Deposition rate distribution of GdF3 optical coating prepared by ion beam sputtering

-

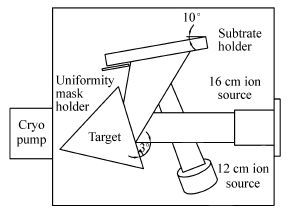

摘要: 本文采用离子束溅射方法制备GdF3薄膜,并研究其沉积速率分布特征。首先,采用膜厚仪测量得出GdF3薄膜在行星盘平面的二维沉积速率分布图,通过拟合模型得到二维沉积速率分布公式。其次,分析了束流束压及靶材角度对沉积速率分布特征的影响。最后,以二维沉积速率分布公式为基础,通过计算机编程设计均匀性挡板,并进行膜厚均匀性实验验证。结果表明,沉积速率在水平方向上满足ECS函数分布,在竖直方向上满足标准Gauss分布,拟合公式残差为2.05×10-6。改变离子源的束流和束压,沉积速率分布特征保持不变。而随着靶材角度的增大,Gauss分布的半峰宽值ω逐渐增大,峰值位置xc逐渐增大,在θ=292°时,GdF3薄膜的沉积速率最大。通过挡板修调实验,可将270 mm口径平面元件的膜厚均匀性调整为97.9%。Abstract: The deposition rate distribution of single GdF3 layer deposited by ion beam sputtering(IBS) has been investigated in this paper. First, Two dimension deposition rate distribution of GdF3 thin films are measured by an UV-film thickness measuring instrument, and the expression of two dimension deposition rate distribution are obtained by using fitting models. Second, the influence of beam current, beam voltage and the angle of target on deposition rate distribution feature is analyzed. Finally, the experiments of thickness uniformity have been carried out using designed mask, based on the expression of two dimension deposition rate. Experimental results indicate that the deposition rate in horizontal direction is satisfied with the ECS function. And in vertical direction it is satisfied with standard Gauss function. The residual error of fitting expression is 2.05×10-6. The feature of deposition rate distribution remains the same when the beam current and beam voltage are changed. With the increase of the target angle, the value of peak width at half height of Gauss function are increased. The peak position is changing, and the maximum of deposition rate can be reached when the target angle is 292°. The thickness uniformity is adjusted to 97.9% for a plane element with radius of 270 mm by using mask.

-

表 1 沉积速率分布公式拟合参数

Table 1. Parameters of fitting expression for deposition rate

A(x) xc A ω a3 a4 268.137 411 977.62 172.314 -2.524 5 3.841 9 ω(x) b0 b1 b2 b3 b4 277.133 -0.503 05 9.24×10-4 -3.507×10-7 3.498×10-8 -

[1] 薛春荣,范正修,邵建达.真空紫外光学薄膜及薄膜材料[J].激光与光电子学进展,2008,45(1):57-64.XUE CH R,FAN ZH X,SHAO J D. Vaccum ultraviolet optical coatings and film materials[J]. Laser & Optoelectronics Progress,2008,45(1):57-64.(in Chinese) [2] 张立超,才玺坤,时光. 深紫外光刻光学薄膜[J].中国光学,2015,8(2):.ZHANG L CH,CAI X K,SHI G. Optical coating for DUV lithography[J]. Chinese Optics,2015,8(2):.(in Chinese) [3] 张立超,高劲松.长春光机所深紫外光学薄膜技术研究进展[J].光学 精密工程,2012,20(11):2395-2401.ZHANG L CH,GAO J S. Developments of DUV coating technologies in CIOMP[J]. Opt. Precision Eng.,2012,20(11):2395-2401.(in Chinese) [4] 才玺坤,张立超,梅林,等.热蒸发和离子束溅射制备LaF3薄膜的光学特性[J].中国光学,2014,.CAI X K,ZHANG L CH,MEI L,et al.. Optical properties of LaF3 thin films prepared by thermalevaporation and ion beam sputtering[J]. Chinese Optics,2014,. [5] DETLEV R. Ion beam sputter coating for laser technology[J]. SPIE,2005,5963:1-12. [6] SVETLANA D,MARK G,ANATOLI C. Ultra-low-reflectance, high-uniformity, multilayer-antireflection coatings on large substrates deposited using a ion-beam sputtering system with a customized planetary rotation stage[J]. SPIE,2011,8168:1-8 [7] 唐晋法,顾培夫,刘旭,等.现代光学薄膜技术[M].杭州:浙江大学出版社,2006.TANG J F,GU P F,LIU X,et al.. Modern Optical Thin Film Technology[M]. Hangzhou:Zhejiang University Press,2006.(in Chinese) [8] 董磊,赵元安,易葵,等.不同类型蒸发源对平面夹具薄膜均匀性的影响[J].强激光与粒子束,2005,17(10):1515-1522.DONG L,ZHAO Y A,YI K,et al.. Influence of different kinds of evaporation sources on films uniformity[J]. High Power Laser and Particle Beams,2005,17(10):1515-1522.(in Chinese) [9] 潘栋梁,熊胜明,张云洞,等.行星夹具膜厚均匀性计算[J].强激光与粒子束,2000,12(3):277-280.PAN D L,XIONG SH M,ZHANG Y D,et al.. Film uniformity calculation of large caliber coating machine[J]. High Power Laser and Particle Beams,2000,12(3):277-280.(in Chinese) [10] 张立超,高劲松.基于遮挡矩阵的膜厚修正挡板的设计[J].光学 精密工程,2013,21(11):2757-2763.ZHANG L CH,GAO J S. Design of uniformity correction masks based on shadow matrix[J]. Opt. Precision Eng.,2013,3676:724-734.(in Chinese) [11] 张以忱,等.真空镀膜技术[M].北京:冶金工业出版社,2009.ZHANG Y SH,et al.. Vacuum Coating Technology[M]. Beijing: Metallurgical Industry Press,2009.(in Chinese) [12] GROSS M,DLIGATCH S,CHTANOV A. Optimization of coating uniformity in an ion beam sputtering system using a modified planetary rotation method[J]. Applied Optics,2011,50(9):C316-C320. [13] 汤雪飞,范修正,王之江.离子束溅射沉积光学薄膜速率分布[J].中国激光,1992,A20(5):345-348.TANG X F,FAN ZH X,WANG ZH J. Optical coating deposition rate distribution by ion beam sputtering[J]. Chinese J. Lasers,1992,A20(5):345-348.(in Chinese) [14] AKIO F. Calculation of thickness distribution for ion beam sputter deposition[J]. J. Vac. Sci. Technol.,1991,A 9(1):141. [15] 刘金声.离子束沉积薄膜技术及应用[M].北京:国防工业出版社,2003.LIU J SH. Ion Beam Deposition Film Technology and Application[M]. Beijing:National Defence of Industry Press,2003.(in Chinese) [16] 盛骤,谢式千,潘承毅.概率论与数理统计[M].北京:高等教育出版社,2005.SHENG ZH,XIE SH Q,PAN CH Y,et al.. Probability Theory & Mathematical Statistics[M]. Beijing:Higher Education Press,2005.(in Chinese) [17] 邹斯勤,靖大为.累计量算法原理及应用[J].华北电力技术,1985.ZOU S Q,JING D W. Cumulant algorithm principle and application[J]. North China Electric Power,1985,3(3):1-12(in Chinese) -

下载:

下载: