磨料水射流抛光熔石英玻璃的多目标参数优化

Multi-objective parameter optimization of abrasive water jet polishing for fused silica

doi: 10.37188/CO.EN-2025-0006

-

摘要:

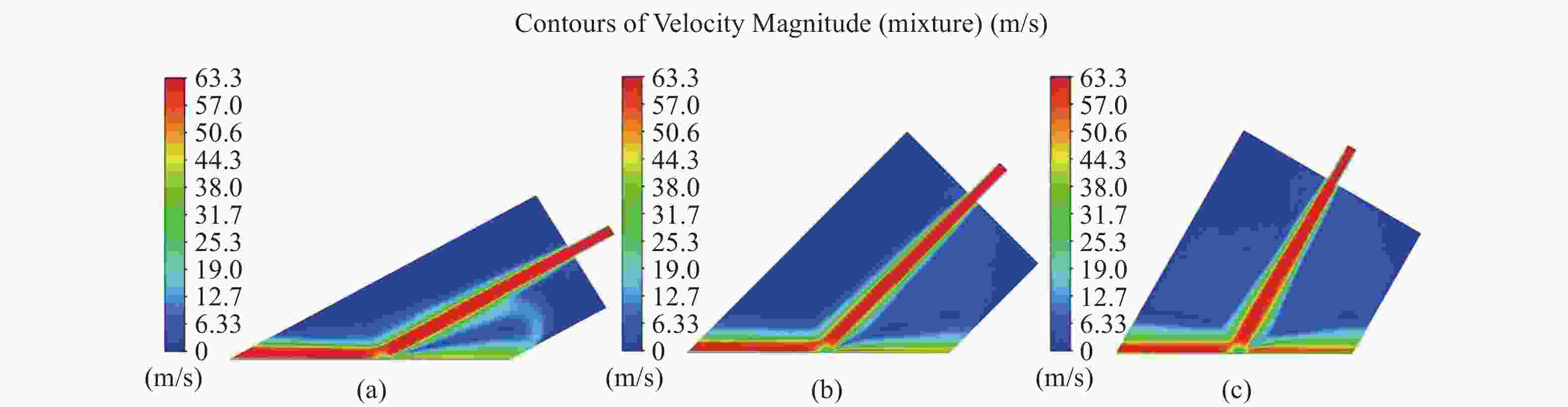

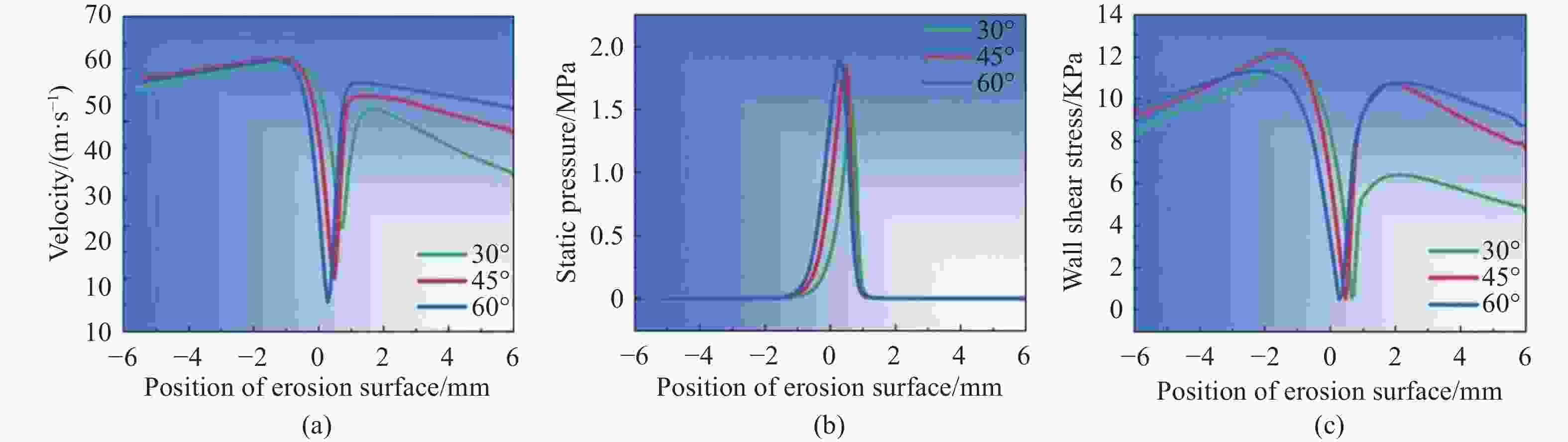

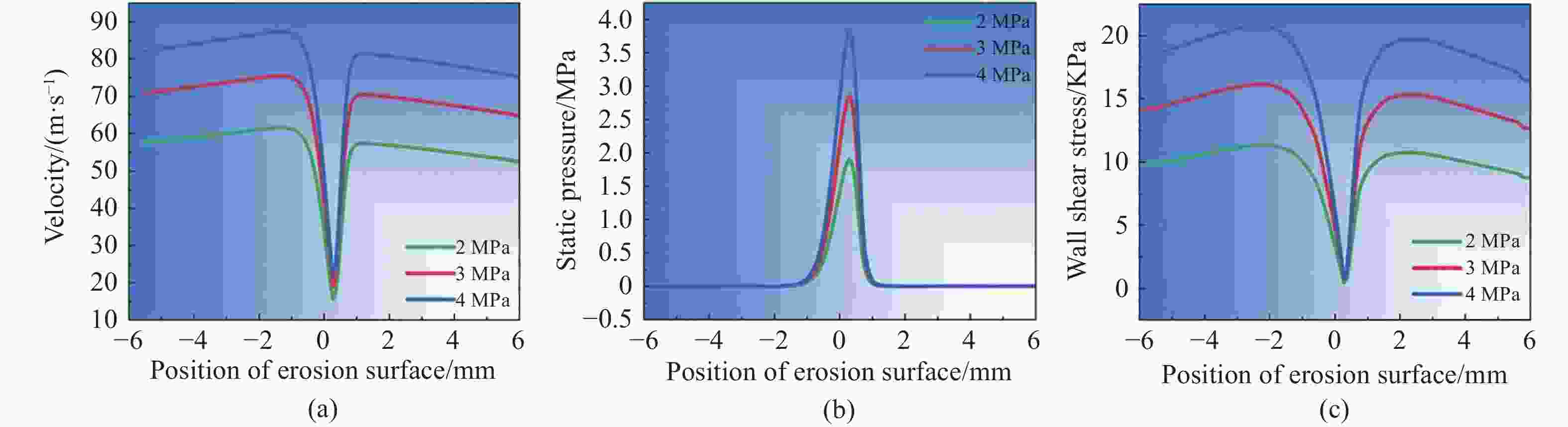

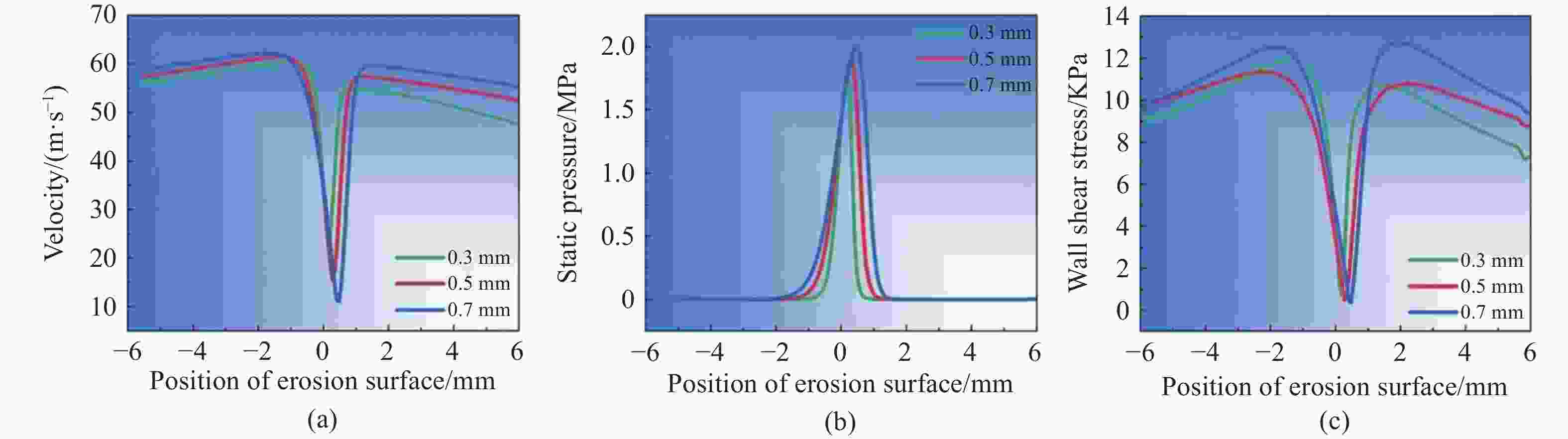

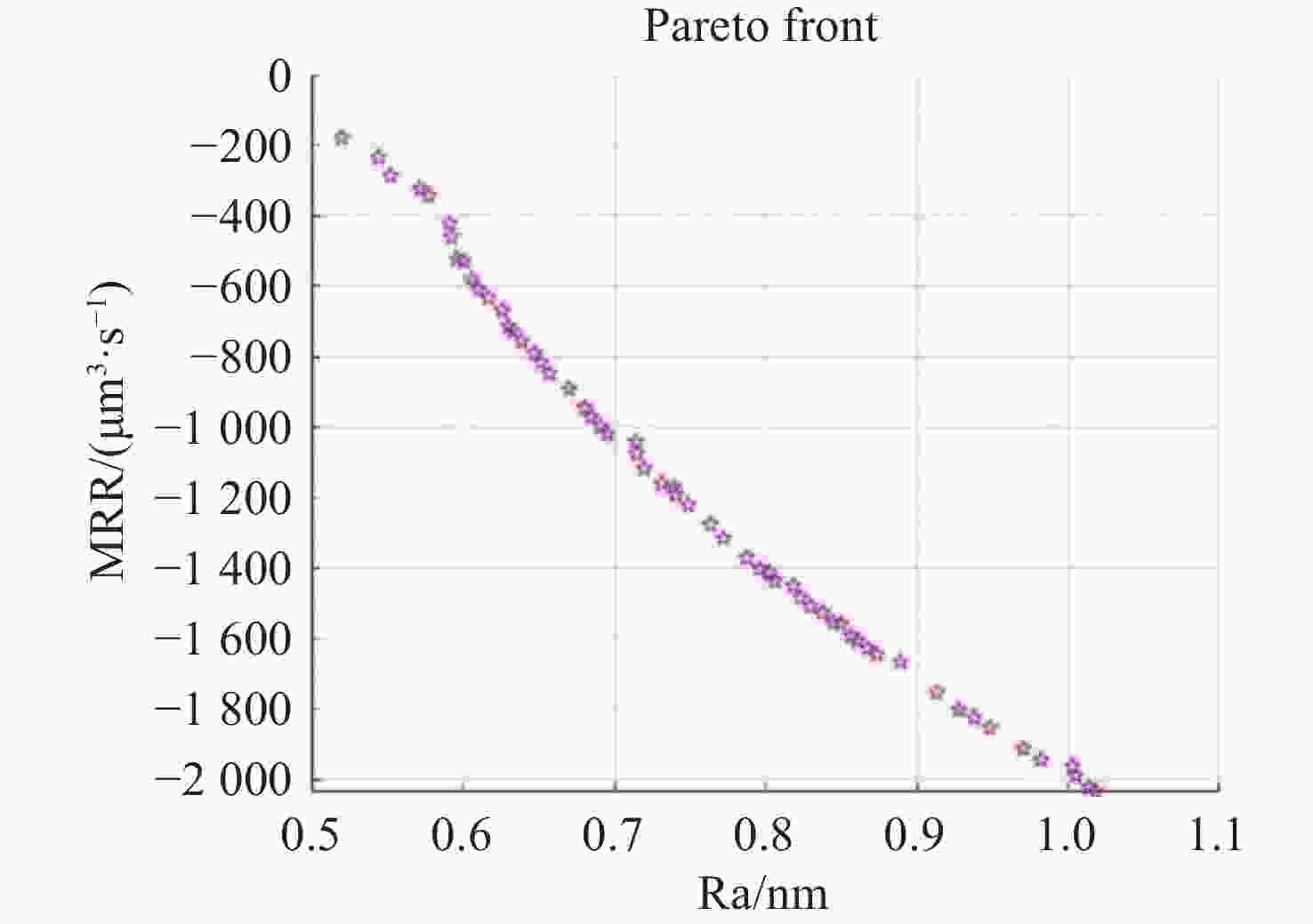

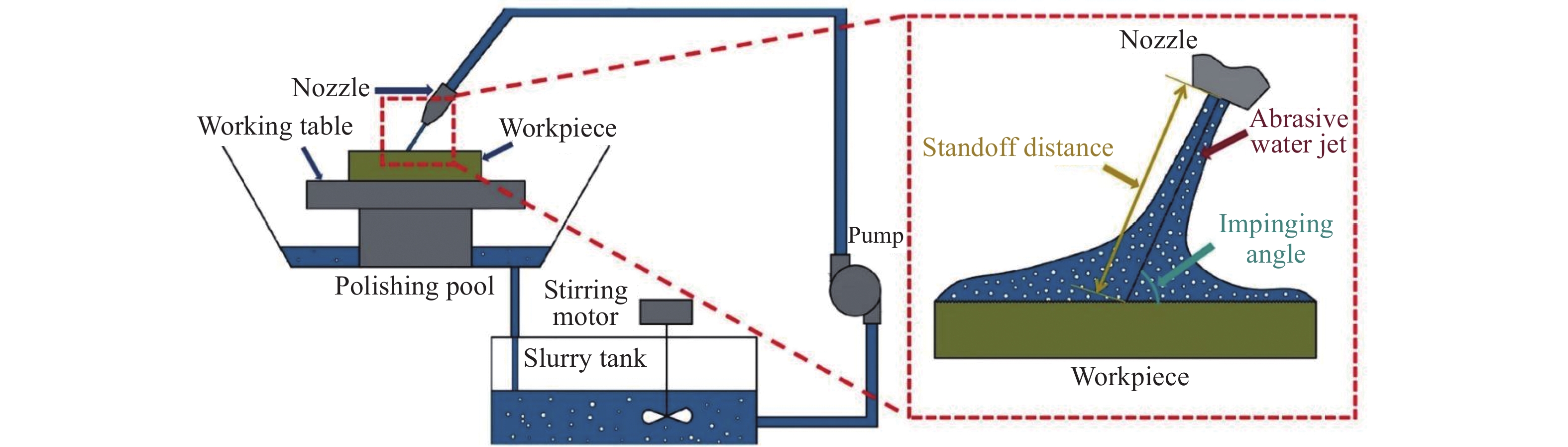

磨料水射流抛光技术作为一种非接触式超精密加工方法,凭借其稳定的材料去除函数、无亚表面损伤特性及强形状适应性,在光学元件加工领域具有重要应用价值。本研究通过计算流体动力学(CFD)数值模拟方法,系统分析了射流压力、喷嘴直径及入射角度对抛光流场压力分布、速度分布及壁面剪切力分布的作用规律。基于Box-Behnken实验设计,构建了响应面回归模型,系统研究了工艺参数对熔石英玻璃的材料去除率(MRR)和表面粗糙度(Ra)的影响机制。实验结果表明:通过增大射流压力和喷嘴直径可显著提高MRR,该规律与流场仿真揭示的剪切应力分布特征一致;但增大射流压力和入射角度会导致Ra增大,不利于表面质量提升。通过遗传算法(GA)多目标优化建立Pareto解集,成功实现了加工效率与表面质量的协同优化,在射流压力2 MPa、喷嘴直径0.3mm和入射角度30°的参数组合下MRR达169.05 μm³/s、Ra低至0.50 nm;实验验证表明,模型预测值与实测值误差仅为4.4%(MRR)和3.8%(Ra),验证了模型的可靠性。本研究建立的参数优化体系为复杂曲面光学元件的超精密抛光提供了理论依据与技术支持。

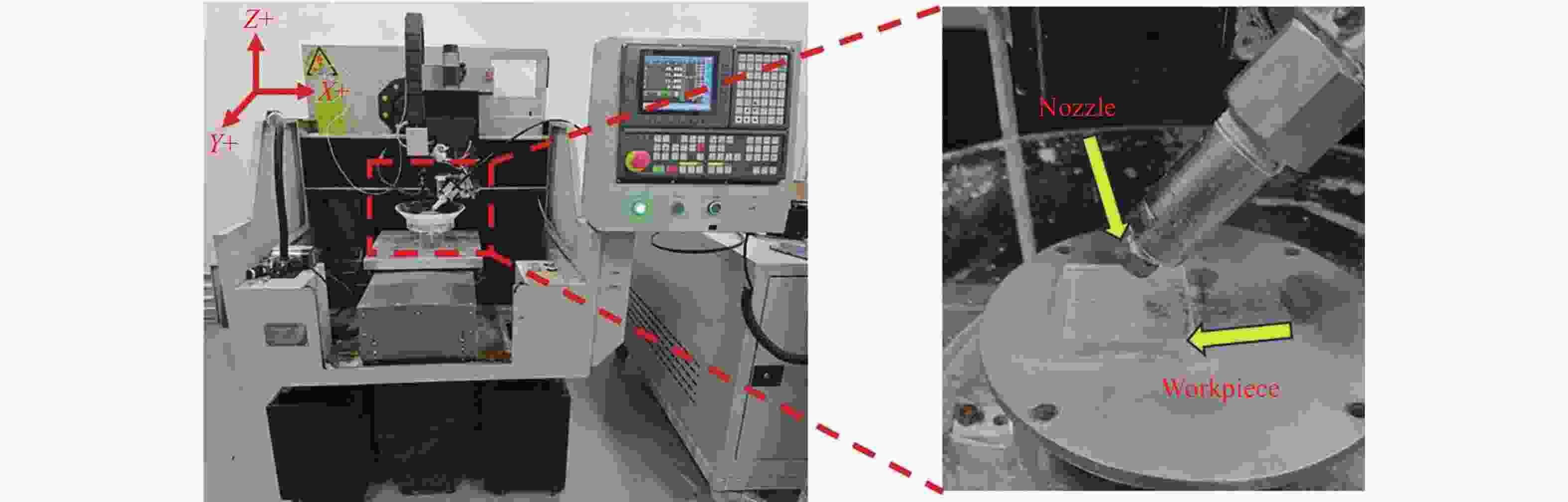

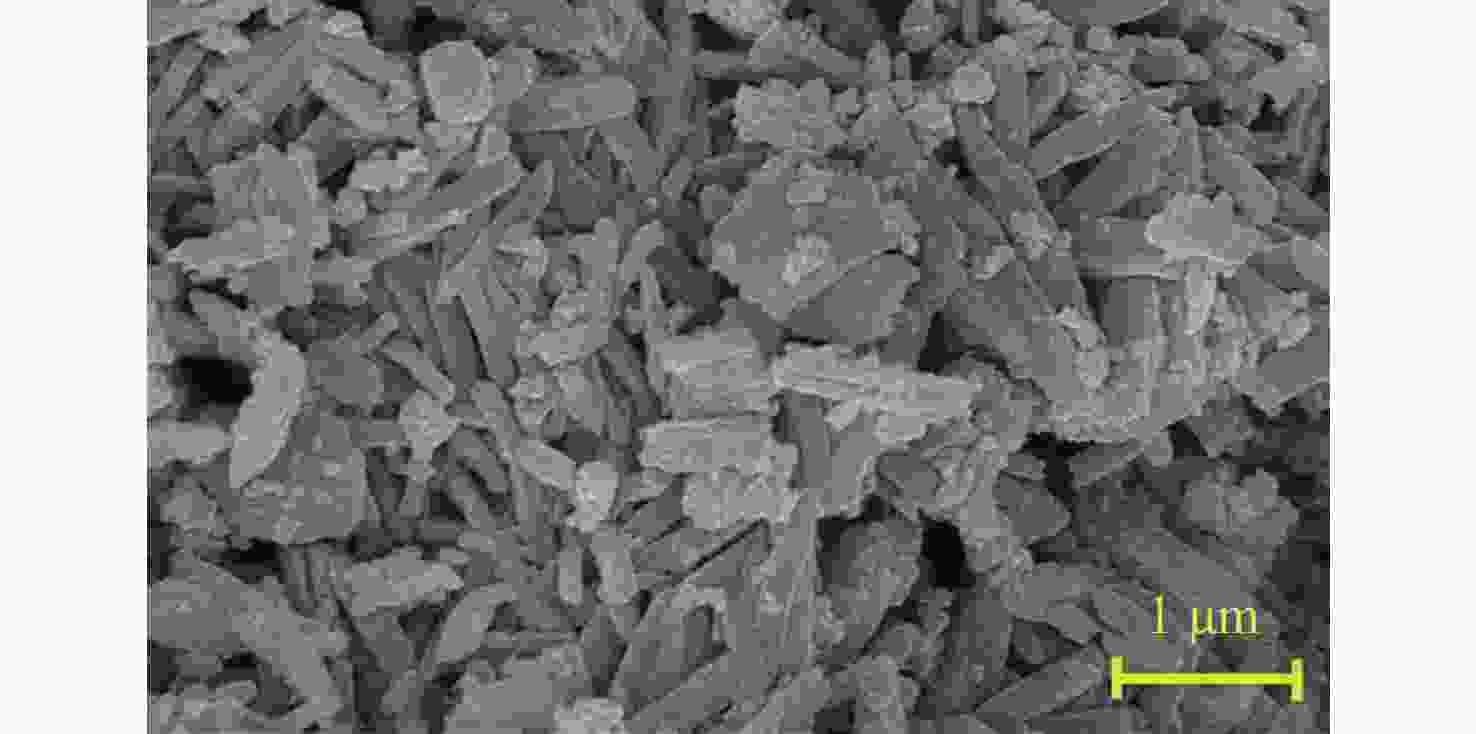

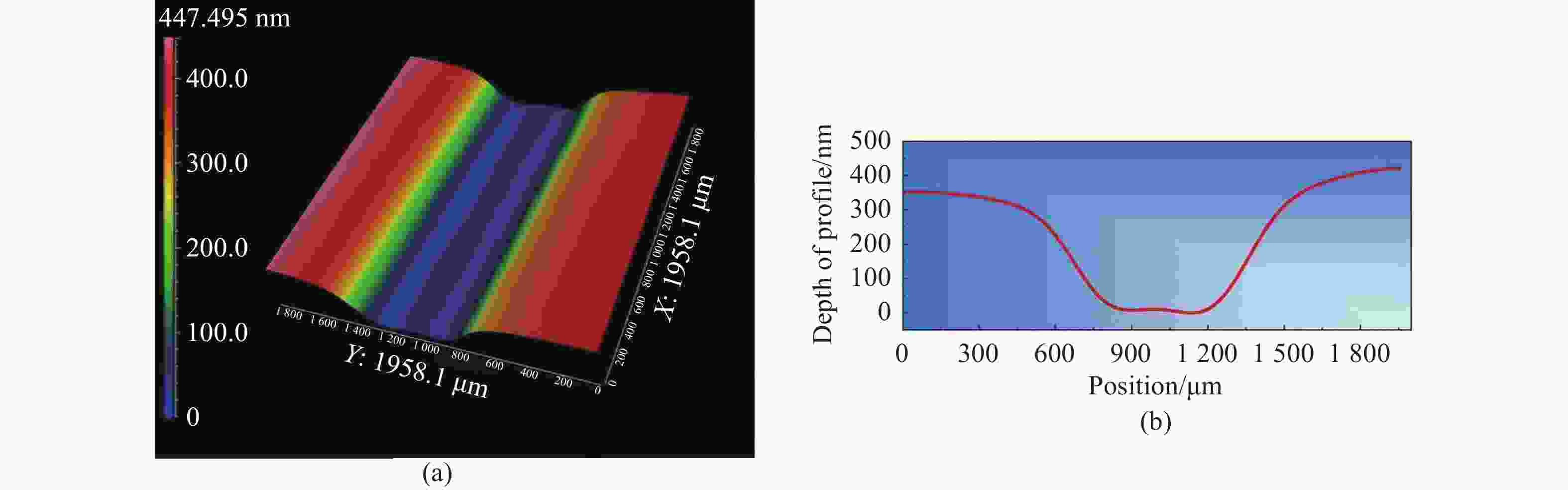

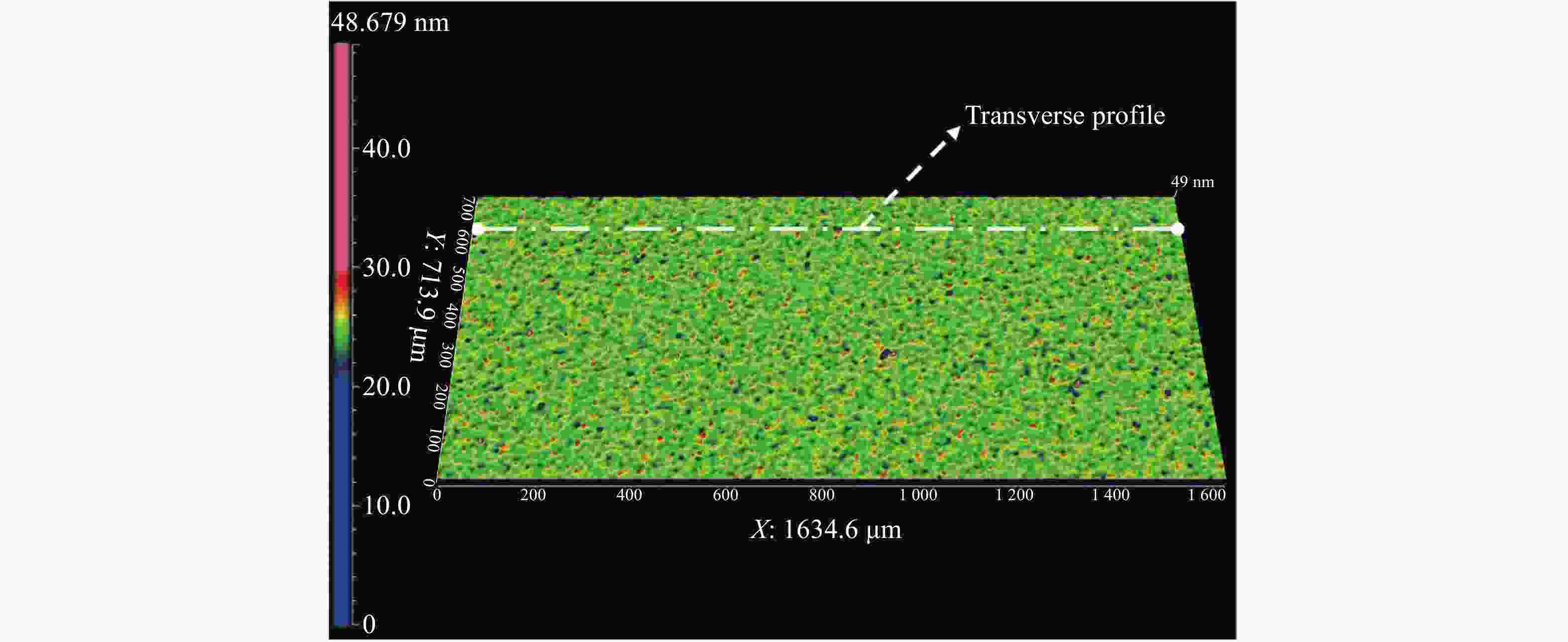

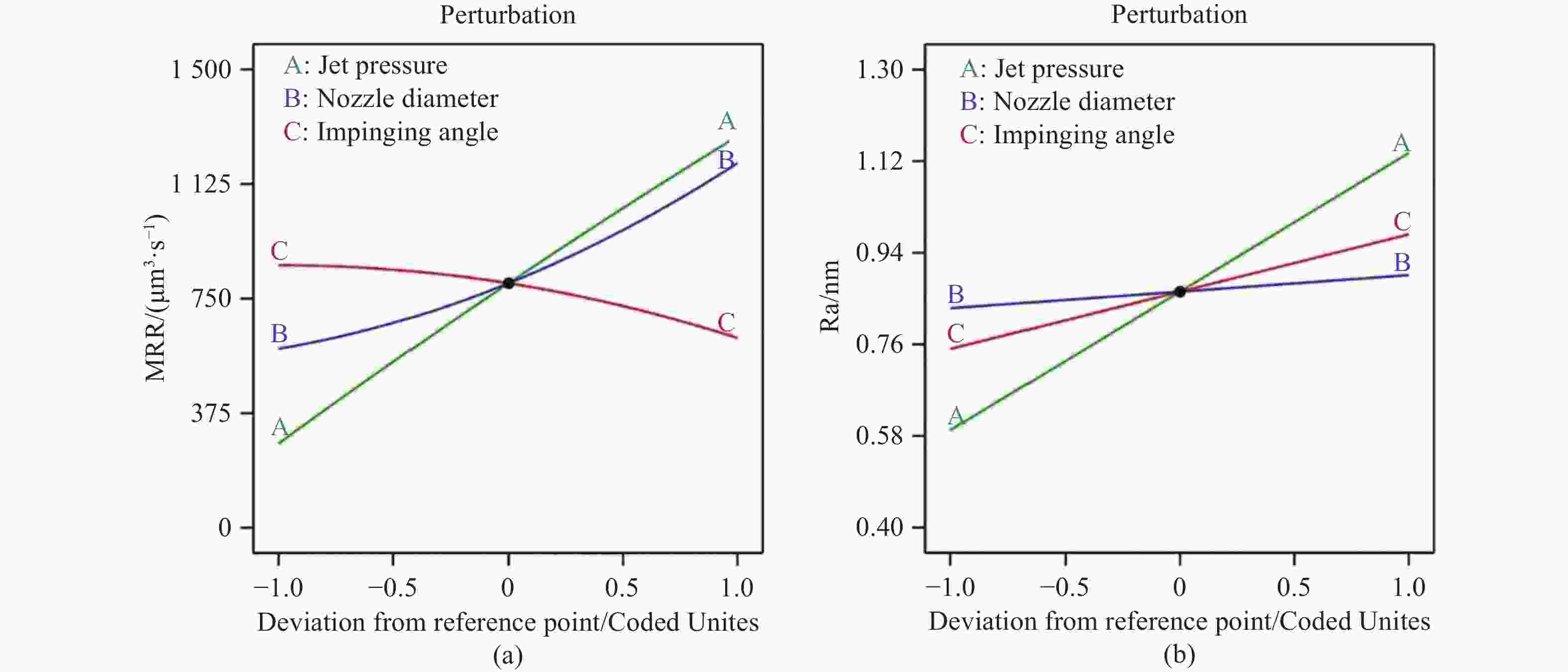

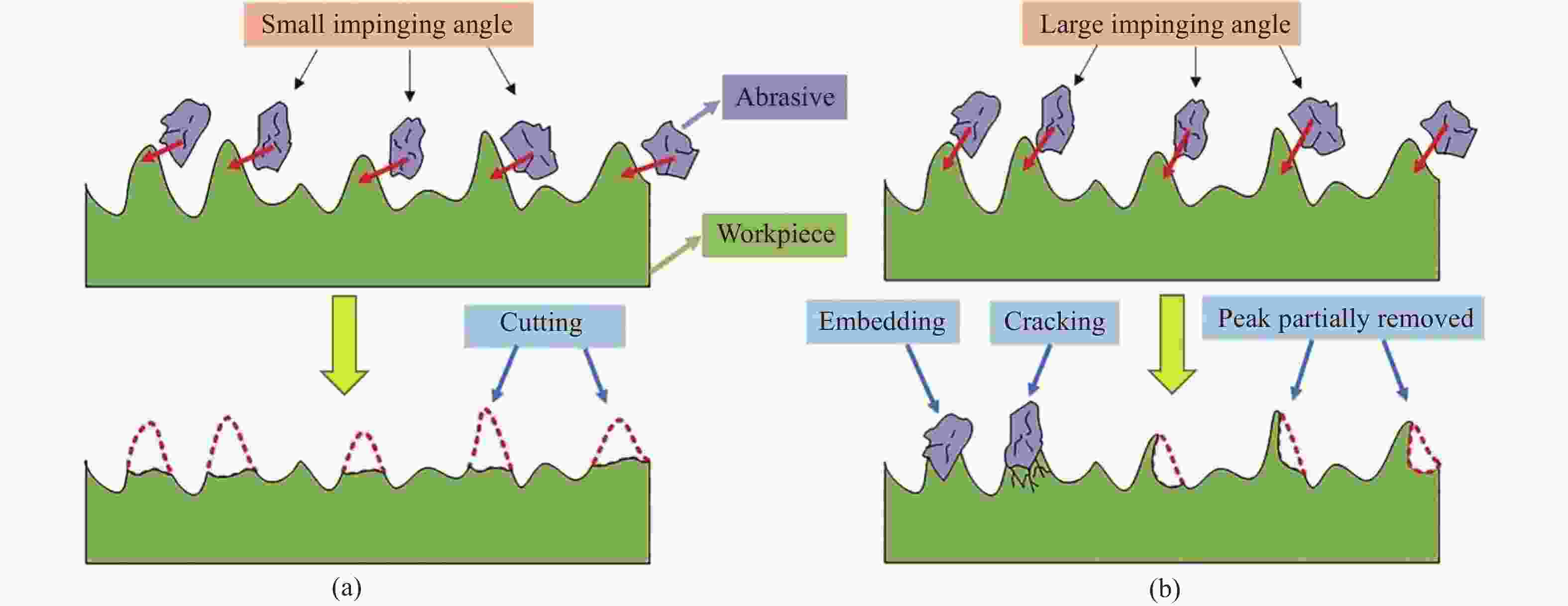

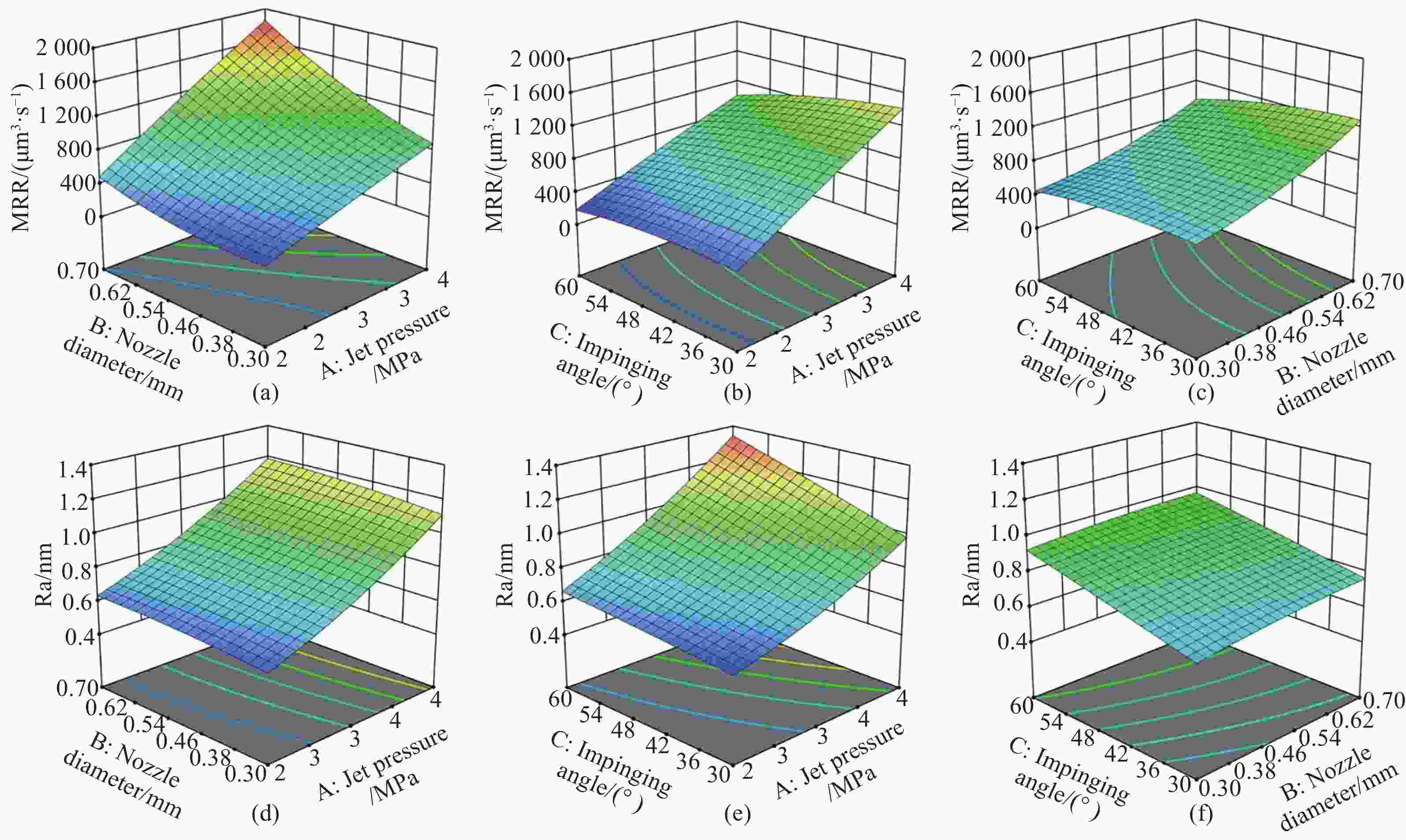

Abstract:As a non-contact ultra-precision machining method, abrasive water jet polishing (AWJP) has significant application in optical elements processing due to its stable tool influence function (TIF), no subsurface damage and strong adaptability to workpiece shapes. In this study, the effects of jet pressure, nozzle diameter and impinging angle on the distribution of pressure, velocity and wall shear stress in the polishing flow field were systematically analyzed by computational fluid dynamics (CFD) simulation. Based on the Box-Behnken experimental design, a response surface regression model was constructed to investigate the influence mechanism of process parameters on material removal rate (MRR) and surface roughness (Ra) of fused silica. And experimental results showed that increasing jet pressure and nozzle diameter significantly improved MRR, consistent with shear stress distribution revealed by CFD simulations. However, increasing jet pressure and impinging angle caused higher Ra values, which was unfavorable for surface quality improvement. Genetic algorithm (GA) was used for multi-objective optimization to establish Pareto solutions, achieving concurrent optimization of polishing efficiency and surface quality. A parameter combination of 2 MPa jet pressure, 0.3 mm nozzle diameter, and 30° impinging angle achieved MRR of 169.05 μm³/s and Ra of 0.50 nm. Experimental verification showed prediction errors of 4.4% (MRR) and 3.8% (Ra), confirming model reliability. This parameter optimization system provides theoretical basis and technical support for ultra-precision polishing of complex curved optical components.

-

Table 1. AWJP parameters

AWJP parameters levels −1 0 1 Jet pressure (MPa) 2 3 4 Nozzle diameter (mm) 0.3 0.5 0.7 Impinging angle (°) 30 45 60 Table 2. The results of the response surface regression experiments

AWJP parameters Output responses Run jet pressure (MPa) nozzle diameter (mm) impinging angle (°) MRR (μm3/s) Ra (nm) 1 2 0.5 30 262.75 0.56 2 4 0.3 45 907.42 1.12 3 3 0.5 45 735.50 0.81 4 3 0.5 45 846.42 0.87 5 2 0.3 45 221.42 0.55 6 3 0.5 45 766.75 0.86 7 3 0.5 45 821.33 0.80 8 4 0.7 45 1873.25 1.22 9 2 0.5 60 208.67 0.71 10 4 0.5 30 1391.92 0.94 11 3 0.3 60 439.33 0.91 12 3 0.3 30 613.08 0.72 13 4 0.5 60 1011.42 1.35 14 3 0.5 45 831.25 0.92 15 2 0.7 45 470.08 0.63 16 3 0.7 60 961.42 0.93 17 3 0.7 30 1304.92 0.78 Table 3. Analysis of variance for MRR

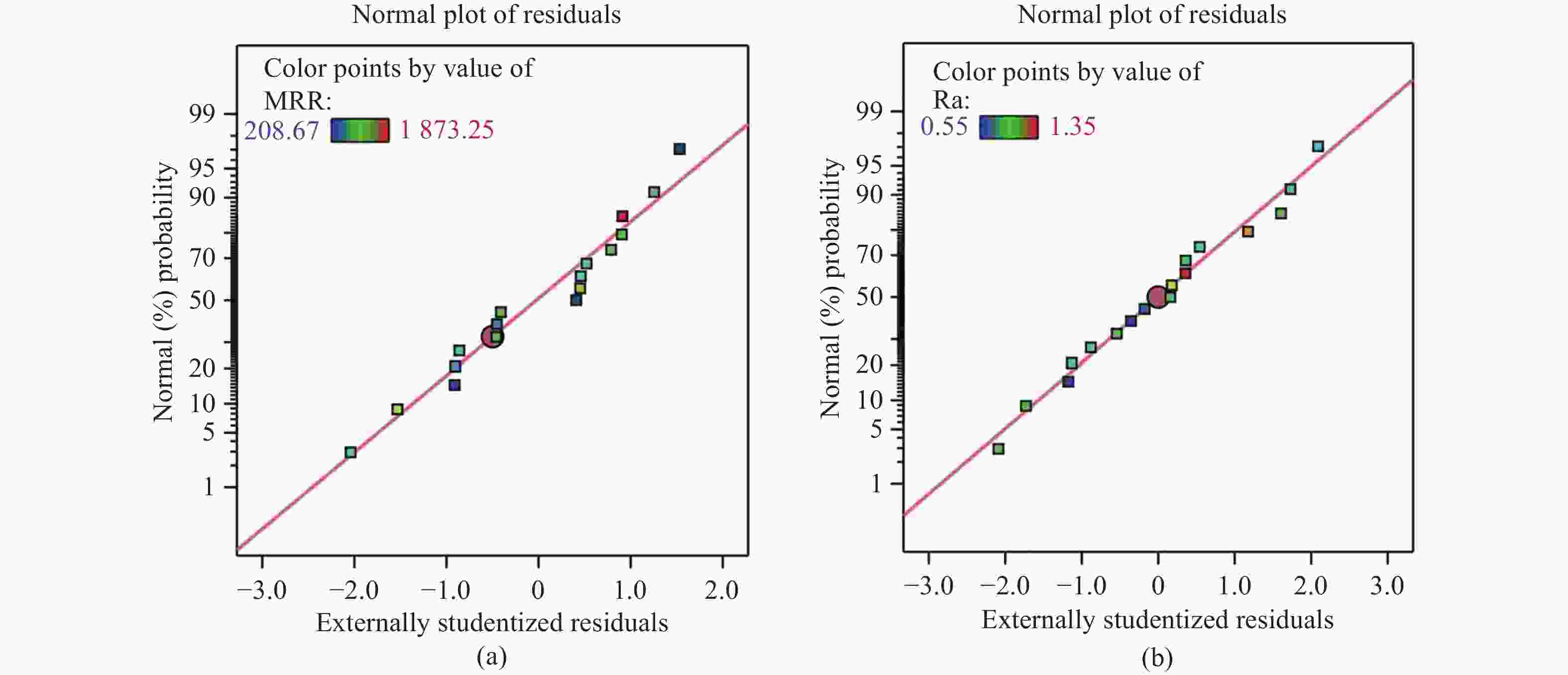

Source Sum of squares Degree of Freedom Mean square F-value P-value Significance Model 3.082$ e $+06 9 3.425$ e $+05 187.33 < 0.0001 significant A-jet pressure 2.021$ e $+06 1 2.021$ e $+06 1105.56 < 0.0001 B-nozzle diameter 7.372$ e $+05 1 7.372$ e $+05 403.22 < 0.0001 C-impinging angle 1.132$ e $+05 1 1.132$ e $+05 61.95 0.0001 AB 1.286$ e $+05 1 1.286$ e $+05 70.33 < 0.0001 AC 26637.50 1 26637.50 14.57 0.0066 BC 7203.77 1 7203.77 3.94 0.0875 A2 1964.92 1 1964.92 1.07 0.3343 B2 33648.28 1 33648.28 18.41 0.0036 C2 15136.43 1 15136.43 8.28 0.0237 Residual 12797.12 7 1828.16 Lack of Fit 3945.28 3 1315.09 0.5943 0.6512 not significant Pure Error 8851.85 4 2212.96 Cor Total 3.095$ \mathrm{e} $$ e $+06 16 Table 5. Fit statistics of ANOVA

Std.Dev. Mean C.V.% R2 Adjusted R2 Predicted R2 Adeq Precision MRR 42.76 803.94 5.32 0.9959 0.9905 0.9751 51.073 Ra 0.0524 0.8635 6.07 0.9743 0.9413 0.7717 19.1547 Table 4. Analysis of variance for Ra

Source Sum of squares Degree of Freedom Mean square F-value P-value Significance Model 0.7290 9 0.0810 29.48 < 0.0001 significant A-jet pressure 0.5940 1 0.5940 216.24 < 0.0001 B-nozzle diameter 0.0084 1 0.0084 3.08 0.1229 C-impinging angle 0.1012 1 0.1012 36.86 0.0005 AB 0.0001 1 0.0001 0.0364 0.8541 AC 0.0169 1 0.0169 6.15 0.0422 BC 0.0004 1 0.0004 0.1456 0.7141 A2 0.0073 1 0.0073 2.64 0.1483 B2 0.0008 1 0.0008 0.2793 0.6135 C2 0.0001 1 0.0001 0.0188 0.8949 Residual 0.0192 7 0.0027 Lack of Fit 0.0098 3 0.0033 1.37 0.3720 not significant Pure Error 0.0095 4 0.0024 Cor Total 0.7482 16 Table 6. Partial Pareto solution set for multi-objective optimization

run A B C $ f(MRR) $ $ f(Ra) $ 1 2.00 0.3 30 176.86 0.52 2 2.10 0.3 30 218.77 0.53 3 3.90 0.7 30 1955.06 0.99 4 2.32 0.7 30 743.00 0.64 5 2.00 0.6 30 390.57 0.59 6 2.68 0.7 30 1045.99 0.70 7 3.93 0.7 30 1982.46 1.00 8 2.10 0.7 30 512.08 0.60 9 4.00 0.7 30 2036.53 1.02 10 3.25 0.7 30 1473.19 0.82 11 2.96 0.7 30 1253.51 0.76 12 3.20 0.7 30 1433.27 0.81 ··· ··· ··· ··· Table 7. Comparative analysis of experiments

Run Indicator Pareto solutions Experimental value Error 1 MRR

(μm3/s)176.86 169.05 4.4% 8 512.08 507.65 0.9% 11 1253.51 1247.25 0.5% 1 Ra(nm) 0.52 0.50 3.8% 8 0.60 0.58 3.3% 11 0.76 0.78 2.6% -

[1] ZHANG H L, LIU H, XU W B, et al. Large aperture diffractive optical telescope: a review[J]. Optics & Laser Technology, 2020, 130: 106356. [2] WANG H, ZHAO K, SHEN H, et al. Experimental study on direct fabrication of micro channel on fused silica by picosecond laser[J]. Journal of Manufacturing Processes, 2020, 55: 87-95. doi: 10.1016/j.jmapro.2020.03.057 [3] RASHEED I A, CHHABRA I M, GUPTA M K, et al. Surface preparation and analysis on fused silica glass substrate with deterministic grinding method[J]. Materials Today: Proceedings, 2021, 46: 8239-8247. doi: 10.1016/j.matpr.2021.03.221 [4] ZHAO J, HUANG J F, WANG R, et al. Investigation of the optimal parameters for the surface finish of K9 optical glass using a soft abrasive rotary flow polishing process[J]. Journal of Manufacturing Processes, 2020, 49: 26-34. doi: 10.1016/j.jmapro.2019.11.011 [5] CAO ZH CH, WANG M, YAN SH Q, et al. Surface integrity and material removal mechanism in fluid jet polishing of optical glass[J]. Journal of Materials Processing Technology, 2023, 311: 117798. doi: 10.1016/j.jmatprotec.2022.117798 [6] CAO ZH CH, WANG M, LIU H T, et al. Modeling and analysis for material removal and surface roughness in fluid jet polishing of optical glass[J]. Friction, 2024, 12(7): 1548-1563. doi: 10.1007/s40544-023-0832-9 [7] WANG C J, CHEUNG C F, LIU M Y. Numerical modeling and experimentation of three dimensional material removal characteristics in fluid jet polishing[J]. International Journal of Mechanical Sciences, 2017, 133: 568-577. doi: 10.1016/j.ijmecsci.2017.09.018 [8] CARON J, BAUMER S. Progress in freeform mirror design for space applications[J]. Proceedings of SPIE, 2021, 11852: 118521S. [9] YANG ZH CH, ZHU L D, ZHANG G X, et al. Review of ultrasonic vibration-assisted machining in advanced materials[J]. International Journal of Machine Tools and Manufacture, 2020, 156: 103594. doi: 10.1016/j.ijmachtools.2020.103594 [10] KUMAR S, TONG ZH, JIANG X Q. Advances in the design and manufacturing of novel freeform optics[J]. International Journal of Extreme Manufacturing, 2022, 4(3): 032004. doi: 10.1088/2631-7990/ac7617 [11] WAN S L, WEI CH Y, HU CH, et al. Novel magic angle-step state and mechanism for restraining the path ripple of magnetorheological finishing[J]. International Journal of Machine Tools and Manufacture, 2021, 161: 103673. doi: 10.1016/j.ijmachtools.2020.103673 [12] FÄHNLE O W, VAN BRUG H, FRANKENA H J. Fluid jet polishing of optical surfaces[J]. Applied Optics, 1998, 37(28): 6771-6773. doi: 10.1364/AO.37.006771 [13] FÄHNLE O W. Shaping and finishing of aspherical optics L surfaces[D]. Delft: Delft University of Technology, 1998. [14] FÄHNLE O W, HAUSER K. Abrasive jet polishing approaches to the manufacture of micro-optics with complex shapes[C]. Optical Fabrication and Testing 2012, Optica Publishing Group, 2012. (查阅网上资料, 未找到本条文献页码, 请确认). [15] FAEHNLE O, DOETZ M, DAMBON O. Analysis of critical process parameters of ductile mode grinding of brittle materials[J]. Advanced Optical Technologies, 2017, 6(5): 349-358. doi: 10.1515/aot-2017-0045 [16] ZHANG L, DING CH, HAN Y J, et al. Investigation into a novel pulsating cavitation air jet polishing method for Ti-6Al-4V alloy[J]. Tribology International, 2022, 175: 107837. doi: 10.1016/j.triboint.2022.107837 [17] CHEN F J, MIAO X L, TANG Y, et al. A review on recent advances in machining methods based on abrasive jet polishing (AJP)[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1-4): 785-799. doi: 10.1007/s00170-016-9405-7 [18] PAWLUS P, REIZER R, KROLCZYK G M. Modelling and prediction of surface textures after abrasive machining processes: a review[J]. Measurement, 2023, 220: 113337. doi: 10.1016/j.measurement.2023.113337 [19] ZHAO J, GE J Y, KHUDOLEY A, et al. Numerical and experimental investigation on the material removal profile during polishing of inner surfaces using an abrasive rotating jet[J]. Tribology International, 2024, 191: 109125. doi: 10.1016/j.triboint.2023.109125 [20] ZHU H T, HUANG C Z, WANG J, et al. Experimental study on abrasive waterjet polishing for hard–brittle materials[J]. International Journal of Machine Tools and Manufacture, 2009, 49(7-8): 569-578. doi: 10.1016/j.ijmachtools.2009.02.005 [21] MATSUMURA T, MURAMATSU T, FUEKI S. Abrasive water jet machining of glass with stagnation effect[J]. CIRP Annals, 2011, 60(1): 355-358. doi: 10.1016/j.cirp.2011.03.118 [22] LI Z Z, WANG J M, PENG X Q, et al. Removal of single point diamond-turning marks by abrasive jet polishing[J]. Applied Optics, 2011, 50(16): 2458-2463. doi: 10.1364/AO.50.002458 [23] TSAI F C, YAN B H, KUAN C Y, et al. A Taguchi and experimental investigation into the optimal processing conditions for the abrasive jet polishing of SKD61 mold steel[J]. International Journal of Machine Tools and Manufacture, 2008, 48(7-8): 932-945. doi: 10.1016/j.ijmachtools.2007.08.019 [24] WANG C J, CHEUNG C F, HO L T, et al. A novel multi-jet polishing process and tool for high-efficiency polishing[J]. International Journal of Machine Tools and Manufacture, 2017, 115: 60-73. doi: 10.1016/j.ijmachtools.2016.12.006 [25] KUMARAN S T, KO T J, UTHAYAKUMAR M, et al. Prediction of surface roughness in abrasive water jet machining of CFRP composites using regression analysis[J]. Journal of Alloys and Compounds, 2017, 724: 1037-1045. doi: 10.1016/j.jallcom.2017.07.108 [26] CAO ZH CH, CHEUNG B C F, KONG L B. Computational fluid dynamics–based analysis of material removal characteristics in fluid jet polishing[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2016, 230(6): 1035-1048. doi: 10.1177/0954405414564809 [27] ZHANG Z L, CHEUNG C F, GUO J, et al. Pressure-dependent material removal rate model of fluid jet polishing[J]. International Journal of Mechanical Sciences, 2024, 281: 109517. doi: 10.1016/j.ijmecsci.2024.109517 [28] YANG Y Y, YANG M, LI CH H, et al. Machinability of ultrasonic vibration-assisted micro-grinding in biological bone using nanolubricant[J]. Frontiers of Mechanical Engineering, 2023, 18(1): 1. doi: 10.1007/s11465-022-0717-z [29] XIA Z B, FANG F ZH, AHEARNE E, et al. Advances in polishing of optical freeform surfaces: a review[J]. Journal of Materials Processing Technology, 2020, 286: 116828. doi: 10.1016/j.jmatprotec.2020.116828 [30] LI J H, MA W H, HOU X. Modeling and experiment on elastic material removal in nanoparticle jet polishing[J]. Journal of Manufacturing Processes, 2024, 120: 317-336. doi: 10.1016/j.jmapro.2024.04.033 [31] CHEUNG C F, WANG C J, CAO Z C, et al. Development of a multi-jet polishing process for inner surface finishing[J]. Precision Engineering, 2018, 52: 112-121. doi: 10.1016/j.precisioneng.2017.11.018 [32] ZHANG X P, YAO P, ZHOU P F, et al. Removal mechanism and grinding performance of ZTA nanocomposite ceramics using ternary-hybrid nanofluid minimum quantity lubrication technology[J]. Journal of Manufacturing Processes, 2024, 132: 1-13. doi: 10.1016/j.jmapro.2024.10.060 [33] QU SH SH, YAO P, GONG Y D, et al. Environmentally friendly grinding of C/SiCs using carbon nanofluid minimum quantity lubrication technology[J]. Journal of Cleaner Production, 2022, 366: 132898. doi: 10.1016/j.jclepro.2022.132898 [34] QU SH SH, WEI CH X, YANG Y Y, et al. Grinding mechanism and surface quality evaluation strategy of single crystal 4H-SiC[J]. Tribology International, 2024, 194: 109515. doi: 10.1016/j.triboint.2024.109515 [35] QU SH SH, YAO P, GONG Y D, et al. Modelling and grinding characteristics of unidirectional C-SiCs[J]. Ceramics International, 2022, 48(6): 8314-8324. doi: 10.1016/j.ceramint.2021.12.036 [36] GREENLAND S, SENN S J, ROTHMAN K J, et al. Statistical tests, P values, confidence intervals, and power: a guide to misinterpretations[J]. European Journal of Epidemiology, 2016, 31(4): 337-350. doi: 10.1007/s10654-016-0149-3 [37] MONTGOMERY D C. Design and Analysis of Experiments[M]. 2nd ed. Hoboken: John Wiley & Sons, 1983. [38] AMUTHA J, SHARMA S, SHARMA S K. Strategies based on various aspects of clustering in wireless sensor networks using classical, optimization and machine learning techniques: review, taxonomy, research findings, challenges and future directions[J]. Computer Science Review, 2021, 40: 100376. doi: 10.1016/j.cosrev.2021.100376 -

下载:

下载: