The normal alignment method for freeform surfaces based on multiple laser sensor assembly

-

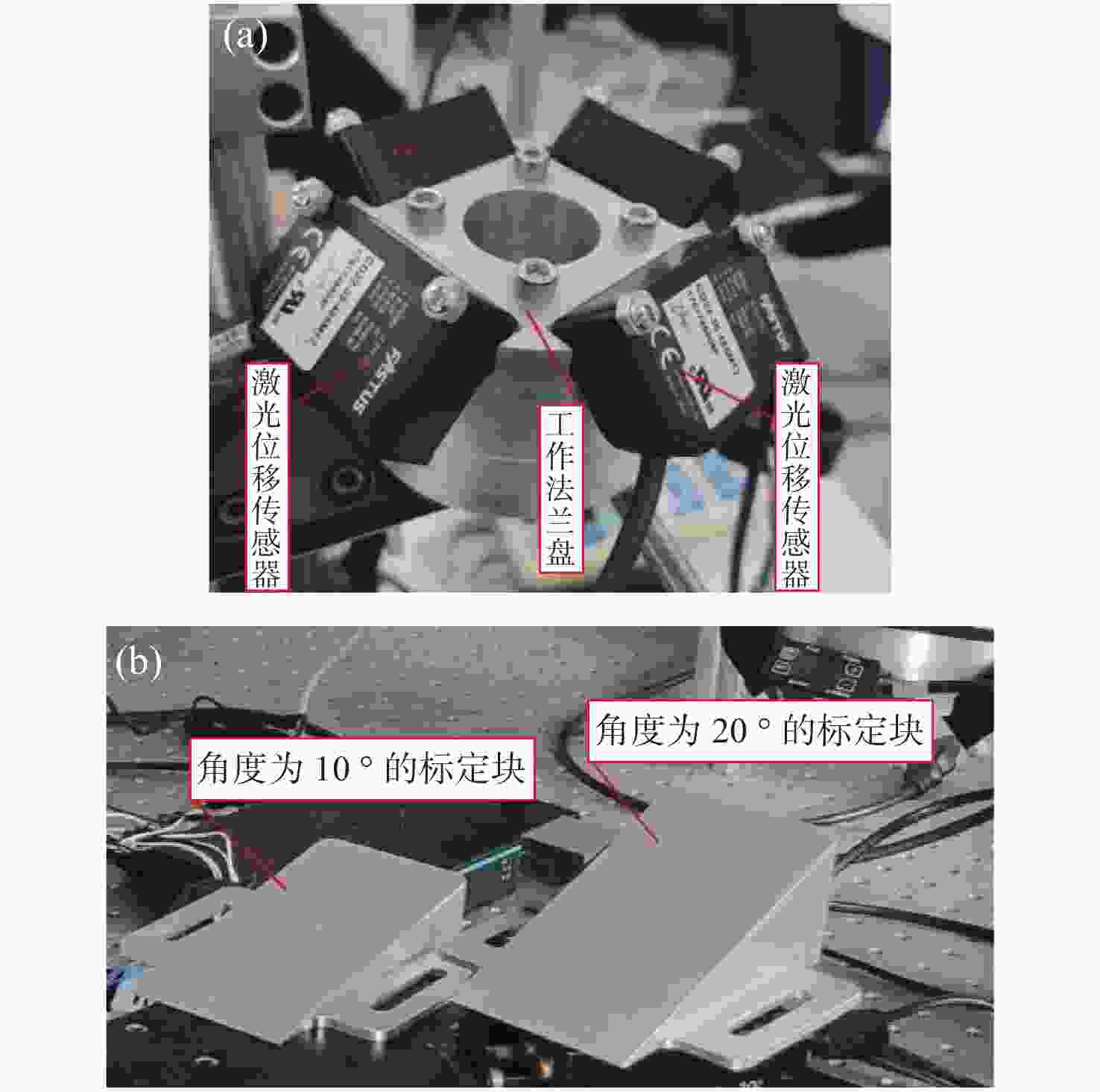

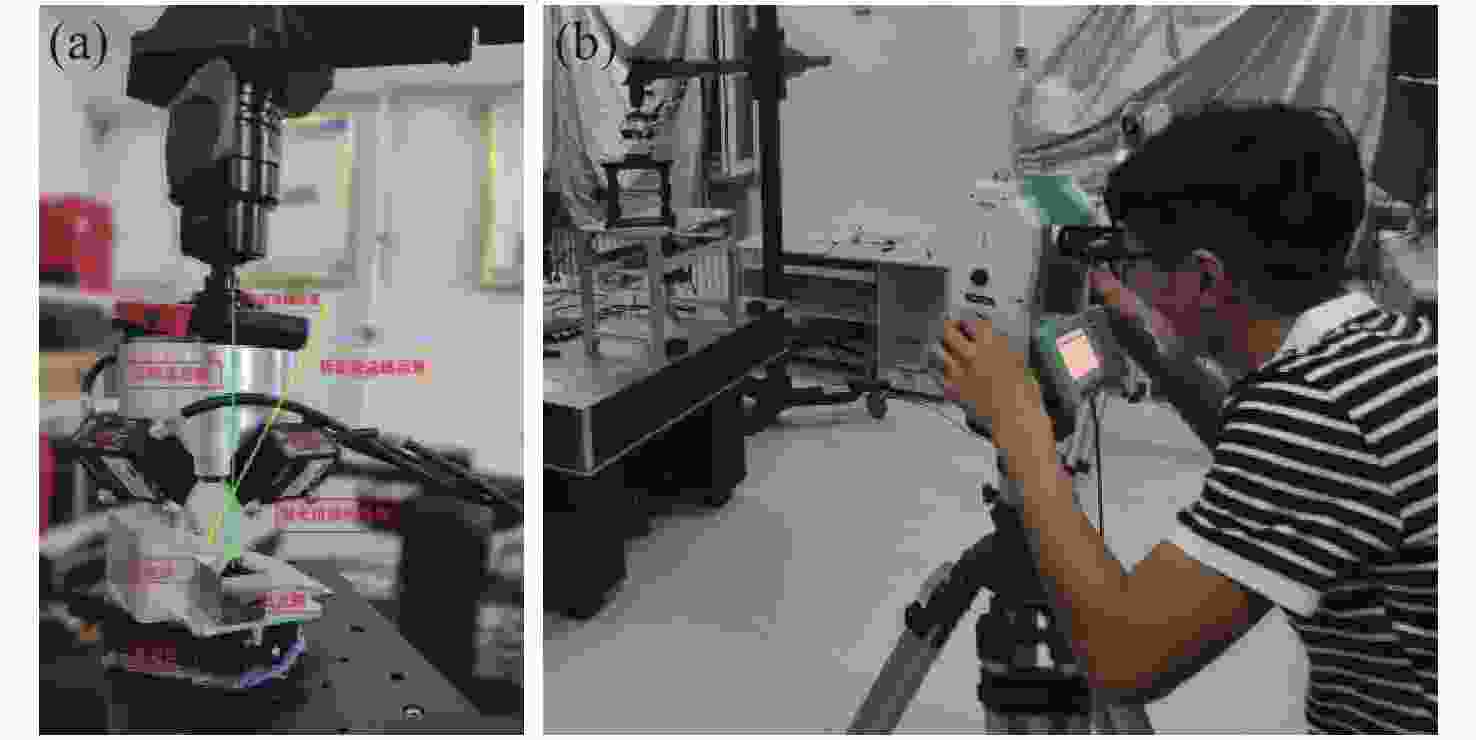

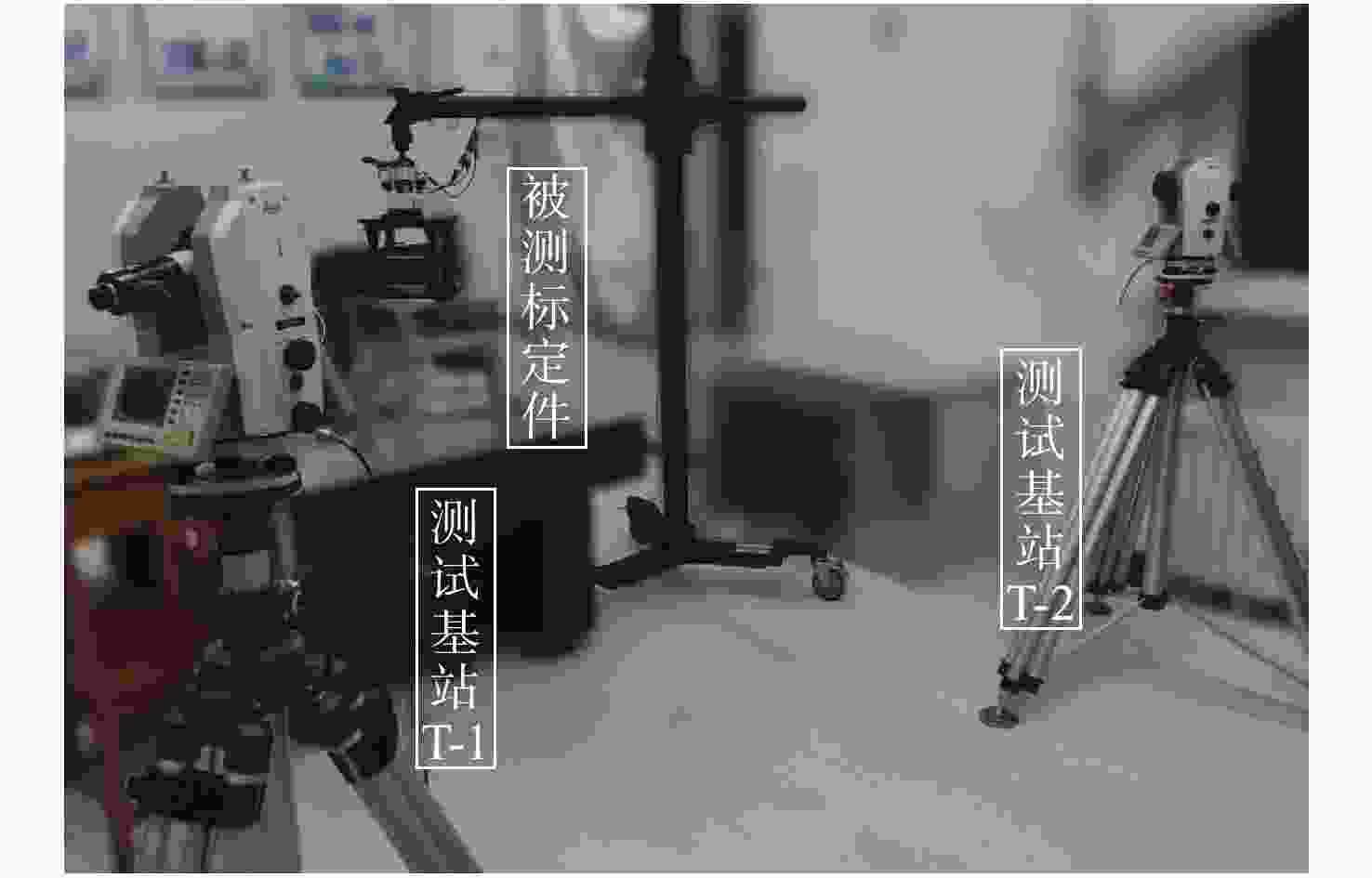

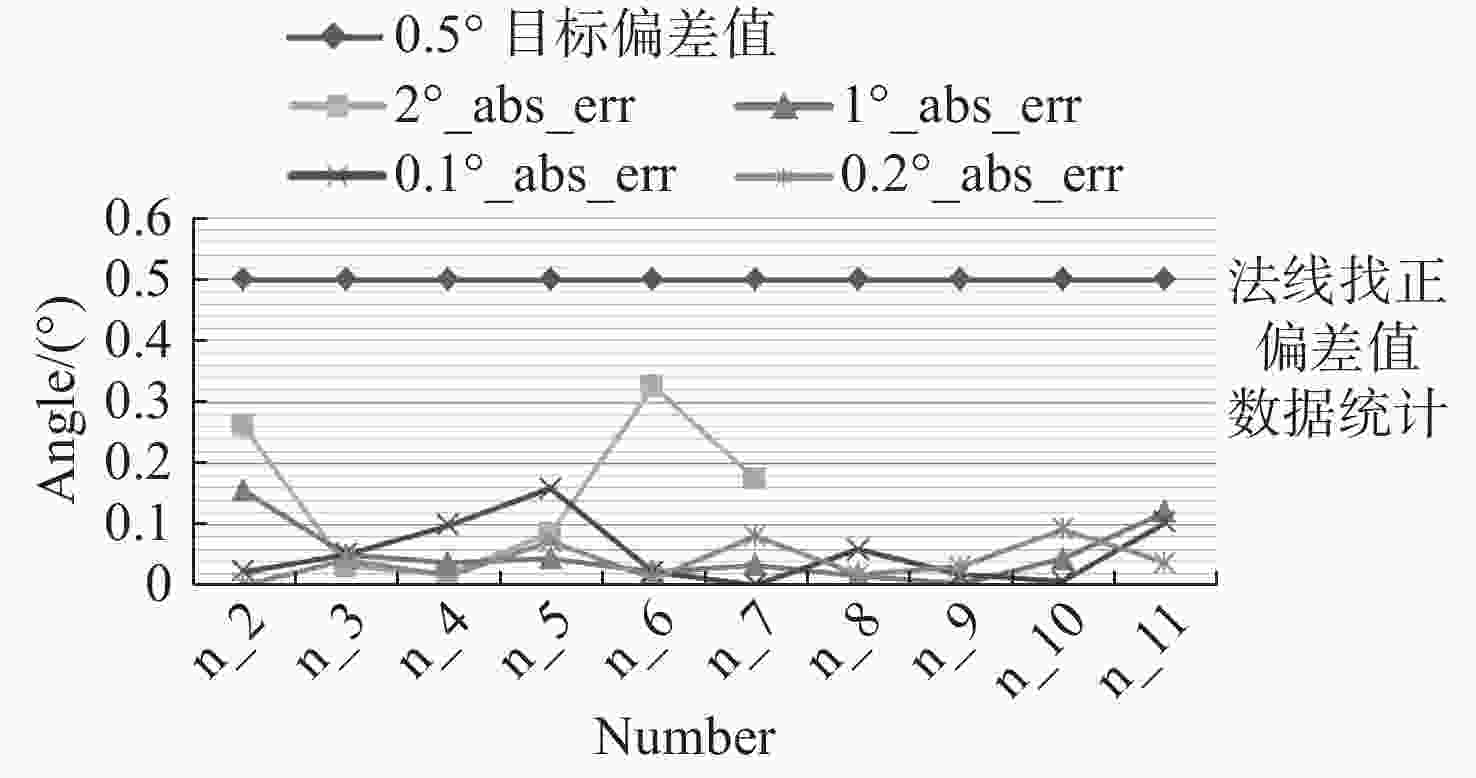

摘要: 在国产化、技术自主化的大型飞机项目上,对孔位精度的标准正逐步升高,钻头的垂直度又是这一标准中最受关注的条件。机器人自动钻铆系统工作时,所产生的装配误差、磕碰、偏移等状况,不仅降低了制造及检测的准确度,还影响了整个结构件的疲劳性能。针对这一问题,提出了基于多激光传感器装配的自适应自由曲面法线检测技术,搭建了以该方法进行姿态找正的数学模型,并研究了检测装置的标定方法及流程。同时,着重讨论了在自适应方法检测时,利用电子经纬仪等装置进行误差补偿的相关技术。该方法的验证实验结果显示,多组实验数据均达到了法向精度<±0.5°的关键技术指标要求,找正后的法线平均偏差值为0.0667°。该方法能有效补偿在制孔工作中所产生的相关误差,进一步提高机器人的定位精度及法线方向检测精度。Abstract: In large aircraft product automation, the accuracy requirements for hole position detection are gradually increasing, and the vertical accuracy of a drill is the most important evaluation condition for this standard. When drilling and riveting are performed by automatic robotic systems, assembly error, bumps, offsets and other adverse conditions can reduce the accuracy of manufacturing and detection, and in turn the fatigue performance of the entire structure. To solve this problem, we proposed a technique for detecting a freeform surface’s normal-direction based on the adaptive alignment method using multiple laser sensor assemblies, built a mathematical model for posture alignment, and studied the calibration method and process required by the detection device. Additionally, we investigated techniques for error compensation using an electronic theodolite and other devices when the adaptive method is used for detection. In our verification experiments, multiple sets of results demonstrated that the key technical indicators were as follows: normal accuracy < ±0.5°, average deviation after correction is 0.0667°. This method can effectively compensate for the errors affecting hole making in automated manufacturing, and further improve the positioning accuracy and normal-direction detection accuracy of a robot.

-

表 1 转动角度为1°/次时法线找正实验验证数据

Table 1. Verification data of normal-direction alignment with rotation angle of 1°/time

实验编号 传感器实时测量值/(mm) 计算的法线

变化量/(°)经纬仪测量的法线

变化量/(°)误差标定结果

/(°)h1 h2 h3 h4 n1_1 41.64 31.17 40.05 27.17 \ \ \ n1_2 41.81 30.97 40.10 26.80 0.5305 0.6863 0.1558 n1_3 42.20 38.99 40.38 26.59 0.7295 0.7809 0.0514 n1_4 42.60 31.04 40.73 26.48 0.7602 0.7987 0.0386 n1_5 43.03 31.09 41.03 26.28 0.7813 0.8269 0.0456 n1_6 43.01 31.09 40.99 26.30 0.7869 0.8113 0.0244 n1_7 43.45 31.15 41.32 26.16 0.8573 0.8222 0.0351 n1_8 44.05 31.40 41.67 26.05 0.7708 0.7889 0.0181 n1_9 44.45 31.51 42.06 25.94 0.7819 0.7772 0.0047 n1_10 44.96 31.70 42.41 25.90 0.9539 0.9091 0.0449 n1_11 45.63 32.06 42.88 25.94 0.8128 0.6916 0.1212 表 2 验证实验后所统计的法线偏差值(abs_err)数据

Table 2. Statistical data of normal deviation value (abs_err) in validated experiments

实验编号 2°_abs_err 1°_abs_err 0.1°_abs_err 0.2°_abs_err n_2 0.2594 0.1558 0.0241 0.0025 n_3 0.0314 0.0514 0.0522 0.0433 n_4 0.0222 0.0386 0.0995 0.0175 n_5 0.0858 0.0456 0.1592 0.0723 n_6 0.3257 0.0244 0.0229 0.0136 n_7 0.1747 0.0351 0.0026 0.0810 n_8 / 0.0181 0.0599 0.0191 n_9 / 0.0047 0.0191 0.0315 n_10 / 0.0449 0.0079 0.0937 n_11 / 0.1212 0.1041 0.0379 -

[1] 喻龙, 章易镰, 王宇晗, 等. 飞机自动钻铆技术研究现状及其关键技术[J]. 航空制造技术,2017(9):16-25.YU L, ZHANG Y L, WANG Y H, et al. Research status of aircraft automatic drilling and riveting system and its key technology[J]. Aeronautical Manufacturing Technology, 2017(9): 16-25. (in Chinese) [2] 陈文亮, 王慧, 王珉, 等. 具有冗余自由度的混联自动钻铆机运动学分析[J]. 华南理工大学学报(自然科学版),2019,47(10):51-59.CHEN W L, WANG H, WANG M, et al. Kinematic analysis of hybrid automatic drilling and riveting machine with redundant degree of freedom[J]. Journal of South China University of Technology (Natural Science Edition) , 2019, 47(10): 51-59. (in Chinese) [3] SONG T, XI F F, GUO SH, et al. A comparison study of algorithms for surface normal determination based on point cloud data[J]. Precision Engineering, 2015, 39: 47-55. doi: 10.1016/j.precisioneng.2014.07.005 [4] LEI CH Y, BI Y B, LI J X, et al. Slug rivet assembly modeling and effects of procedure parameters on the quality of riveted lap joints[J]. Advances in Mechanical Engineering, 2018, 10(9): 1-12. [5] 陈允全. 自动钻铆机托架变形分析及处理方法研究[D]. 西安: 西北工业大学, 2007.CHEN Y Q. Research on the analysis of bracket deformation and its handling method[D]. Xi’an: Northwestern Polytechnical University, 2007. (in Chinese) [6] 董一巍, 卜昆, 陈允全, 等. 基于VC的自动钻铆机铆接数据库系统的开发[J]. 科学技术与工程,2007,7(16):4088-4093. doi: 10.3969/j.issn.1671-1815.2007.16.027DONG Y W, BU K, CHEN Y Q, et al. Development of automatic rivet gun’s riveting database system based on VC6.0[J]. Science Technology and Engineering, 2007, 7(16): 4088-4093. (in Chinese) doi: 10.3969/j.issn.1671-1815.2007.16.027 [7] 胡小平, 许瑛, 郑文峰, 等. 飞机自动装配机器人设计及仿真[J]. 制造业信息化,2009(1):69-70.HU X P, XU Y, ZHENG W F, et al. Design and dynamic analysis of automatic aircraft assembly robot[J]. Mechanical Engineer, 2009(1): 69-70. (in Chinese) [8] 李菡. 基于双机器人协同的自动钻铆终端器及其自动供钉装置的设计与研究[D]. 杭州: 浙江大学, 2010.LI H. Study on dual-robot-based drilling & riveting end-effector and automated rivet feeding apparatus[D]. Hangzhou: Zhejiang University, 2010. (in Chinese) [9] 张杨, 高明辉, 周万勇, 等. 自动钻铆系统中工业机器人协同控制技术研究[J]. 航空制造技术,2013(20):87-90, 94. doi: 10.3969/j.issn.1671-833X.2013.20.016ZHANG Y, GAO M H, ZHOU W Y, et al. Research on industrial robot cooperative control technology for automatic drilling and riveting system[J]. Aeronautical Manufacturing Technology, 2013(20): 87-90, 94. (in Chinese) doi: 10.3969/j.issn.1671-833X.2013.20.016 [10] 凌扬洋, 李西宁, 李卫平, 等. 适应自动钻铆的壁板预装配柔性定位装置设计[J]. 机械科学与技术,2014,33(3):465-468.LING Y Y, LI X N, LI W P, et al. Designing flexible positioning device for aircraft’s pre-assembled panel to accommodate automatic drilling and riveting[J]. Mechanical Science and Technology for Aerospace Engineering, 2014, 33(3): 465-468. (in Chinese) [11] 公茂震, 袁培江, 王田苗, 等. 航空制孔机器人末端垂直度智能调节方法[J]. 北京航空航天大学学报,2012,38(10):1400-1404.GONG M Z, YUAN P J, WANG T M, et al. Intelligent verticality-adjustment method of end-effector in aeronautical drilling robot[J]. Journal of Beijing University of Aeronautics and Astronautics, 2012, 38(10): 1400-1404. (in Chinese) [12] 战强, 陈祥臻. 机器人钻铆系统研究与应用现状[J]. 航空制造技术,2018,61(4):24-30.ZHAN Q, CHEN X ZH. Research status of robot drilling and riveting system and its applications[J]. Aeronautical Manufacturing Technology, 2018, 61(4): 24-30. (in Chinese) [13] 杜宝瑞, 冯子明, 姚艳彬, 等. 用于飞机部件自动制孔的机器人制孔系统[J]. 航空制造技术,2010(2):47-50. doi: 10.3969/j.issn.1671-833X.2010.02.007DU B R, FENG Z M, YAO Y B, et al. Robot drilling system for automatic drilling of aircraft[J]. Aeronautical Manufacturing Technology, 2010(2): 47-50. (in Chinese) doi: 10.3969/j.issn.1671-833X.2010.02.007 [14] JAYAWEERA N, WEBB P. Adaptive robotic assembly of compliant aero-structure components[J]. Robotics and Computer-Integrated Manufacturing, 2007, 23(2): 180-194. doi: 10.1016/j.rcim.2006.04.002 [15] XI F F, YU L, TU X W. Framework on robotic percussive riveting for aircraft assembly automation[J]. Advances in Manufacturing, 2013, 1(2): 112-122. doi: 10.1007/s40436-013-0014-5 [16] FROMMKNECHT A, KUEHNLE J, EFFENBERGER I, et al. Multi-sensor measurement system for robotic drilling[J]. Robotics and Computer-Integrated Manufacturing, 2017, 47: 4-10. doi: 10.1016/j.rcim.2017.01.002 [17] EGUTI C C A, TRABASSO L G, VILLANI E, et al. Development of a robotic end-effector of drilling and fasteners inserter for aircraft structures[C]. Proceedings of SAE 2012 Aerospace Manufacturing and Automated Fastening Conference & Exhibition, SAE, 2012: 1858. [18] 李震宇, 田威, 廖文和. 用于复材自动钻铆末端执行器的设计及应用[J]. 机电一体化,2016,22(5):54-58, 63.LI ZH Y, TIAN W, LIAO W H. Design and application of automatic drilling and riveting end executor using in composite materials processing[J]. Mechatronics, 2016, 22(5): 54-58, 63. (in Chinese) [19] 秦远, 曹国华, 丁红昌, 等. 白车身抗凹性能仿真实验研究[J]. 新型工业化,2019,9(3):32-36, 49.QIN Y, CAO G H, DING H CH, et al. Experimental study on anti-concave performance of white body[J]. The Journal of New Industrialization, 2019, 9(3): 32-36, 49. (in Chinese) [20] 吴朋. 轻型自主移动机器人制孔系统任务规划与自适应控制技术[D]. 南京: 南京航空航天大学, 2017.WU P. Task planning and adaptive control technology for lightweight autonomous mobile robot drilling system[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017. (in Chinese) [21] 周卫雪. 面向飞机装配的机器人运动轨迹和姿态离线规划与在线调整方法研究[D]. 南京: 南京航空航天大学, 2012.ZHOU W X. Research on robotic route and posture off-line planning and on-line calibrating method for aircraft assembly[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012. (in Chinese) [22] 孟繁擘. 基于视觉的立方镜瞄准技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.MENG F B. Research on reflector collimation technology based on robot vision[D]. Harbin: Harbin Institute of Technology, 2015. (in Chinese) [23] VLIEG R. Robotic trailing edge flap drilling system[C]. Proceedings of Aerospace Technology Conference and Exposition, SAE, 2009: 3244. [24] 王珉, 陈文亮, 郝鹏飞, 等. 飞机数字化自动钻铆系统及其关键技术[J]. 航空制造技术,2013(1-2):80-83.WANG M, CHEN W L, HAO P F, et al. Aircraft automatic drilling and riveting system and its key technology[J]. Aeronautical Manufacturing Technology, 2013(1-2): 80-83. (in Chinese) -

下载:

下载: