Laser-assisted water jet machining of high quality micro-trap structures on stainless steel surfaces

doi: 10.37188/CO.EN-2024-0004

-

摘要:

金属表面二次电子发射的抑制对于提高粒子加速器的稳定性、发射度及寿命具有十分重要的作用,已成为新一代加速器面临的最为关键的问题。本文采用激光辅助水射流技术在粒子加速器组成的重要材料316L不锈钢表面开展了高质量微陷阱结构的加工研究。系统分析了激光重复频率、脉冲宽度、平均功率、射流压力、重复次数、水射流偏置距离、焦平面位置、槽间偏置距离和加工速度对316L不锈钢表面形貌、槽深、槽宽和“井”字陷阱结构形貌的影响规律。研究结果表明:微槽深度随激光功率增加而增大,随射流压力增加而减小,随加工速度增加而减小,受重复次数影响较小;槽宽随激光功率增加而增大,随加工速度增加而减小,随重复次数增加而增大。通过参数优化,可以加工得到尺寸规整且表面质量较高的“井”字陷阱结构。本研究测试了“井”字结构的二次电子发射系数,较加工前最大降低了0.5,有效抑制了二次电子发射。本研究结果对于构建材料表面微陷阱结构具有非常重要的应用参考,激光辅助水射流加工技术有望应用于金属表面二次电子抑制加工。

Abstract:Secondary electron emission (SEE) has emerged as a critical issue in next-generation accelerators. Mitigating SEE on metal surfaces is crucial for enhancing the stability and emittance of particle accelerators while extending their lifespan. This paper explores the application of laser-assisted water jet technology in constructing high-quality micro-trap structures on 316L stainless steel, a key material in accelerator manufacturing. The study systematically analyzes the impact of various parameters such as laser repetition frequency, pulse duration, average power, water jet pressure, repeat times, nozzle offset, focal position, offset distance between grooves, and processing speed on the surface morphology of stainless steel. The findings reveal that micro-groove depth increases with higher laser power but decreases with increasing water jet pressure and processing speed. Interestingly, repeat times have minimal effect on depth. On the other hand, micro-groove width increases with higher laser power and repeat times but decreases with processing speed. By optimizing these parameters, the researchers achieved high-quality pound sign-shaped trap structure with consistent dimensions. We tested the secondary electron emission coefficient of the "well" structure. The coefficient is reduced by 0.5 at most compared to before processing, effectively suppressing secondary electron emission. These results offer indispensable insights for the fabrication of micro-trap structures on material surfaces. Laser-assisted water jet technology demonstrates considerable potential in mitigating SEE on metal surfaces.

-

Figure 7. Surface morphology of micro-grooves with different parameters at nozzle offset distance with repetition frequency are 0, 100 kHz, respectively. (a) Surface morphology of micro-grooves when the scanning speed is 1 mm/s, the waterjet pressure is 4 M, the laser power is 30~40 W, respectively. (b) Surface morphology of micro-grooves when the scanning speed is 2 mm/s, the waterjet pressure is 16 M, the laser power is 50~60 W, respectively. (c) Surface morphology of micro-grooves when the scanning speed is 2 mm/s, the waterjet pressure is 6~8 M, the laser power is 70 W, respectively. (d) Surface morphology of micro-grooves when the scanning speed is 1 mm/s, the waterjet pressure is 8~9 M, the laser power is 90 W, respectively

Figure 10. The surface morphology of the pround sign shaped structure. (a) Surface morphology of the pound sign shaped structure when the repetition frequency is 100 kHz, the scanning speed is 1 mm/s and the laser power is 70 W, respectively. (b) Surface morphology of the “well” when the repetition frequency is 490 kHz, the scanning speed is 1 mm/s, the waterjet pressure is 10 M and the laser power is 40 W, respectively. (c) Surface morphology of the “well” when the repetition frequency is 315 kHz, the scanning speed is 1 mm/s, the waterjet pressure is 12 M, and the laser power is 40 W, respectively

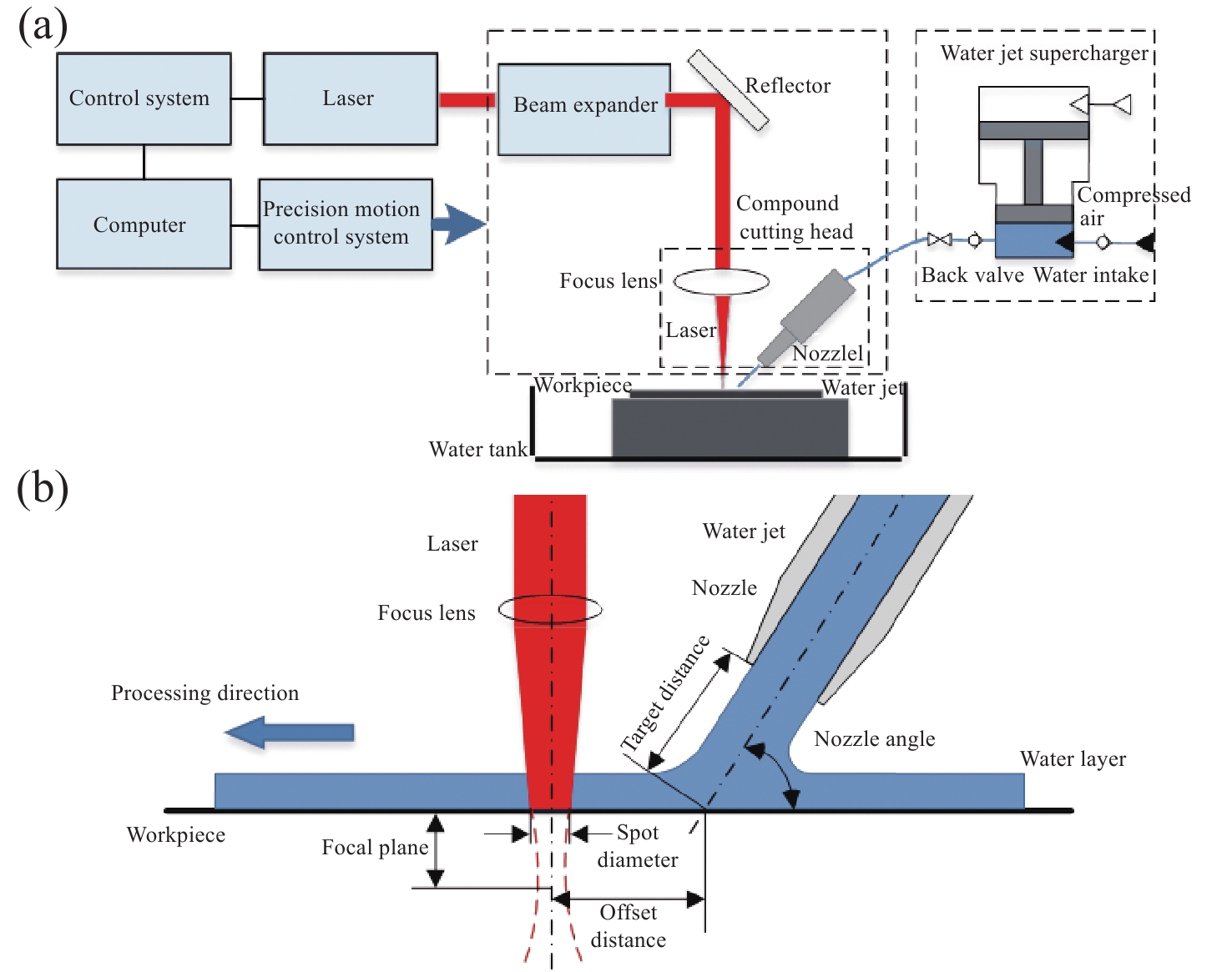

Table 1. Parameters of 316L stainless steel processed by laser-assisted water jet technology

Processing parameters numerical value Repetition rate(kHz) 100,315,490 Focal plane(mm) 0,0.035 Target distance(mm) 0.6 Nozzle angle 45° Offset distance(mm) 0,0.5 Number of repetitions 1,2,3,4,5 Row spacing(μm) 70,80,90,100 Jet pressure(MPa) 4,6,8,10,12,14,16,18,20 Laser power(W) 10,20,30,40,50,60,70,80,90,100 Processing speed(mm/s) 1,2,3 -

[1] LI SH J, YU X, DANG X Q, et al. A novel double dielectric barrier discharge reactor with high field emission and secondary electron emission for toluene abatement[J]. Plasma Science and Technology, 2022, 24(1): 015504. doi: 10.1088/2058-6272/ac17e4 [2] PINTO P C, CALATRONI S, NEUPERT H, et al. Carbon coatings with low secondary electron yield[J]. Vacuum, 2013, 98: 29-36. doi: 10.1016/j.vacuum.2013.03.001 [3] AYZATSKY M I, DOVBNYA A N, ZAKUTIN V V, et al. The electron accelerator based on the secondary emission electron source for material-surface treatment[C]. Proceedings of RuPAC 2006, 2022. [4] WANG D, CAI Y H, HE Y N, et al. Electron emission properties of silver oxide and its impact on the secondary emission yield of air-exposed silver[J]. Results in Physics, 2022, 33: 105231. doi: 10.1016/j.rinp.2022.105231 [5] CUI X, GILARDONI S, GIOVANNOZZI M, et al. Numerical simulations of electron-cloud build up in circular accelerators in the presence of multimode-distribution beams[J]. Europhysics Letters, 2020, 129(2): 24003. doi: 10.1209/0295-5075/129/24003 [6] DONG Y, DONG ZH W, YANG W Y, et al. Monte Carlo simulation of multipactor discharge suppressing on grooved dielectric surface[J]. High Power Laser and Particle Beams, 2013, 25(2): 399-406. (in Chinese). doi: 10.3788/HPLPB20132502.0399 [7] BOZEMAN S P, BAUMANN P K, WARD B L, et al. Electron emission measurements from CVD diamond surfaces[J]. Diamond and Related Materials, 1996, 5(6-8): 802-806. doi: 10.1016/0925-9635(95)00417-3 [8] TOKUDA N, UMEZAWA H, SAITO T, et al. Surface roughening of diamond (001) films during homoepitaxial growth in heavy boron doping[J]. Diamond and Related Materials, 2007, 16(4-7): 767-770. doi: 10.1016/j.diamond.2006.12.024 [9] LIU Y, LIANG CH H, MEI C X, et al. Influence of coating on the secondary electron emission coefficient of metal surface[J]. Journal of Xianyang Normal College, 2018, 33(6): 50-52. (in Chinese). doi: 10.3969/j.issn.1672-2914.2018.06.012 [10] WEI Q, WU SH L, FU M L, et al. Attenuation mechanism of secondary electron effect of MgO film under electron bombardment[J]. Journal of Xi'an Jiaotong University, 2017, 51(11): 125-129. (in Chinese). doi: 10.7652/xjtuxb201711017 [11] VALIZADEH R, MALYSHEV O B, WANG S H, et al. Low secondary electron yield engineered surface for electron cloud mitigation[J]. Applied Physics Letters, 2014, 105(23): 231605. doi: 10.1063/1.4902993 [12] WANG Y G, ZHANG W L, WANG S H, et al. Influence of primary electron incident angle and electron bombardment on the secondary electron yield of laser-treated copper[J]. Journal of Vacuum Science & Technology B, 2021, 39(3): 034201. [13] CHENG B, DING Y, LI Y, et al. Coaxial helical gas assisted laser water jet machining of SiC/SiC ceramic matrix composites[J]. Journal of Materials Processing Technology, 2021, 293: 117067. doi: 10.1016/j.jmatprotec.2021.117067 [14] NARGUNDKAR A, GULIA V, KHAN A. Nanoabrasives-assisted abrasive water jet machining of bio-composites— an experimental and optimization approach[J]. Journal of Advanced Manufacturing Systems, 2023, 22(4): 799-822. doi: 10.1142/S0219686723500373 [15] TANGWARODOMNUKUN V, WANG J, HUANG C Z, et al. An investigation of hybrid laser–waterjet ablation of silicon substrates[J]. International Journal of Machine Tools and Manufacture, 2012, 56: 39-49. doi: 10.1016/j.ijmachtools.2012.01.002 [16] 惠庆志. 激光辅助水射流加工4H-SiC材料的工艺与去除机理研究[D]. 济南: 山东大学, 2018: 29-31, 49-52.HUI Q ZH. Study on process and material removal mechanism for micromachining 4H-SiC by laser assisted waterjet[D]. Jinan: Shandong University, 2018: 29-31, 49-52. (in Chinese). [17] FENG SH CH, HUANG CH ZH, WANG J, et al. Material removal of single crystal 4H-SiC wafers in hybrid laser-waterjet micromachining process[J]. Materials Science in Semiconductor Processing, 2018, 82: 112-125. doi: 10.1016/j.mssp.2018.03.035 [18] 张晨旭. 激光辅助水射流切割氧化铝陶瓷的可加工性研究[D]. 济南: 山东大学, 2016: 35-41, 47-48.ZHANG CH X. Study on the machinability of alumina ceramics by laser assisted waterjet[D]. Jinan: Shandong University, 2016: 35-41, 47-48. (in Chinese). [19] ZHAI SH J, FENG Q G, YANG H, et al. Liquid-phase assisted laser preparation of 304 stainless steel surface texture and tribological properties evaluated[J]. Industrial Lubrication and Tribology, 2022, 74(6): 654-662. doi: 10.1108/ILT-12-2021-0499 [20] ELSHORBAGY M H, SÁNCHEZ-BREA L M, BUENCUERPO J, et al. Polarization conversion using customized subwavelength laser-induced periodic surface structures on stainless steel[J]. Photonics Research, 2022, 10(9): 2024-2031. doi: 10.1364/PRJ.454451 [21] LI Y CH, ZHANG X B, MAO ZH, et al. Study on size and morphology control of 316L stainless steel microgrooves processed by ultraviolet nanosecond laser[J]. Applied Laser, 2019, 39(6): 994-1001. (in Chinese). [22] DUAN R H, LIU ZH Q, WANG X, et al. Effect of abrasive water jet - plasma nitriding duplex treatment on friction property of 316 stainless steel surface[J]. Surface Technology, 2020, 49(7): 149-158. (in Chinese). [23] LI Q, SUN G F, LU Y, et al. Experimental research on fiber laser underwater cutting of 1 mm thick 304 stainless steel[J]. Chinese Journal of Lasers, 2016, 43(6): 57-66. (in Chinese). -

下载:

下载: