High accuracy alignment of spectral-polarimetric modulator

-

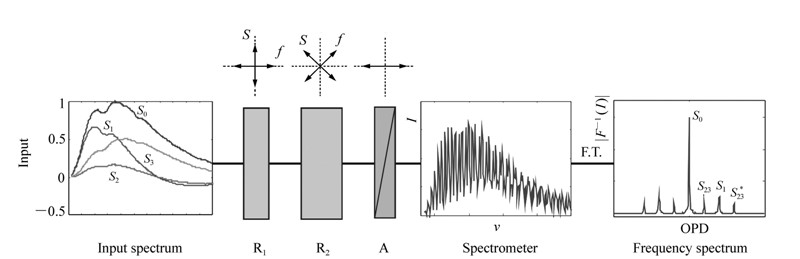

摘要: 为了提高光谱偏振调制器的探测精度,提出了光谱偏振调制器的高精度装调方法。首先,分析了光谱偏振调制器的调制原理,提出了采用三片多级相位延迟器加线偏振器的装调方案;然后,建立了调制器装调的数理模型,设计了校准多级相位延迟器的厚度;最后,对成像过程进行了计算机仿真实验验证,并模拟了成像系统的装调过程。结果表明:利用该方法能够灵敏检测偏振器件间的微小相对旋转角度误差,可实现调制器的高精度装调,在输入本文设定的校准光谱条件下,绝对精度可达0.2°。该方法保留了传统光谱调制器充分利用通道带宽的优势,保证了复原光谱的分辨率,为强度调制型光谱偏振成像系统的精密装调提供了一定的理论参考。Abstract: To improve the detecting precision of the spectral-polarimetric modulator, a high accuracy alignment of the modulator is established.First, based on the modulation principle of the spectral-polarimetric modulator, a method of alignment using three pieces of thick birefringent retarder and an analyzer to correct the errors is proposed in this paper.Then, the corresponding mathematical model is established, and the thickness of the thick birefringent retarder for calibration is designed.Finally, the simulated demonstrations of system alignment and spectral-polarimetric imaging are also presented.The results show that the method is sensitive to the relative rotation angle errors between the polarization devices, which has the ability to realize the precise alignment of the spectral-polarimetric modulator.And the accuracy can reach 0.2°with the input calibration spectrum set in this paper.The method also keeps the advantage of the traditional method, which guarantees the resolution of the reconstructed Stokes parameters.The research provides theoretical reference for the precision alignment of spectral-polarimetric imaging system.

-

Key words:

- spectral-polarimetric imaging /

- intensity modulation /

- system alignment /

- error analysis

-

表 1 校准前后均方差的比较

Table 1. Comparison of variance before and after calibration

Δ0 Δ1 Δ2 Δ3 校准前 1.99×10-5 0.001 8 0.011 2 0.031 4 校准后 1.95×10-5 6.52×10-5 1.82×10-4 2.77×10-4 表 2 不同角度误差时不同通道频谱与中心通道频谱的高度比

Table 2. Height ratio of different channel frequency spectra and center channel frequency spectra in different angle error

0.1° 0.2° 0.3° 0.4° 0.5° 0.6° 0.7° 0.8° 0.9° 1.0° hA/h0 0.000 7 0.001 4 0.002 2 0.002 9 0.003 7 0.004 5 0.005 2 0.006 0 0.006 7 0.007 5 hR1,max/h0 0.000 4 0.000 7 0.001 1 0.001 5 0.001 8 0.002 2 0.002 6 0.003 0 0.003 4 0.003 7 hR2/h0 0.000 7 0.001 4 0.002 2 0.002 9 0.003 7 0.004 4 0.005 2 0.006 0 0.006 7 0.007 5 -

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] -

下载:

下载: