Adjusting the compactness and hydrophobicity of color filters to decrease gas release during TFT-LCD fabrication

doi: 10.37188/CO.EN-2023-0029

-

摘要:

TFT-LCD产业正朝着高效率、低成本的方向发展。在TFT-LCD制造过程中,发现不同的光刻胶需要不同的真空干燥时间。为了减少制造时间,提高面板成品率,有必要明确影响真空时间的因素。本文探讨了抽运时间与光刻胶材料性能的关系。发现光刻胶的热稳定性与抽运时间的关系可以忽略不计。光刻胶的致密性和疏水性与真空干燥时间密切相关。致密性和高疏水性可以有效避免水蒸气在制造过程中侵入和储存在光刻胶中,减少泵送次数。总的来说,这项工作可以为未来TFT-LCD工业新型光刻胶的开发提供一定的参考。

Abstract:The TFT-LCD industry is moving towards high efficiency and low costs. During the manufacturing process, it has been found that various photoresists require different vacuum drying times. To reduce manufacturing time and increase panel yields, clarifying the factors that can influence and reduce the vacuum time is necessary. This paper explored the relationship between pumping time and the properties of photoresist materials. It finds that the thermal stability of the photoresist has a negligible relationship with the pumping time. The compactness and hydrophobicity of the photoresist correlated strongly with the vacuum drying time. High compactness and high hydrophobicity can effectively prevent water vapor intrusion and storage in the photoresist during fabrication and consequently reduce pumping times. Overall, this work could guide the future development of new photoresists for the TFT-LCD industry.

-

Key words:

- TFT-LCD /

- color filter /

- gas release /

- compactness /

- hydrophobicity

-

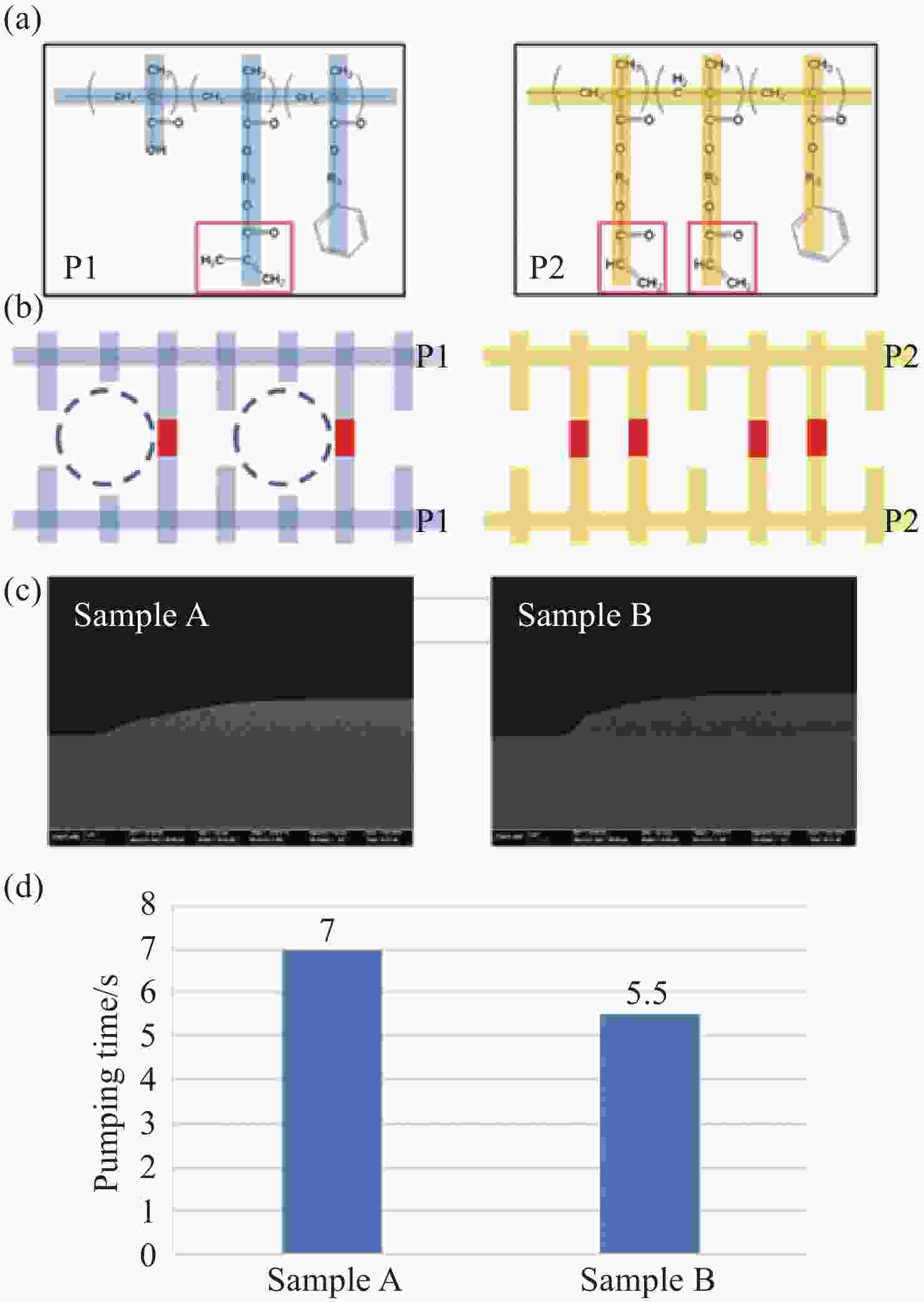

Figure 4. (a) The molecular structures of P1 and P2. (b) The schematic illustration of the porous structures. The red bars represent the crosslinking and the dotted circles represent the voids. P1 has large voids and P2 is more compact. (c) SEM images of sample A and sample B. (d) Pumping time of the two samples

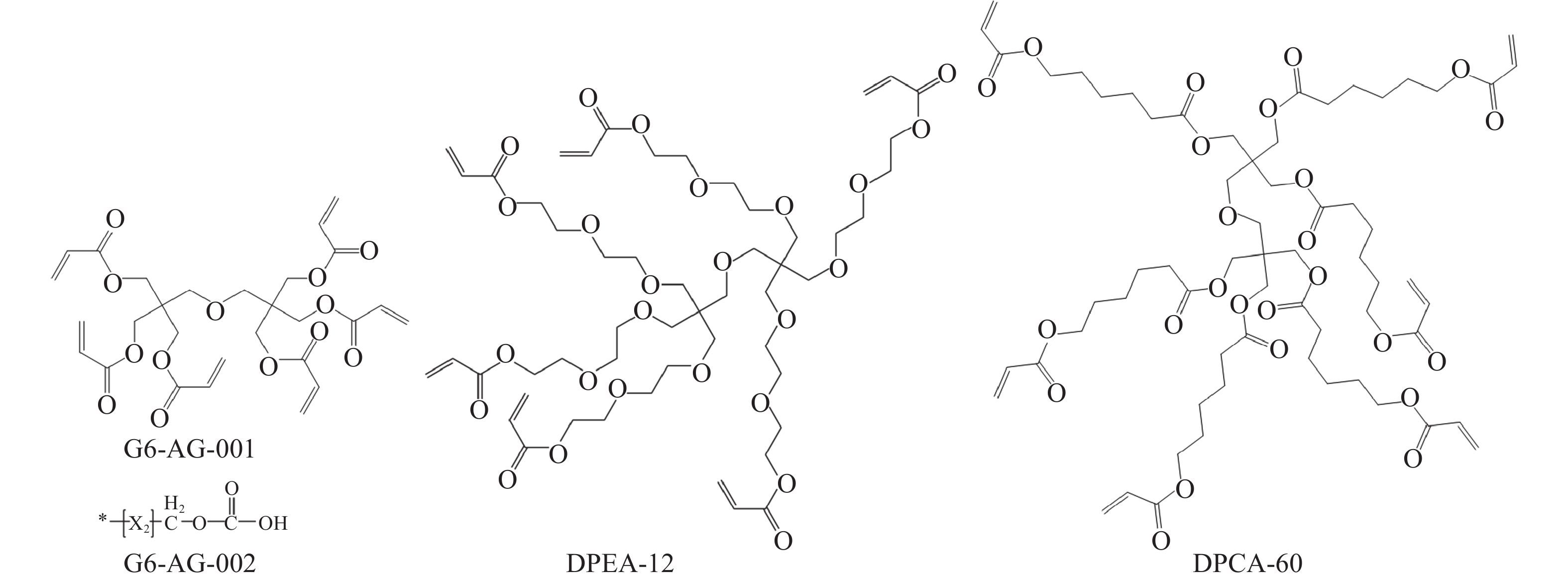

Table 1. Compositions of CFs

Compositions Sample PT-1 PT-2 A B C D E F Color Paste G58+Y138 Polymer

(wt%)P1 P1 P1 50% P1

50% P2P1 P1 P1 50% P1

50% P2Monomers G6-AG-001

DPCA-60G6-AG-001 G6-AG-001

DPEA-12G6-AG-001

DPEA-12G6-AG-001 G6-AG-001

G6-AG-002G6-AG-001

DPCA-60G6-AG-001

DPCA-60Polymer/Monomer (wt%) 40%/60% 40%/60% 35%/65% 35%/65% 35%/65% 35%/65% 35%/65% 35%/65% Photoinitiator (wt%) 0.15% Additive (wt%) 0.15% Solvent PGMEA+MBA Table 2. Pumping time of vacuum drying and mass loss

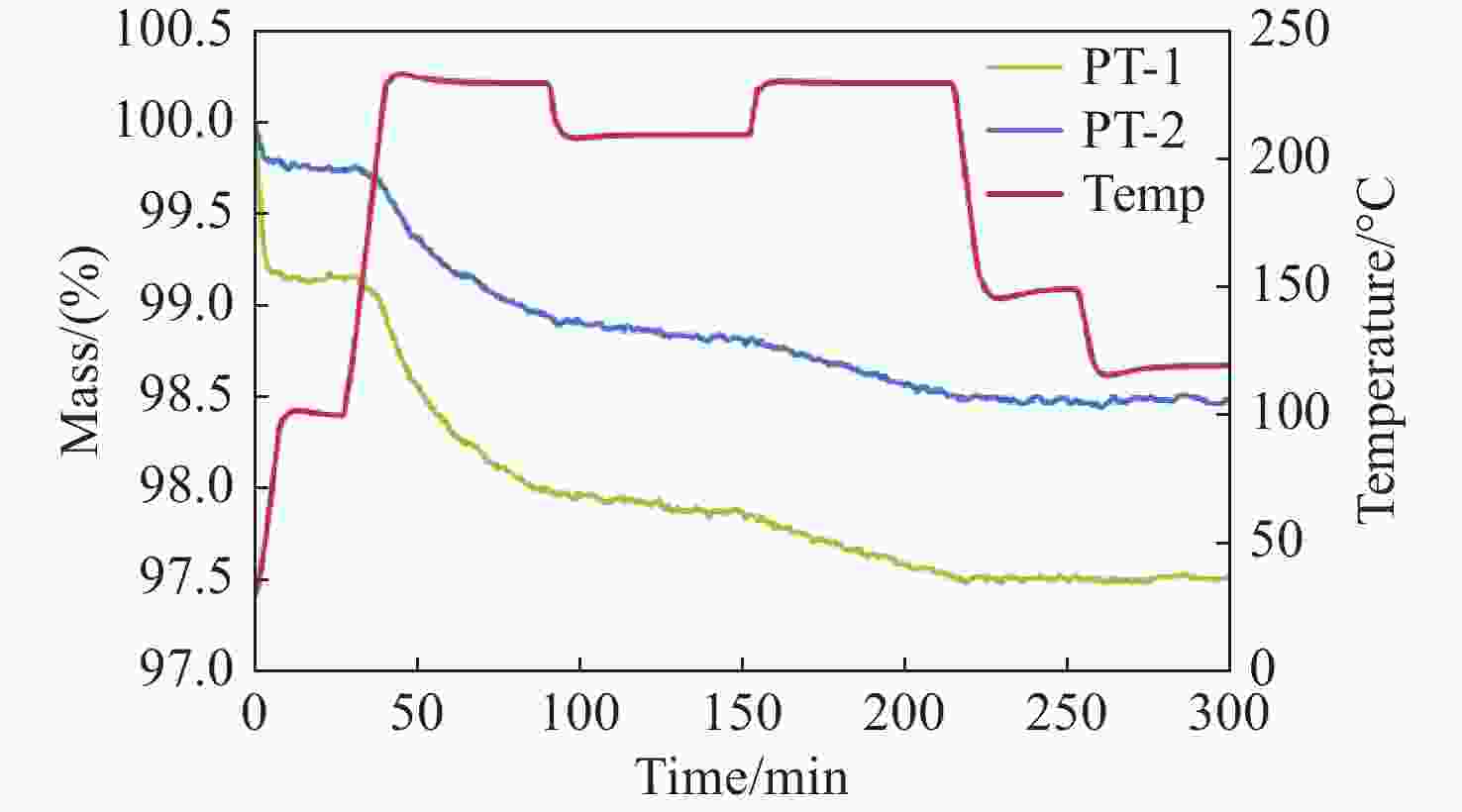

Items CF PT-1 PT-2 Pumping time/s 62.3 65.8 Mass loss (40−215 min) 2.46% 1.50% Mass loss (0−30 min) 0.20% 0.85% Table 3. The thickness and shrinkage of the photoresist layer before and after UV exposure

Sample Items d1/μm d2/μm Shrinkage (%) Pumping time/s Sample A 2.04 2.04 0.37 7 Sample B 2.17 2.15 0.76 5.5 Table 4. Data of the three samples CE

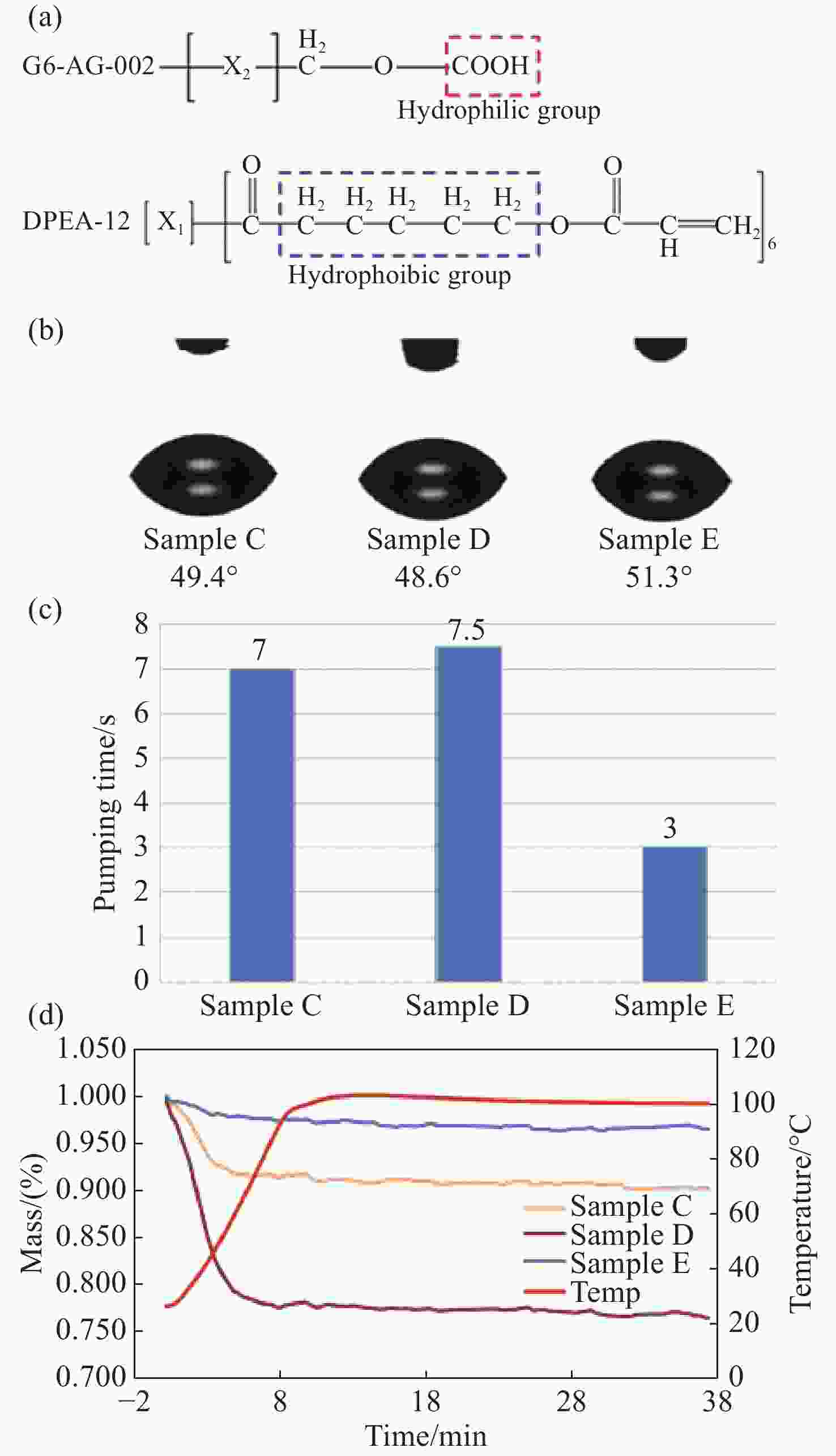

Sample Monomer Proportion Contact angle/(°) Developing time/s Property Mass loss Pumping time/s C M1 100% 49.4 24 / 9.7% 7 D M1+M2 70%+30% 48.6 21 More hydrophilic 23.4% 7.5 E M1+M3 70%+30% 51.3 29 More hydrophobic 3.5% 3 Table 5. Optical and VCD characteristics of reference CF and sample F

Item Reference CF Sample F Rx 0.642 0.642 Ry 0.337 0.337 Gx 0.301 0.301 Gy 0.607 0.607 Bx 0.150 0.149 By 0.07 0.068 Wx 0.276 0.278 Wy 0.297 0.301 Tr% 5.85% 5.89% NTSC 70.8% 71% Pumping time/s 62.3 62 -

[1] CHEN K S, WANG C H, CHEN H T. A MAIC approach to TFT-LCD panel quality improvement[J]. Microelectronics Reliability, 2006, 46(7): 1189-1198. doi: 10.1016/j.microrel.2005.10.003 [2] HUANG C Y, LU H H. Evaluating key factors for selecting capital equipment suppliers a study of small and medium-sized TFT-LCD manufacturers[C]. Proceedings of 2016 International Conference on Applied System Innovation, IEEE, 2016: 1-3. [3] JANG Y J, CHOI G H. Introduction to automated material handling systems in LCD panel production lines[C]. Proceedings of 2006 IEEE International Conference on Automation Science and Engineering, IEEE, 2006: 223-229. [4] TSUDA K. Colour filters for LCDs[J]. Displays, 1993, 14(2): 115-124. doi: 10.1016/0141-9382(93)90078-J [5] CHAE K H, SUNG K H. A polymeric photobase generator containing oxime–urethane groups: crosslinking reaction and application to negative photoresist[J]. Journal of Polymer Science Part A:Polymer Chemistry, 2004, 42(4): 975-984. doi: 10.1002/pola.11032 [6] KIM D G, KWON S J, HONG S K, et al. ArF photoresist polymers with nitrogen or sulfone moieties for negative tone development process[J]. Proceedings of SPIE, 2014, 9051: 905126. [7] SUGITA H, KANAI D, MASHIMA H, et al. Poly(vinyl alcohol)-based photosensitive water-borne coating for low-temperature color-filter production[J]. Displays, 2021, 69: 102057. doi: 10.1016/j.displa.2021.102057 [8] SUGITA H, EBATA S, SUZUKI H, et al. Polyvinyl-alcohol-based color resist for low-temperature color-filter production[J]. Displays, 2023, 77: 102393. doi: 10.1016/j.displa.2023.102393 [9] SABNIS R W. Color filter technology for liquid crystal displays[J]. Displays, 1999, 20(3): 119-129. doi: 10.1016/S0141-9382(99)00013-X [10] JANG S H, LEE G, LEE S Y, et al. Synthesis and characterisation of triphenylmethine dyes for colour conversion layer of the virtual and augmented reality display[J]. Dyes and Pigments, 2022, 204: 110419. doi: 10.1016/j.dyepig.2022.110419 [11] KWAK M, KIM Y, HAN S, et al. Past, present, and future of WCG technology in display[J]. Journal of the Society for Information Display, 2019, 27(11): 691-699. doi: 10.1002/jsid.843 [12] XIE D N, QI Y L, ZHANG B, et al. Ultra-high color gamut system achieved by quantum dot photoresist and color filter system[J]. Ferroelectrics, 2018, 528(1): 66-74. doi: 10.1080/00150193.2018.1448627 [13] ZHAN H M, XU ZH, TIAN CH, et al. Achieving standard wide color gamut by tuning LED backlight and color filter spectrum in LCD[J]. Journal of the Society for Information Display, 2014, 22(11): 545-551. doi: 10.1002/jsid.274 [14] ZHENG W W, KANG C T. Ite/Sid. The study on relation between color gamut and luminous efficiency basic on the shift of color filter and LED spectrum[C]. Proceedings of the 19th International Display Workshops / Asia Display 2012, IDW-International Display Workshops, 2012: 515-517. [15] TATSUMI Y, INOUE M. 40-4: Development of color resists containing novel dyes for liquid crystal displays[J]. SID Symposium Digest of Technical Papers, 2016, 47(1): 521-523. doi: 10.1002/sdtp.10728 [16] YOON C, CHOI J H. Synthesis of tricyanopyrrolidone derivatives as synergists for improving contrast ratio of liquid crystal displays[J]. Dyes and Pigments, 2014, 101: 344-350. doi: 10.1016/j.dyepig.2013.10.017 [17] JHUN C G, GWAG J S. Size effect of light scattering on the nano-sized color filter pigment in liquid crystal display[J]. Journal of the Optical Society of Korea, 2014, 18(2): 184-187. doi: 10.3807/JOSK.2014.18.2.184 [18] UTSUMI Y, HIYAMA I, TOMIOKA Y, et al. Analysis of light leakage caused by color filter between crossed polarizers[J]. Japanese Journal of Applied Physics, 2007, 46(3R): 1047-1050. doi: 10.1143/JJAP.46.1047 [19] UTSUMI Y, HIYAMA I, TOMIOKA Y, et al. Quantitative analysis method for measuring light leakage intensity of three primary color filters placed between crossed polarizers[J]. Japanese Journal of Applied Physics, 2008, 47(5): 3518-3521. [20] NEǏMAN M B, KOVARSKAYA B M, GOLUBENKOVA L I, et al. The thermal degradation of some epoxy resins[J]. Journal of Polymer Science, 1962, 56(164): 383-389. doi: 10.1002/pol.1962.1205616408 [21] VENGER A E, FRAITNAN Y E. Thermogravimetric analysis of the kinetics of thermal decomposition processes in polymer materials[J]. Journal of Engineering Physics, 1981, 40(2): 168-174. doi: 10.1007/BF00826026 [22] ISMAIL A F, MANSOURIZADEH A. A comparative study on the structure and performance of porous polyvinylidene fluoride and polysulfone hollow fiber membranes for CO2 absorption[J]. Journal of Membrane Science, 2010, 365(1-2): 319-328. doi: 10.1016/j.memsci.2010.09.021 [23] AVILA J, ČERVINKA C, DUGAS P Y, et al. Porous ionic liquids: structure, stability, and gas absorption mechanisms[J]. Advanced Materials Interfaces, 2021, 8(9): 2001982. doi: 10.1002/admi.202001982 -

下载:

下载: