Error modeling and analysis of dual-frequency laser interferometry in scanning beam interference lithography system

-

摘要:

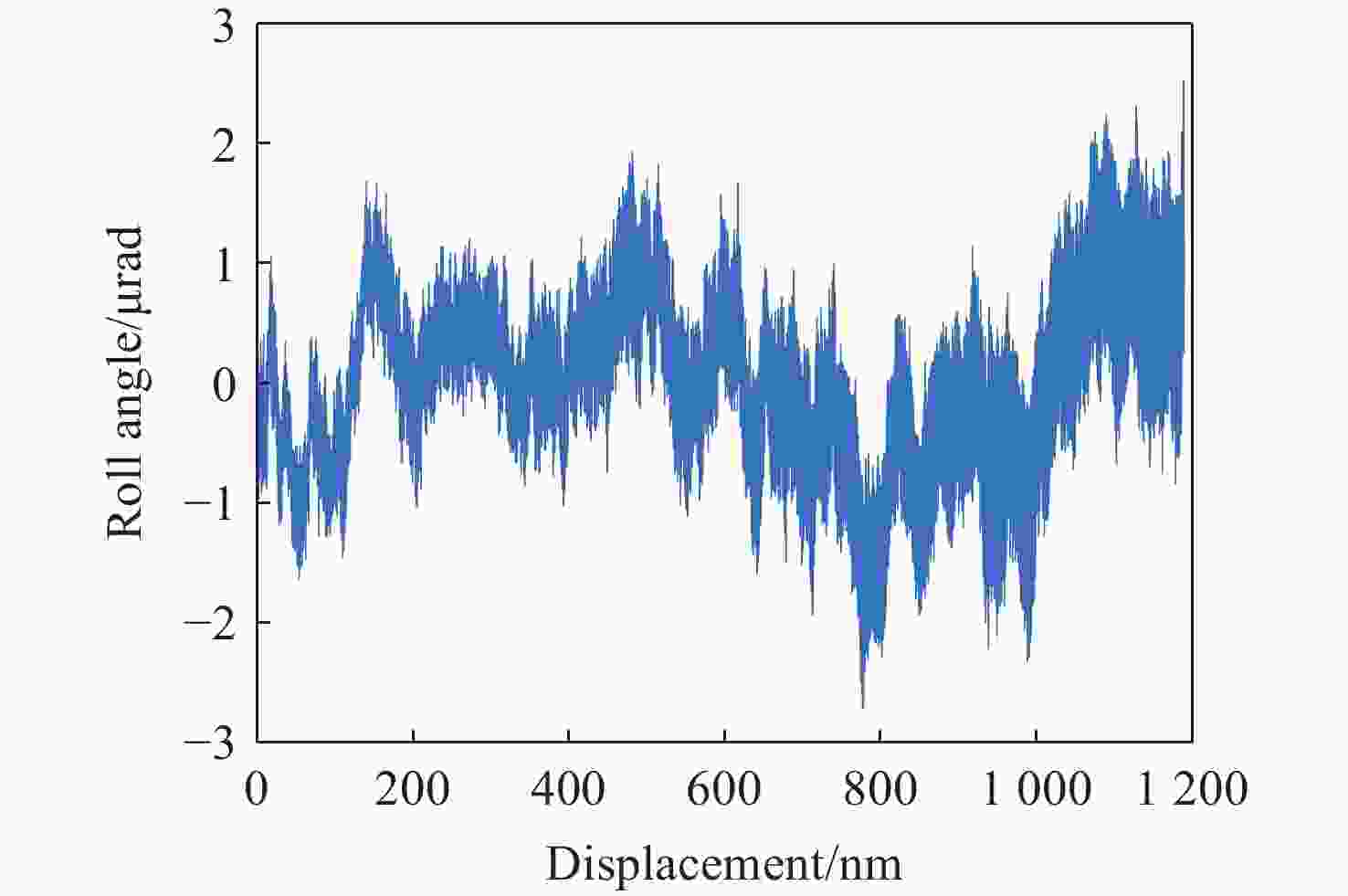

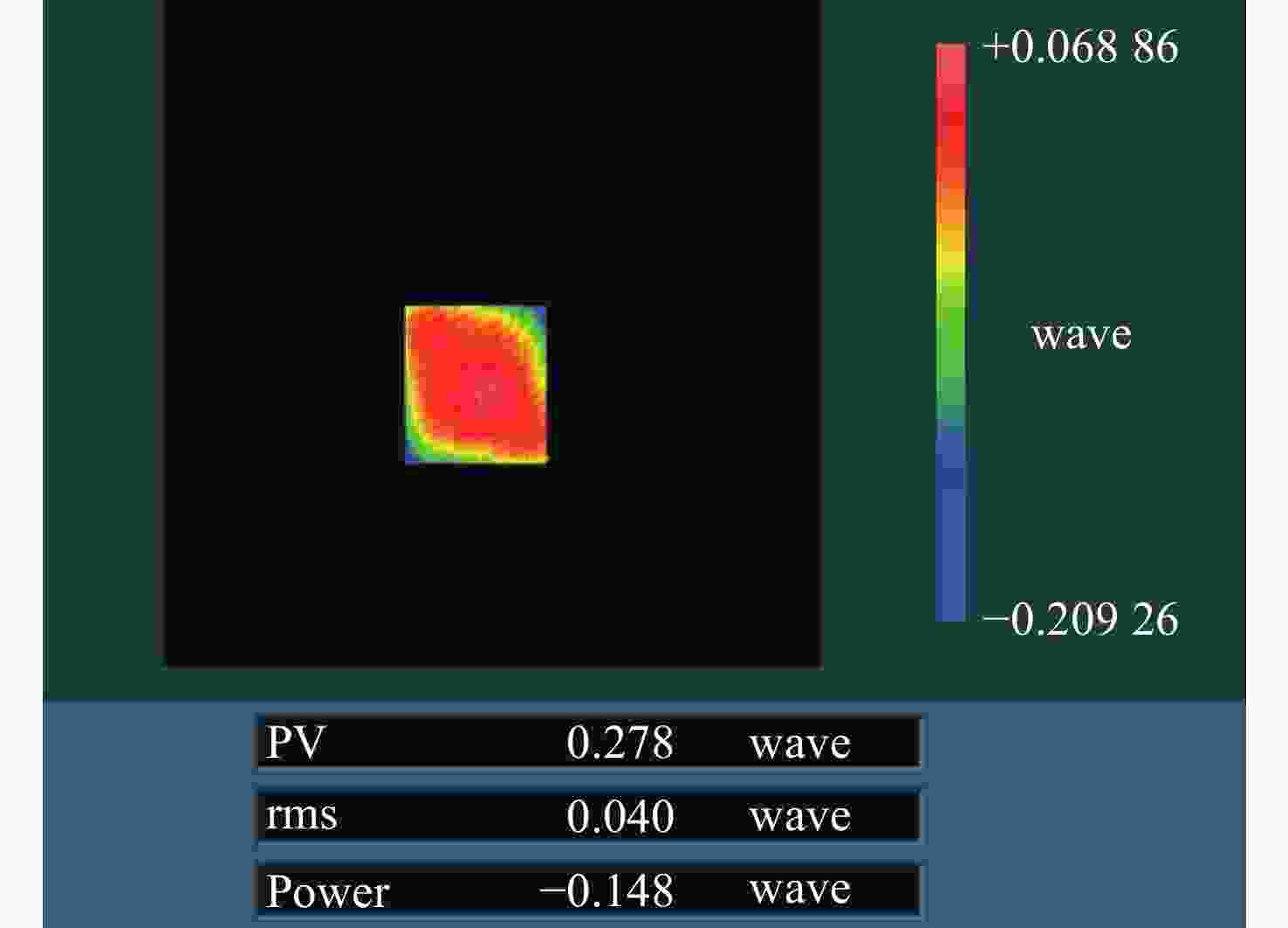

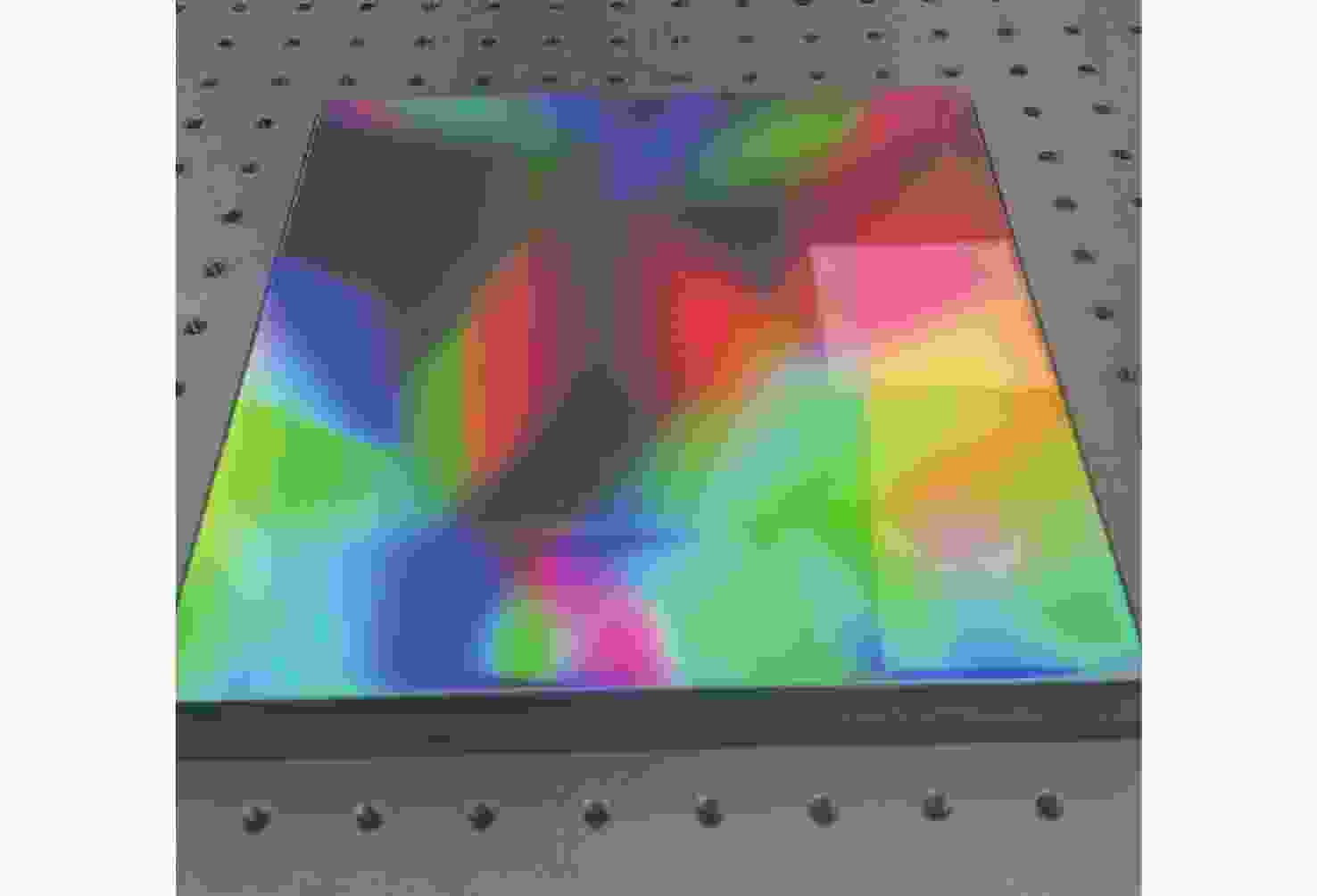

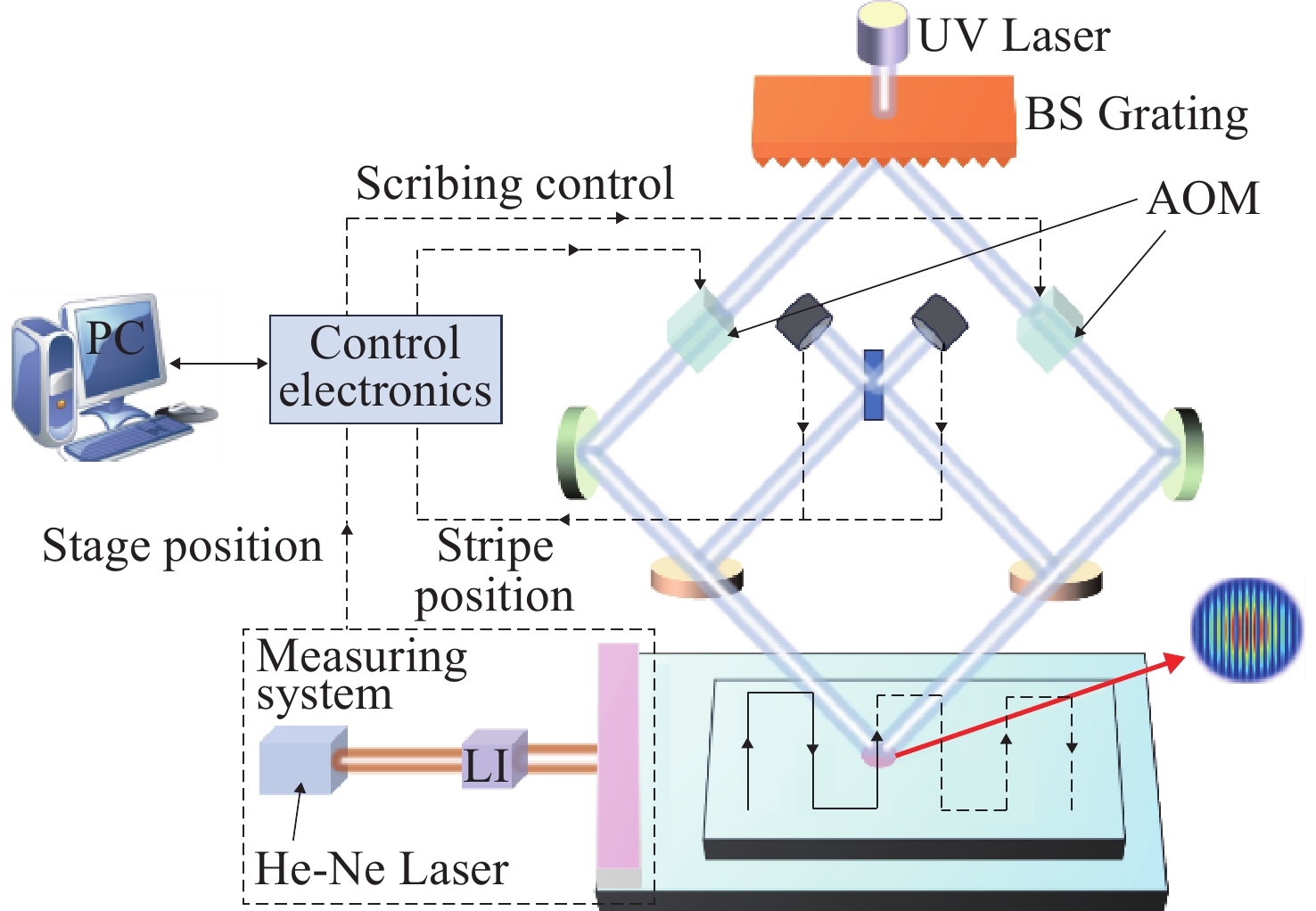

扫描干涉场曝光技术(SBIL)是制作单体大面积高精度光栅的有效途径,采用双频激光干涉仪反馈工作台位置进行干涉条纹的精确拼接,会不可避免地引入光栅刻线误差,导致光栅衍射波前质量降低。针对工作台的位移测量误差,分析了激光干涉仪自身结构因素引起的本征误差,提出了复杂环境下激光干涉仪本征误差的指标评价方法。建立了实际工况与经验公式相结合的死程误差和测量光程变化误差理论模型。通过构建平移和旋转算子,推导了工作台任意点旋转和平移之间的耦合关系,模拟了不同工作台姿态滚转角下的测量误差。进行了位移误差实验和光栅扫描曝光实验。实验结果表明,位移误差与理论计算结果一致,制作200 mm×200 mm光栅的衍射波前为0.278

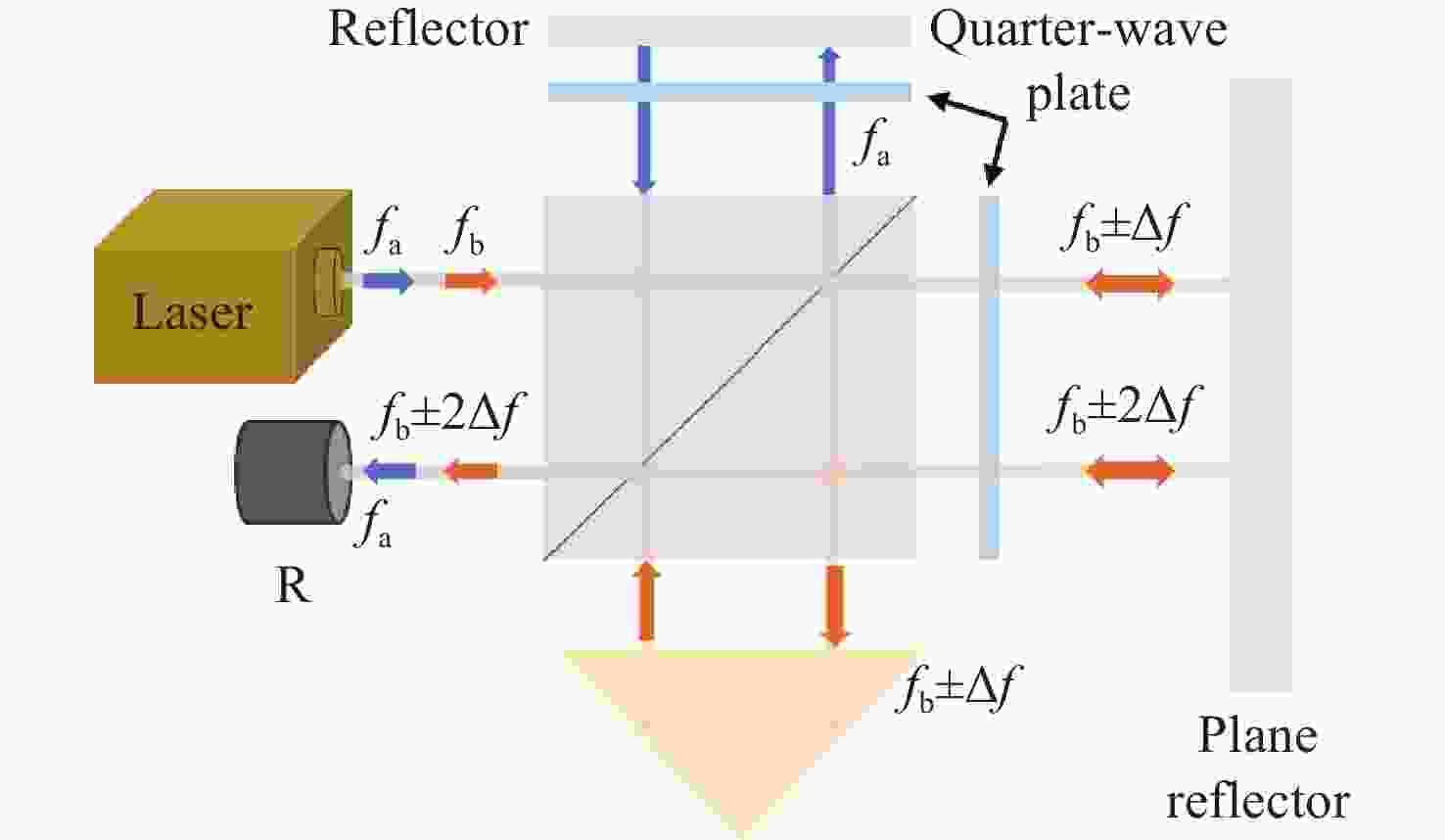

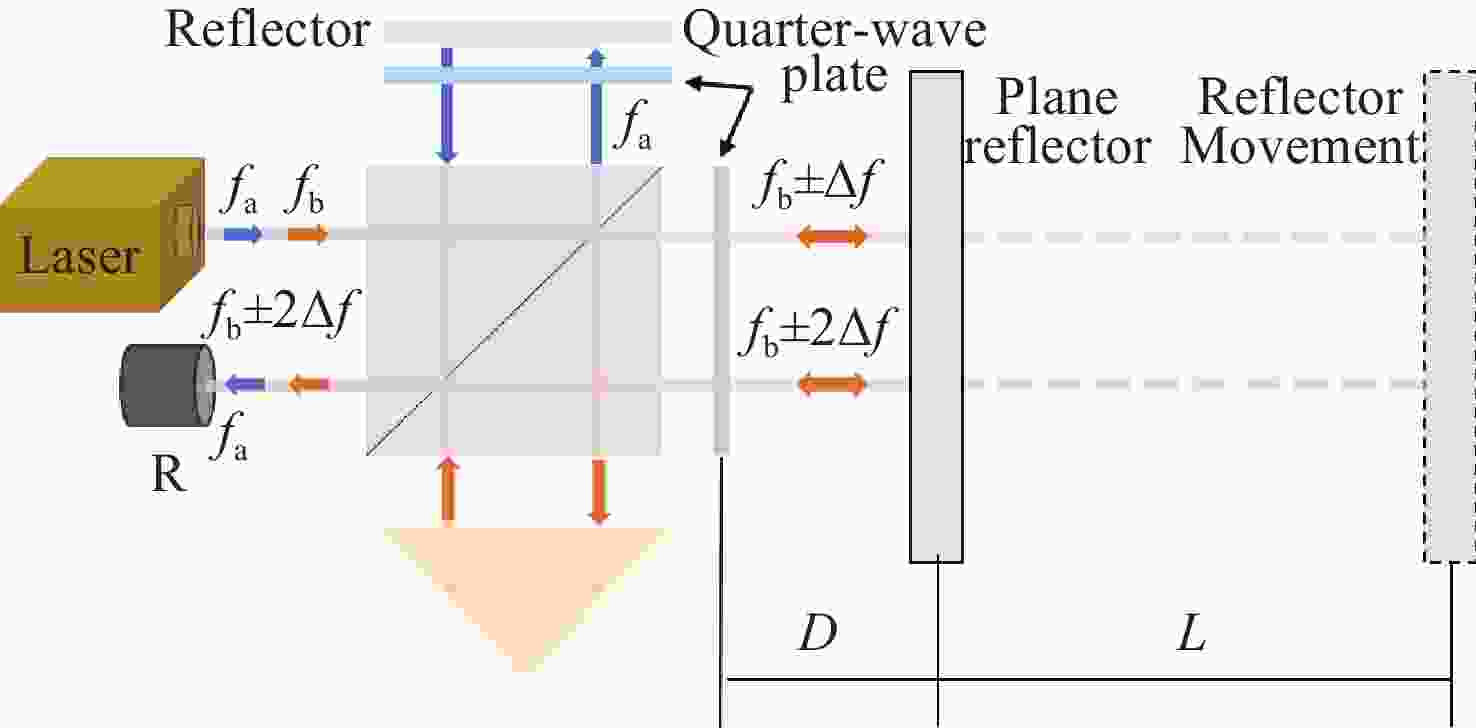

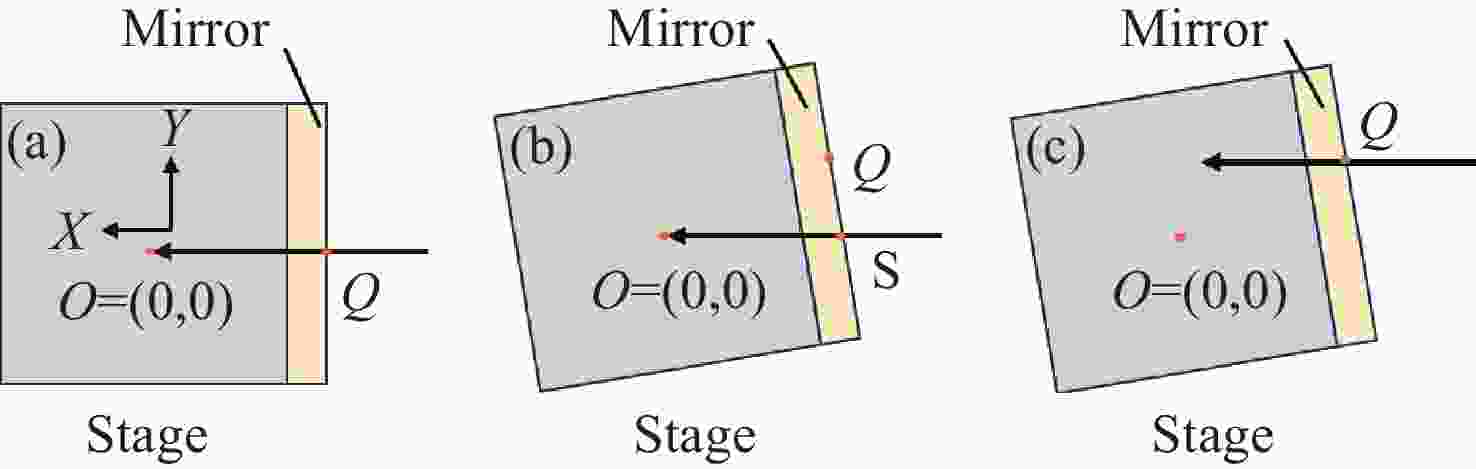

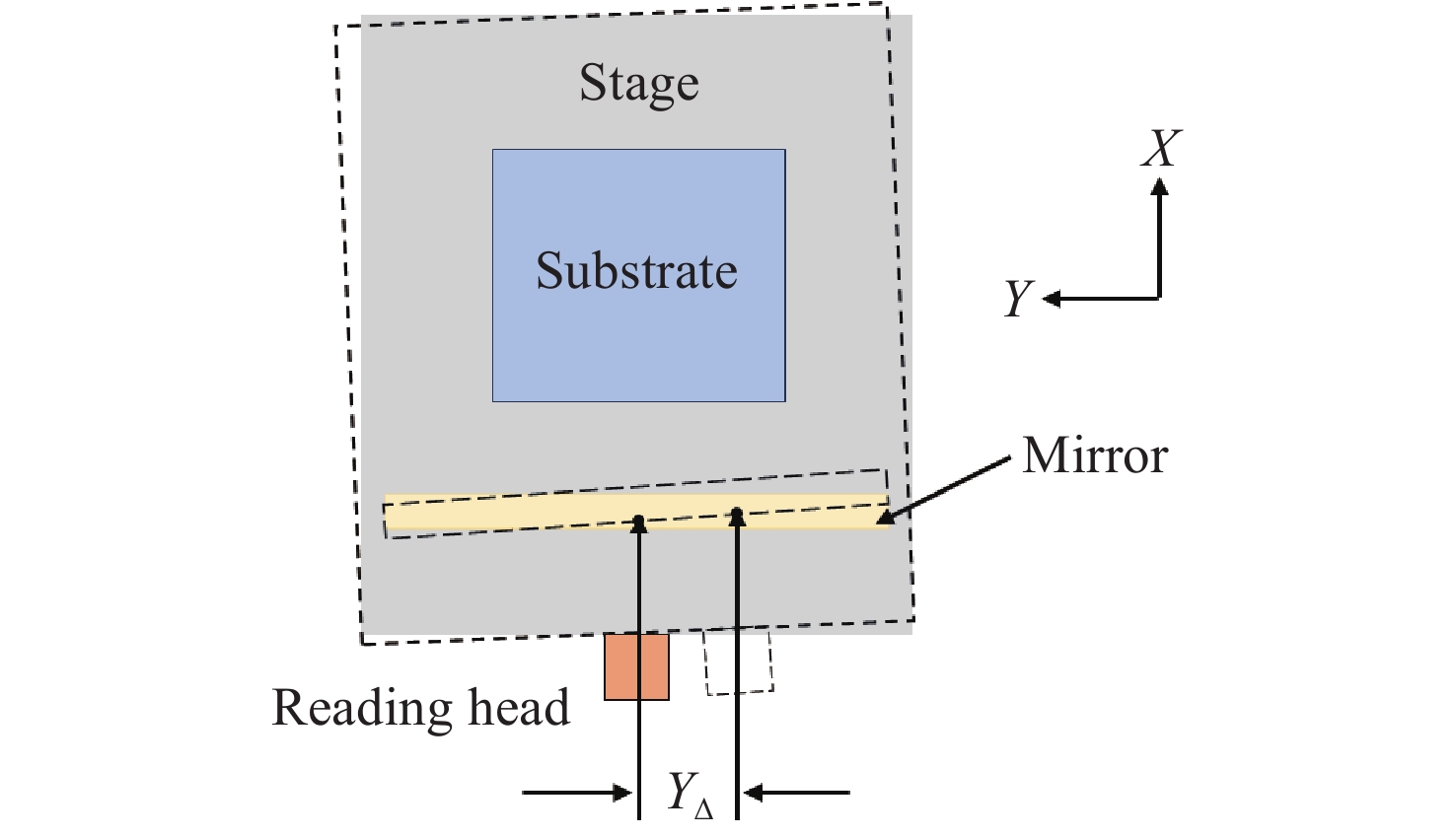

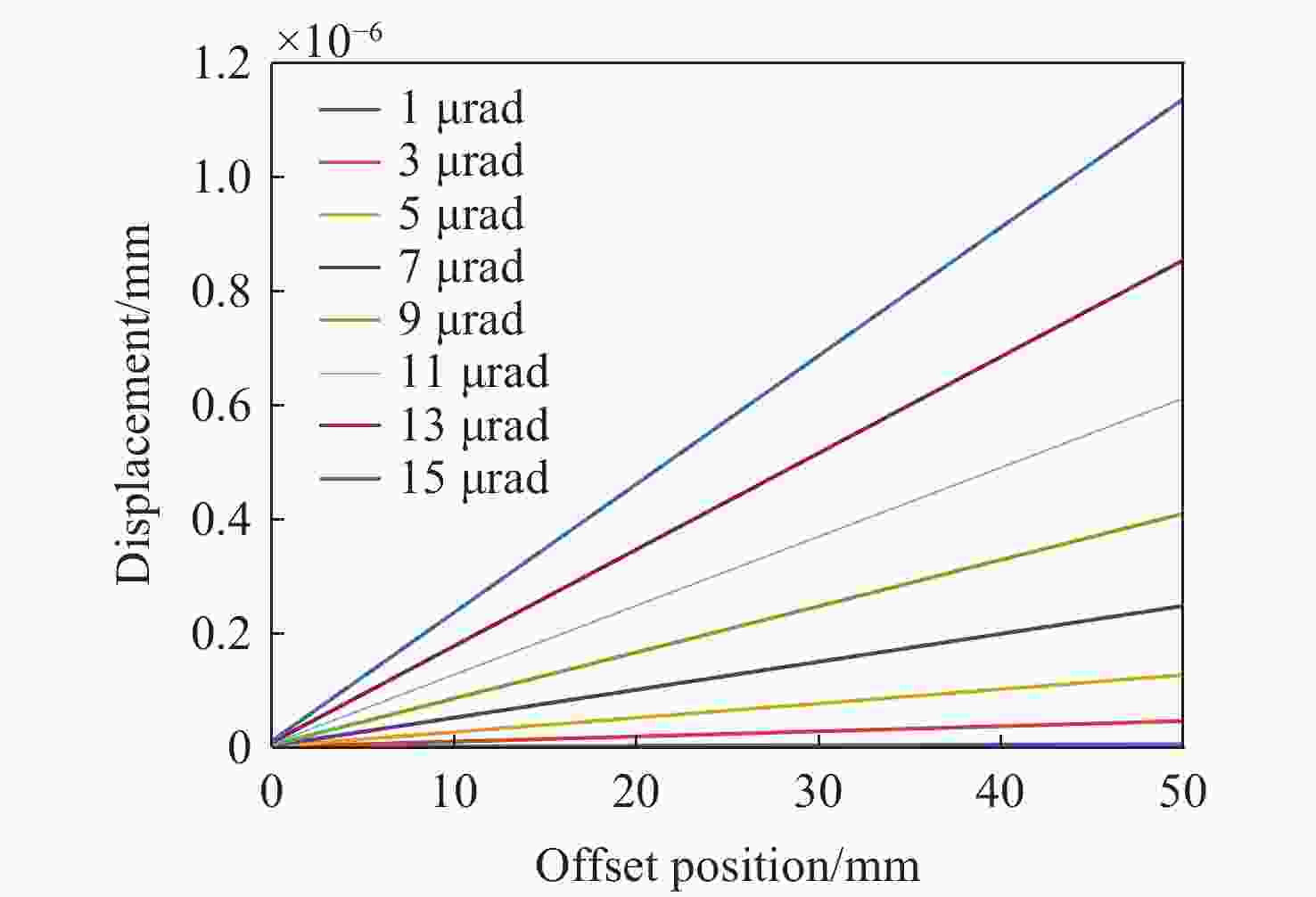

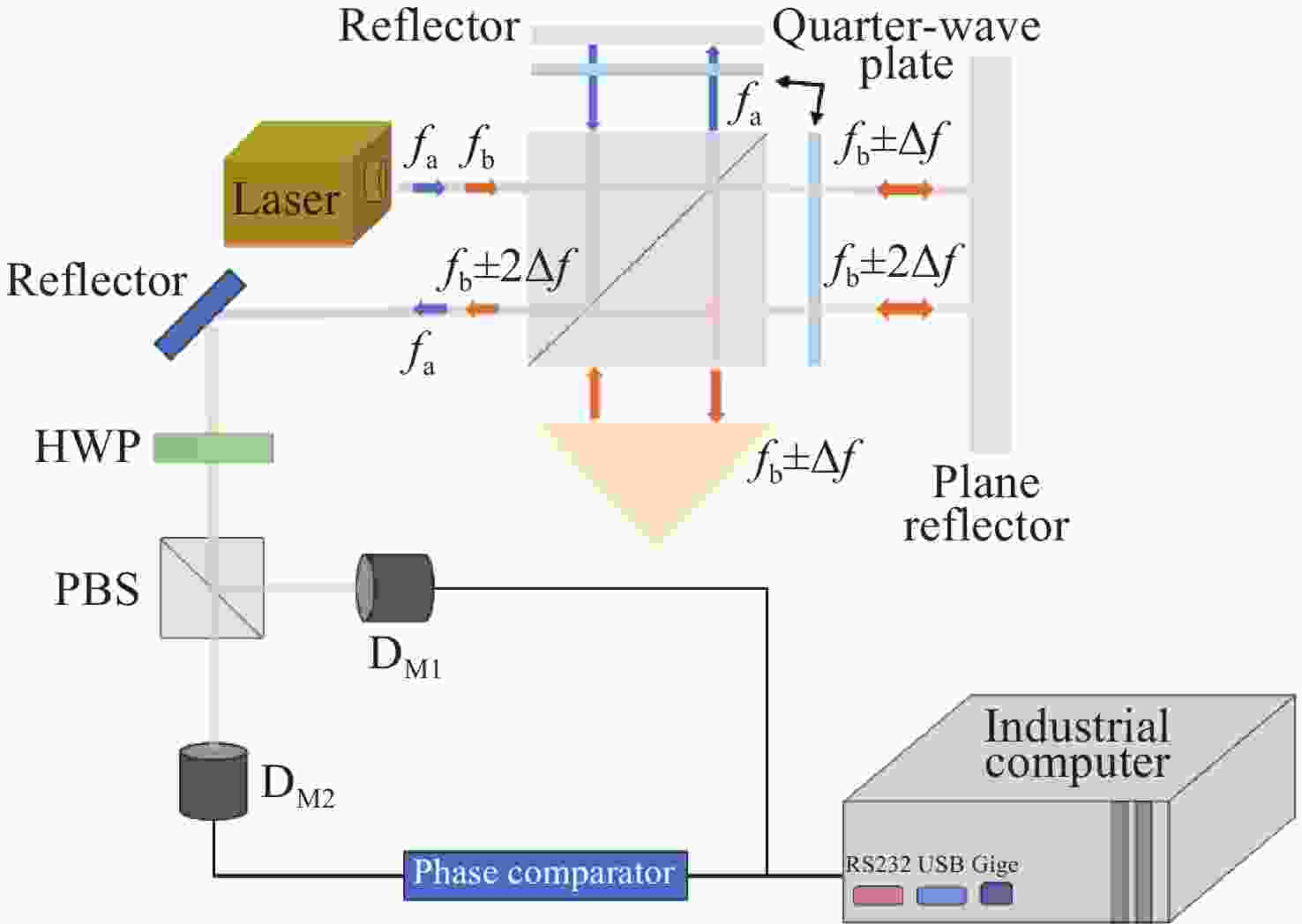

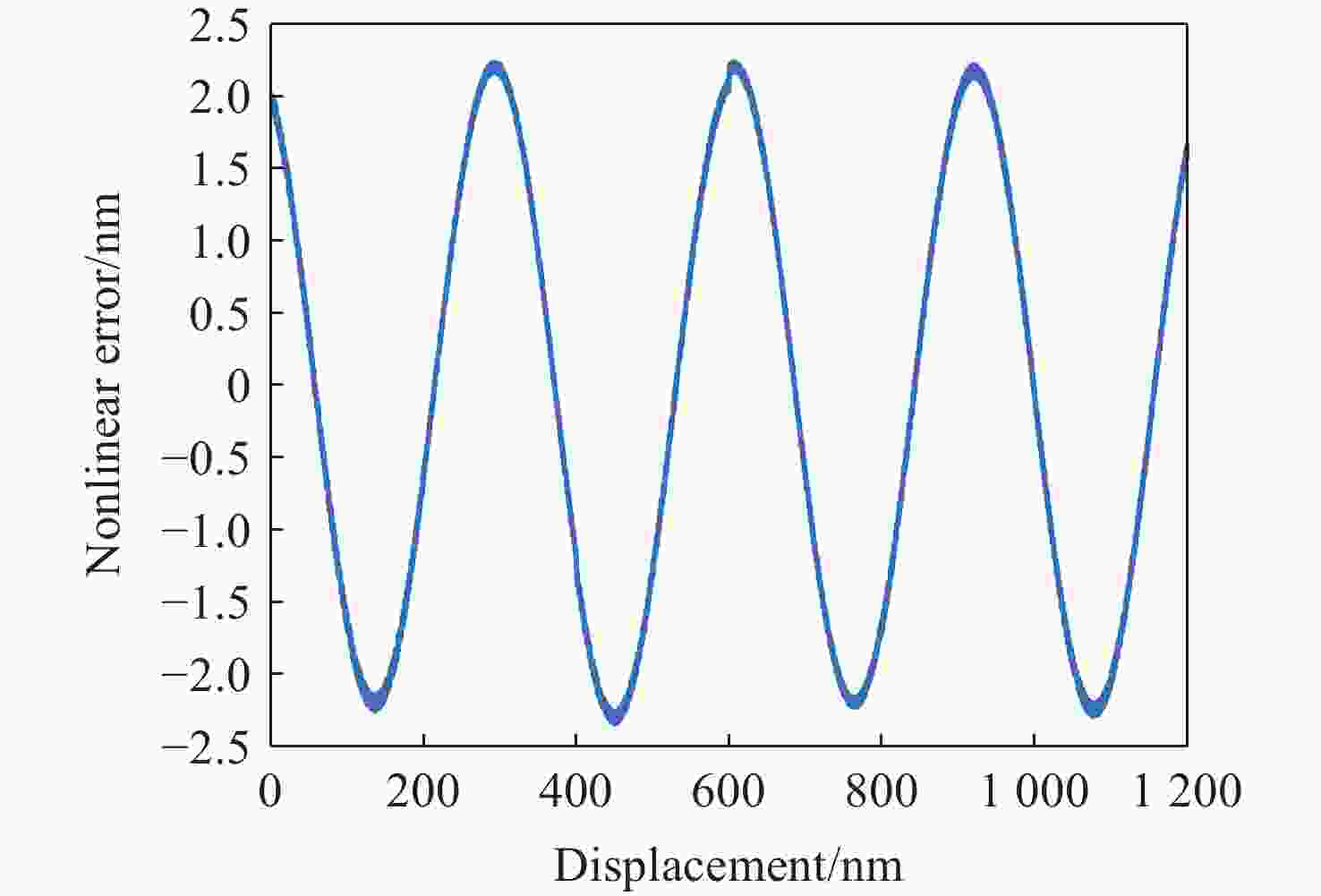

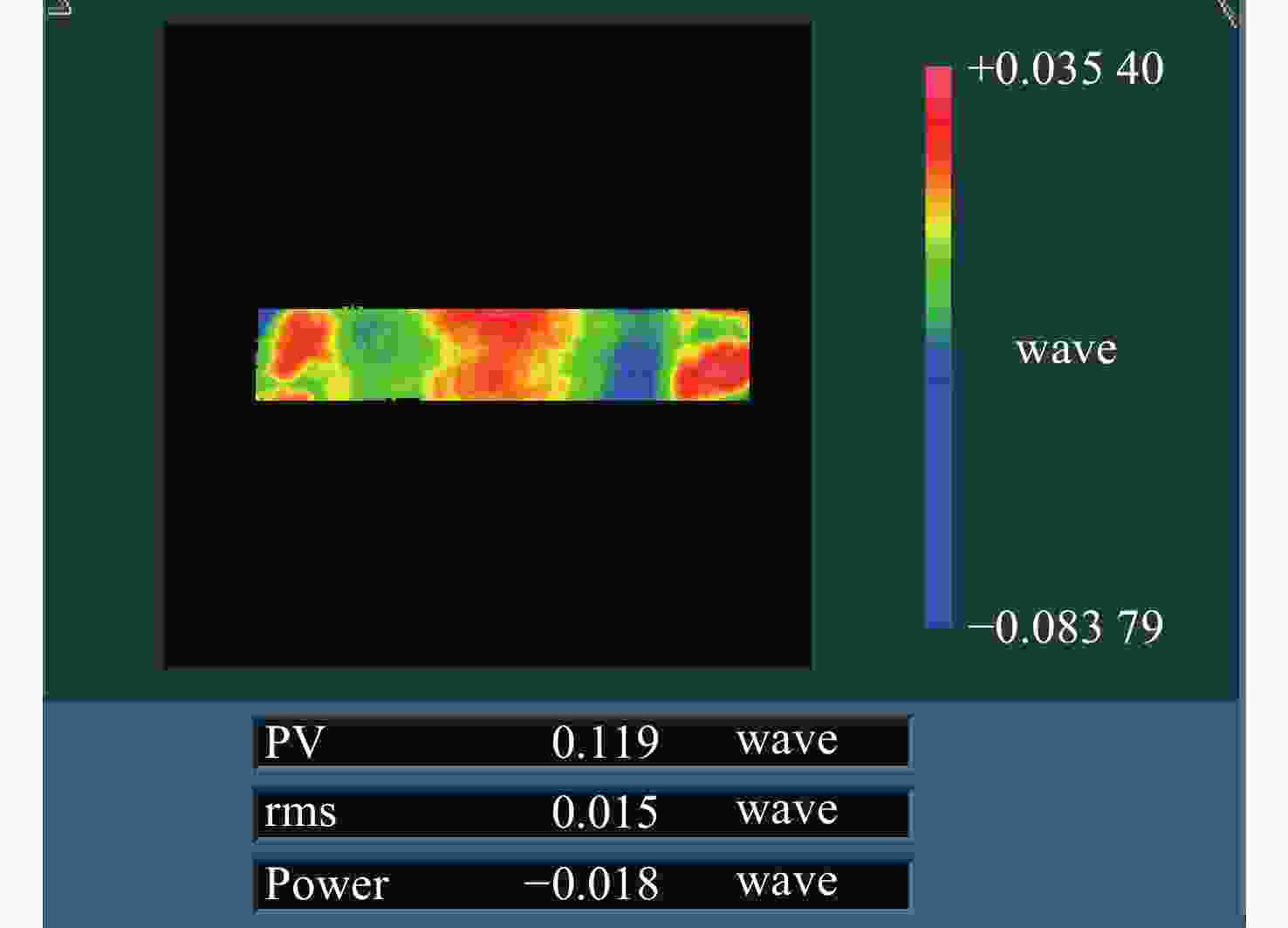

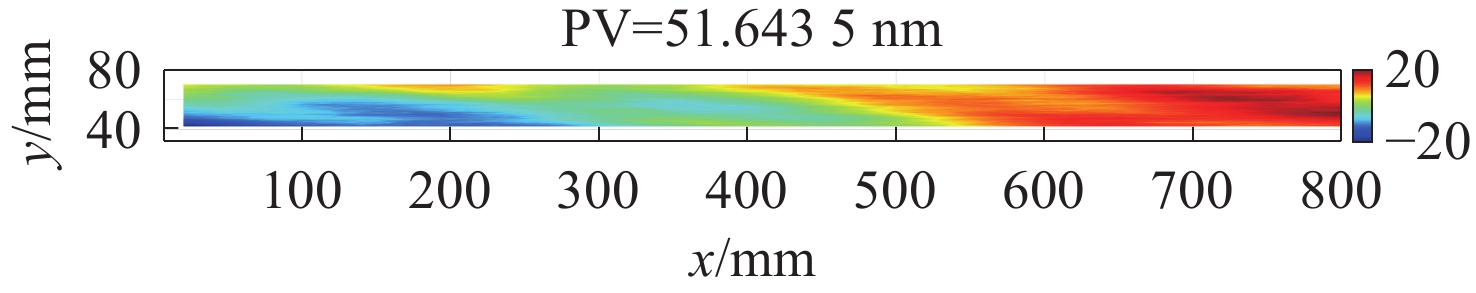

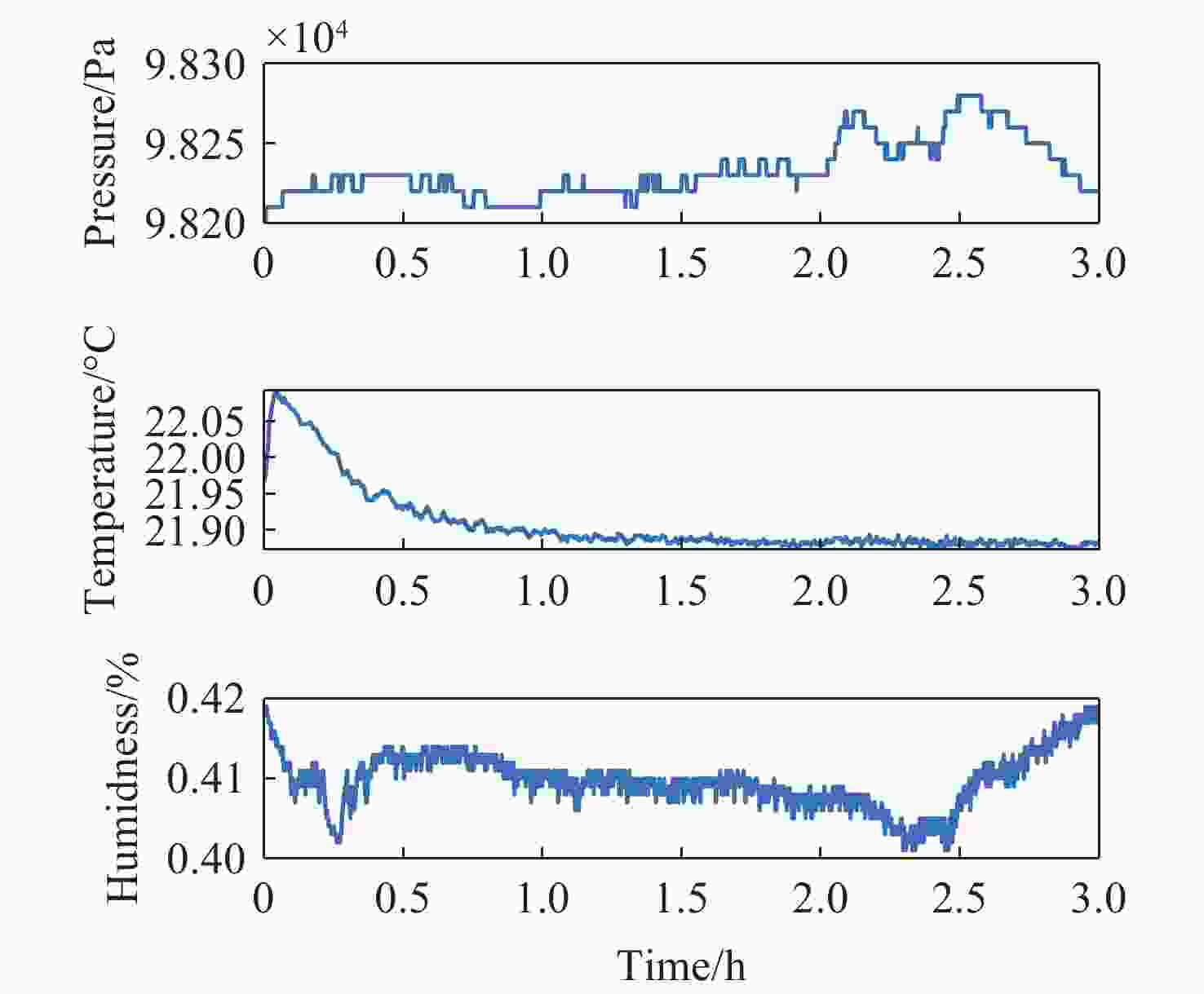

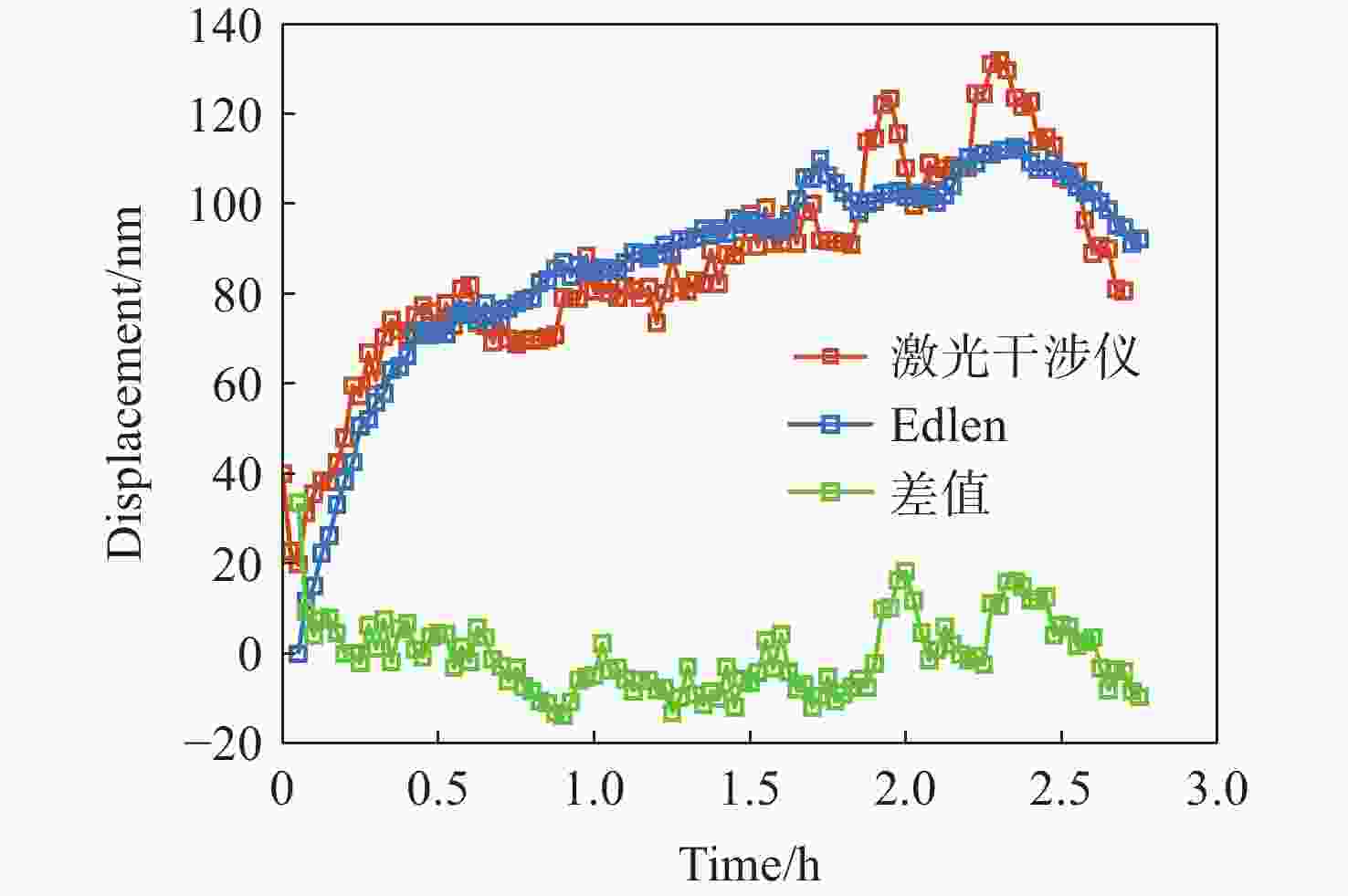

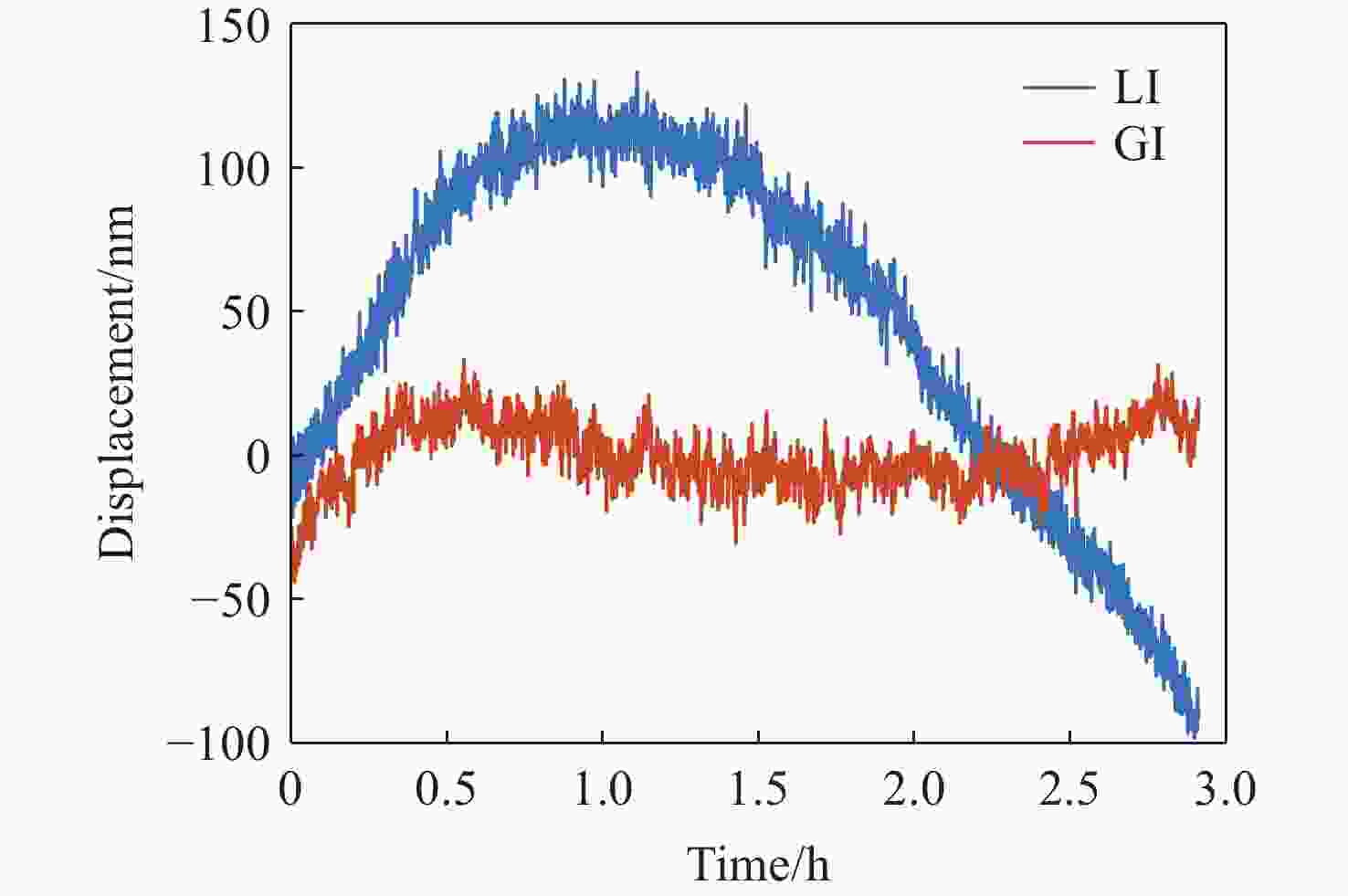

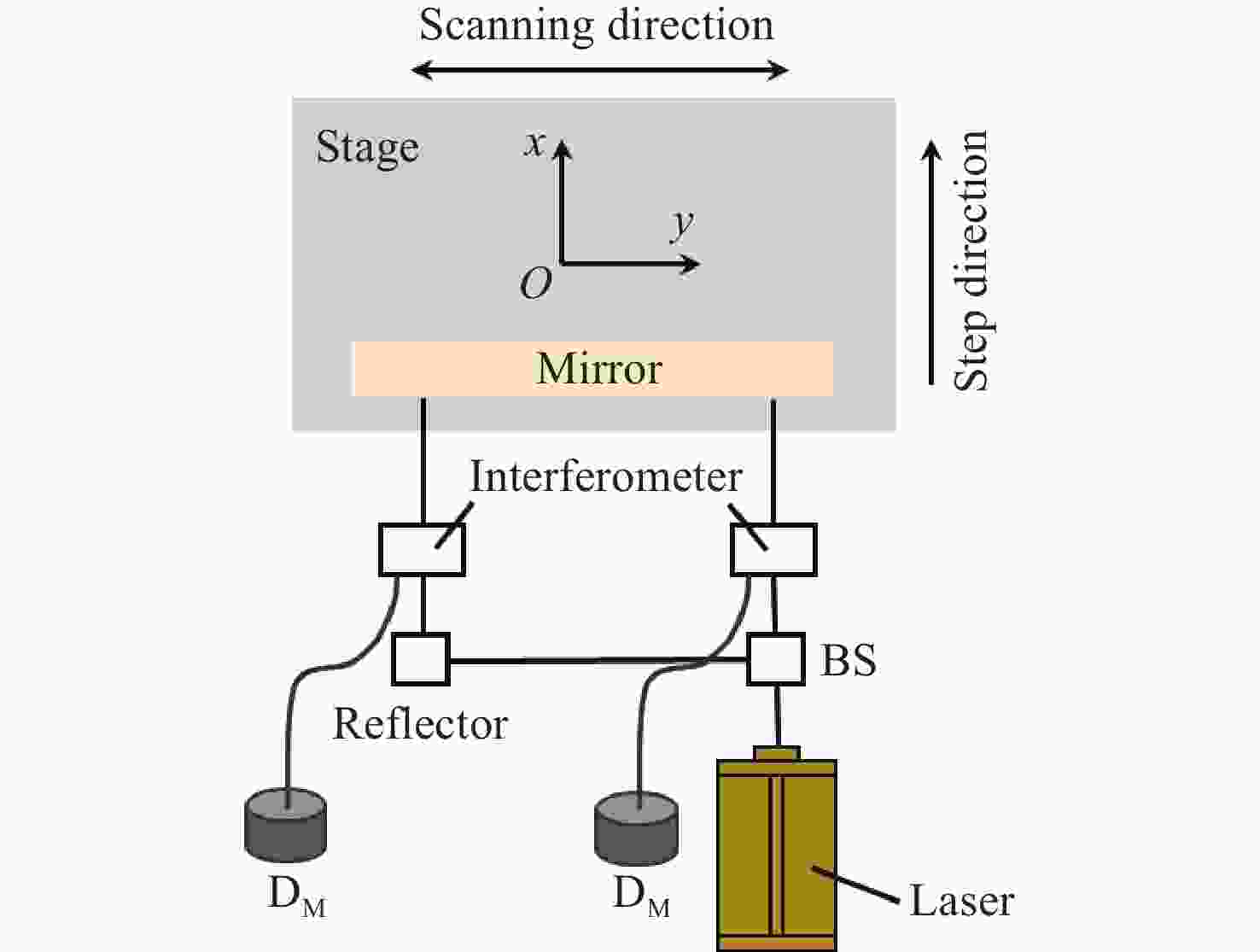

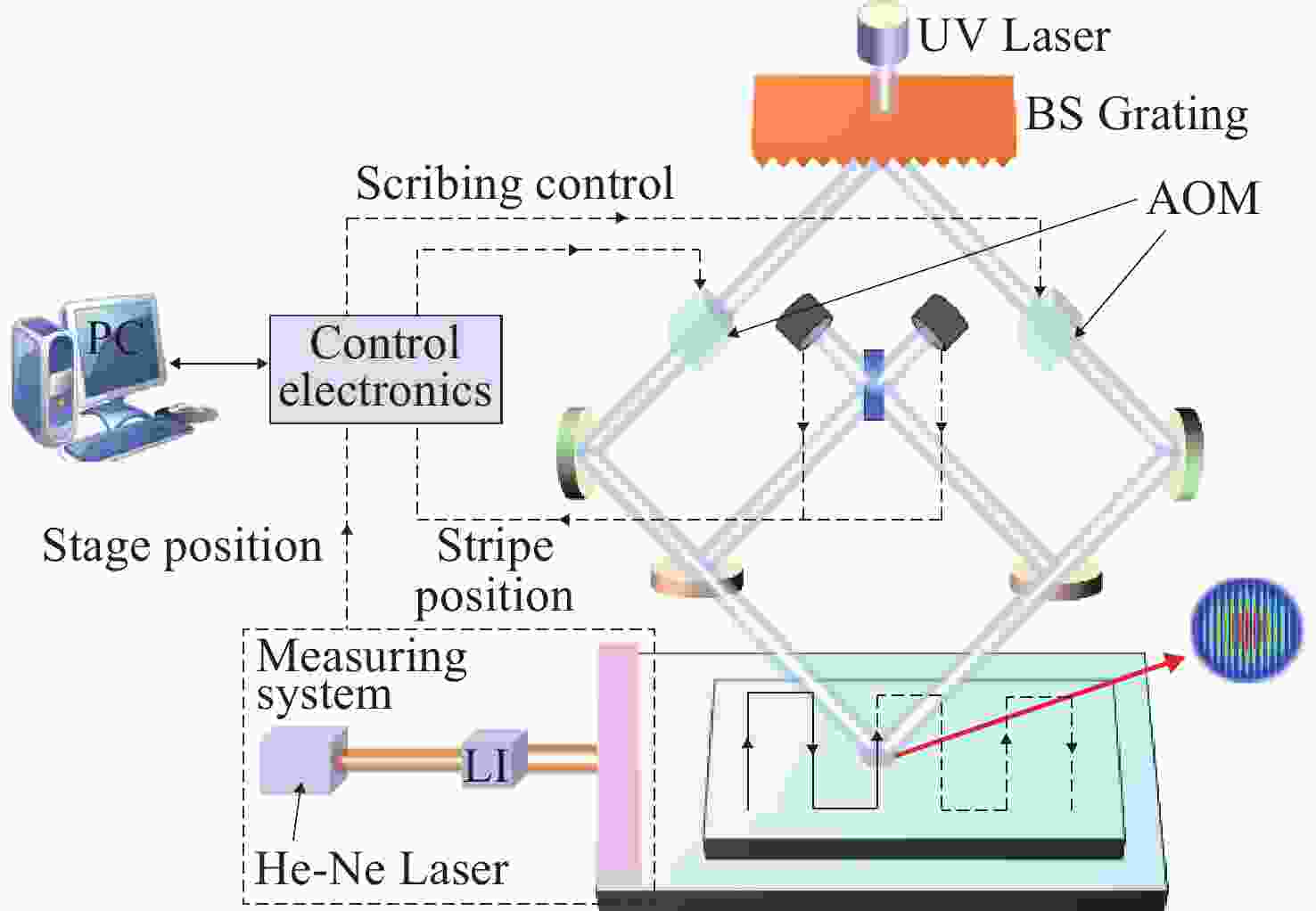

λ @632.8 nm。本文分析方法贯通了光栅衍射波前与测量误差的传递链路,为制作米级尺寸纳米精度全息光栅奠定了理论和实验基础。Abstract:Scanning Beam Interference Lithography (SBIL) is an effective way to fabricate monomeric large-area high-precision gratings. Using dual-frequency laser interferometer feedback table position to splice interference fringes accurately, the measurement error will inevitably introduce grating engraving error and reduce the diffraction wavefront quality of grating. The intrinsic error caused by the laser interferometer’s structure was analyzed, and the evaluation method of the intrinsic error index of the laser interferometer in complex environments was proposed. The theoretical models of dead path error and measuring optical path variation error combined with actual working conditions and empirical formulas were established. The coupling relationship between rotation and displacement of any table point was deduced by constructing translation and rotation operators, and the measurement errors under different table attitude roll angles were simulated. The displacement error experiment and grating scanning exposure experiment were carried out. The experimental results show that the displacement error is consistent with the theoretical calculation results. The diffraction wavefront of the 200 mm×200 mm grating is 0.278λ@632.8 nm. The analytical method in this paper connects the transmission link between the grating diffraction wavefront and the measurement error, laying a theoretical and experimental foundation for the fabrication of meter-size nano-precision holographic gratings.

-

图 5 滚转角对激光干涉仪测量精度的影响。(a) 理想情况下,x轴测量镜测量点Q的位置;(b) 工作台在原点O处旋转α角;(c) 工作台在标记点Q旋转α角。

Figure 5. The impact of roll angle on laser interferometers measurement accuracy. (a) The position of measuring point Q when the workbench is not rotating. (b) Workbench rotates α at origin O. (c) Workbench rotates α around point Q

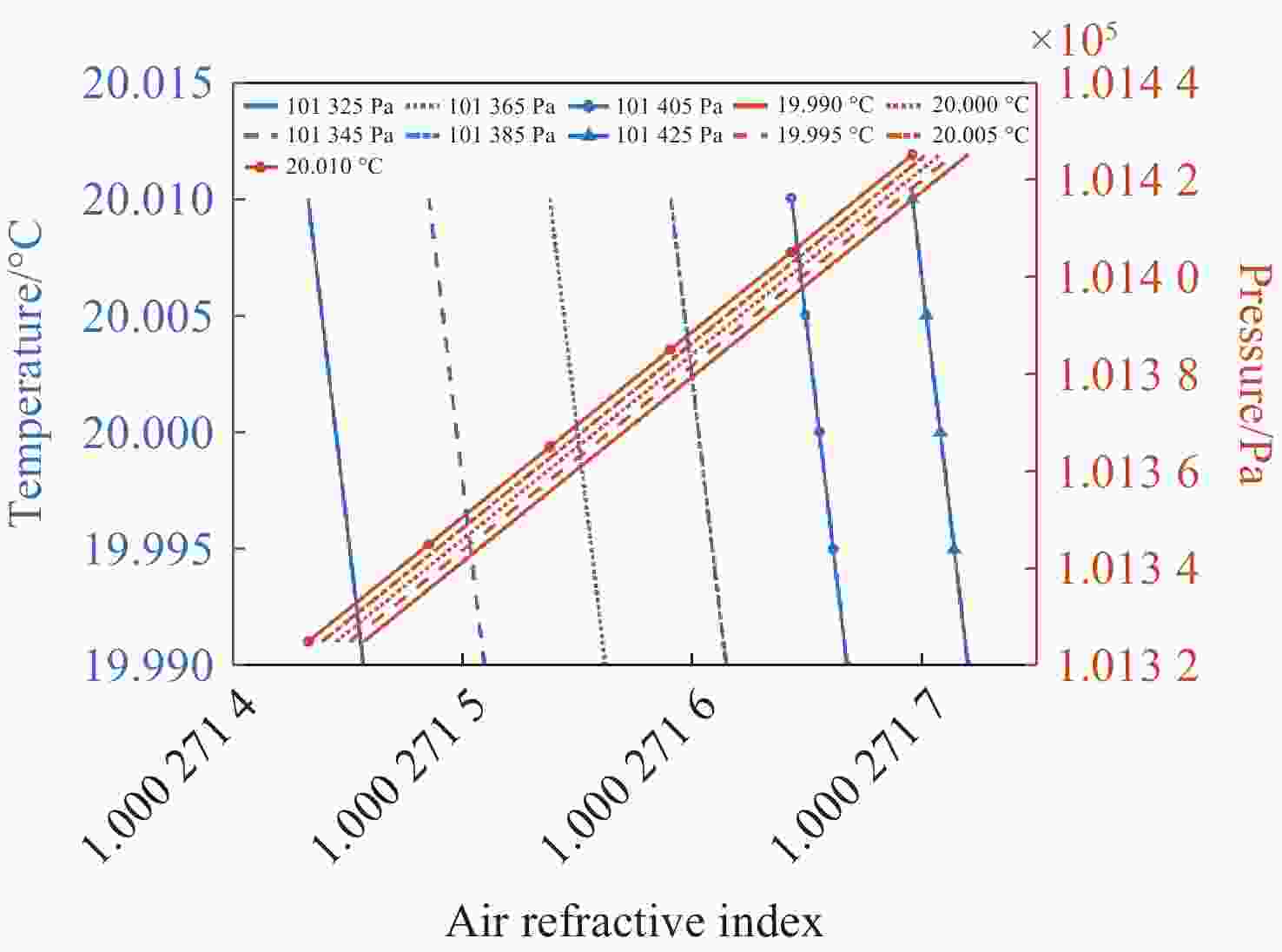

表 1 空气折射率影响系数

Table 1. Influence coefficient of air refractive index

参数 数值 标准空气折射率 1.000273 激光器真空波长/nm 632.991528 空气波长/nm 632.818663 温度敏感性/°C−1 −1.004×10−6 湿度敏感性/(%RH)−1 −6.401×10−9 压强敏感性/Pa−1 0.200×10−8 表 2 测量系统精度

Table 2. Measurement system error

(nm) 误差项 误差值 激光器波长稳定性 8.00 电子学误差 0.15 光学非线性误差 4.40 光学温度漂移误差 0.08 测量镜面形误差 51.64 死程误差 79.73 光程变化误差 12.80 工作台姿态误差 18.00 RSS 97.95 -

[1] 罗凯元, 郑文炜, 杨霖. 基于激光干涉的多轴运动平台垂直度测量[J]. 光学 精密工程,2024,32(17):2654-2662. doi: 10.37188/OPE.20243217.2654LUO K Y, ZHENG W W, YANG L. Perpendicularity measurement of multi-axis motion platform based on laser interferometry[J]. Optics and Precision Engineering, 2024, 32(17): 2654-2662. doi: 10.37188/OPE.20243217.2654 [2] 李星辉, 崔璨. 光栅干涉精密纳米测量技术[J]. 光学 精密工程,2024,32(17):2591-2611. doi: 10.37188/OPE.20243217.2591LI X H, CUI C. Grating interferometric precision nanometric measurement technology[J]. Optics and Precision Engineering, 2024, 32(17): 2591-2611. doi: 10.37188/OPE.20243217.2591 [3] 赵思霖, 穆全全, 李大禹. 基于液晶光栅的大视场红外凝视成像系统设计[J]. 光学 精密工程,2024,32(12):1824-1835. doi: 10.37188/OPE.20243212.1824ZHAO S L, MU Q Q, LI D Y. A large field of view infrared staring imaging system based on liquid crystal grating[J]. Optics and Precision Engineering, 2024, 32(12): 1824-1835. doi: 10.37188/OPE.20243212.1824 [4] HAN Y X, LI ZH Y, ZHANG Y B, et al. 400nm ultra-broadband gratings for near-single-cycle 100 Petawatt lasers[J]. Nature Communications, 2023, 14(1): 3632. doi: 10.1038/s41467-023-39164-3 [5] WANG R X, ANSARI M A, AHMED H, et al. Compact multi-foci metalens spectrometer[J]. Light: Science & Applications, 2023, 12(1): 103. [6] WANG Y F, XU X, DAI Z R, et al. Frequency-swept feedback interferometry for noncooperative-target ranging with a stand-off distance of several hundred meters[J]. PhotoniX, 2022, 3(1): 21. doi: 10.1186/s43074-022-00067-z [7] LI Y B, JIANG SH, CHEN X SH, et al. Accurate measurement and adjustment method for interference fringe direction in a scanning beam interference lithography system[J]. Optics Express, 2023, 31(17): 28145-28160. doi: 10.1364/OE.485488 [8] KONKOL P T. Design and analysis of a scanning beam interference lithography system for patterning gratings with nanometer-level distortions[D]. Cambridge: Massachusetts Institute of Technology, 2003. [9] 王玮, 巴音贺希格, 宋莹, 等. 扫描干涉场曝光光束自动对准及其收敛性分析[J]. 中国激光,2016,43(12):1205001. doi: 10.3788/CJL201643.1205001WANG W, BAYANHESHIG, SONG Y, et al. Beam alignment and convergence analysis of scanning beam interference lithography system[J]. Chinese Journal of Lasers, 2016, 43(12): 1205001. (in Chinese). doi: 10.3788/CJL201643.1205001 [10] 姜珊, 巴音贺希格, 李文昊, 等. 扫描干涉场曝光系统中周期设定对曝光刻线相位的影响[J]. 光学学报,2014,34(9):0905003. doi: 10.3788/AOS201434.0905003JIANG SH, BAYANHESHIG, LI W H, et al. Effect of period setting value on printed phase in scanning beam interference lithography system[J]. Acta Optica Sinica, 2014, 34(9): 0905003. (in Chinese). doi: 10.3788/AOS201434.0905003 [11] CHEN C G. Beam alignment and image metrology for scanning beam interference lithography: fabricating gratings with nanometer phase accuracy[D]. Cambridge: Massachusetts Institute of Technology, 2003. [12] 鲁森, 杨开明, 朱煜, 等. 用于扫描干涉场曝光的超精密微动台设计与控制[J]. 光学学报,2017,37(10):1012006. doi: 10.3788/AOS201737.1012006LU S, YANG K M, ZHU Y, et al. Design and control of ultra-precision fine positioning stage for scanning beam interference lithography[J]. Acta Optica Sinica, 2017, 37(10): 1012006. (in Chinese). doi: 10.3788/AOS201737.1012006 [13] 刘兆武, 李文昊, 王敬开, 等. 纳米精度二维工作台测量镜的面形误差在线检测[J]. 光学 精密工程,2016,24(9):2134-2141. doi: 10.3788/OPE.20162409.2134LIU ZH W, LI W H, WANG J K, et al. Online detection of profile deviation for nano precision 2-D stage mirror[J]. Optics and Precision Engineering, 2016, 24(9): 2134-2141. (in Chinese). doi: 10.3788/OPE.20162409.2134 [14] LIU ZH W, YANG H, LI Y B, et al. Active control technology of a diffraction grating wavefront by scanning beam interference lithography[J]. Optics Express, 2021, 29(23): 37066-37074. doi: 10.1364/OE.437593 [15] LIU ZH W, LI W H, BAYANHESHIG, et al. Two-color heterodyne laser interferometry for long-distance stage measurement with correction of uncertainties in measured optical distances[J]. Scientific Reports, 2017, 7: 8173. doi: 10.1038/s41598-017-07741-4 [16] HORI Y, GONDA S, BITOU Y, et al. Periodic error evaluation system for linear encoders using a homodyne laser interferometer with 10 picometer uncertainty[J]. Precision Engineering, 2018, 51: 388-392. doi: 10.1016/j.precisioneng.2017.09.009 [17] YUAN G H, ZHELUDEV N I. Detecting nanometric displacements with optical ruler metrology[J]. Science, 2019, 364(6442): 771-775. doi: 10.1126/science.aaw7840 [18] YIN Y F, LIU ZH W, JIANG SH, et al. High-precision 2D grating displacement measurement system based on double-spatial heterodyne optical path interleaving[J]. Optics and Lasers in Engineering, 2022, 158: 107167. doi: 10.1016/j.optlaseng.2022.107167 [19] LV Q, LIU ZH W, WANG W, et al. Fast method to detect and calculate displacement errors in a Littrow grating-based interferometer[J]. Applied Optics, 2019, 58(12): 3193-3199. doi: 10.1364/AO.58.003193 [20] LIU L, LIU ZH W, JIANG SH, et al. Polarization modulated grating interferometer by conical diffraction[J]. Optics Express, 2022, 30(2): 689-699. doi: 10.1364/OE.438490 [21] BAI Y, HU P C, LU Y F, et al. A six-axis heterodyne interferometer system for the joule balance[J]. IEEE Transactions on Instrumentation and Measurement, 2017, 66(6): 1579-1585. doi: 10.1109/TIM.2016.2634758 [22] 谈宜东, 徐欣, 张书练. 激光干涉精密测量与应用[J]. 中国激光,2021,48(15):1504001. doi: 10.3788/CJL202148.1504001TAN Y D, XU X, ZHANG SH L. Precision measurement and applications of laser interferometry[J]. Chinese Journal of Lasers, 2021, 48(15): 1504001. (in Chinese). doi: 10.3788/CJL202148.1504001 [23] 林荣炜, 程真英, 何亚雄, 等. XY工作台六自由度误差在线测量和补偿[J]. 光学 精密工程,2023,31(12):1761-1773. doi: 10.37188/OPE.20233112.1761LIN R W, CHENG ZH Y, HE Y X, et al. On-line six-degree-of-freedom errors measurement and compensation for XY stages[J]. Optics and Precision Engineering, 2023, 31(12): 1761-1773. (in Chinese). doi: 10.37188/OPE.20233112.1761 [24] 吴炳阳, 于晋龙, 王菊, 等. 小型化空气折射率测量装置的精度修正[J]. 激光与光电子学进展,2018,55(4):040102.WU B Y, YU J L, WANG J, et al. Accuracy correction of miniaturization device for air refractive index measurement[J]. Laser & Optoelectronics Progress, 2018, 55(4): 040102. (in Chinese). [25] 宋磊. 光刻机工件台六自由度测量系统研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.SONG L. Research on 6-degree-of-freedom measurement system of wafer stage[D]. Harbin: Harbin Institute of Technology, 2013. (in Chinese). [26] 宋莹. 全息光栅曝光系统干涉条纹静态及动态相位锁定技术研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2014.SONG Y. Research on the interference fringe static and dynamic phase-locking technology in the lithography system of the holographic grating[D]. Changchun: Graduate School of Chinese Academy of Sciences (Changchun Institute of Optics, Fine Mechanics and Physics), 2014. (in Chinese). [27] BIRCH K P, DOWNS M J. An updated Edlén equation for the refractive index of air[J]. Metrologia, 1993, 30(3): 155-162. doi: 10.1088/0026-1394/30/3/004 [28] BIRCH K P, DOWNS M J. Correction to the updated Edlén equation for the refractive index of air[J]. Metrologia, 1994, 31(4): 315-316. doi: 10.1088/0026-1394/31/4/006 [29] YANG Y, DENG Y, TAN Y D, et al. Nonlinear error analysis and experimental measurement of Birefringence-Zeeman dual-frequency laser interferometer[J]. Optics Communications, 2019, 436: 264-268. doi: 10.1016/j.optcom.2018.12.030 [30] YOKOZEKI S, SAWA S. Interferometric testing of gratings using moiré method[J]. Japanese Journal of Applied Physics, 1975, 14(S1): 465-470. doi: 10.7567/JJAPS.14S1.465 -

下载:

下载: