SERS characteristics analysis of composite Ag/SiO2 sinusoidal grating

doi: 10.3788/CO.20191201.0059

-

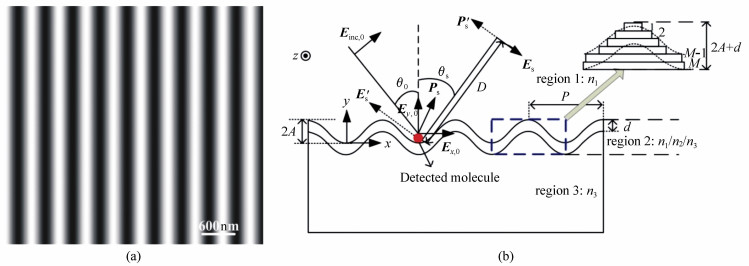

摘要: 当前微流控表面增强拉曼散射(SERS)检测领域常用的贵金属纳米颗粒溶胶单位体积内热点区域数量有限且热点区域范围较小,而贵金属纳米三维阵列结构加工时间长,成本高昂并存在"记忆效应"。本文提出了集成到微流道的复合Ag/SiO2正弦光栅SERS基底结构,可以利用激光干涉光刻技术进行制备,无需预制掩膜版,可实现大面积、低成本SERS基底简易快速制备。利用严格耦合波分析方法(RCWA)建立了复合正弦光栅表面电场增强数学评估模型,推导了表面等离子体共振(SPP)耦合吸收率数学模型,分析了入射光、复合正弦光栅结构与外界环境介电常数的优化匹配关系,得到了入射光785 nm条件下的最佳复合正弦光栅结构。通过制备加工并实验验证了复合正弦光栅的SERS性能,SERS增强因子(EF)能够达到104。Abstract: In current microfluidic-SERS(surface-enhanced Raman scattering) detection fields, noble metal nanoparticle sols are commonly used but a limited number of hot spots exist per unit of its volume and the areas of these hot spots are very small. Another common SERS substrate, the noble metal nano-three-dimensional array, has a time-consuming fabrication process and is costly to manufacture, while also succumbing to the memory effect. In this paper, a composite Ag/SiO2 sinusoidal grating SERS substrate structure integrated into a microchannel is proposed, which can be fabricated by laser interference photolithography and has no need for prefabricated photomasks. Large area and low-cost SERS substrates can be created simply and rapidly by using this method. The mathematical evaluation model of electric field enhancement near the composite sinusoidal grating surface is established with rigorous coupled wave analysis(RCWA). The mathematical model of the surface plasmon polaritons(SPP) coupling absorption is derived. The optimization matching relation of incident light, the composite sinusoidal grating structure and the dielectric constant of the external environment are analyzed. The optimal composite sinusoidal grating structure was obtained when the wavelength of incident light was 785 nm. The composite sinusoidal grating was prepared and its SERS performance was verified experimentally, proving that the SERS enhancement factor(EF) can reach 104.

-

Key words:

- RCWA /

- composite sinusoidal grating /

- SERS /

- microfluidics

-

表 1 Theoretical EF values of the three gratings

Table 1. Theoretical EF values of the three gratings

Grating category EF Sine Water/Ag/SiO2 grating 7.4×104 Sine Water/Au/SiO2 grating 2.0×104 Rectangular Water/Ag/SiO2 grating 4.4×104 -

[1] LI M, CUSHING S K, LIANG H, et al.. Plasmonic nanorice antenna on triangle nanoarray for surface-enhanced Raman scatteri detection of hepatitis B virus DNA[J]. Anal. Chem., 2013, 85:2072-2078. doi: 10.1021/ac303387a [2] ARON H, PER O A, MICHAEL S S, et al.. Explosive and chemical threat detection by surface-enhanced Raman scattering:a review[J]. Anal. Chim. Acta., 2015, 893(233853):1-13. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dcf75f3477374bdd6fd0ac08ea682e18 [3] LI D W, ZHAI W L, LI Y T, et al.. Recent progress in surface enhanced Raman spectroscopy for the detection of environmental pollutants[J]. Microchim Acta, 2014, 181:23-43. doi: 10.1007/s00604-013-1115-3 [4] 史云胜, 刘秉琦, 杨兴.超润滑石墨表面的光谱表征研究[J].光学 精密工程, 2017, 25(6):1513-1518. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201706015SHI Y SH, LIU B Q, YANG X. Research on spectral characterization of superlubricity graphite surface[J]. Opt. Precision Eng., 2017, 25(6):1513-1518.(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201706015 [5] 刘燕德, 靳昙昙, 王海阳.基于拉曼光谱的三组分食用调和油快速定量检测[J].光学 精密工程, 2015, 23(9):2490-2496. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201509009LIU Y D, JIN T T, WANG H Y. Rapid quantitative determination of components in ternary blended edible oil based on Raman spectroscopy[J]. Opt. Precision Eng., 2015, 23(9):2490-2496.(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201509009 [6] BRIAN D P, SEUNG J L, MARTIN M, et al.. Free-surface microfluidics/surface enhanced Raman spectroscopy for real-time trace vapor detection of explosives[J]. Anal. Chem., 2012, 84:9700-9705. doi: 10.1021/ac302497y [7] YUAN J, AKRAM H, GEORGE C, et al.. Ordered gold nanoparticle arrays on glass and their characterization[J]. J. Colloid Interface Sci, 2013, 410:1-10. doi: 10.1016/j.jcis.2013.07.070 [8] ZHAO Y Q, ZHANG Y L, HUANG J A, et al.. Plasmonic nanopillar array embedded microfluidic chips:an in situ SERS monitoring platform[J]. J. Mater. Chem. A, 2015, 3:6408-6413. doi: 10.1039/C4TA07076C [9] XU T T, HUANG J A, HE L F, et al.. Ordered silicon nanocones arrays for label-free DNA quantitative analysis by surface enhanced Raman spectroscopy[J]. Appl. Phys. Lett., 2011, 99(153116):1-4. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=3c38934fefd4d1ca96ab74609f836bbe [10] PAUL R M, LAURA F. Understanding nanoparticle assembly:a simulation approach to SERS-active dimers[J]. J. Colloid Interface Sci., 2012, 369:134-143. doi: 10.1016/j.jcis.2011.11.052 [11] LEEM J, KANG H W, KO H S, et al.. Controllable Ag nanostructure patterning in a microfluidic channel for real-time SERS systems[J]. Nanoscale, 2014, 6:2895-2901. doi: 10.1039/c3nr04829b [12] TONG L M, XU H X, MIKAEL K. Nanogaps for SERS applications[J]. Mrs Bulletin, 2014, 39:163-168. doi: 10.1557/mrs.2014.2 [13] BHAVYA S, CARDINAL M F, SAMUEL L K, et al.. High-performance SERS substrates:advances and challenges[J]. MRS Bull., 2013, 38:615-624. doi: 10.1557/mrs.2013.161 [14] LIN X M, CUI Y, XU Y H, et al.. Surface-enhanced Raman spectroscopy:substrate related issues[J]. Anal Bioanal Chem., 2009, 394:1729-1745. doi: 10.1007/s00216-009-2761-5 -

下载:

下载: