Femtosecond pulsed laser induced damage characteristics on Si-based multi-layer film

doi: 10.3788/CO.20191202.0371

-

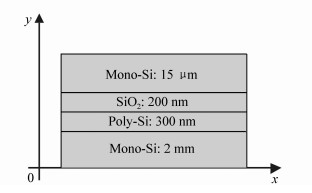

摘要: 为了明确超快激光损伤典型成像探测器膜层结构的物理机制,对飞秒脉冲激光辐照硅基多层膜的损伤特性,以及各种损伤效应对应的激光能量通量范围和阈值条件进行研究。利用波长为800 nm、脉冲宽度为100 fs的脉冲激光和金相显微镜研究了硅基多层膜在不同激光能量通量和不同脉冲累积下的损伤效应。在能量通量为1.01~24.7 J/cm2的激光单脉冲辐照下,激光作用区域可观察到氧化/无定形化、非热烧蚀和激光诱导等离子体烧蚀所引起的表面损伤,其损伤效应与激光能量通量有明显联系,激光作用区域尺寸随能量通量线性增大。在2.42 J/cm2到24.7 J/cm2激光能量通量范围内,可在辐照表面观察到激光诱导压力导致的多层损伤,损伤概率随激光能量通量的增加由1%增大到51%。在激光能量通量为1.01 J/cm2的连续多脉冲辐照下,烧蚀区域尺寸几乎不变,但烧蚀深度逐渐增加,其多层损伤机制为表面损伤的累积效应。通过单脉冲损伤实验数据拟合计算确定,飞秒激光诱导硅基多层膜表面损伤阈值为0.543 J/cm2,应力多层损伤阈值为2.16 J/cm2。低激光能量通量(≤ 1.01 J/cm2)多脉冲辐照累积作用同样可造成硅基多层膜深层损伤。Abstract: In order to understand the ultrafast laser-induced damage mechanisms of typical imaging sensor's film structures, the damage characteristics of Si-based multi-layer films irradiated by a femtosecond pulsed laser were investigated, and the laser pulse fluence ranges and threshold conditions corresponding to various damage phenomena were evaluated. Si-based multi-layer films that were similar in structure of CCD were prepared by electron beam deposition. The damage characteristics of these films irradiated by a femtosecond pulsed laser with wavelength of 800 nm and pulse width of 100 fs under different pulse fluences and numbers were investigated using a metallurgical microscope. Experimental results showed that the laser-affected zone size increased linearly with pulse fluence in the range of 1.01 to 24.7 J/cm2. Surface damage caused by oxidation/amorphization, non-thermal ablation, and laser-induced plasma ablation could be observed in the laser irradiated zone, which tightly depended on the pulse fluence. Multi-layer damage could be observed and the damage probability increased from 1% to 51% in the pulse fluence range from 2.42 to 24.7 J/cm2. Irradiated by sequent pulses at a fluence of 1.01 J/cm2, the laser affected zone remained almost unchanged and the ablated depth increased with the pulse number. From the single pulse damage experiment data, the femtosecond pulse laser-induced surface damage threshold was evaluated to be 0.543 J/cm2 and laser-induced multi-layer stress damage threshold was linearly fitted to be 2.16 J/cm2. Sequent pulse irradiation with low fluence(≤ 1.01 J/cm2) also could lead to deep damage on the multi-layer film.

-

Key words:

- laser ablation /

- laser damage /

- Si-based multi-layer film /

- damage threshold

-

图 2 飞秒激光诱导损伤的实验装置示意图,图中包括格兰棱镜(G)、半波片(HWP)、分束镜(BS)、功率计(PM)、离轴抛面反射镜(L)、平移台(TS)和样品(S)

Figure 2. Schematic of femtosecond laser-induced damage experiment setup, including a Glan prism(G), a half wave plate(HWP), a beam splitting mirror(BS), a power meter(PM), an off-axis parabolic mirror(L), a translation stage(TS) and a sample(S)

-

[1] FEDOSEJEVS R, KIRKWOOD S E, HOLENSTEIN R. Femtosecond interaction processes near threshold:damage and ablation[J]. Proceedings of SPIE, 2007, 6403:640302. http://d.old.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ0228082377/ [2] CRAWFORD T H R, YAMANAKA J, BOTTON C A. High-resolution observations of an amorphous layer and subsurface damage formed by femtosecond laser irradiation of silicon[J]. Journal of Applied Physics, 2008, 103(5):053104. doi: 10.1063/1.2885111 [3] RUBLACK T, HARTNAUER S, MERGNER M. Mechanism of selective removal of transparent layers on semiconductors using ultrashort laser pulses[J]. Proceedings of SPIE, 2012, 8247:82470Z. doi: 10.1117/12.905741 [4] 王涛涛, 付跃刚, 汤伟, 等.单CCD彩色相机激光干扰模型及外场干扰实验[J].发光学报, 2015, 36(5):588-594. http://d.old.wanfangdata.com.cn/Periodical/fgxb201505018WANG T T, FU Y G, TANG W, et al.. Laser jamming model and out-field laser jamming experiment of single CCD colour imaging system[J]. Chinese Journal of Luminescence, 2015, 36(5):588-594.(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/fgxb201505018 [5] BONSE J, BAUDACH S, KRVGER J, et al.. Femtosecond laser ablation of silicon modification thresholds and morphology[J]. Applied Physics A, 2002, 74(1):19-25. doi: 10.1007/s003390100893 [6] JIA J, LI M, THOMPSON C V. Amorphization of silicon by femtosecond laser pulses[J]. Applied Physics Letters, 2004, 84(16):3025. doi: 10.1063/1.1699448 [7] AMER M S, EL-ASHRY M A, DOSSER L R, et al.. Femtosecond versus nanosecond laser machining: comparison of induced stresses and structural changes in silicon wafers[J]. Applied Surface Science, 2005, 242(1-2):162-167. doi: 10.1016/j.apsusc.2004.08.029 [8] 郭春凤, 于继平, 王德飞, 等.超短脉冲激光辐照硅膜的热弹性[J].强激光与粒子束, 2008, 20(6):907-911. http://d.old.wanfangdata.com.cn/Periodical/qjgylzs200806007GUO CH F, YU J P, WANG D F, et al.. Thermoelasticity effect on Si film irradiated by ultra-short pulse laser[J]. High Power Laser and Particle Beams, 2008, 20(6):907-911.(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/qjgylzs200806007 [9] CRAWFORD T H R, YAMANAKA J, HSU E M. Femtosecond laser irradiation of metal and thermal oxide layers on silicon: studies utilising cross-sectional transmission electron microscopy[J]. Applied Physics A, 2008, 91(3):473-478. doi: 10.1007/s00339-008-4433-2 [10] 杨宏道, 李晓红, 李国强, 等.不同气体环境下532 nm激光诱导硅表面形貌的研究[J].中国光学, 2011, 4(1):86-92. doi: 10.3969/j.issn.2095-1531.2011.01.014YANG H D, LI X H, LI G Q, et al.. Surface morphology of silicon induced by 532 nm nanosecond laser under different ambient atmospheres[J]. Chinese Optics, 2011, 4(1):86-92.(in Chinese) doi: 10.3969/j.issn.2095-1531.2011.01.014 [11] 马鹏飞, 王克栋, 常方高, 等.不同能量密度的飞秒激光辐照对单晶硅的影响研究[J].人工晶体学报, 2013, 42(2):273-277. doi: 10.3969/j.issn.1000-985X.2013.02.016MA P F, WANG K D, CHANG F G, et al.. Effects of the irradiation on silicon by femtosecond laser of various energy densities[J]. Journal of Synthetic Crystals, 2013, 42(2):273-277.(in Chinese) doi: 10.3969/j.issn.1000-985X.2013.02.016 [12] 齐立涛.真空条件下不同波长固体激光烧蚀单晶硅的实验研究[J].中国光学, 2014, 7(3):442-448. http://www.chineseoptics.net.cn/CN/abstract/abstract9156.shtmlQI L T. Different wavelength solid-state laser ablation of silicon wafer in vacuum[J]. Chinese Optics, 2014, 7(3):442-448.(in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract9156.shtml [13] 邵俊峰, 郭劲, 王挺峰.飞秒激光与硅的相互作用过程理论研究[J].红外与激光工程, 2014, 43(8):2419-2424. doi: 10.3969/j.issn.1007-2276.2014.08.005SHAO J F, GUO J, WANG T F. Theoretical research on dynamics of femto-second laser ablation crystal silicon[J]. Infrared and Laser Engineering, 2014, 43(8):2419-2424.(in Chinese) doi: 10.3969/j.issn.1007-2276.2014.08.005 [14] 张震, 周孟莲, 张检民, 等.CCD中的激光光斑阴影现象及机理[J].光学 精密工程, 2013, 21(5):1365-1371. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201305037ZHANG ZH, ZHOU M L, ZHANG J M, et al.. Shadows of laser spots in CCD and their mechanism[J]. Opt. Precision Eng., 2013, 21(5):1365-1371.(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201305037 [15] 邵俊峰, 刘阳, 王挺峰, 等.皮秒激光对电荷耦合器件多脉冲损伤效应研究[J].兵工学报, 2014, 35(9):1408-1413. doi: 10.3969/j.issn.1000-1093.2014.09.012SHAO J F, LIU Y, WANG T F, et al.. Damage effect of charged coupled device with multiple-pulse picosecond laser[J]. Acta Armamentarii, 2014, 35(9):1408-1413.(in Chinese) doi: 10.3969/j.issn.1000-1093.2014.09.012 [16] 王明, 王挺峰, 邵俊峰.面阵CCD相机的飞秒激光损伤分析[J].中国光学, 2013, 6(1):96-102. http://www.chineseoptics.net.cn/CN/abstract/abstract8846.shtmlWANG M, WANG T F, SHAO J F. Analysis of femtosecond laser induced damage to array CCD camera[J]. Chinese Optics, 2013, 6(1):96-102.(in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract8846.shtml [17] 张健, 林广平, 张睿, 等.准分子激光相位掩模法制备大晶粒尺寸多晶硅薄膜[J].光学 精密工程, 2012, 20(1):58-63. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201201009ZHANG J, LIN G P, ZHANG R, et al.. Fabrication of large grain size p-Si film by phase modulated excimer laser crystallization[J]. Opt. Precision Eng., 2012, 20(1):58-63.(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201201009 [18] 冯爱新, 庄绪华, 薛伟, 等.1064 nm、532 nm、355 nm波长脉冲激光辐照多晶硅损伤特性研究[J].红外与激光工程, 2015, 44(2):461-465. doi: 10.3969/j.issn.1007-2276.2015.02.011FENG A X, ZHUANG X H, XUE W, et al.. Damage characteristics of polysilicon under wavelengths of 1064 nm, 532 nm and 355 nm laser irradiation[J]. Infrared and Laser Engineering, 2015, 44(2):461-465.(in Chinese) doi: 10.3969/j.issn.1007-2276.2015.02.011 [19] 韩振春, 薛伟, 冯爱新, 等.不同波长的纳秒脉冲激光对多晶硅损伤特性研究[J].应用激光, 2013, 33(3):313-317. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yyjg201303019HAN ZH CH, XUE W, FENG A X, et al.. A Different wavelength of nanosecond pulse laser damage characteristics of polycrystalline silicon research[J]. Applied Laser, 2013, 33(3):13-317.(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yyjg201303019 [20] 孙承伟, 陆启生, 范正修, 等.激光辐照效应[M].北京:国防工业出版社, 2002.SUN CH W, LU Q SH, FAN ZH X, et al.. Laser Irradiation Effect[M]. Beijing:National Defense Industry Press, 2002.(in Chinese) [21] 徐斌, 伍晓宇, 罗烽, 等.0Cr18Ni9不锈钢箔的飞秒激光烧蚀[J].光学 精密工程, 2012, 20(1):45-51. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201201007XU B, WU X Y, LUO F, et al.. Ablation of 0Cr18Ni9 stainless steel films by femtosecond laser[J]. Opt. Precision Eng., 2012, 20(1):45-51.(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201201007 -

下载:

下载: