A high precision image angular displacement measurement device with self-adaptive installation

-

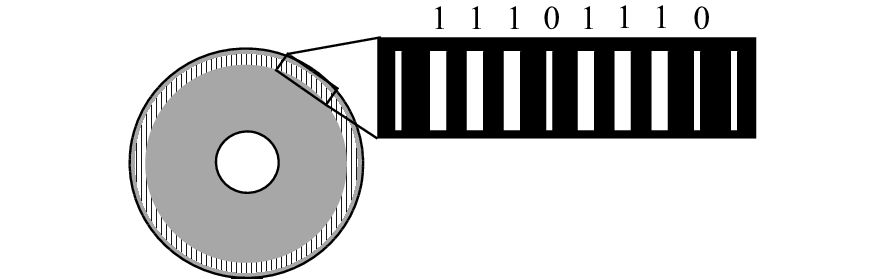

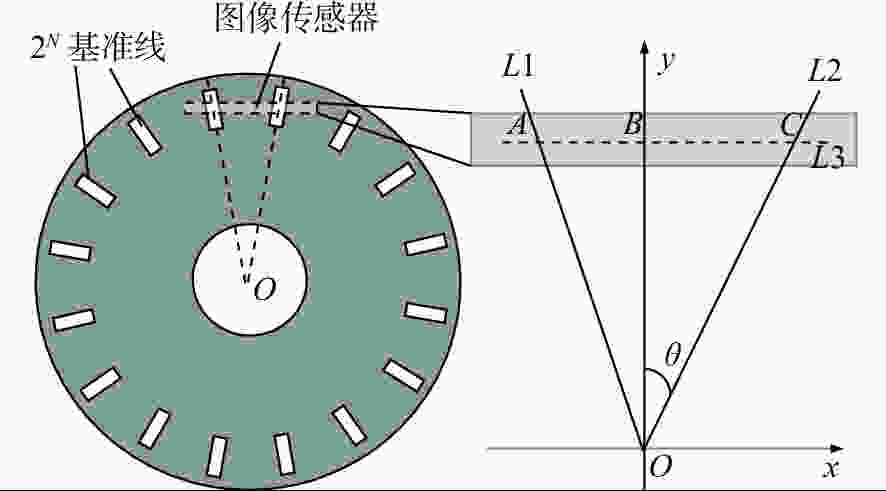

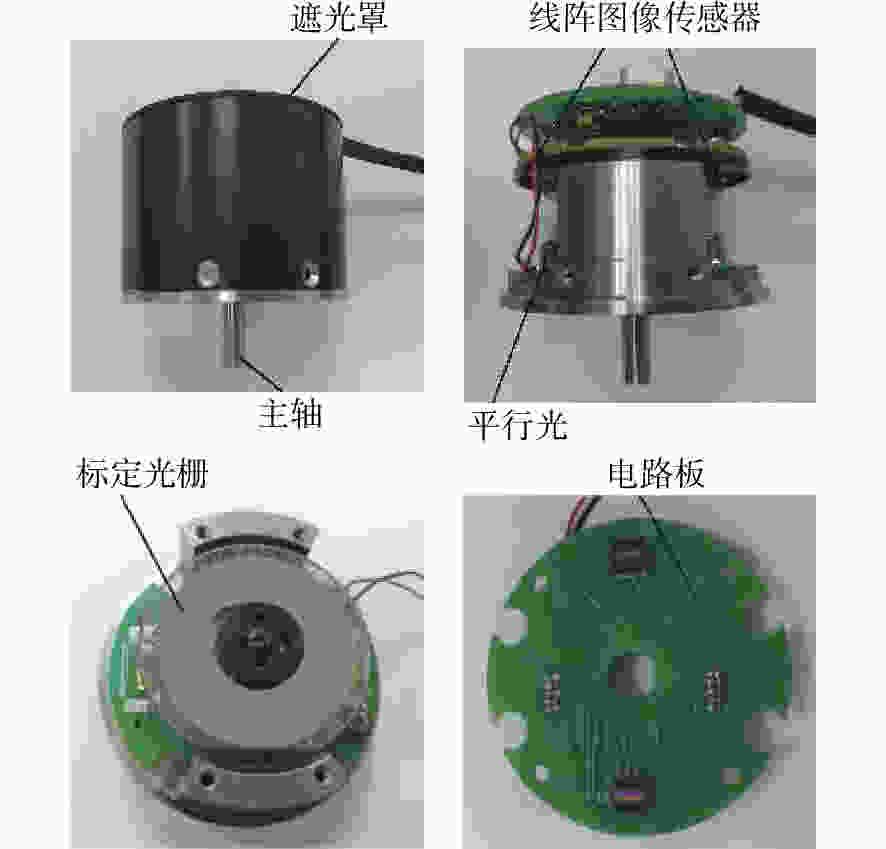

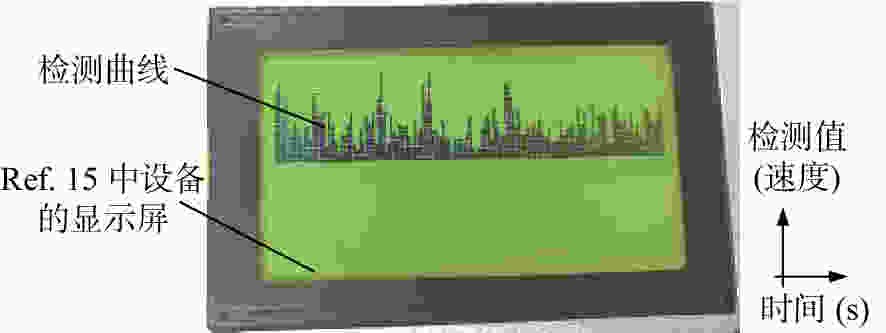

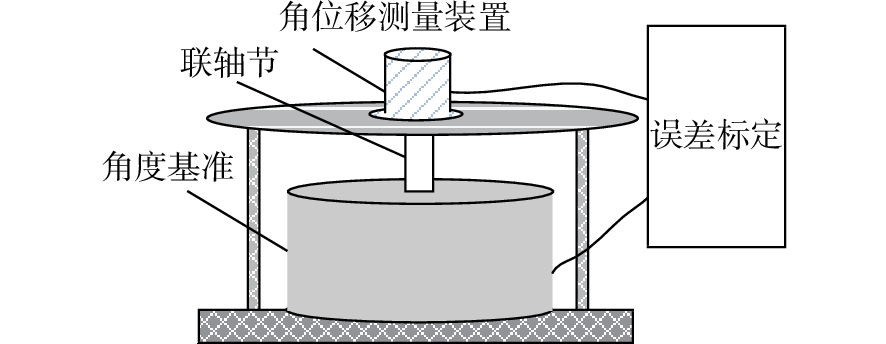

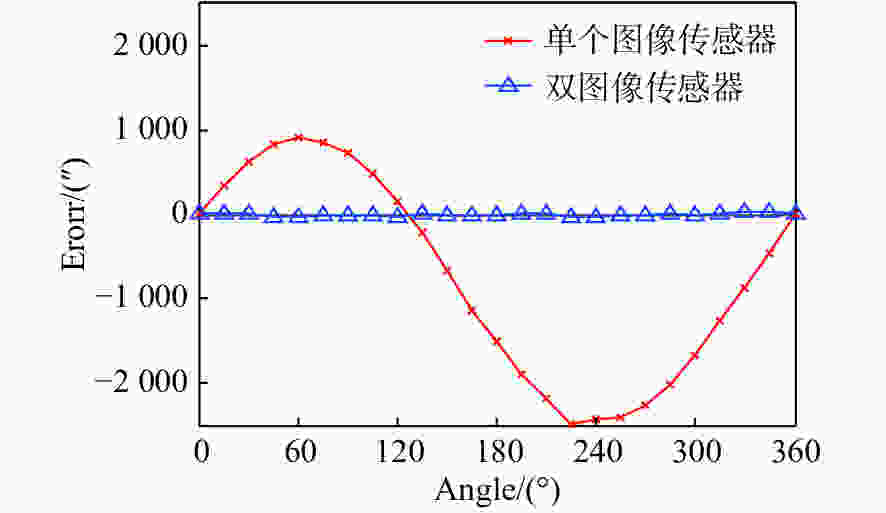

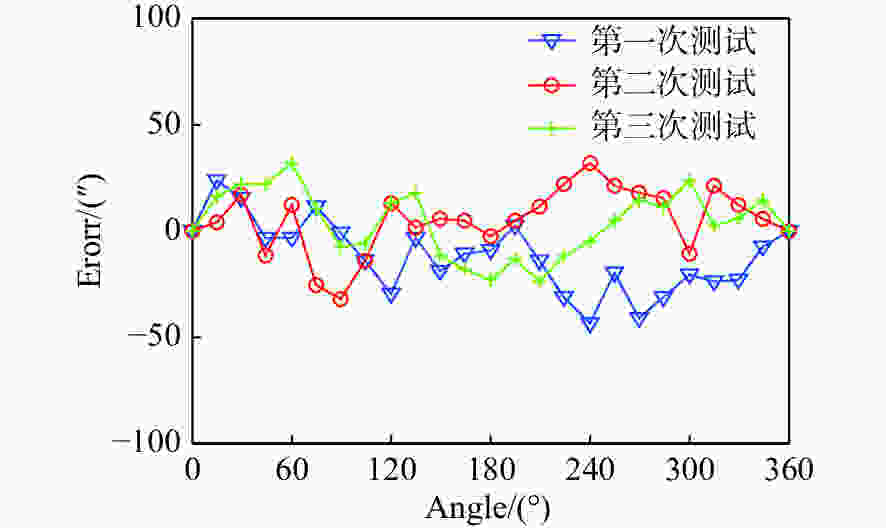

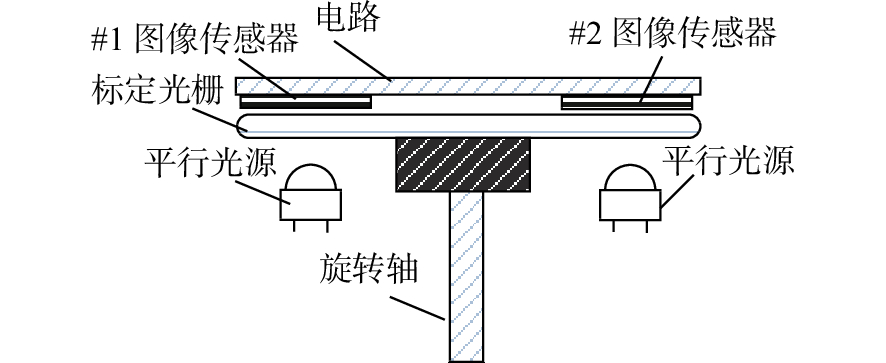

摘要: 采用图像探测器的角位移测量技术可实现高精度高分辨力角位移测量。为提高角位移测量装置的鲁棒性,本文设计了一种自适应安装的高精度图像式角位移测量装置。其装调过程非常简便,且可以保证在标定光栅存在偏心时具有高分辨力和高精度测量输出。首先,提出了基于双线阵图像传感器的测角装置设计原理,并设计了单圈绝对式标定光栅。然后,采用基于质心算法的高分辨力细分算法进行细分,并采用双线阵图像传感器对测角误差进行误差补偿。最后,设计实验装置测试自适应安装的性能。实验结果表明,当标定光栅的偏心度在±1 mm以内时,所设计装置可以实现高精度和高分辨力的角位移测量。本文所设计的装置可以在标定光栅存在±1 mm的安装偏心时保证输出精度,为小型角位移测量装置适应性的提高给出了解决方案。Abstract: The angular displacement measurement technology based on image detector is a hot research to realize high-precision and high-resolution angular displacement measurement. In order to improve the robustness of the angular displacement measuring devices, a high precision image displacement measurement device with self-adaptive installation techniques is designed in this paper. The installation and adjustment processes are very simple, and high resolution and high precision measurement output can be guaranteed in the presence of eccentricity in the calibration grating. Firstly, the angle measurement device using dual linear imaging sensors is proposed and a single-ring absolute grating is designed. Then, a high-resolution subdivision algorithm based on a centroid algorithm is used to subdivide the image, and dual linear image sensors are used to compensate for the angle measurement error. Finally, an experimental device is designed to test the performance of the adaptive installation. Experiments show that when the eccentricity of the grating is within ±1 mm, the designed device can achieve highly precise angular displacement measurements with high resolution. The device designed in this paper guarantee the output accuracy when the grating has an installation eccentricity of ±1 mm, which lays a foundation for improving the adaptability of small angular displacement measuring devices.

-

表 1 标定误差结果(″)

Table 1. Results of calibration error (″)

Angles/(°) Errors Angles/(°) Errors Angles/(°) Errors 0 0 120 −28.1 240 −25.1 15 13.5 135 0.8 255 −2.1 30 6.9 150 −1.5 270 −11.2 45 −21.4 165 −2.0 285 12.3 60 −26.6 180 −6.1 300 −11.3 75 −17.2 195 5.6 315 16 90 −19.7 210 0.8 330 25.1 105 −12.2 225 −22 345 32.7 -

[1] 董莉莉, 熊经武, 万秋华. 光电轴角编码器的发展动态[J]. 光学 精密工程,2000,8(2):198-202.DONG L L, XIONG J W, WAN Q H. Development of photoelectric rotary encoders[J]. Optics and Precision Engineering, 2000, 8(2): 198-202. (in Chinese) [2] 叶盛祥. 光电位移精密测量技术[M]. 乌鲁木齐: 新疆科技卫生出版社, 2003.YE SH X. Optoelectronic Displacement Precision Measurement Technology[M]. Urumqi: Xinjiang Science and Technology Health Press, 2003. (in Chinese) [3] 熊经武, 万秋华. 二十三位绝对式光电轴角编码器[J]. 光学机械,1990(2):52-60.XIONG J W, WAN Q H. A 23-bit absolute photo-electric rotary encoder[J]. Optics and Precision Engineering, 1990(2): 52-60. (in Chinese) [4] LEVITON D B, FREY B. Ultra-high resolution, absolute position sensors for cryostatic applications[J]. Proceedings of SPIE, 2003, 4850: 776-787. doi: 10.1117/12.461799 [5] LEVITON D B, GARZA M S. Recent advances and applications of NASA's new, ultrahigh-sensitivity absolute optical pattern recognition encoders[J]. Proceedings of SPIE, 2000, 4091: 375-384. doi: 10.1117/12.405797 [6] BAJIĆ J S, STUPAR D Z, DAKIĆ B M, et al. An absolute rotary position sensor based on cylindrical coordinate color space transformation[J]. Sensors and Actuators A:Physical, 2014, 213: 27-34. doi: 10.1016/j.sna.2014.03.036 [7] SUGIYAMA Y, MATSUI Y, TOYODA H, et al. A 3.2 kHz, 14-bit optical absolute rotary encoder with a CMOS profile sensor[J]. IEEE Sensors Journal, 2008, 8(8): 1430-1436. doi: 10.1109/JSEN.2008.920709 [8] TRESANCHEZ M, PALLEJÀ T, TEIXIDÓ M, et al. Using the image acquisition capabilities of the optical mouse sensor to build an absolute rotary encoder[J]. Sensors and Actuators A:Physical, 2010, 157(1): 161-167. doi: 10.1016/j.sna.2009.11.002 [9] KIM J A, KIM J W, KANG C S, et al. Absolute angle measurement using a phase-encoded binary graduated disk[J]. Measurement, 2016, 80: 288-293. doi: 10.1016/j.measurement.2015.11.037 [10] WANG Y N, YAUN B, NI X X. Subdivision technique of absolute angular encoder using array detector[J]. Journal of Zhejiang University (Engineering Science) , 2011, 45(2): 370-374. [11] 齐荔荔, 万秋华. 图像式光电编码器的测角技术及其硬件实现[J]. 光学学报,2013,33(4):0412001. doi: 10.3788/AOS201333.0412001QI L L, WAN Q H. Angle-measurement technology of an optical pattern rotary encoder and its hardware implementation[J]. Acta Optica Sinica, 2013, 33(4): 0412001. (in Chinese) doi: 10.3788/AOS201333.0412001 [12] YU H, WAN Q H, LU X R, et al. Small-size, high-resolution angular displacement measurement technology based on an imaging detector[J]. Applied Optics, 2017, 56(3): 755-760. doi: 10.1364/AO.56.000755 [13] YU H, WAN Q H, LU X R, et al. A robust sub-pixel subdivision algorithm for image-type angular displacement measurement[J]. Optics and Lasers in Engineering, 2018, 100: 234-238. doi: 10.1016/j.optlaseng.2017.09.006 [14] 于海, 万秋华, 赵长海, 等. 图像式光电编码器高分辨力细分算法及误差分析[J]. 光学学报,2017,37(3):0312001. doi: 10.3788/AOS201737.0312001YU H, WAN Q H, ZHAO CH H, et al. A high-resolution subdivision algorithm for photographic encoders and its error analysis[J]. Acta Optica Sinica, 2017, 37(3): 0312001. (in Chinese) doi: 10.3788/AOS201737.0312001 [15] 赵长海, 万秋华, 孙莹. 光电轴角编码器的误码检测系统[J]. 电子测量与仪器学报,2012,26(5):463-468.ZHAO CH H, WAN Q H, SUN Y. Code error detection system for photoelectric shaft encoder[J]. Journal of Electronic Measurement and Instrument, 2012, 26(5): 463-468. (in Chinese) [16] 于海, 万秋华, 梁立辉, 等. 光电编码器的动态误码检测系统[J]. 红外与激光工程,2016,45(9):0917001. doi: 10.3788/IRLA201645.0917001YU H, WAN Q H, LIANG L H, et al. Dynamic code error detection system of photoelectric encoder[J]. Infrared and Laser Engineering, 2016, 45(9): 0917001. (in Chinese) doi: 10.3788/IRLA201645.0917001 -

下载:

下载: