-

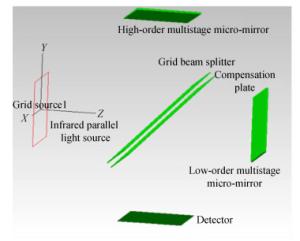

摘要: 为了实现傅立叶变换光谱仪的微型化与轻量化,设计了轻型栅条分束器结构,代替传统的平行平板分束器,分析了轻型栅条分束器的栅棱对光谱复原的影响,提出了制作误差容限。对微型傅立叶变换光谱仪进行了建模仿真,得到了轻型栅条分束器的最佳结构。通过系统仿真进行光谱反演,得到了复原光谱,并计算了轻型栅条分束器引入的光谱误差。完成了原理样机的搭建与调试,得到了实际系统的复原光谱,证明了微型化系统的可行性。该微型化系统相对于传统傅立叶变换光谱仪,具有体积小,稳定性好的优点,可用于在线监测。

-

关键词:

- 微型傅立叶变换红外光谱仪 /

- 轻型栅条分束器 /

- 光谱复原

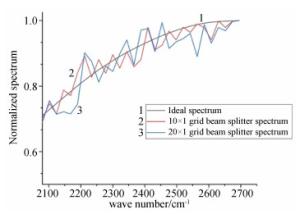

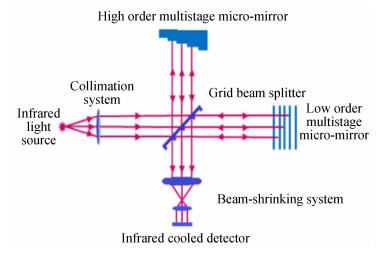

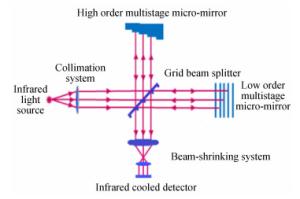

Abstract: In order to achieve the goal of miniaturization and light weight of Fourier transform spectrometer, a light-weight grid beam splitter structure was designed instead of the traditional parallel plate beam splitter. The influence of the grid edge of the grid beam splitter on spectrum reconstruction was analyzed, and the tolerance of production error was proposed. The micro-Fourier transform spectrometer was modeled and simulated, and the optimal structure of the grid beam splitter was obtained. The spectral inversion was performed by system simulation, and the restored spectrum was obtained. The spectral error introduced by the grid beam splitter was calculated. The construction and debugging of the prototype was completed, and the recovered spectrum of the actual system was obtained, which proved the feasibility of the miniaturized system. Compared with the traditional Fourier transform spectrometer, the miniaturization system has the advantages of small volume and good stability, and can be used for online monitoring. -

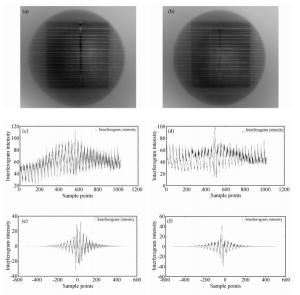

图 8 系统仿真结果。(a)理想干涉图像;(b)带有栅条分束器的干涉图像;(c)理想干涉图采样序列;(d)带有栅条分束器的干涉采样序列;(e)理想复原光谱;(f)带有栅条分束器的复原光谱

Figure 8. System simulation results. (a) Ideal interferogram image; (b) interferogram image with beam splitter; (c)ideal interferogram sampling sequence; (d)interferogram sampling sequence with beam splitter; (e)ideal recovered spectrum; (f) recovered spectrum with beam splitter

图 14 (a) 10周期栅条分束器干涉条纹图;(b)20周期栅条分束器干涉条纹图;(c)10周期栅条分束器干涉采样图;(d)20周期栅条分束器干涉采样图;(e)校正后10周期栅条分束器干涉采样图;(f)校正后20周期栅条分束器干涉采样图

Figure 14. (a) Interference fringe pattern of 10-period grid beam splitter; (b) interference fringe pattern of 20-period grid beam splitter; (c) interference sampling diagram of 10-period grid beam splitter; (d) interference sampling diagram of 20-period grid beam splitter; (e) interference sampling diagram of 10-period grid beam splitter after correction; (f) interference sampling diagram of 20-period grid beam splitter after correction

-

[1] BRACHET F, HÉBERT P J, CANSOT E, et al..Static Fourier transform spectroscopy breadboards for atmospheric chemistry and climate[J]. Proceedings of SPIE, 2008, 7100:710019. doi: 10.1117/12.797686 [2] LACAN A, BRÉON F M, ROSAK A, et al..A static Fourier transform spectrometer for atmospheric sounding:concept and experimentalimplementation[J]. Optics Express, 2010, 18(8):8311-8331. doi: 10.1364/OE.18.008311 [3] 付建国, 梁静秋, 梁中翥.一种静态傅里叶变换红外光谱仪的光学系统分析与设计[J].光学学报, 2012, 32(2):0222006. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201202042FU J G, LIANG J Q, LIANG ZH ZH. Analysis and design for the optical system of a static infrared Fourier transform spectrometer[J]. Acta Optica Sinica, 2012, 32(2):0222006. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201202042 [4] 李相贤, 徐亮, 高闽光, 等.分析温室气体及CO2碳同位素比值的傅里叶变换红外光谱仪[J].光学 精密工程, 2014, 22(9):2359-2368. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201409011LI X X, XU L, GAO M G, et al..Fourier transform infrared greenhouse analyzer for gases and carbon isotope ratio[J]. Opt. Precision Eng., 2014, 22(9):2359-2368. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201409011 [5] WALLRABE U, SOLF C, MOHR J, et al..Miniaturized Fourier transform spectrometer for the near infrared wavelength regime incorporating an electromagnetic linear actuator[J]. Sensors and Actuators A:Physical, 2005, 123-124:459-467. doi: 10.1016/j.sna.2005.05.014 [6] FENG C, WANG B, LIANG ZH ZH, et al..Miniaturization of step mirrors in a static Fourier transform spectrometer:theory and simulation[J]. Journal of the Optical Society of America B, 2011, 28(1):128-133. doi: 10.1364/JOSAB.28.000128 [7] IVANOVE V. Static Fourier transform spectroscopy with enhanced resolving power[J]. Journal of Optics A:Pure and Applied Optics, 2000, 2(6):519-528. doi: 10.1088/1464-4258/2/6/304 [8] FENG C, LIANG J Q, LIANG ZH ZH. Spectrum constructing with nonuniform samples using least-squares approximation by cosine polynomials[J]. Applied Optics, 2011, 50(34):6377-6383. doi: 10.1364/AO.50.006377 [9] 陈少杰, 齐向东, 巴音贺希格, 等.用于激光诱导等离子体光谱分析的便携式中阶梯光栅光谱仪设计[J].发光学报, 2013, 34(5):672-677. http://d.old.wanfangdata.com.cn/Periodical/fgxb201305024CHEN SH J, QI X D, BAYANHESHIG, et al..A portable echelle spectrograph design for laser-induced breakdown spectroscopy[J]. Chinese Journal of Luminescence, 2013, 34(5):672-677. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/fgxb201305024 [10] 吕金光, 梁静秋, 梁中翥, 等.空间调制傅里叶变换红外光谱仪分束器楔形误差分析[J].光学学报, 2014, 34(10):1030001. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201410043LV J G, LIANG J Q, LIANG ZH ZH, et al..Analysis of wedge error of beam splitter in spatial modulation Fourier transform infrared spectrometer[J]. Acta Optica Sinica, 2014, 34(10):1030001. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201410043 [11] 李晚侠, 卢启鹏, 宋源, 等.基于双直角分束器的反射式静态傅里叶光谱仪光学系统[J].光学学报, 2017, 37(8):0812004. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201708022LI W X, LU Q P, SONG Y, et al..Reflective static Fourier spectrometer optical system based on double right-angle beam splitter[J]. Acta Optica Sinica, 2017, 37(8):0812004. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201708022 -

下载:

下载: