-

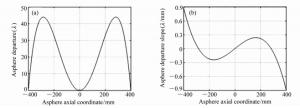

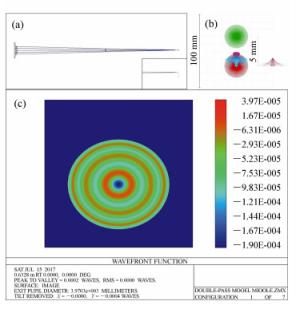

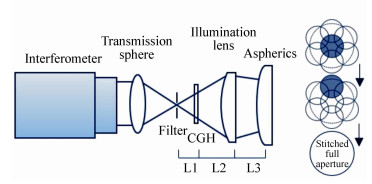

摘要: 本文提出了一种改良的检测方法用于实现对超大口径凸非球面反射镜进行高精度的面形检测。该方法利用计算机再现全息和照明透镜混合补偿,实现对超大口径凸非球面的高精度检测。首先,对该方法的基本原理进行了分析和研究;然后,以一块口径为800 mm的超大口径凸非球面为例,进行了子孔径规划和检测光路中相关光学元件的设计;最后,以中心子孔径为例,系统分析了该检测装置的敏感度。仿真实验结果表明:计算全息补偿器的设计残差均方根值小于0.001 3 nm,该检测系统的综合检测精度可以优于6 nm RMS。结果表明该检测系统满足超大口径凸非球面反射镜高精度面形检测的要求。Abstract: In order to achieve high-accuracy measurements of ultra-large aperture convex aspheric mirrors, a modified surface testing method is proposed. This method combines a Computer-Generated Hologram(CGH) and an illumination lens to create highly accurate and efficient measurements for ultra-large convex aspheres. Firstly, the basic principles of the method are researched. Then, a simulation is performed for an aspheric mirror with an aperture of 800 mm and a subaperture plan and CGH are designed. Finally, the sensitivity of this configuration is analyzed. Simulation results indicate that the residual aberrations are less than 0.001 3 nm RMS and that the accuracy of this testing method can be greater than 6 nm RMS. This method can satisfy the requirements for high accuracy surface testing in ultra-large convex aspheric surfaces.

-

Key words:

- surface testing /

- aspherics /

- aberration compensation /

- diffractive optics

-

表 1 凸非球面的结构参数

Table 1. Structure parameters of the convex aspheric surface

顶点曲率半径/mm 非球面系数 口径/mm 材料 3 000 -0.937 800 SiC 表 2 中心子孔径检测系统及相关光学元件的参数

Table 2. Central subaperture detection system and parameters of related optical components

CGH主要参数 数值/mm 检测系统主要参数 数值/mm 离轴偏移量 20.077 L1 3 800 CGH厚度 10 L2 4 600 CGH主区域口径 168 L3 40 CGH最小线宽 39.7 μm (0, 2) 1.2 照明透镜参数 数值/mm (2, 0) 1.2 干扰级次与光轴的距离 (1, 0) 4.0 中心厚度 40 (1, 2) 4.0 曲率半径 1150 (-1, 3) 5.8 口径 420 (3, -1) 5.0 材料 BK7 表 3 外围子孔径检测系统及相关光学元件的参数

Table 3. Outer subaperture test system and parameters of related optical components

CGH主要参数 数值/mm 检测系统主要参数 数值/mm 离轴偏移量 27.44 L1 4 000 CGH厚度 10 L2 4 200 CGH主区域口径 194 L3 40 CGH最小线宽 36.5μm (0, 2) 1.2 照明透镜参数 数值/mm (2, 0) 1.2 干扰级次与光轴的距离 (1, 0) 13.5 中心厚度 40 (1, 2) 14.0 曲率半径 1 150 (-1, 3) 6.0 口径 420 (3, -1) 5.5 材料 BK7 表 4 中心子孔径检测系统中光学元件加工、调整的敏感度分析

Table 4. Processing and adjustment sensitivity analysis of optical components in central sub-aperture detection system

参数 允差 波前误差(λ) L1 10 μm 0.000 15 L2 10 μm 0.002 7 L3 10μm 0.001 5 CGH倾斜量 X 1 μm 0.000 4 Y 1 μm 0.000 4 CGH偏心量 X 1 μm 0.001 9 Y 1 μm 0.001 9 透镜倾斜量 X 1 μm 0.007 3 Y 1 μm 0.007 3 透镜偏心量 X 1 μm 0.003 Y 1 μm 0.003 透镜中心厚度 10 μm 0.000 9 透镜凸面曲率半径 5 μm 0.009 透镜面形误差 1/100λ 0.004 透镜材料折射率均匀性 2×10-6 0.003 CGH综合误差 - 0.007 其余误差 - 0.001 综合 - 0.017 表 5 拼接检测系统的最优检测精度

Table 5. Optimal detection accuracy of the testing system

参数 允差 波前误差(λ) L3 10 μm 0.001 5 透镜中心厚度 10 μm 0.000 9 透镜材料折射率均匀性 2×10-6 0.003 CGH综合误差 - 0.007 拼接误差 - 0.004 综合 - 0.008 8 -

[1] YABE A. Optimal selection of aspheric surfaces in optical design[J]. Optics Express, 2005, 13(18):7233-7242. doi: 10.1364/OPEX.13.007233 [2] LI J F, XUAN B, SUN Y. Hindle test of SiC convex conic hyperboloid[J]. Proceedings of SPIE, 2012, 8417:841716. doi: 10.1117/12.971203 [3] OH C J, LOWMAN A E, DUBIN M, et al.. Modern technologies of fabrication and testing of large convex secondary mirrors[J]. Proceedings of SPIE, 2016, 9912:99120R. [4] ABDULKADYROV M A, BELOUSOV S P, PRIDNYA V V, et al.. Optimizing the shaping technology and test methods for convex aspheric surfaces of large optical items[J]. Journal of Optical Technology, 2013, 80(4):219-225. doi: 10.1364/JOT.80.000219 [5] WYANT J C. Computerized interferometric surface measurements[Invited] [J]. Applied Optics, 2013, 52(1):1-8. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7c19f62c1daa4197cbc2599203f65e0d [6] KIM Y S, KIM B Y, LEE Y W. Design of null lenses for testing of elliptical surfaces[J]. Applied Optics, 2001, 40(19):3215-3219. doi: 10.1364/AO.40.003215 [7] KIM T, BURGE J H, LEE Y, et al.. Null test for a highly paraboloidal mirror[J]. Applied Optics, 2004, 43(18):3614-3618. doi: 10.1364/AO.43.003614 [8] LI F ZH, ZHAO J L, LI R G, et al.. Design and Fabrication of CGH for aspheric surface testing and its experimental comparison with null lens[J]. Proceedings of SPIE, 2010, 7656:765643. doi: 10.1117/12.867627 [9] WANG Z W, GUO P J, CHEN X, et al.. Design of null lens system for f/0.5 hyperboloid mirror[J]. Proceedings of SPIE, 2016, 9683:96831A. doi: 10.1117/12.2241623 [10] MURPHY P, DEVRIES G, FLEIG J, et al.. Measurement of high-departure aspheric surfaces using subaperture stitching with variable null optics[J]. Proceedings of SPIE, 2009, 7426:74260P. doi: 10.1117/12.826544 [11] XUE SH, CHEN SH Y, SHI F, et al.. Sub-aperture stitching test of a cylindrical mirror with large aperture[J]. Proceedings of SPIE, 2016, 9684:96840C. [12] 王孝坤, 王丽辉, 张学军, 等.子孔径拼接干涉法检测非球面[J].光学 精密工程, 2007, 15(2):192-198. doi: 10.3321/j.issn:1004-924X.2007.02.008WANG X K, WANG L H, ZHANG X J, et al.. Testing asphere by subaperture stitching interferometric method[J]. Opt. Precision Eng., 2007, 15(2):192-198.(in Chinese) doi: 10.3321/j.issn:1004-924X.2007.02.008 [13] BURGE J H, ANDERSON D S, MILSTER T D, et al.. Measurement of a convex secondary mirror using a holographic test plate[J]. Proceedings of SPIE, 1994, 2199:193-198. doi: 10.1117/12.176180 [14] ZHANG Y H, CHEN Q. Testing the large convex aspheric surfaces with aspheric test plate[J]. Proceedings of SPIE, 2014, 9280:928014. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC0214518561 [15] DUBIN M B, SU P, BURGE J H. Fizeau interferometer with spherical reference and CGH correction for measuring large convex aspheres[J]. Proceedings of SPIE, 2015, 7426:74260S. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC0210217542 [16] PENG J T, CHEN ZH, ZHANG X X, et al.. Optimal design of tilt carrier frequency computer-generated holograms to measure aspherics[J]. Applied Optics, 2015, 54(24):7433-7441. doi: 10.1364/AO.54.007433 [17] PENG J T, REN J Y, ZHANG X X, et al.. Analytical investigation of the parasitic diffraction orders of tilt carrier frequency computer-generated holograms[J]. Applied Optics, 2015, 54(13):4033-4041. doi: 10.1364/AO.54.004033 [18] 黎发志, 罗霄, 赵晶丽, 等.离轴非球面的计算全息图高精度检测技术[J].光学 精密工程, 2011, 19(4):709-716. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201104001LI F ZH, LUO X, ZHAO J L, et al.. Test of off-axis aspheric surfaces with CGH[J]. Opt. Precision Eng., 2011, 19(4):709-716.(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201104001 [19] 王孝坤, 郑立功, 张斌智, 等.子孔径拼接检测大口径非球面技术的研究[J].应用光学, 2009, 30(2):273-278. doi: 10.3969/j.issn.1002-2082.2009.02.021WANG X K, ZHENG L G, ZHANG B ZH, et al.. Testing of large aspheric surfaces by subaperture stitching interferometry[J]. Journal of Applied Optics, 2009, 30(2):273-278.(in Chinese) doi: 10.3969/j.issn.1002-2082.2009.02.021 -

下载:

下载: