-

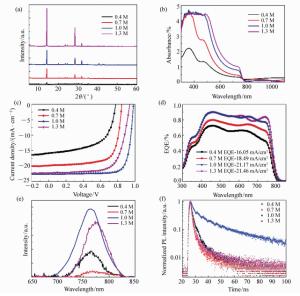

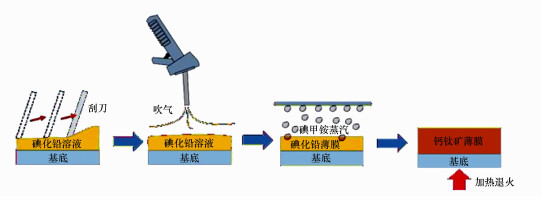

摘要: 由于具有高效率以及可溶液法制备等优点,钙钛矿太阳能电池受到了广泛关注。溶液法制备钙钛矿薄膜通常使用旋涂法。然而,溶液旋涂法具有厚度不均匀、原料浪费严重等缺点,因而不适合制备大面积钙钛矿薄膜。目前,制备大面积均匀的钙钛矿太阳能电池仍是一项挑战。为此,本文使用一种新方法(气相辅助刮刀涂布法)来克服这一问题。该方法能够制备出大面积、高结晶度的均匀钙钛矿薄膜。此外,通过改变前驱液的浓度,能够得到不同厚度的钙钛矿薄膜。进一步研究发现,当前驱溶液浓度为1.0 M时,可以制备出光伏性能最佳的钙钛矿太阳能电池。当电池活性面积分别为0.112 5 cm2和1.0 cm2时,在AM1.5G(100 mW/cm2)模拟太阳光下,其光电转化效率的最高值为17.76%(平均效率16.9%)和16.3%。这为大面积钙钛矿太阳能电池的制备提供了新思路。Abstract: Perovskite solar cells(PSCs) have attracted widespread attention due to their high efficiency and easy preparation with solution method. Normally, perovskite thin films are prepared via spin coating. Spin coating is not suitable for large-area preparation due to its drawbacks, including nonuniformity of film thickness and excessive waste of materials. Large-area preparation of uniform perovskite solar cells is still a big challenge today. Therefore, a vapor-assisted doctor blading(VADB) process is demonstrated here to prepare large-area and highly crystallized perovskite thin films. In addition, by changing the concentration of the precursor solution, perovskite films of different thicknesses are produced. Furthermore, we find that the performance of PSCs with a precursor concentration of 1.0 M is the best. The devices show the highest efficiencies of 17.76%(average 16.9%) and 16.3% under simulated AM1.5G(100 mW/cm2) solar light on an active area of 0.112 5 cm2 and 1.0 cm2, respectively. This provides a new possible way for the large-area preparation of PSCs.

-

Key words:

- perovskite solar cell /

- vapor assisted doctor blading /

- large area

-

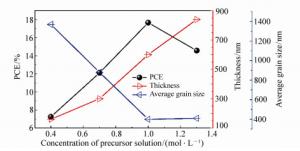

图 4 不同前驱溶液浓度(0.4 M、0.7 M、1.0 M以及1.3 M)钙钛矿对应的(a) X射线衍射图;(b)紫外可见吸收光谱图;(c)电流密度-电压曲线;(d)外部量子效率图;(e)稳态光致发光光谱图以及(f)时间分辨荧光光谱图

Figure 4. (a)XRD; (b)UV-Vis absorption spectra; (c)current density-voltage(J-V) curves; (d)EQE spectra; (e)steady-state PL and (f)time-resolved photoluminescence(TRPL) spectra corresponding to different precursor concentrations(0.4 M, 0.7 M, 1.0 M, and 1.3 M)

图 5 气相辅助刮刀涂布法制备钙钛矿器件的(a)小面积J-V曲线(活性面积为0.112 5 cm2)和(b)大面积J-V曲线(活性面积为1 cm2); (c)器件光电转换效率统计图和(d)白光LED照射下(50 mW/cm2)器件的最大功率点输出图

Figure 5. (a)Small-area J-V curve(active area of 0.112 5 cm2) and (b)large-area J-V curve(active area of 1 cm2) of VADB processed PSCs; (c)histogram of the power conversion efficiency of devices; (d)the maximum-power-point output results under the illumination of a white LED(50 mW/cm2) for the perovskite devices prepared by VADB process

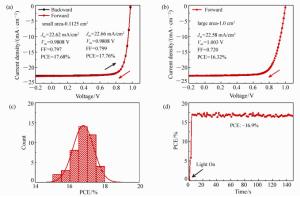

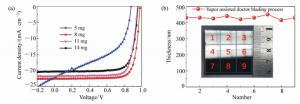

图 6 气相辅助刮刀涂布法制备的(a)基于1.0 M前驱液、不同MAI量所对应的J-V曲线,(b)大面积钙钛矿薄膜(4 cm×4 cm)的厚度统计图,插图是薄膜照片

Figure 6. (a)J-V curves of PSCs prepared with different amounts of MAI and 1.0 M precursor solution and (b)the thickness distribution of a large-area perovskite film (4 cm×4 cm) prepared via the VADB process. The inset is a photograph of the film

表 1 不同前驱液浓度制备的钙钛矿太阳能电池效率对比

Table 1. Comparison of efficiencies of perovskite solar cells prepared with different precursor concentrations

Concentration/(mol·L-1) JSC/(mA·cm-2) VOC/V FF/% PCE/% 1.3 22.34 0.939 4 69.5 14.58 1.0 22.62 0.980 8 79.7 17.68 0.7 19.89 0.846 5 72.0 12.12 0.4 15.85 0.775 5 58.9 7.24 表 2 不同前驱液浓度制备的钙钛矿薄膜的TRPL拟合结果

Table 2. Fitting results of TRPL spectra of perovskite films prepared with different precursor concentrations

Concentration/(mol·L-1) τ1/ns τ2/ns τAvg/ns A1/% A2/% 1.3 29.24 3.12 8.00 19 81 1.0 46.21 9.94 22.29 34 66 0.7 25.48 3.25 7.24 18 82 0.4 20.35 3.13 5.42 13 87 表 3 文献报道不同面积PSCs(不包括组件)效率对比

Table 3. Efficiency comparison of large- and small-area PSCs(module not included) reported in literatures

方法 组分(下标省略) 效率/% 面积/cm2 发表年份 旋涂(溶剂浴) MAPbI 17.1 0.12 2015 [43] 15.3 1.2 真空快抽旋涂 FAMAPbIBr 20.6 0.16 2016[44] 19.6 1 刮刀涂布 MAPbI 18.5 0.12 2017 [45] 17.3 1.2 旋涂 FAMAPbIBr 22.6 0.09 2018[8] 20.9 1 喷墨打印 MAPbICl 18.6 0.04 2018[46] 17.7 2.02 旋涂(吹气) FAMACsPbIBr 20.6 0.1 2018[47] 19.6 1.02 气相辅助喷涂 FAPbIBr 16.2 0.1 2019[33] 16.1 2 气相辅助刮刀涂布 MAPbI 17.7 0.11 本文 16.3 1 表 4 不同MAI量制备的钙钛矿太阳能电池效率对比

Table 4. Comparison of efficiencies of perovskite solar cells prepared with different amounts of MAI

MAI/mg JSC/(mA·cm-2) VOC/V FF/% PCE/% 14 20.3 0.959 77.9 15.2 11 21.8 0.953 78.9 16.4 8 22.6 0.981 79.7 17.7 5 22.3 0.880 48.3 9.47 -

[1] 丁武昌.光管理在晶体硅电池中的应用[J].中国光学, 2013, 6(5):717-728. http://www.chineseoptics.net.cn/CN/abstract/abstract9056.shtmlDING W CH. Light management in crystalline silicon solar cells[J]. Chinese Optics, 2013, 6(5):717-728.(in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract9056.shtml [2] 苏彦勋, 柯沅锋, 蔡士良, 等.层层自组装金纳米粒子表面等离子体引发光电流应用于等离子体增感太阳能电池[J].中国光学, 2014, 7(2):267-273. http://www.chineseoptics.net.cn/CN/abstract/abstract9127.shtmlSU Y X, KE Y F, CAI SH L, et al.. Layer self-assembly of gold nanoparticles surface plasmon triggered photoelectric current applied plasmon sensitized solar cell[J]. Chinese Optics, 2014, 7(2):267-273.(in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract9127.shtml [3] 谢世伟, 肖啸, 谭建军, 等.基于石墨烯基电极染料敏化太阳能电池的研究进展[J].中国光学, 2014, 7(1):47-56. http://www.chineseoptics.net.cn/CN/abstract/abstract9095.shtmlXIE SH W, XIAO X, TAN J J, et al.. Recent progress in dye-sensitized solar cells using graphene-based electrodes[J]. Chinese Optics, 2014, 7(1):47-56.(in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract9095.shtml [4] WANG Q, DONG Q F, LI T, et al.. Thin insulating tunneling contacts for efficient and water-resistant perovskite solar cells[J]. Advanced Materials, 2016, 28(31):6734-6739. doi: 10.1002/adma.201600969 [5] DONG Q F, FANG Y J, SHAO Y CH, et al.. Electron-hole diffusion lengths >175μm in solution-grown CH3NH3PbI3 single crystals[J]. Science, 2015, 347(6225):967-970. doi: 10.1126/science.aaa5760 [6] ZHAO Y CH, ZHOU W K, ZHOU X, et al.. Quantification of light-enhanced ionic transport in lead iodide perovskite thin films and its solar cell applications[J]. Light:Science & Applications, 2017, 6(5):e16243. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gkxyyy-e201702013 [7] KOJIMA A, TESHIMA K, SHIRAI Y, et al.. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells[J]. Journal of the American Chemical Society, 2009, 131(17):6050-6051. doi: 10.1021/ja809598r [8] JEON N J, NA H, JUNG E H, et al.. A fluorene-terminated hole-transporting material for highly efficient and stable perovskite solar cells[J]. Nature Energy, 2018, 3(8):682-689. doi: 10.1038/s41560-018-0200-6 [9] National Renewable Energy Laboratory. Best research-cell efficiencies[EB/OL]. https://upload.wikimedia.org/wikipedia/commons/3/38/CellPVeff%28rev190416%29.pdf. [10] XIAO ZH G, BI CH, SHAO Y CH, et al.. Efficient, high yield perovskite photovoltaic devices grown by interdiffusion of solution-processed precursor stacking layers[J]. Energy & Environmental Science, 2014, 7(8):2619-2623. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=d7d8fbb60f78a940110831cc33e82faa [11] XIAO ZH G, DONG Q F, BI CH, et al.. Solvent annealing of perovskite-induced crystal growth for photovoltaic-device efficiency enhancement[J]. Advanced Materials, 2014, 26(37):6503-6509. doi: 10.1002/adma.201401685 [12] ZHAO P J, KIM B J, REN X D, et al.. Antisolvent with an ultrawide processing window for the one-step fabrication of efficient and large-area perovskite solar cells[J]. Advanced Materials, 2018, 30(49):1802763. doi: 10.1002/adma.201802763 [13] DING J, HAN Q W, GE QQ, et al.. Fully air-bladed high-efficiency perovskite photovoltaics[J]. Joule, 2019, 3(2):402-416. doi: 10.1016/j.joule.2018.10.025 [14] BARROWS A T, PEARSON A J, KWAK C K, et al.. Efficient planar heterojunction mixed-halide perovskite solar cells deposited via spray-deposition[J]. Energy & Environmental Science, 2014, 7(9):2944-2950. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0dcfc504ae06035b04e399af189270b4 [15] HUANG H B, SHI J J, ZHU L F, et al.. Two-step ultrasonic spray deposition of CH3NH3PbI3for efficient and large-area perovskite solar cell[J]. Nano Energy, 2016, 27:352-358. doi: 10.1016/j.nanoen.2016.07.026 [16] BU T L, LI J, ZHENG F, et al.. Universal passivation strategy to slot-die printed SnO2 for hysteresis-free efficient flexible perovskite solar module[J]. Nature Communications, 2018, 9(1):4609. doi: 10.1038/s41467-018-07099-9 [17] GIL-ESCRIG L, MOMBLONA C, LA-PLACA M G, et al.. Vacuum deposited triple-cation mixed-halide perovskite solar cells[J]. Advanced Energy Materials, 2018, 8(14):1703506. doi: 10.1002/aenm.201703506 [18] CHEN X M, CAO H Q, YU H, et al.. Large-area, high-quality organic-inorganic hybrid perovskite thin films via a controlled vapor-solid reaction[J]. Journal of Materials Chemistry A, 2016, 4(23):9124-9132. doi: 10.1039/C6TA03180C [19] ZHAO Z B, CAO H Q, LI J ZH, et al.. Strategies to obtain stoichiometric perovskite by sequential vapor deposition learned by modeling the diffusion-dominated formation of perovskite films[J]. Applied Physics Express, 2018, 11(10):105501. doi: 10.7567/APEX.11.105501 [20] LI J B, MUNIR R, FAN Y Y, et al.. Phase transition control for high-performance blade-coated perovskite solar cells[J]. Joule, 2018, 2(7):1313-1330. doi: 10.1016/j.joule.2018.04.011 [21] CHEN H, YE F, TANG W T, et al.. A solvent-and vacuum-free route to large-area perovskite films for efficient solar modules[J]. Nature, 2017, 550(7674):92-95. doi: 10.1038/nature23877 [22] DENG Y H, DONG Q F, BI CH, et al.. Air-stable, efficient mixed-cation perovskite solar cells with Cu electrode by scalable fabrication of active layer[J]. Advanced Energy Materials, 2016, 6(11):1600372. doi: 10.1002/aenm.201600372 [23] DENG Y H, PENG E, SHAO Y CH, et al.. Scalable fabrication of efficient organolead trihalide perovskite solar cells with doctor-bladed active layers[J]. Energy & Environmental Science, 2015, 8(5):1544-1550. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=3559c26d91f8fe0c4fc0e296cdf89c52 [24] MOHAMAD D K, GRIFFIN J, BRACHER C, et al.. Spray-cast multilayer organometal perovskite solar cells fabricated in air[J]. Advanced Energy Materials, 2016, 6(22):1600994. doi: 10.1002/aenm.201600994 [25] VRIJ A, PATERSON B, NUNKOOSING K, et al.. Perceived advantages and disadvantages of secrets disclosure[J]. Personality and Individual Differences, 2003, 35(3):593-602. doi: 10.1016/S0191-8869(02)00221-0 [26] LIANG CH, LI P W, GU H, et al.. One-Step inkjet printed perovskite in air for efficient light harvesting(Solar RRL 2/2018)[J]. Solar RRL, 2018, 2(2):1770150. http://cn.bing.com/academic/profile?id=c814dc05f198f47b33cba0b84b31866c&encoded=0&v=paper_preview&mkt=zh-cn [27] MATHIES F, EGGERS H, RICHARDS B S, et al.. Inkjet-printed triple cation perovskite solar cells[J]. ACS Applied Energy Materials, 2018, 1(5):1834-1839. doi: 10.1021/acsaem.8b00222 [28] WHITAKER J, KIM D H, LARSON B W, et al.. Scalable slot-die coating of high performance perovskite solar cells[J]. Sustainable Energy & Fuels, 2018, 2(11):2442-2449. http://cn.bing.com/academic/profile?id=04b429b66a469684dc1ad2d98a9b89ca&encoded=0&v=paper_preview&mkt=zh-cn [29] LEE D, JUNG Y S, HEO Y J, et al.. Slot-die coated perovskite films using mixed lead precursors for highly reproducible and large-area solar cells[J]. ACS Applied Materials & Interfaces, 2018, 10(18):16133-16139. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b259cfb798c34cfd70d17a2df87cf1f4 [30] VILA J, MOMBLONA C, BOIX P P, et al.. Vapor-deposited perovskites:the route to high-performance solar cell production?[J]. Joule, 2017, 1(3):431-442. doi: 10.1016/j.joule.2017.07.014 [31] LONGO G, MOMBLONA C, LA-PLACA M G, et al.. Fully vacuum-processed wide band gap mixed-halide perovskite solar cells[J]. ACS Energy Letters, 2018, 3(1):214-219. doi: 10.1021/acsenergylett.7b01217 [32] 刘娜, 樊哲一, 任杰灵, 等.蒸汽辅助溶液过程制备钙钛矿材料及钙钛矿太阳能电池[J].中国光学, 2017, 10(5):568-577. http://www.chineseoptics.net.cn/CN/abstract/abstract9544.shtmlLIU N, FAN ZH Y, REN J L, et al.. Preperation of perovskite materials and perovskite solar cells by vapor-assisted solution process[J]. Chinese Optics, 2017, 10(5):568-577.(in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract9544.shtml [33] JIANG Y, REMEIKA M, HU ZH H, et al.. Negligible-Pb-waste and upscalable perovskite deposition technology for high-operational-stability perovskite solar modules[J]. Advanced Energy Materials, 2019, 9(13):1803047. doi: 10.1002/aenm.201803047 [34] CHEN X M, CAO H Q, YU H, et al.. Large-area, high-quality organic-inorganic hybrid perovskite thin films via a controlled vapor-solid reaction[J]. Journal of Materials Chemistry A, 2016, 4(23):9124-9132. doi: 10.1039/C6TA03180C [35] CHOU Y T, KO Y T, YAN M F. Fluid flow model for ceramic tape casting[J]. Journal of the American Ceramic Society, 1987, 70(10):C-280-C-282. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1111/jace.12295 [36] KIM H J, KRANE M J M, TRUMBLE K P, et al.. Analytical fluid flow models for tape casting[J]. Journal of the American Ceramic Society, 2006, 89(9):2769-2775. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1111/j.1551-2916.2006.01163.x [37] ZHAO Y X, ZHU K. Organic-inorganic hybrid lead halide perovskites for optoelectronic and electronic applications[J]. Chemical Society Reviews, 2016, 45(3):655-689. doi: 10.1039/C4CS00458B [38] ZHAO Y CH, LI Q, ZHOU W K, et al.. Double-side-passivated perovskite solar cells with ultra-low potential loss[J]. Solar RRL, 2019, 3(2):1800296. doi: 10.1002/solr.201800296 [39] LIU Z H, HU J N, JIAO H Y, et al.. Chemical reduction of intrinsic defects in thicker heterojunction planar perovskite solar cells[J]. Advanced Materials, 2017, 29(23):1606774. doi: 10.1002/adma.201606774 [40] PHAM N D, TIONG V T, CHEN P, et al.. Enhanced perovskite electronic properties via a modified lead(Ⅱ) chloride lewis acid-base adduct and their effect in high-efficiency perovskite solar cells[J]. Journal of Materials Chemistry A, 2017, 5(10):5195-5203. doi: 10.1039/C6TA11139D [41] YANG I S, SOHN M R, SUNG S D, et al.. Formation of pristine CuSCN layer by spray deposition method for efficient perovskite solar cell with extended stability[J]. Nano Energy, 2017, 32:414-421. doi: 10.1016/j.nanoen.2016.12.059 [42] STOLTERFOHT M, WOLFF C M, M RQUEZ J A, et al.. Visualization and suppression of interfacial recombination for high-efficiency large-area pin perovskite solar cells[J]. Nature Energy, 2018, 3(10):847-854. doi: 10.1038/s41560-018-0219-8 [43] YANG M J, ZHOU Y Y, ZENG Y N, et al.. Square-centimeter solution-processed planar CH3NH3PbI3 perovskite solar cells with efficiency exceeding 15%[J]. Advanced Materials, 2015, 27(41):6363-6370. doi: 10.1002/adma.201502586 [44] LI X, BI D Q, YI CH Y, et al.. A vacuum flash-assisted solution process for high-efficiency large-area perovskite solar cells[J]. Science, 2016, 353(6294):58-62. doi: 10.1126/science.aaf8060 [45] YANG M J, LI ZH, REESE M O, et al.. Perovskite ink with wide processing window for scalable high-efficiency solar cells[J]. Nature Energy, 2017, 2(5):17038. doi: 10.1038/nenergy.2017.38 [46] LI P W, LIANG CH, BAO B, et al.. Inkjet manipulated homogeneous large size perovskite grains for efficient and large-area perovskite solar cells[J]. Nano Energy, 2018, 46:203-211. doi: 10.1016/j.nanoen.2018.01.049 [47] ZHANG M, WILKINSON B, LIAO Y X, et al.. Electrode design to overcome substrate transparency limitations for highly efficient 1 cm2 mesoscopic perovskite solar cells[J]. Joule, 2018, 2(12):2694-2705. doi: 10.1016/j.joule.2018.08.012 -

下载:

下载: