-

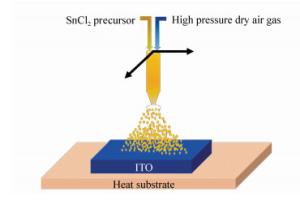

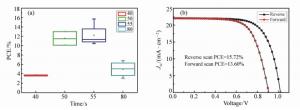

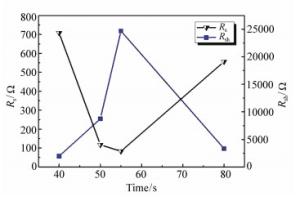

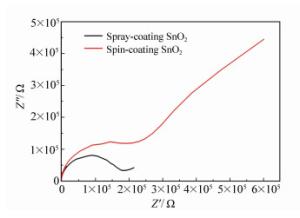

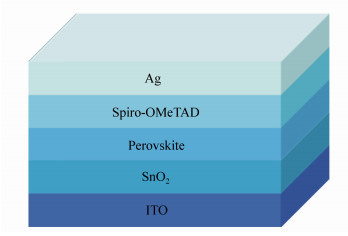

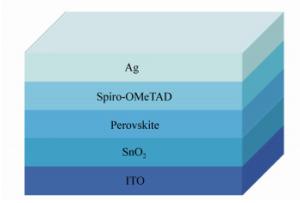

摘要: 电子传输层对于钙钛矿太阳能电池载流子的抽取与传输起着至关重要的作用,氧化锡由于其优异特性被作为电子传输层广泛应用于正式平板结构钙钛矿太阳能电池中。而目前制备氧化锡薄膜的工艺方法无法满足大面积、自动化等工业需求,亟待发掘新的工艺手段。为解决此问题,本文使用喷涂法成功制备了高质量的氧化锡薄膜。实验结果表明,基于喷涂法制备氧化锡薄膜的钙钛矿太阳能电池对于氧化锡薄膜的厚度有较高的依赖性,通过优化薄膜厚度,电池的光电转化效率可达到15.72%;喷涂得到的氧化锡薄膜存在咖啡环现象,使得串联电阻提高,限制了光电转化效率,但可以通过进一步细化液滴来解决。本文为钙钛矿产业化进程中高质量氧化锡薄膜的制备提供了新的思路与方法。Abstract: The electron transport layer(ETL) plays a crucial role in carrier extraction and transportation in perovskite solar cells. Tin(Ⅳ) oxide is widely used as ETL-material in planar perovskite solar cells due to its excellent properties. However, current processes for tin oxide film preparation can hardly meet industrial requirements, such as large-scale and automatic fabrication. Therefore, developing a new fabrication method suitable for industrialization is in urgent demanded. To solve this problem, a high-quality tin oxide film was successfully created using the spray coating method. Experimental results show that the performance of the perovskite solar cells is highly dependent on the thickness of the spray-coated tin oxide film. By optimizing film thickness, power conversion efficiency(PCE) can be improved to 15.72%. The film exhibits a coffee ring phenomenon, which increases the series resistance and limits the PCE. That can be solved by further decreasing the size of the droplets. This paper demonstrates a new method for the fabrication of high-quality, highly adaptable tin oxide films for the industrialization of perovskite solar cells.

-

Key words:

- perovskite solar cells /

- electron transport layer /

- tin oxide /

- spraying-coating method

-

表 1 不同喷涂时间下氧化锡器件的光电性能

Table 1. Photoelectric performance of devices with spray-coating SnO2 films prepared with different spraying time

Time/s Voc/V Jsc/(A·cm-2) PCE/% FF/% 40 0.84 13.02 3.80 34.62 50 0.95 21.87 13.03 62.87 55 1.02 22.03 15.72 70.03 80 0.87 18.65 6.87 42.16 表 2 两种工艺之间最优器件性能对比

Table 2. Photoelectrical performance comparison for the devices prepared by spinning coating and spraying coating devices

Type Voc/V Jsc/(A·cm-2) PCE/% FF/% Spinnig coating 1.04 22.43 18.14 77.48 Spraying coating 1.02 22.03 15.72 70.03 -

[1] KOJIMA A, TESHIMA K, SHIRAI Y, et al.. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells[J]. Journal of the American Chemical Society, 2009, 131(17):6050-6051. doi: 10.1021/ja809598r [2] ZHOU H P, CHEN Q, LI G, et al.. Interface engineering of highly efficient perovskite solar cells[J]. Science, 2014, 345(6196):542-546. doi: 10.1126/science.1254050 [3] YANG W S, NOH J H, JEON N J, et al.. High-performance photovoltaic perovskite layers fabricated through intramolecular exchange[J]. Science, 2015, 348(6240):1234-1237. doi: 10.1126/science.aaa9272 [4] BI D Q, YI C Y, LUO J SH, et al.. Polymer-templated nucleation and crystal growth of perovskite films for solar cells with efficiency greater than 21%[J]. Nature Energy, 2016, 1(10):16142. doi: 10.1038/nenergy.2016.142 [5] National Renewable Energy Laboratory. Best research-cell efficiency[EB/OL]. https://www.nrel.gov/pv/assets/images/efficiency-chart.png. [6] LEIJTENS T, EPERON G E, PATHAK S, et al.. Overcoming ultraviolet light instability of sensitized TiO2 with meso-superstructured organometal tri-halide perovskite solar cells[J]. Nature Communications, 2013, 4:2885. doi: 10.1038/ncomms3885 [7] JIANG Q, ZHANG X W, YOU J B. SnO2:a wonderful electron transport layer for perovskite solar cells[J]. Small, 2018, 14(31):1801154. doi: 10.1002/smll.201801154 [8] JIANG Q, CHU Z M, WANG P Y, et al.. Planar-structure perovskite solar cells with efficiency beyond 21%[J]. Advanced Materials, 2017, 29(46):1703852. doi: 10.1002/adma.201703852 [9] BAENA J P C, STEIER L, TRESS W, et al.. Highly efficient planar perovskite solar cells through band alignment engineering[J]. Energy & Environmental Science, 2015, 8(10):2928-2934. http://d.old.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ0235545163/ [10] ANARAKI E H, KERMANPUR A, STEIER L, et al.. Highly efficient and stable planar perovskite solar cells by solution-processed tin oxide[J]. Energy & Environmental Science, 2016, 9(10):3128-3134. http://cn.bing.com/academic/profile?id=324103d1934e557bbf32b0424bc07363&encoded=0&v=paper_preview&mkt=zh-cn [11] YANG G, LEI H W, TAO H, et al.. Reducing hysteresis and enhancing performance of perovskite solar cells using low-temperature processed Y-doped SnO2 nanosheets as electron selective layers[J]. Small, 2017, 13(2):1601769. doi: 10.1002/smll.201601769 [12] LIU X, TSAI K W, ZHU Z L, et al.. A low-temperature, solution processable tin oxide electron-transporting layer prepared by the dual-fuel combusion method for efficient perovskite solar cells[J]. Advanced Materials Interfaces, 2016, 3(13):1600122. doi: 10.1002/admi.201600122 [13] CHEN J Y, CHUEH C C, ZHU Z L, et al.. Low-temperature electrodeposited crystalline SnO2 as an efficient electron-transporting layer for conventional perovskite solar cells[J]. Solar Energy Materials and Solar Cells, 2017, 164:47-55. doi: 10.1016/j.solmat.2017.02.008 [14] 胡明江, 晋兵营.基于CuO/ZnO异质结纳米花的薄膜型丙酮传感器研究[J].分析化学, 2019, 47(3):363-370. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fxhx201903005HU M J, JIN B Y. Research on film type acetone sensor based on copper oxide/zinc oxide heterostructure nanoflower[J]. Chinese Journal of Analytical Chemistry, 2019, 47(3):363-370.(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fxhx201903005 [15] 王艺, 姜晓, 谭峰, 等.新型氧化铈/氧化锆-梯度扩散薄膜技术用于水体和沉积物中无机砷的形态分析[J].分析化学, 2018, 46(11):1829-1835. doi: 10.11895/j.issn.0253-3820.181395WANG Y, JIANG X, TAN F, et al.. CeO2/ZrO2-based diffusive gradients in thin films technique for measurement of As(Ⅲ) and As(Ⅴ) in water and sediment[J]. Chinese Journal of Analytical Chemistry, 2018, 46(11):1829-1835.(in Chinese) doi: 10.11895/j.issn.0253-3820.181395 [16] 黄芳龙, 陈旦初.金属氧化物薄膜的超声雾化喷涂[J].太阳能学报, 1989, 10(4):418-420. http://www.cnki.com.cn/Article/CJFDTotal-TYLX198904014.htmHUANG F L, CHEN D CH. Ultrasonic atomization spraying of metal oxide film[J]. Acta Energiae Solaris Sinica, 1989, 10(4):418-420.(in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-TYLX198904014.htm [17] 贾莉, 吕喆, 黄喜强, 等.用于燃料电池的氧化锆薄膜制备方法进展[J].电源技术, 2004, 28(7):449-451. doi: 10.3969/j.issn.1002-087X.2004.07.016JIA L, LÜ ZH, HUANG X Q, et al.. Progress on manufacturing of zirconia film for fuel cells[J]. Chinese Journal of Power Sources, 2004, 28(7):449-451.(in Chinese) doi: 10.3969/j.issn.1002-087X.2004.07.016 [18] KRUNKS M, MELLIKOV E. Zinc oxide thin films by the spray pyrolysis method[J]. Thin Solid Films, 1995, 270(1-2):33-36. doi: 10.1016/0040-6090(95)06893-7 [19] SHINDE V R MAHADIK S B, GUJAR T P, et al.. Supercapacitive cobalt oxide (Co3O4) thin films by spray pyrolysis[J]. Applied Surface Science, 2006, 252(20):487-7492. https://www.sciencedirect.com/science/article/pii/S0169433205012602 [20] PEREDNIS D, GAUCKLER L J. Thin film deposition using spray pyrolysis[J]. Journal of Electroceramics, 2005, 14(2):103-111. doi: 10.1007/s10832-005-0870-x [21] SHAMALA K S, MURTHY L C S, RAO K N. Studies on tin oxide films prepared by electron beam evaporation and spray pyrolysis methods[J]. Bulletin of Materials Science, 2004, 27(3):295-301. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b62d9607fcfac572799a0964339740cc [22] CHEN B, YANG M J, PRIYA S, et al.. Origin of J-V hysteresis in perovskite solar cells[J]. The Journal of Physical Chemistry Letters, 2016, 7(5):905-917. doi: 10.1021/acs.jpclett.6b00215 [23] TU B, SHAO Y F, CHEN W, et al.. Novel molecular doping mechanism for n-doping of SnO2 via triphenylphosphine oxide and its effect on perovskite solar cells[J]. Advanced Materials, 2019, 31(15):1805944. doi: 10.1002/adma.201805944 [24] GUILLÉN E, RAMOS F J, ANTA J A, et al.. Elucidating transport-recombination mechanisms in perovskite solar cells by small-perturbation techniques[J]. The Journal of Physical Chemistry C, 2014, 118(40):22913-22922. doi: 10.1021/jp5069076 [25] 孙加振, 邝旻翾, 宋延林.喷墨打印中"咖啡环"效应的调控及应用[J].化学进展, 2015, 27(8):979-985. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hxjz201508001SUN J ZH, KUANG M X, SONG Y L. Control and application of "coffee ring" effect in inkjet printing[J]. Progress in Chemistry, 2015, 27(8):979-985.(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hxjz201508001 [26] SEARS W M, GEE M A. Mechanics of film formation during the spray pyrolysis of tin oxide[J]. Thin Solid Films, 1988, 165(1):265-277. doi: 10.1016/0040-6090(88)90698-0 [27] 张培旭, 金永日, 崔俐, 等.基于超声喷泉的超声雾化结合固相萃取法提取西洋参叶中8种人参皂苷[J].分析化学, 2018, 46(4):594-600. http://d.old.wanfangdata.com.cn/Periodical/fxhx201804019ZHANG P X, JIN Y R, CUI L, et al.. Extraction of eight ginsenosides from leaves of Panax quinquefolium L. by ultrasoinc fountain-based ultrasonic-assisted nebulization extraction coupled with solid phase extraction[J]. Chinese Journal of Analytical Chemistry, 2018, 46(4):594-600.(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/fxhx201804019 -

下载:

下载: