-

摘要: 纤维增强碳化硅复合材料具有优异的力学及热学性能被广泛应用在航空航天、核能、汽车、化工等诸多领域,特别是在光学反射镜方面有良好的应用前景。本文介绍了纤维增强碳化硅复合材料的特点以及其相对传统反射镜材料的优势,对比分析了不同纤维增强碳化硅复合材料制备工艺的优缺点,阐述了不同界面层对纤维的保护作用及对复合材料性能的影响,综述了国内外纤维增强碳化硅复合材料在光学反射镜领域的应用进展,最后总结了纤维增强碳化硅反射镜坯实现大规模应用所需进一步开展的研究方向。Abstract: Fiber-reinforced silicon carbide composites with excellent mechanical and thermal properties are widely used in aerospace, nuclear energy, automobile, chemical industry and many other fields, especially in optical mirrors. This paper introduces the characteristics of fiber-reinforced silicon carbide composites. The advantages and disadvantages of different preparation processes of fiber-reinforced silicon carbide composites are compared. The protective effects of different interface layers on fibers and composites are expounded. The application progress of fiber-reinforced silicon carbide composites in the field of optical mirrors at home and abroad is summarized. Finally, the research direction to be carried out for realizing large-scale application of fiber-reinforced silicon carbide mirror blanks is analyzed.

-

Key words:

- silicon carbide /

- composite materials /

- carbon fiber /

- silicon carbide fiber /

- optical mirrors

-

表 1 不同纤维增强碳化硅制备方法的优缺点对比

Table 1. Comparison of advantages and disadvantages of different preparation methods for fiber-reinforced silicon carbide

制备方法 优点 缺点 先驱体浸渍裂解法(PIP) 裂解温度低,

纤维损伤小,

可制备形状复杂构件易产生裂纹,

孔隙率高,

生产周期长化学气相渗透(CVI) 基体纯度高,

可制备形状复杂构件生产周期较长,

成本高,

不适合制备厚壁构件反应浸渗(RI) 生产周期短,

可制备形状复杂构件,

近净尺寸成型残硅量高,

硅化反应造成纤维损伤纳米浸渍,瞬时共晶(NITE) 致密度高,

生产周期短纤维易产生损伤,

基体含杂质,

不适合制备复杂形状构件 -

[1] 徐宏, 关英俊. 空间相机1m口径反射镜组件结构设计[J]. 光学 精密工程,2013,21(6):1488-1495. doi: 10.3788/OPE.20132106.1488XU H, GUAN Y J. Structural design of 1m diameter space mirror component of space camera[J]. Optics and Precision Engineering, 2013, 21(6): 1488-1495. (in Chinese) doi: 10.3788/OPE.20132106.1488 [2] 贾建禄, 王建立, 赵金宇, 等. 可扩展式自适应光学系统波前处理器的硬件设计[J]. 液晶与显示,2011,26(3):370-373. doi: 10.3788/YJYXS20112603.0370JIA J L, WANG J L, ZHAO J Y, et al. Hardware design for extendible adaptive optics system wave-front processor[J]. Chinese Journal of Liquid Crystals and Displays, 2011, 26(3): 370-373. (in Chinese) doi: 10.3788/YJYXS20112603.0370 [3] 李志来, 徐宏, 关英俊. 1.5m口径空间相机主镜组件的结构设计[J]. 光学 精密工程,2015,23(6):1635-1641. doi: 10.3788/OPE.20152306.1635LI ZH L, XU H, GUAN Y J. Structural design of 1.5 m mirror subassembly for space camera[J]. Optics and Precision Engineering, 2015, 23(6): 1635-1641. (in Chinese) doi: 10.3788/OPE.20152306.1635 [4] 张景旭. 地基大口径望远镜系统结构技术综述[J]. 中国光学,2012,5(4):327-336. doi: 10.3969/j.issn.2095-1531.2012.04.004ZHANG J X. Overview of structure technologies of large aperture ground-based telescopes[J]. Chinese Optics, 2012, 5(4): 327-336. (in Chinese) doi: 10.3969/j.issn.2095-1531.2012.04.004 [5] 陈浩, 宣丽, 胡立发, 等. 望远镜的紧凑型闭环液晶自适应光学系统设计[J]. 液晶与显示,2010,25(3):379-385. doi: 10.3969/j.issn.1007-2780.2010.03.017CHEN H, XUAN L, HU L F, et al. Design on compact type closed-loop liquid crystal adaptive optical system for telescope[J]. Chinese Journal of Liquid Crystals and Displays, 2010, 25(3): 379-385. (in Chinese) doi: 10.3969/j.issn.1007-2780.2010.03.017 [6] 宣丽, 李大禹, 刘永刚. 液晶自适应光学在天文学研究中的应用展望[J]. 液晶与显示,2015,30(1):1-9.XUAN L, LI D Y, LIU Y G. Prospect of liquid crystal adaptive optics in astronomy application[J]. Chinese Journal of Liquid Crystals and Displays, 2015, 30(1): 1-9. (in Chinese) [7] 张德坷, 曹英斌, 刘荣军, 等. C/SiC复合材料空间光机结构的研究进展与展望[J]. 材料导报,2012,26(13):7-11. doi: 10.3969/j.issn.1005-023X.2012.13.002ZHANG D K, CAO Y B, LIU R J, et al. Progress and prospect of C/SiC composites used in space opto-mechanical structures[J]. Materials Review, 2012, 26(13): 7-11. (in Chinese) doi: 10.3969/j.issn.1005-023X.2012.13.002 [8] 张学军, 李志来, 张忠玉. 基于SiC材料的空间相机非球面反射镜结构设计[J]. 红外与激光工程,2007,36(5):577-582. doi: 10.3969/j.issn.1007-2276.2007.05.001ZHANG X J, LI ZH L, ZHANG ZH Y. Space telecope aspherical mirror structure design based on SiC material[J]. Infrared and Laser Engineering, 2007, 36(5): 577-582. (in Chinese) doi: 10.3969/j.issn.1007-2276.2007.05.001 [9] 董吉洪. 大孔径光学反射镜球铰支撑设计与分析[J]. 光机电信息,2010,27(9):29-34.DONG J H. Ball hinge support design and analysis for large aperture optical mirror[J]. OME Information, 2010, 27(9): 29-34. (in Chinese) [10] 刘韬, 周一鸣, 江月松. 国外空间反射镜材料及应用分析[J]. 航天返回与遥感,2013,34(5):90-99. doi: 10.3969/j.issn.1009-8518.2013.05.013LIU T, ZHOU Y M, JIANG Y S. Research and application of foreign space mirror materials[J]. Spacecraft Recovery &Remote Sensing, 2013, 34(5): 90-99. (in Chinese) doi: 10.3969/j.issn.1009-8518.2013.05.013 [11] 王永杰, 解永杰, 马臻, 等. 空间反射镜新材料研究进展[J]. 材料导报,2016,30(4):143-147, 153.WANG Y J, XIE Y J, MA ZH, et al. Research progress of new space mirror materials[J]. Materials Review, 2016, 30(4): 143-147, 153. (in Chinese) [12] 黄禄明, 张长瑞, 刘荣军, 等. C/SiC复合材料轻型反射镜光学改性涂层技术研究进展[J]. 硅酸盐通报,2016,35(5):1514-1519.HUANG L M, ZHANG CH R, LIU R J, et al. Progress of the preparation of C/SiC composites and coatings used in space mirror[J]. Bulletin of the Chinese Ceramic Society, 2016, 35(5): 1514-1519. (in Chinese) [13] EALEY M A, WEAVER G Q. Developmental history and trends for reaction-bonded silicon carbide mirrors[J]. Proceedings of SPIE, 1996, 2857: 66-72. doi: 10.1117/12.258288 [14] 张舸, 赵汝成, 赵文兴. 空间用反应烧结碳化硅反射镜坯体制备技术研究[J]. 空间科学学报,2011,31(3):401-405. doi: 10.11728/cjss2011.03.401ZHANG G, ZHAO R CH, ZHAO W X. Study on fabrication technology of reaction bonded silicon carbide mirror blank for space[J]. Chinese Jorunal of Space Science, 2011, 31(3): 401-405. (in Chinese) doi: 10.11728/cjss2011.03.401 [15] 黄禄明, 张长瑞, 刘荣军, 等. C/SiC复合材料反射镜研究进展[J]. 宇航材料工艺,2016,46(6):26-29.HUANG L M, ZHANG CH R, LIU R J, et al. Process of C/SiC composites used in space mirror[J]. Aerospace Materials &Technology, 2016, 46(6): 26-29. (in Chinese) [16] 张玉娣, 张长瑞, 周新贵, 等. SiC基反射镜制备工艺研究进展[J]. 硅酸盐通报,2005,24(1):89-93. doi: 10.3969/j.issn.1001-1625.2005.01.021ZHANG Y D, ZHANG CH R, ZHOU X G, et al. Development of process to fabricate SiC mirror[J]. Bulletin of the Chinese Ceramic Society, 2005, 24(1): 89-93. (in Chinese) doi: 10.3969/j.issn.1001-1625.2005.01.021 [17] ZHANG G, ZHAO R CH, ZHAO W X, et al. Manufacture of Ф1.2m reaction bonded silicon carbide mirror blank CFID[J]. Proceedings of SPIE, 2010, 7654: 76541B. doi: 10.1117/12.866700 [18] 任建岳, 陈长征, 何斌, 等. SiC和SiC/Al在TMA空间遥感器中的应用[J]. 光学 精密工程,2008,16(12):2537-2543.REN J Y, CHEN CH ZH, HE B, et al. Application of SiC and SiC/Al to TMA optical remote sensor[J]. Optics and Precision Engineering, 2008, 16(12): 2537-2543. (in Chinese) [19] 李双, 张宇民, 韩杰才, 等. 反应烧结碳化硅中碳短纤维的形貌及增强作用[J]. 硅酸盐学报,2013,41(7):916-922. doi: 10.7521/j.issn.0454-5648.2013.07.07LI SH, ZHANG Y M, HAN J C, et al. Morphology and reinforcin behavior of short carbon fiber in reaction bonded silicon carbide[J]. Journal of the Chinese Ceramic Society, 2013, 41(7): 916-922. (in Chinese) doi: 10.7521/j.issn.0454-5648.2013.07.07 [20] 马青松, 刘海韬, 潘余, 等. C/SiC复合材料在超燃冲压发动机中的应用研究进展[J]. 无机材料学报,2013,28(3):247-255. doi: 10.3724/SP.J.1077.2013.12466MA Q S, LIU H T, PAN Y, et al. Research progress on the application of C/SiC composites in scramjet[J]. Journal of Inorganic Materials, 2013, 28(3): 247-255. (in Chinese) doi: 10.3724/SP.J.1077.2013.12466 [21] 何柏林, 孙佳. 碳纤维增强碳化硅陶瓷基复合材料的研究进展及应用[J]. 硅酸盐通报,2009,28(6):1197-1202, 1207.HE B L, SUN J. Progress and application of carbon fibers reinforced silicon carbide ceramic matrix composites[J]. Bulletin of the Chinese Ceramic Society, 2009, 28(6): 1197-1202, 1207. (in Chinese) [22] 刘海韬. 夹层结构SiCf/SiC雷达吸波材料设计、制备及性能研究[D]. 长沙: 国防科学技术大学, 2010LIU H T. Design, Preparations and properties of the SiCf/SiC radar absorbing materials with sandwich structures[D]. Changsha: National University of Defense Technology, 2010. (in Chinese) [23] 王鸣, 董志国, 张晓越, 等. 连续纤维增强碳化硅陶瓷基复合材料在航空发动机上的应用[J]. 航空制造技术,2014(6):10-13. doi: 10.3969/j.issn.1671-833X.2014.06.001WANG M, DONG ZH G, ZHANG X Y, et al. Application of continuous fiber reinforced ceramic matrix composites in aeroengine[J]. Aeronautical Manufacturing Technology, 2014(6): 10-13. (in Chinese) doi: 10.3969/j.issn.1671-833X.2014.06.001 [24] CHEN X W, DONG S M, KAN Y M, et al. 3D Cf/SiC-ZrC-ZrB2 composites fabricated via sol-gel process combined with reactive melt infiltration[J]. Journal of the European Ceramic Society, 2016, 36(15): 3607-3613. doi: 10.1016/j.jeurceramsoc.2016.04.011 [25] 徐兴亚, 张立同, 成来飞, 等. 碳陶刹车材料的研究进展[J]. 航空制造技术,2014(6):100-103, 108. doi: 10.3969/j.issn.1671-833X.2014.06.021XU X Y, ZHANG L T, CHENG L F, et al. Research progress of carbon/silicon carbide brake materials[J]. Aeronautical Manufacturing Technology, 2014(6): 100-103, 108. (in Chinese) doi: 10.3969/j.issn.1671-833X.2014.06.021 [26] 黄飞虎, 王思青, 张长瑞, 等. 高性能刹车材料的研究现状与发展趋势[J]. 材料导报,2012,26(19):59-63. doi: 10.3969/j.issn.1005-023X.2012.19.014HUANG F H, WANG S Q, ZHANG CH R, et al. A review of advanced brake disc materials[J]. Materials Review, 2012, 26(19): 59-63. (in Chinese) doi: 10.3969/j.issn.1005-023X.2012.19.014 [27] ZHOU X, ZHU D M, XIE Q, et al. Friction and wear properties of C/C-SiC braking composites[J]. Ceramics International, 2012, 38(3): 2467-2473. doi: 10.1016/j.ceramint.2011.11.015 [28] FAN S W, ZHANG L T, CHENG L F, et al. Wear mechanisms of the C/SiC brake materials[J]. Tribology International, 2011, 44(1): 25-28. doi: 10.1016/j.triboint.2010.09.003 [29] 王洪磊.反应浸渗制备连续纤维增强SiC基复合材料及其性能研究[D]. 长沙: 国防科学技术大学, 2012.WANG H L. Fabrication and performance of continuous fiber-reinforced silicon carbide matrix composites by reaction infiltration[D]. Changsha: National University of Defense Technology, 2012. (in Chinese) [30] 孙明, 史一宁, 邱海鹏, 等. PIP法制备陶瓷基复合材料构件的弯曲性能研究[J]. 稀有金属材料与工程,2011,40(S1):631-634.SUN M, SHI Y N, QIU H P, et al. Studies of flexural strength of ceramic matrix composite component prepared by PIP process[J]. Rare Metal Materials and Engineering, 2011, 40(S1): 631-634. (in Chinese) [31] 张立同. 纤维增韧碳化硅陶瓷复合材料[M]. 北京: 化学工业出版社, 2009.ZHANG L T. Fiber-reinforced Silicon Carbide Ceramic Composites[M]. Beijing: Chemical Industry Press, 2009. (in Chinese) [32] LIU H T, TIAN H. Mechanical and microwave dielectric properties of SiCf/SiC composites with BN interphase prepared by dip-coating process[J]. Journal of the European Ceramic Society, 2012, 32(10): 2505-2512. doi: 10.1016/j.jeurceramsoc.2012.02.009 [33] UDAYAKUMAR A, GANESH A S, RAJA S, et al. Effect of intermediate heat treatment on mechanical properties of SiCf/SiC composites with BN interphase prepared by ICVI[J]. Journal of the European Ceramic Society, 2011, 31(6): 1145-1153. doi: 10.1016/j.jeurceramsoc.2010.12.018 [34] MU Y, ZHOU W CH, LUO F, et al. Effects of BN/SiC dual-layer interphase on mechanical and dielectric properties of SiCf/SiC composites[J]. Ceramics International, 2014, 40(2): 3411-3418. doi: 10.1016/j.ceramint.2013.09.091 [35] UDAYAKUMAR A, STALIN M, VENKATESWARLU K. Effect of CVD SiC seal coating on the mechanical properties of Cf/SiC composites generated through CVI[J]. Surface and Coatings Technology, 2013, 219: 75-81. doi: 10.1016/j.surfcoat.2013.01.007 [36] YIN X W, HE SH SH, ZHANG L T, et al. Fabrication and characterization of a carbon fibre reinforced carbon-silicon carbide-titanium silicon carbide hybrid matrix composite[J]. Materials Science and Engineering:A, 2010, 527(3): 835-841. doi: 10.1016/j.msea.2009.08.069 [37] LI H J, OUYANG H B, QI L H, et al. Effect of temperature on the synthesis of SiC coating on carbon fibers by the reaction of SiO with the deposited pyrolytic carbon layer[J]. Journal of Materials Science &Technology, 2010, 26(3): 211-216. [38] 周新贵, 游宇, 于海蛟, 等. 碳纤维CVD SiC涂层对C/SiC复合材料力学性能的影响[J]. 稀有金属材料与工程,2008,37(S1):32-35.ZHOU X G, YOU Y, YU H J, et al. Effects of carbon fiber CVD SiC coatings on mechanical properties of C/SiC composites[J]. Rare Metal Materials and Engineering, 2008, 37(S1): 32-35. (in Chinese) [39] SHIMODA K, PARK J S, HINOKI T, et al. Influence of pyrolytic carbon interface thickness on microstructure and mechanical properties of SiC/SiC composites by NITE process[J]. Composites Science and Technology, 2007, 68(1): 98-105. [40] JIA Y, LI K ZH, XUE L ZH, et al. Electromagnetic interference shielding effectiveness of carbon fiber reinforced multilayered (PyC–SiC)n matrix composites[J]. Ceramics International, 2016, 42(1): 986-988. doi: 10.1016/j.ceramint.2015.08.131 [41] KROEDEL M, KUTTER G S, DEYERLER M, et al. Short carbon-fiber-reinforced ceramic–Cesic-for optomechanical applications[J]. Proceedings of SPIE, 2002, 4771: 230-242. doi: 10.1117/12.482164 [42] KROEDEL M R, LICHTSCHEINDL J. Cesic: manufacturing study for next generation telescopes[J]. Proceedings of SPIE, 2004, 5494: 352-355. [43] KRÖDEL M R, OZAKI T. HB-Cesic composite for space optics and structures[J]. Proceedings of SPIE, 2007, 6666: 66660E. [44] MUELLER C E, PAPENBURG U, GOODMAN W A, et al. C/SiC high-precision lightweight components for optomechanical applications[J]. Proceedings of SPIE, 2000, 4198: 249-259. [45] OZAKI T, KUME M, OSHIMA T, et al. Mechanical and thermal performance of C/SiC composites for SPICA mirror[J]. Proceedings of SPIE, 2004, 5868: 58680H. [46] GOODMAN W A. HoneySiC: a new optomechanical material for low-areal cost and density[J]. Proceedings of SPIE, 2013, 8837: 88370F. [47] GOODMAN W A, NEJHAD M N C, WRIGHT S, et al. T300HoneySiC: a new near-zero CTE molded C/SiC material[J]. Proceedings of SPIE, 2015, 9574: 95740E. doi: 10.1117/12.2185638 [48] KOWBEL W, WOIDA R, WITHERS J C. SiC-SiC composites for optical applications[J]. Proceedings of SPIE, 2007, 5868: 586808. [49] HARNISCH B, KUNKEL B, DEYERLER M, et al. Ultra-lightweight C/SiC mirrors and structures[J]. Esa Bulletin, 1998, 95(8): 148-152. [50] ZHOU H, ZHANG CH R, CAO Y B, et al. Lightweight C/SiC mirrors for space application[J]. Proceedings of SPIE, 2006, 6148: 61480L. doi: 10.1117/12.674096 [51] 司亚凯.SiCf/SiC复合材料反射镜坯体的制备与性能研究[D]. 长沙: 国防科技大学, 2010.SI Y K. Study on preparation and performance of SiCf/SiC reflecting mirror composite[D]. Changsha: National University of Defense Technology, 2010. (in Chinese) -

下载:

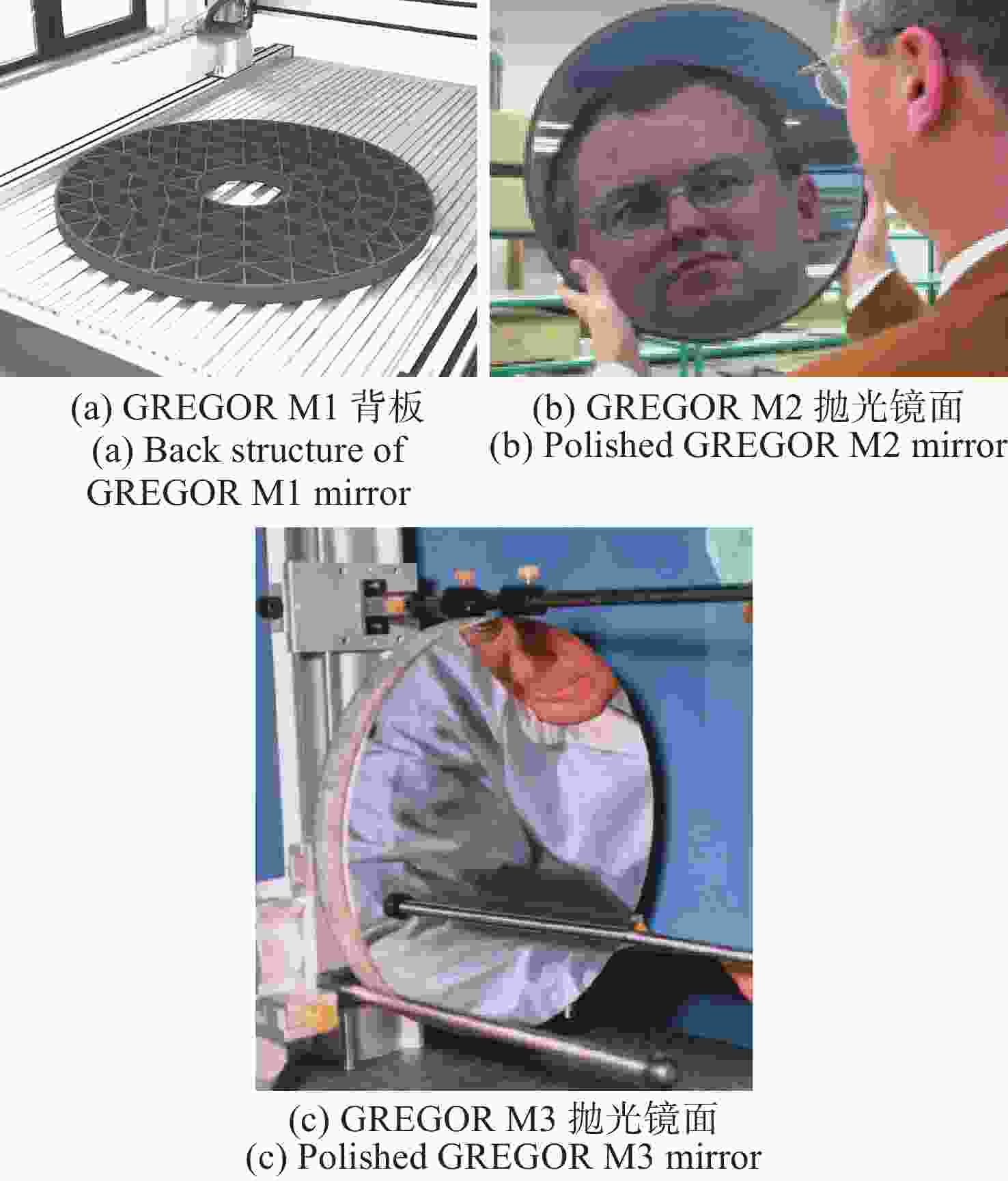

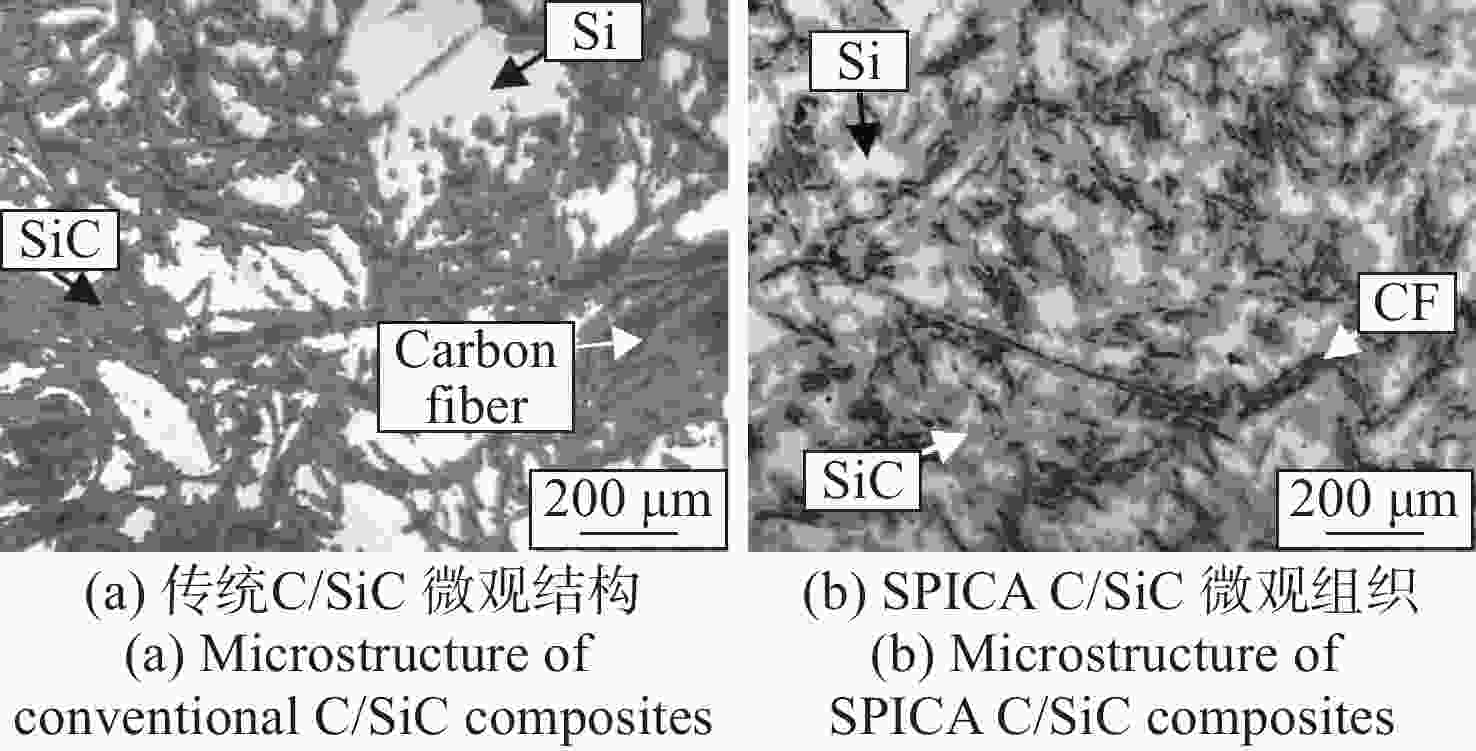

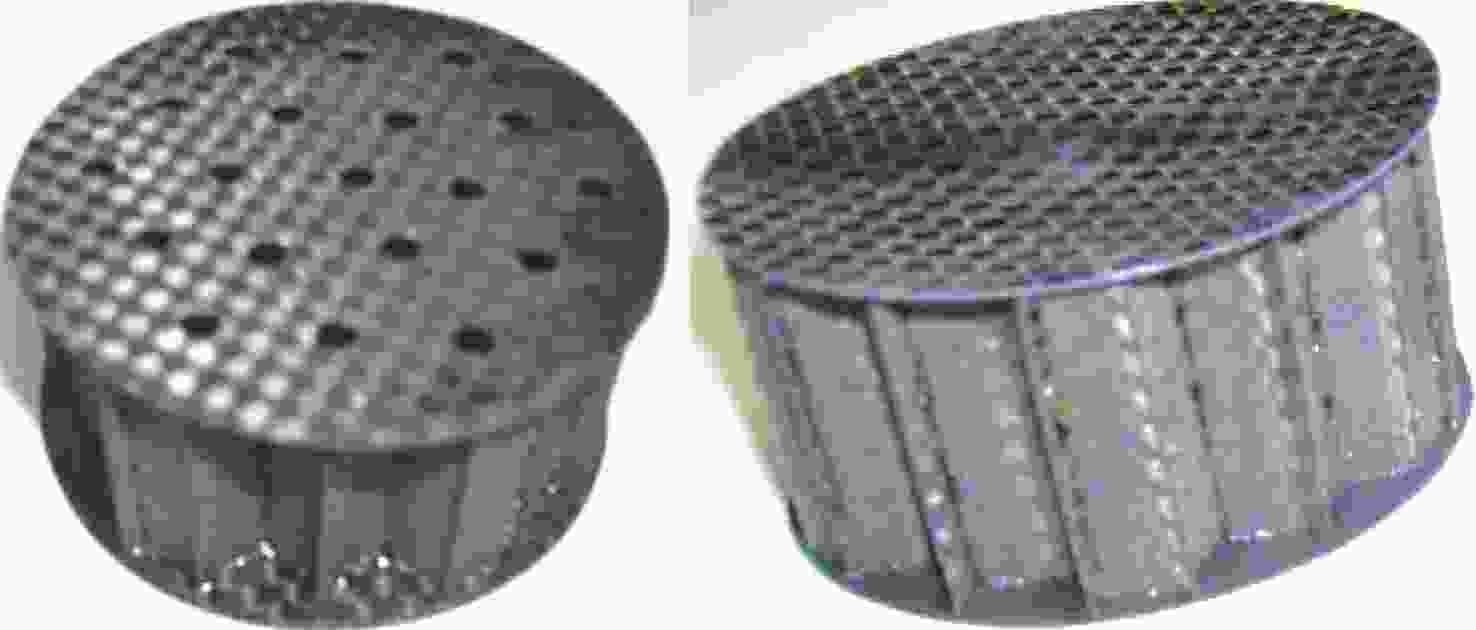

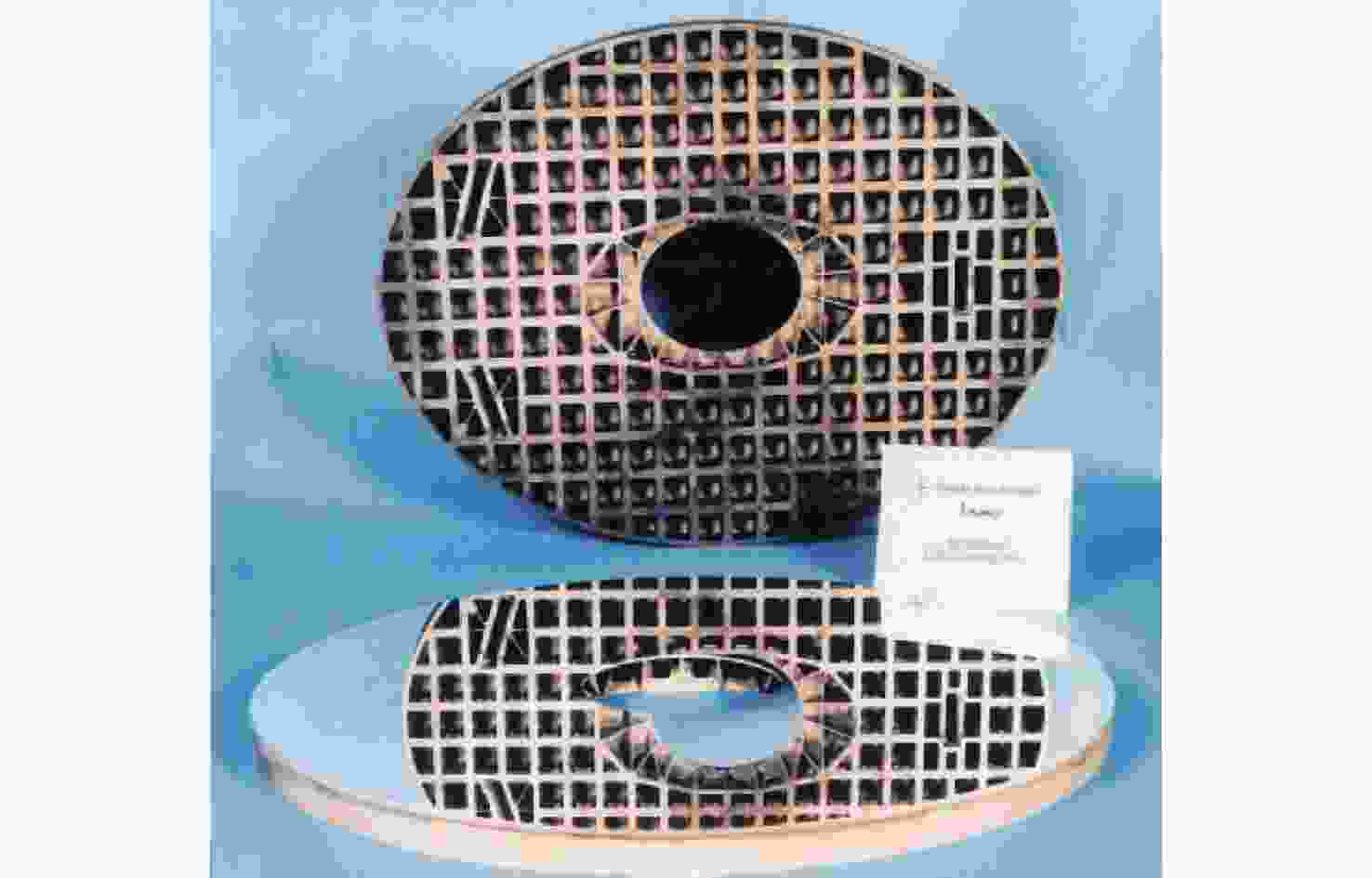

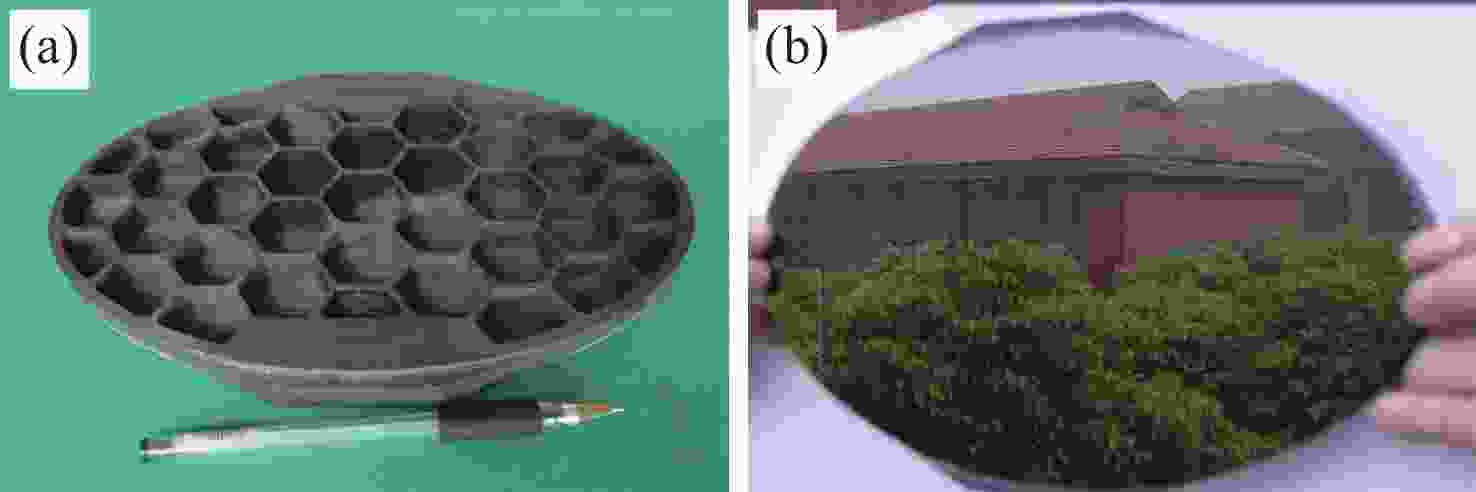

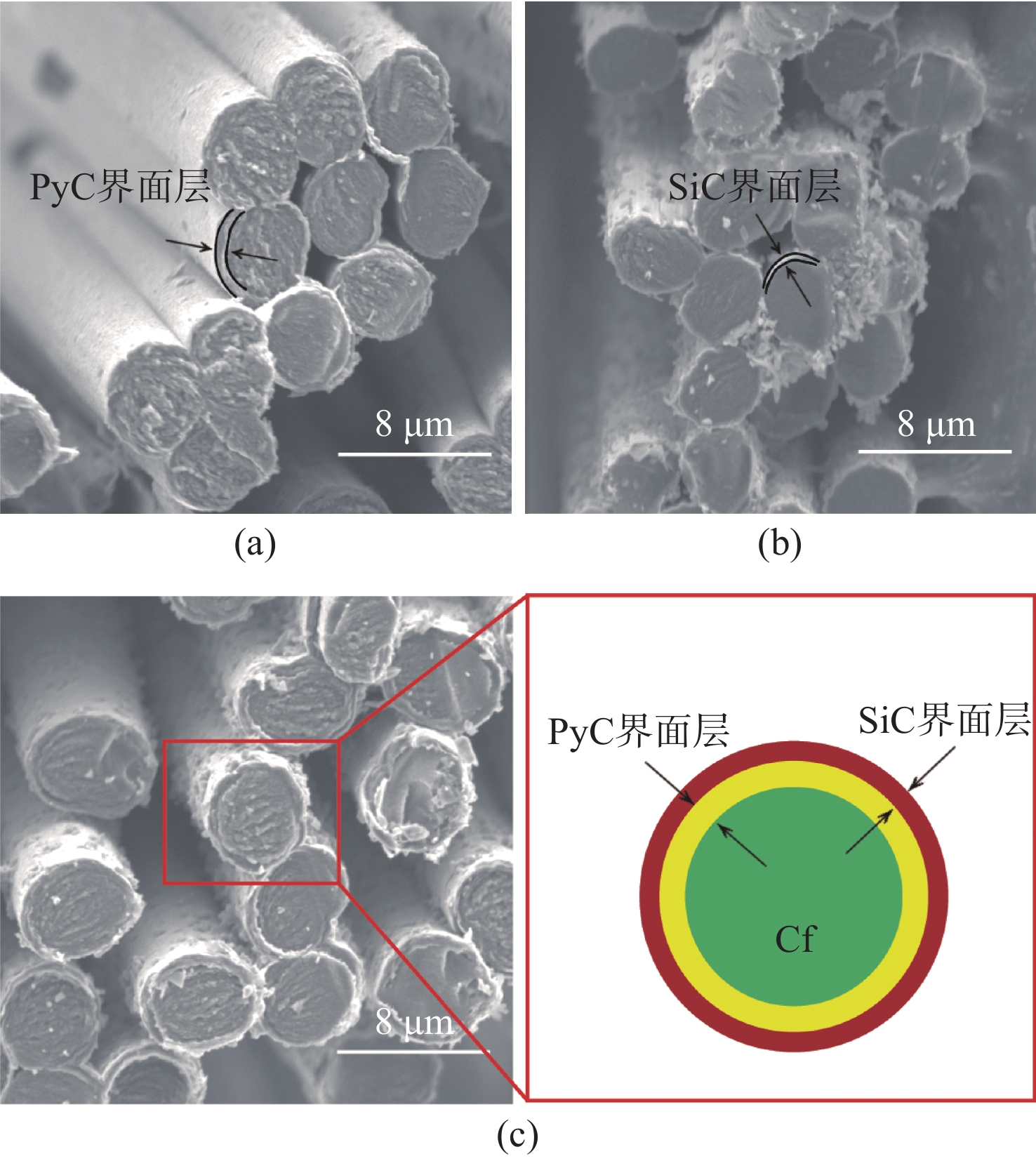

下载: