-

摘要:

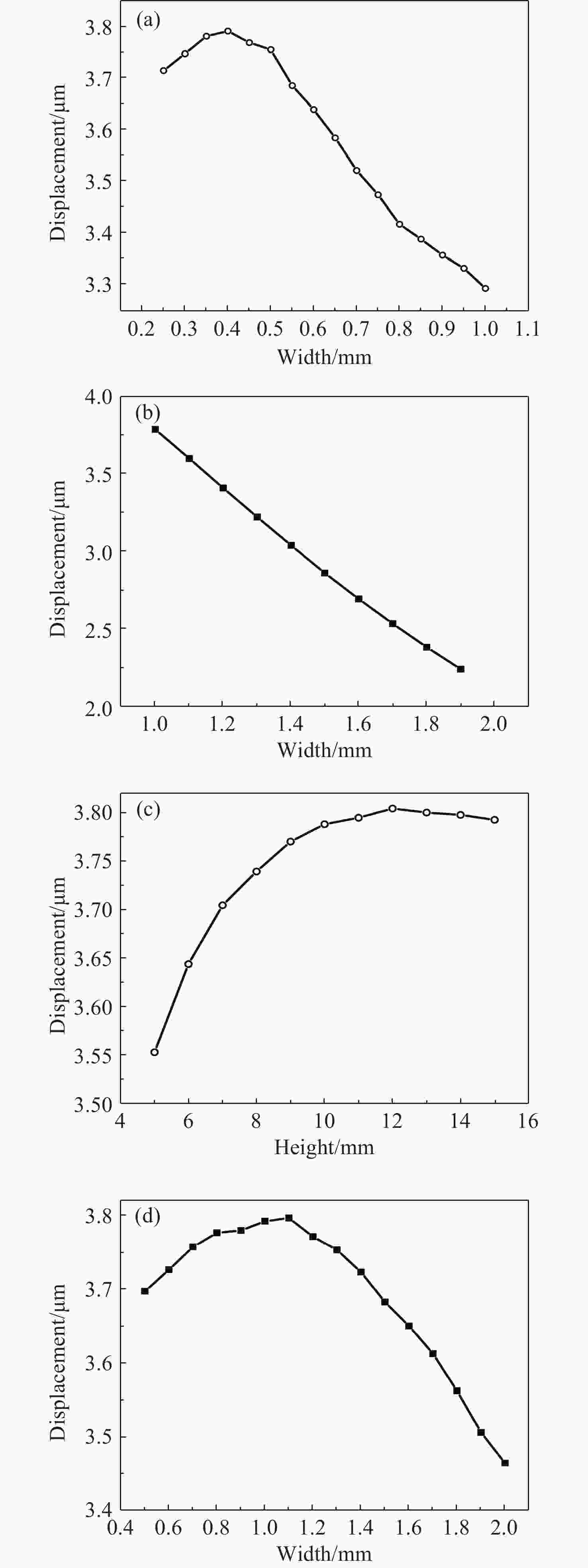

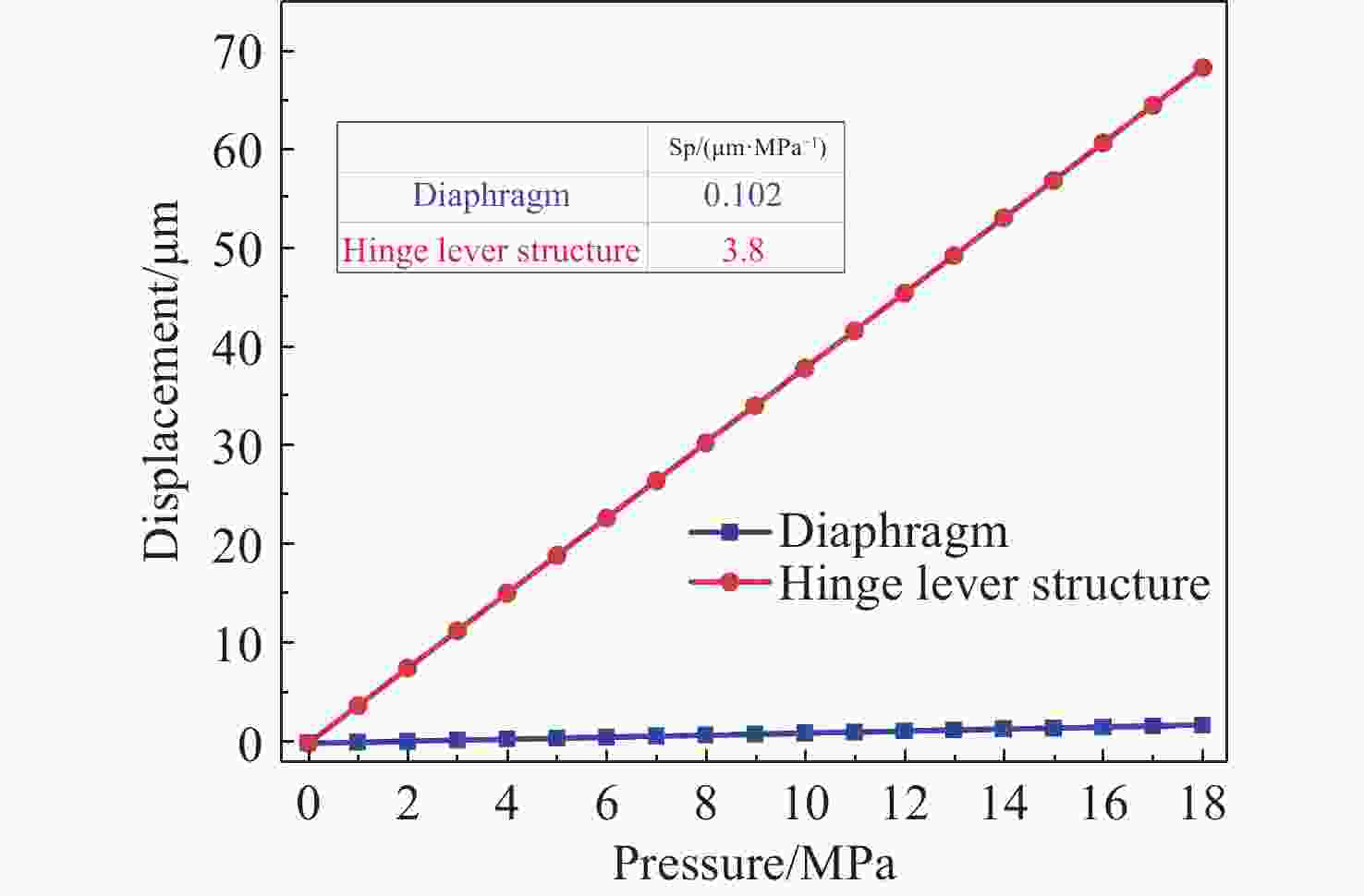

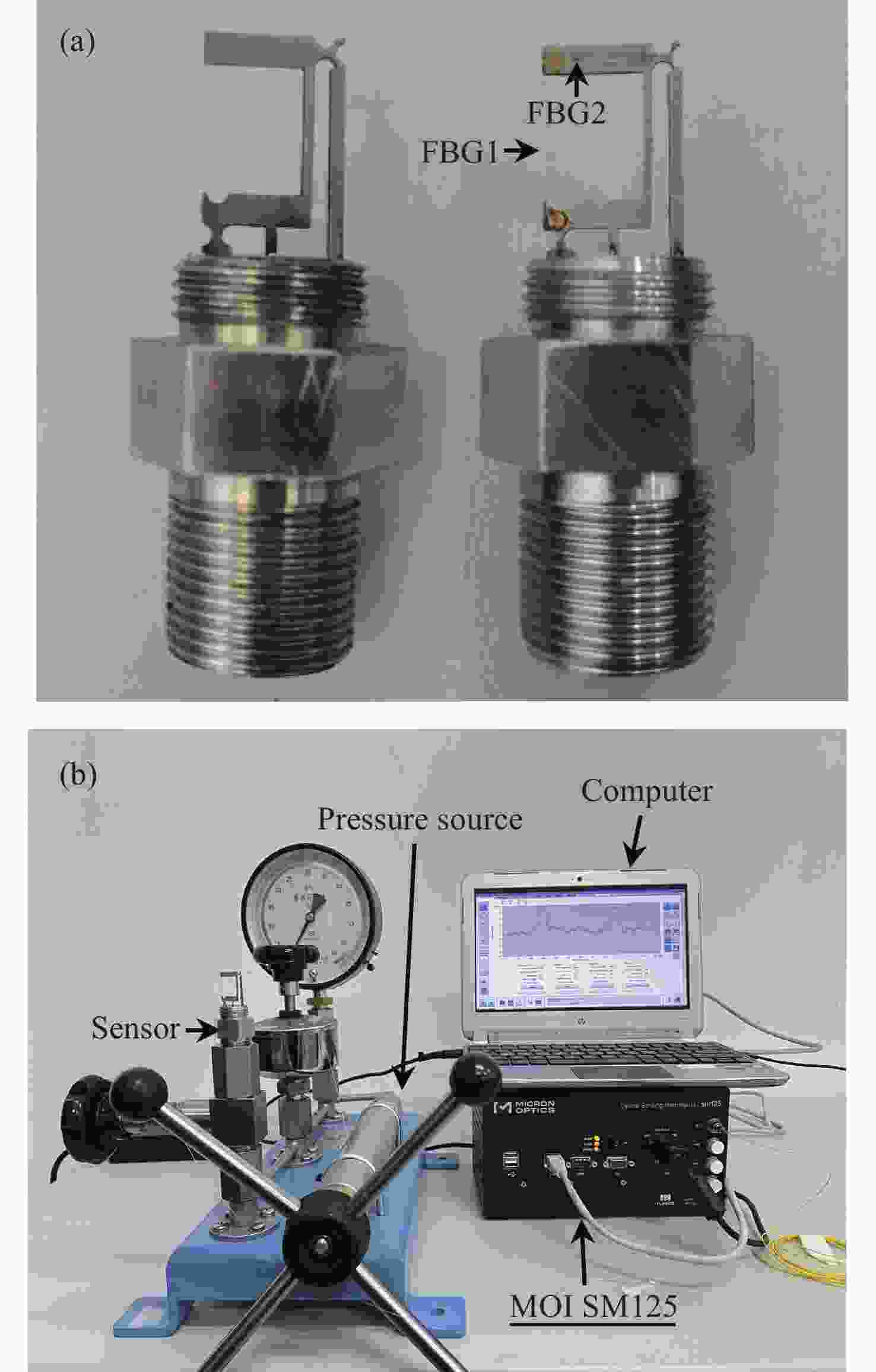

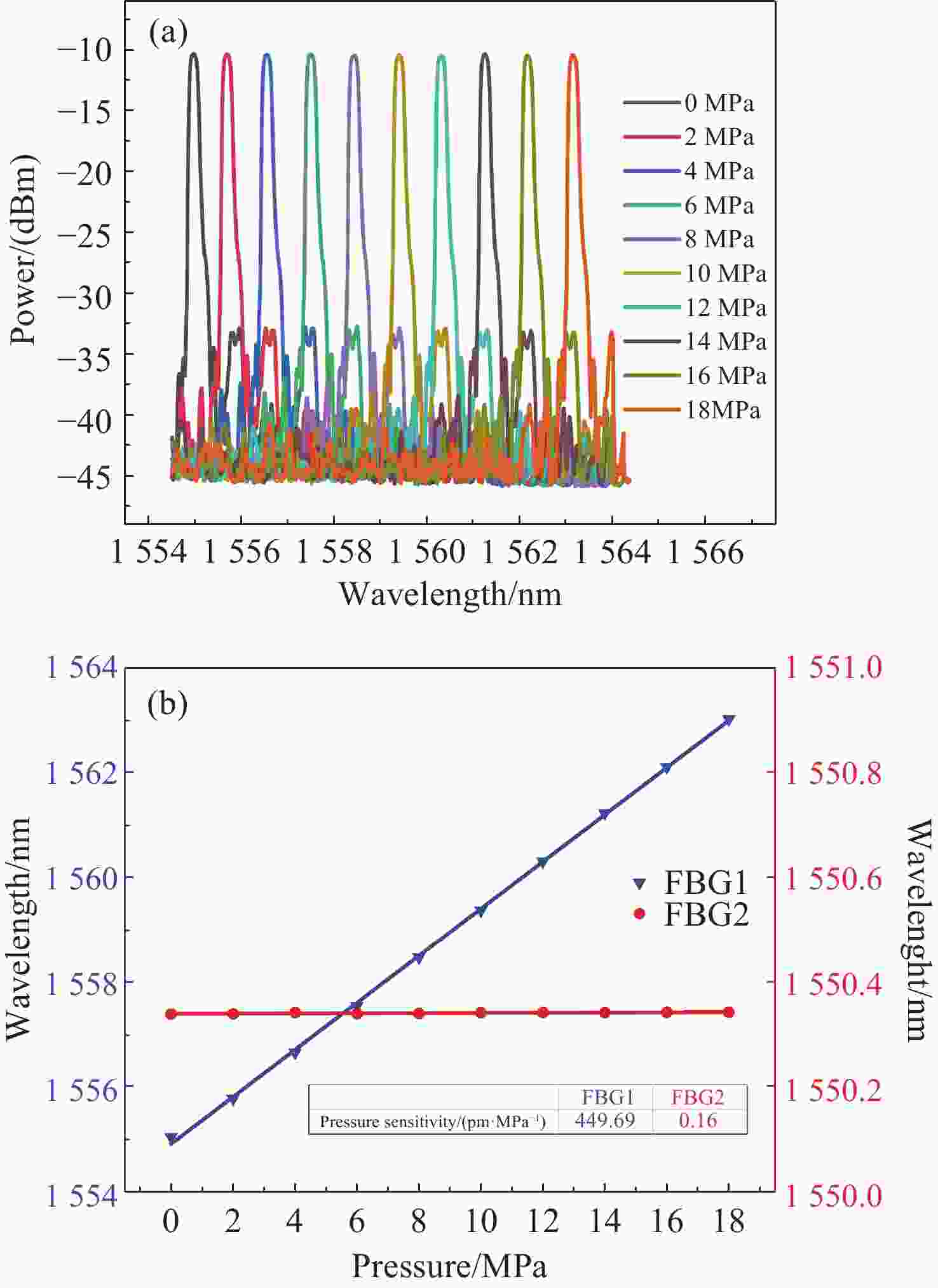

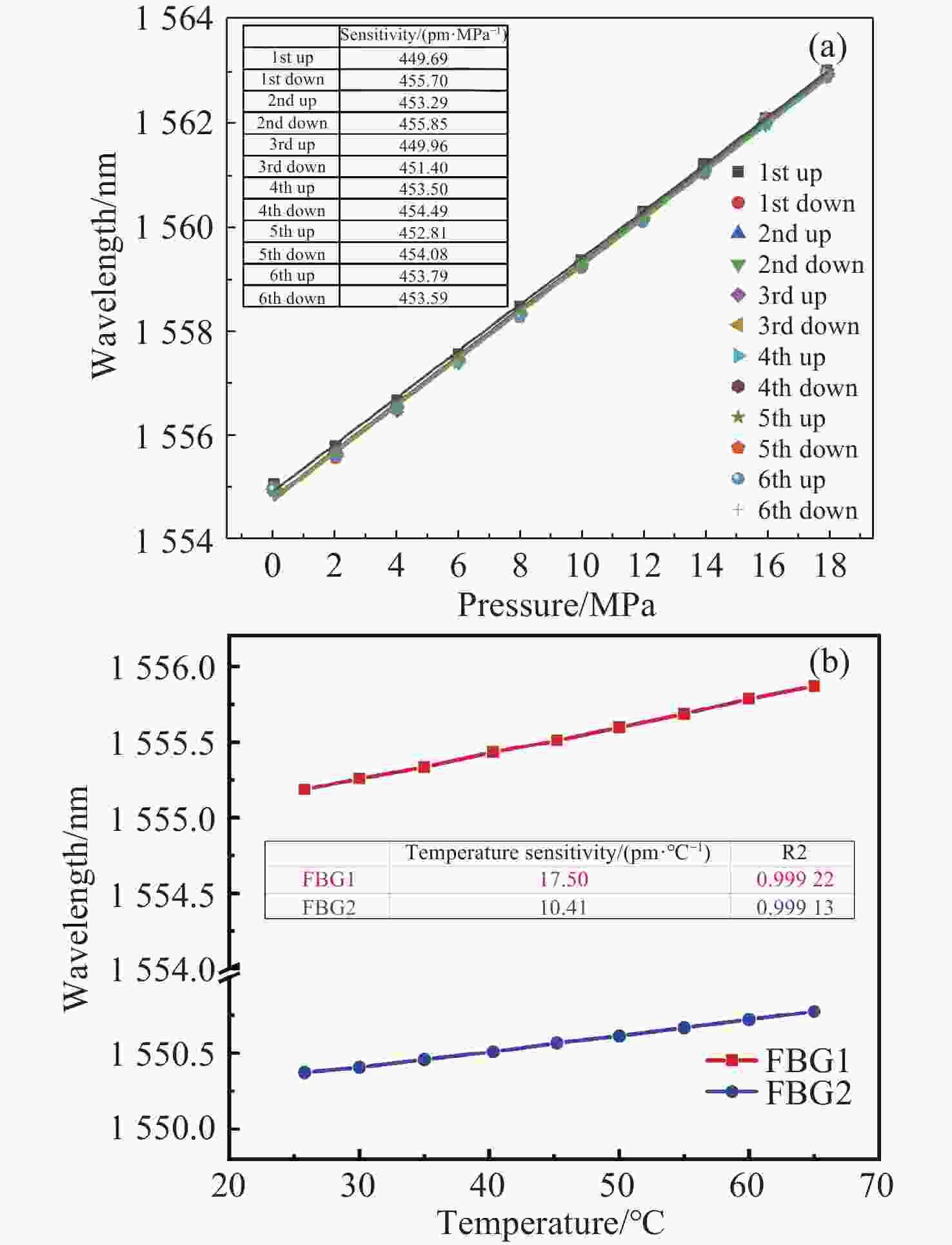

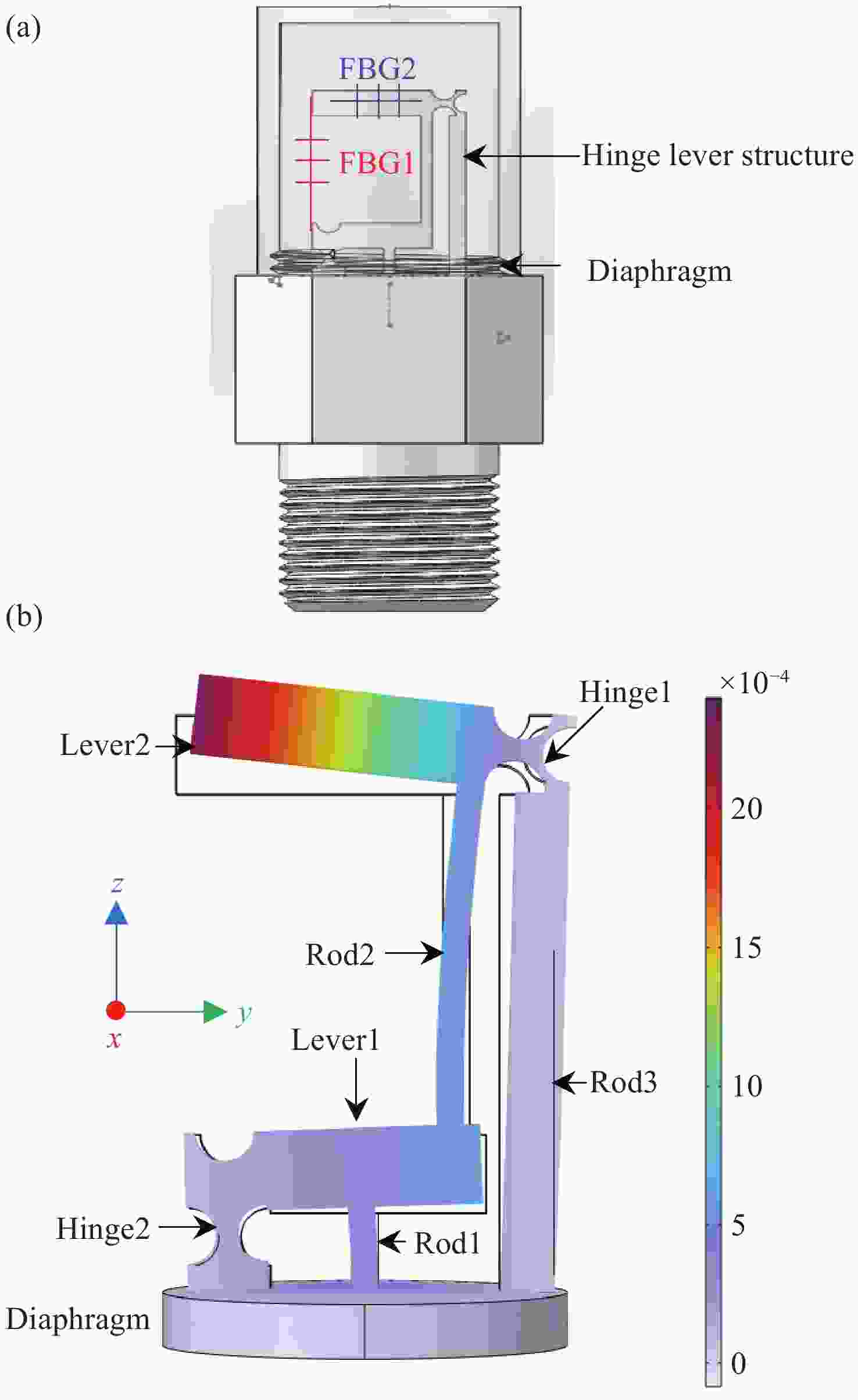

本文设计了一种高灵敏度温度和压力传感器。该传感结构利用膜片将压力传递给双铰链杠杆结构,采用光纤布拉格光栅(FBG1)作为应变传感器实现压力的测量。此外,双铰链杠杆的引入有效提升了传感器的压力测量灵敏度。仿真和实验测量结果证实,该传感器在0~18 MPa的测量范围内,灵敏度达到453.16 pm/MPa。同时,将另外一支光纤布拉格光栅(FBG2)粘贴在杠杆上,以消除压力测量过程中的温度交叉敏感问题,从而实现温度和压力的同时测量。在25~65 °C测量范围内,温度灵敏度为10.41 pm/ °C。由于光纤传感器的抗电磁干扰特性,该类传感器可用于苛刻环境中的温度和压力测量。

Abstract:In this paper, a high-sensitivity temperature and pressure sensor is designed. It utilizes a diaphragm to transfer pressure to a double-hinged lever structure and adopts a fiber Bragg grating (FBG1) as the strain sensor to measure pressure. The introduction of the double-hinged lever effectively improves the sensor's pressure measurement sensitivity. The sensor's measuring range is 0−18 MPa and the sensitivity is 453.16 pm/MPa. At the same time, another fiber Bragg grating (FBG2) is pasted on the lever to eliminate the temperature influence in the pressure measurement process and realize the simultaneous measurement of temperature and pressure. The sensor's temperature sensitivity is 10.41 pm/°C in the 25−65 °C range. Due to their anti-electromagnetic interference characteristics, optical fiber sensors are commonly used to measure temperature and pressure in harsh environments.

-

Key words:

- pressure sensor /

- fiber Bragg grating /

- hinge lever structure /

- temperature sensor

-

表 1 与最近报道的同类传感器性能对比

Table 1. Comparison of the designed sensor and those reported recently

-

[1] 徐国权, 熊代余. 光纤光栅传感技术在工程中的应用[J]. 中国光学,2013,6(3):306-317.XU G Q, XIONG D Y. Applications of fiber Bragg grating sensing technology in engineering[J]. Chinese Optics, 2013, 6(3): 306-317. (in Chinese). [2] SANTOS R G, LOH W, BANNWART A C, et al. An overview of heavy oil properties and its recovery and transportation methods[J]. Brazilian Journal of Chemical Engineering, 2014, 31(3): 571-590. doi: 10.1590/0104-6632.20140313s00001853 [3] 薛兆康, 国旗, 刘善仁, 等. 油气井下光纤光栅温度压力传感器[J]. 中国光学,2021,14(5):1224-1230. doi: 10.37188/CO.2021-0008XUE ZH K, GUO Q, LIU SH R, et al. Fiber Bragg grating temperature and pressure sensor for oil and gas well[J]. Chinese Optics, 2021, 14(5): 1224-1230. (in Chinese). doi: 10.37188/CO.2021-0008 [4] LIU M Y, CAI Q H, SONG H. Regional strain homogenized diaphragm based FBG high pressure sensor[J]. Sensors and Actuators A: Physical, 2023, 355: 114298. doi: 10.1016/j.sna.2023.114298 [5] LIANG M F, FANG X Q, NING Y SH. Temperature compensation fiber Bragg grating pressure sensor based on plane diaphragm[J]. Photonic Sensors, 2018, 8(2): 157-167. doi: 10.1007/s13320-018-0417-9 [6] SONG D C, ZOU J L, WEI ZH X, et al. High-sensitivity fiber Bragg grating pressure sensor using metal bellows[J]. Optical Engineering, 2009, 48(3): 034403. doi: 10.1117/1.3102073 [7] DA SILVA FALCÃO B, GIWELLI A, NOGUEIRA KIEWIET M, et al. Strain measurement with multiplexed FBG sensor arrays: an experimental investigation[J]. Heliyon, 2023, 9(8): e18652. doi: 10.1016/j.heliyon.2023.e18652 [8] HEGDE G, PRASAD M V N, ASOKAN S. Temperature compensated diaphragm based Fiber Bragg Grating (FBG) sensor for high pressure measurement for space applications[J]. Microelectronic Engineering, 2021, 248: 111615. doi: 10.1016/j.mee.2021.111615 [9] LIU X B, LIANG L, JIANG K, et al. Sensitivity-enhanced fiber Bragg grating pressure sensor based on a diaphragm and hinge-lever structure[J]. IEEE Sensors Journal, 2021, 21(7): 9155-9164. doi: 10.1109/JSEN.2020.3045992 [10] SHU Q M, WU L, LU SH ZH, et al. High-sensitivity structure based on fiber Bragg grating sensor and its application in nonintrusive detection of pipeline pressure change[J]. Measurement, 2022, 189: 110444. doi: 10.1016/j.measurement.2021.110444 [11] WU L, LU SH ZH, ZHANG H E, et al. An FBG-based high-sensitivity structure and its application in non-intrusive detection of pipeline[J]. Measurement, 2022, 199: 111498. doi: 10.1016/j.measurement.2022.111498 [12] XU D P, FENG D Q, CHEN Q, et al. Compact-packaged and diaphragm-lever structured fiber-optic temperature and pressure sensors for oil and gas well applications[J]. IEEE Sensors Journal, 2022, 22(23): 22670-22677. doi: 10.1109/JSEN.2022.3215970 [13] FENG D Q, XU D P, CHEN F Y, et al. An FBG temperature–pressure sensor based on diaphragm and special-shaped bracket structure[J]. IEEE Sensors Journal, 2023, 23(4): 3589-3596. doi: 10.1109/JSEN.2022.3232142 [14] XU D P, FENG D Q, CHEN Q, et al. Small-sized temperature and pressure sensors based on fiber Bragg grating for oil and gas wells[J]. Sensors and Actuators A: Physical, 2023, 357: 114397. doi: 10.1016/j.sna.2023.114397 [15] MATVEENKO V P, SHARDAKOV I N, VORONKOV A A, et al. Measurement of strains by optical fiber Bragg grating sensors embedded into polymer composite material[J]. Structural Control and Health Monitoring, 2018, 25(3): e2118. doi: 10.1002/stc.2118 [16] 刘强, 李斌雯, 孙宇丹, 等. 基于长周期光纤光栅的FBG解调方法[J]. 应用光学,2022,43(1):160-166. doi: 10.5768/JAO202243.0108002LIU Q, LI B W, SUN Y D, et al. FBG demodulation method based on long-period fiber gratings[J]. Journal of Applied Optics, 2022, 43(1): 160-166. (in Chinese). doi: 10.5768/JAO202243.0108002 [17] ZENG L, SUN X Y, HU Y W, et al. High sensitivity micro-displacement sensor based on fiber Bragg grating and amplification substrate[J]. Journal of Central South University, 2022, 29(10): 3361-3367. doi: 10.1007/s11771-022-5161-z [18] LIU ZH Y, ZENG L N, XU K, et al. Design of a fiber Bragg grating pressure sensor based on a metal diaphragm and lever structure[J]. Sensors, 2022, 22(14): 5096. doi: 10.3390/s22145096 [19] 傅海威, 傅君眉, 乔学光, 等. 基于平面膜片温度压强同时测量的光纤光栅传感器[J]. 西安电子科技大学学报(自然科学版),2005,32(1):151-155.FU H W, FU J M, QIAO X G, et al. A novel plate diaphragm based in-fiber Bragg grating sensor for simultaneous measurement of temperature and pressure[J]. Journal of Xidian University (Natural Science), 2005, 32(1): 151-155. (in Chinese). [20] GU Y F, ZHAO Y, LV R Q, et al. A practical FBG sensor based on a thin-walled cylinder for hydraulic pressure measurement[J]. IEEE Photonics Technology Letters, 2016, 28(22): 2569-2572. doi: 10.1109/LPT.2016.2605696 [21] LIANG M F, FANG X Q, WU G, et al. A fiber Bragg grating pressure sensor with temperature compensation based on diaphragm-cantilever structure[J]. Optik, 2017, 145: 503-512. doi: 10.1016/j.ijleo.2017.08.014 [22] ZHAO Y, ZHENG H K, LV R Q, et al. A practical FBG pressure sensor based on diaphragm-cantilever[J]. Sensors and Actuators A: Physical, 2018, 279: 101-106. doi: 10.1016/j.sna.2018.06.004 [23] LIU M Y, WU Y B, DU CH R, et al. FBG-based liquid pressure sensor for distributed measurement with a single channel in liquid environment[J]. IEEE Sensors Journal, 2020, 20(16): 9155-9161. doi: 10.1109/JSEN.2020.2986550 -

下载:

下载: