accurately control the shape and thickness of the adhesive layer. The ventilation holes on the bushing promote its full solidification. Simulation analysis indicates that the surface shape accuracy of the primary mirror is 4.199 nm in RMS under 40 °C temperature variation, with 13.748 nm under vertical gravity and 4.187 nm under horizontal gravity, accompanied by the maximum mirror inclination and displacement of 4.722" and 3.597 μm, and the fundamental frequency of the assembly reaches 53.45 Hz. The measured surface shape accuracy of the primary mirror is RMS 0.017λ (λ=632.8 nm). The surface can maintain high precision after extensive heat cycling tests and vacuum coating. The central support structure can significantly improve the temperature adaptability of precise mirrors and has broad application prospects in large-scale ground optoelectronic equipment.

-

表 1 商业地面站中主镜组件的主要设计指标

Table 1. Main design metrics for primary mirror components in commercial ground station

No. Item Requirement 1 Clear aperture Φ500 mm 2 Elevation during pointing From horizontal to vertical 3 Deformation under gravity Tilt: θX≤10″, θY≤10″

Displacement: δX≤20 μm, δY≤20 μm4 Working temperature range −20 °C~40 °C 5 Surface accuracy RMS≤1/30λ (λ=632.8 nm) 6 Mass ≤30 kg 7 Frequency ≥30 Hz 表 2 主镜组件材料物理属性

Table 2. Physical properties of primary mirror assembly components

Property Mirror Adhesive Bushing Support Material & type Zerodur RTV TC4 TC4 Density ρ (g·cm−3) 2.53 1.1 4.4 4.4 Elastic modulus E (MPa) 91000 2.7 109000 109000 Poisson ratio μ 0.24 0.47 0.34 0.34 Thermal expansion

coefficient α (10−6·K−1)0.1 185 9.1 9.1 表 3 主要工况下主镜仿真结果

Table 3. Primary mirror’s simulation results under main load cases (λ=632.8 nm)

Load case Deformation/nm Displacement/ μm Tilt/″ RMS δX δY δZ θX θY Temperature variation(40ºC) 4.199 0 0 58.325 0.008 0.008 Horizontal gravity 4.187 3.597 0 0.001 0.235 4.722 Vertical gravity 13.748 0 0 13.415 0.004 0.004 Compound gravity(45°) 10.161 2.542 0 9.572 0.167 3.339 Design Criterion ≤1/30λ ≤20 ≤20 / ≤10 ≤10 表 4 主镜组件模态分析结果

Table 4. Modal analysis results of primary mirror assembly

Order Frequency/Hz Vibration mode 1st 53.45 Rotation of mirror around Z axis 2nd 66.09 Rotation of mirror around X axis 3rd 66.10 Rotation of mirror around Y axis 表 5 主镜面形精度检测结果

Table 5. Primary mirror’s surface accuracy test results

Surface accuracy Polishing Heat recycle Coating RMS / λ (λ=632.8nm) 0.017 0.018 0.018 -

[1] 徐月, 刘超, 兰斌, 等. 自适应光学在星地激光通信中的研究进展[J]. 激光与光电子学进展,2023,60(5):0500004.XU Y, LIU CH, LAN B, et al. Research progress of adaptive optics in satellite-to-ground laser communication[J]. Laser & Optoelectronics Progress, 2023, 60(5): 0500004. (in Chinese). [2] KAMMERER W, GRENFELL P, HYEST L, et al. CLICK mission flight terminal optomechanical integration and testing[J]. Proceedings of SPIE, 2022, 12777: 1277730. [3] 高世杰, 吴佳彬, 刘永凯, 等. 微小卫星激光通信系统发展现状与趋势[J]. 中国光学,2020,13(6):1171-1181. doi: 10.37188/CO.2020-0033GAO SH J, WU J B, LIU Y K, et al. Development status and trend of micro-satellite laser communication systems[J]. Chinese Optics, 2020, 13(6): 1171-1181. (in Chinese). doi: 10.37188/CO.2020-0033 [4] SCHIELER C M, RIESING K M, BILYEU B C, et al. On-orbit demonstration of 200-Gbps laser communication downlink from the TBIRD CubeSat[J]. Proceedings of SPIE, 2023, 12413: 1241302. [5] 谢军, 何锋赟, 王晶, 等. 经纬仪主镜轴向支撑结构仿真与优化[J]. 红外与激光工程,2016,45(S1):S118001. doi: 10.3788/IRLA201645s1.118001XIE J, HE F Y, WANG J, et al. Simulation and optimization of axial supporting structures for theodolite primary mirror[J]. Infrared and Laser Engineering, 2016, 45(S1): S118001. (in Chinese). doi: 10.3788/IRLA201645s1.118001 [6] 赵天骄, 乔彦峰, 孙宁, 等. 经纬仪主镜在支撑系统下的面形变化[J]. 中国光学,2017,10(4):477-483. doi: 10.3788/co.20171004.0477ZHAO T J, QIAO Y F, SUN N, et al. Surface deformation of theodolite primary mirror under the support system[J]. Chinese Optics, 2017, 10(4): 477-483. (in Chinese). doi: 10.3788/co.20171004.0477 [7] 张岩, 陈宝刚, 李洪文, 等. 700mm光学望远镜结构设计与分析[J]. 光学技术,2020,46(4):385-390.ZHANG Y, CHEN B G, LI H W, et al. Structure design and analysis of 700 mm aperture optical telescope[J]. Optical Technique, 2020, 46(4): 385-390. (in Chinese). [8] 李鑫, 袁健, 龚小雪, 等. 外场热环境作用下地基望远镜温度分布预测[J]. 激光与红外,2023,53(4):589-596.LI X, YUAN J, GONG X X, et al. Prediction of temperature distribution of ground-based telescopes under the influence of external thermal environment[J]. Laser & Infrared, 2023, 53(4): 589-596. (in Chinese). [9] 王洪浩, 王建立, 陈涛, 等. 地基大口径望远镜重力弯曲引起的指向变化检测与修正[J]. 光学 精密工程,2022,30(23):3021-3030. doi: 10.37188/OPE.20223023.3021WANG H H, WANG J L, CHEN T, et al. Measurement and calibration of optical axis changes caused by gravity for ground-based large-aperture telescope[J]. Optics Precision Engineering, 2022, 30(23): 3021-3030. (in Chinese). doi: 10.37188/OPE.20223023.3021 [10] 郭骏立, 安源, 李宗轩, 等. 空间相机反射镜组件的胶结技术[J]. 红外与激光工程,2016,45(3):0313002. doi: 10.3788/irla201645.0313002GUO J L, AN Y, LI Z X, et al. Bonding technique of mirror components in space camera[J]. Infrared and Laser Engineering, 2016, 45(3): 0313002. (in Chinese). doi: 10.3788/irla201645.0313002 [11] 范志刚, 常虹, 陈守谦. 透镜无热装配中粘结层的设计[J]. 光学精密工程,2011,19(11):2573-2581. doi: 10.3788/OPE.20111911.2573FAN ZH G, CHANG H, CHEN SH Q. Design of bonding layer in lens athermal mount[J]. Optics Precision Engineering, 2011, 19(11): 2573-2581. (in Chinese). doi: 10.3788/OPE.20111911.2573 [12] 武永见, 刘涌, 孙欣. 柔性支撑式空间反射镜胶接应力分析与消除[J]. 红外与激光工程,2022,51(4):20210496. doi: 10.3788/IRLA20210496WU Y J, LIU Y, SUN X. Analysis and elimination of adhesive bonding force of flexible supported space mirror[J]. Infrared and Laser Engineering, 2022, 51(4): 20210496. (in Chinese). doi: 10.3788/IRLA20210496 [13] 张家齐, 郭艺博, 张友建, 等. 机载宽温条件下反射镜组件与粘接层设计[J]. 中国光学(中英文),2023,16(3):578-586. doi: 10.37188/CO.2022-0194ZHANG J Q, GUO Y B, ZHANG Y J, et al. Design of reflector assembly and adhesive layer under airborne wide temperature conditions[J]. Chinese Optics, 2023, 16(3): 578-586. (in Chinese). doi: 10.37188/CO.2022-0194 [14] 袁健, 张雷, 姜启福, 等. 1.2 m高轻量化率主反射镜镜坯结构设计[J]. 光电工程,2023,50(4):41-51.YUAN J, ZHANG L, JIANG Q F, et al. Structure design of 1.2 m high lightweight primary mirror blank[J]. Opto-Electronic Engineering, 2023, 50(4): 41-51. (in Chinese). [15] 袁健, 张雷. 大型离轴三反相机主镜组件结构设计与验证[J]. 红外与激光工程,2023,52(1):20220363. doi: 10.3788/IRLA20220363YUAN J, ZHANG L. Structure design and verification of primary mirror assembly for large off-axis TMA camera[J]. Infrared and Laser Engineering, 2023, 52(1): 20220363. (in Chinese). doi: 10.3788/IRLA20220363 [16] 谭淞年, 王福超, 许永森, 等. 航空光电平台两轴快速反射镜结构设计[J]. 光学 精密工程,2022,30(11):1344-1352. doi: 10.37188/OPE.20213000.0757TAN S N, WANG F CH, XU Y S, et al. Structure design of two-axis fast steering mirror for aviation optoelectronic platform[J]. Optics Precision Engineering, 2022, 30(11): 1344-1352. (in Chinese). doi: 10.37188/OPE.20213000.0757 -

下载:

下载: