Identification of the zinc dispersion in rubber blends by libs with a Nd: YAG laser

-

摘要: 激光诱导击穿光谱是一种基于激光的定性、定量分析化学元素的方法,可用于分析混合室中的橡胶共混物。本文采用波长为1 064 nm、脉冲能量为100 mJ的Nd: YAG激光诱导击穿光谱法检测橡胶共混物中锌的分散情况。实验表明,正确混料决定了橡胶产品的质量,较短的混合时间将会导致混料的不均匀分散;焦距等参数设置对光谱线强度影响较大。激发标定样品可产生标定曲线。通过行扫描可分析锌在橡胶共混物中的分散情况。通过估算沿着行扫描方向的强度分布,可检测由于混合时间较短和旋转速度不同而引起的锌均匀性变化。

-

关键词:

- 激光诱导击穿光谱 /

- 橡胶 /

- Nd: YAG激光器 /

- 锌

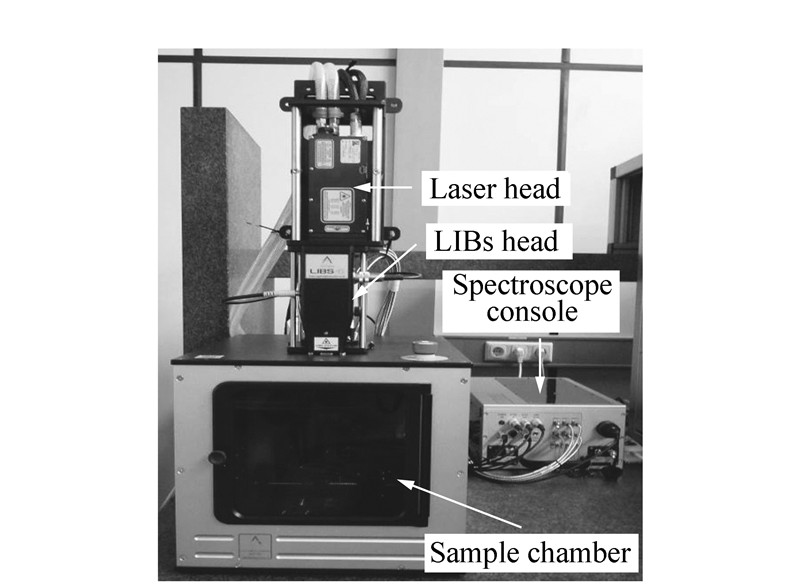

Abstract: Laser-induced breakdown spectroscopy(LIBS) is a laser based method for the qualitative and quantitative analysis of chemical elements. It could be used for the analysis of rubber blends in the mixing room. In this paper, zinc dispersion in rubber blends is detected with LIBS by using a Nd: YAG laser with a wavelength of 1 064 nm and a pulse energy of 100 mJ. Experiments show that the quality of rubber products depends on the correct blending of the mixing components. For example short mixing times can lead to an inhomogeneous dispersion of these components. The intensity of the spectral lines is strongly affected by the setup parameters like the focal position. The use of calibration samples allows creating a calibration curve. Based on line scans, the zinc dispersion in these rubber blends can be analyzed. Variations in the homogeneity of the zinc caused by short mixing times or different rotation speed of the mixer can be detected by the evaluation of the intensity profile along these line scans.-

Key words:

- LIBS /

- rubber /

- Nd: YAG-Laser /

- zinc

-

Table Table 1. Spectroscope specification

Spectroscope Wavelength/nm Grating Resolution/nm 1 314-416 3 600 0.06 2 414-498 2 400 0.09 3 496-718 1 200 0.18 4 716-904 1 200 0.18 5 804-977 1 200 0.18 Table Table 2. Variation coefficient of the zinc intensity at 481.1 nm of different line scans for a mixing process with 40(sample A) and 70(sample B) revolutions per minute

Line scan Variation coefficient/% sample A sample B 1 31.8 7.8 2 37.0 7.8 3 26.3 12.6 4 29.4 7.4 5 30.4 6.7 -

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] -

下载:

下载: