-

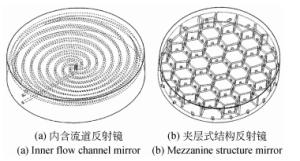

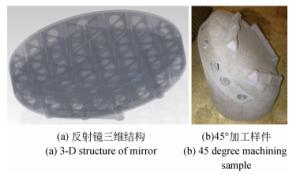

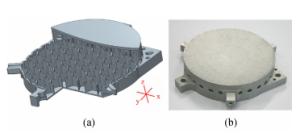

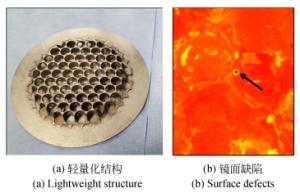

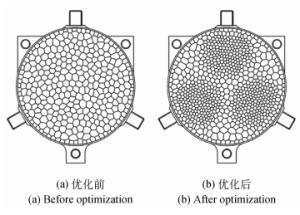

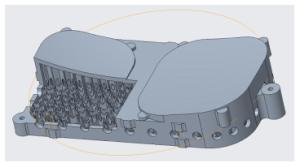

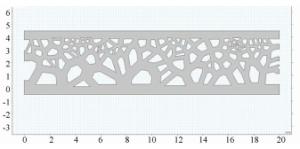

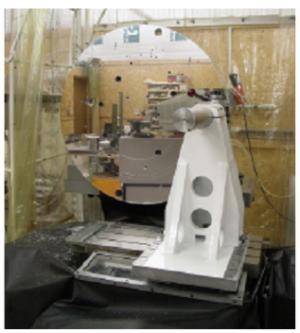

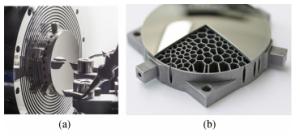

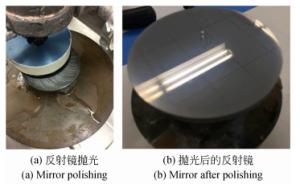

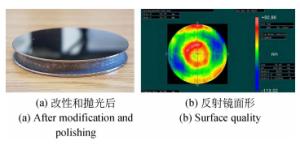

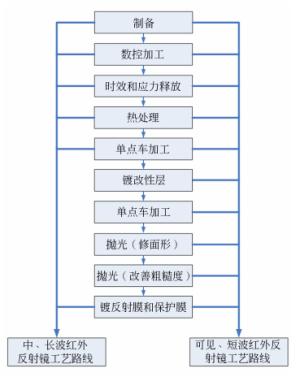

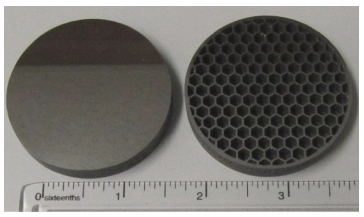

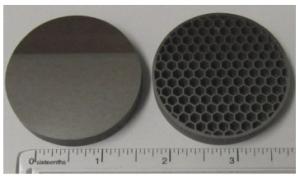

摘要: 随着光学测量与遥感领域的不断发展,折反式光学系统对重量、体积和环境适应性等需求不断提高。基于增材制造技术的金属反射镜以其便于实现优化设计、快速制造和加工工艺性好等优点,逐渐获得国内外学者的关注与研究。与传统金属反射镜相比,增材制造金属反射镜可以提高反射镜的结构刚度,同时可实现更高程度的轻量化。增材制造反射镜可以满足光学系统对环境适应性和快速性的需求。本文首先讨论了金属反射镜的评价指标;其次,综述了国内外在基于增材制造技术制备金属反射镜领域的发展现状和技术参数,从增材制造金属反射镜的基体设计与制备和基体的后处理2个方面展开论述;然后,通过分析,总结了增材制造金属反射镜的技术路线和关键技术;最后,对增材制造反射镜的应用前景提出了展望。Abstract: With the rapid development of optical measurement and remote sensing, the demand for weight, volume and environmental adaptability in folding optical systems are continuously increasing. Metal mirrors based on additive manufacturing technology are gradually gaining the attention and research of scholars at home and abroad for their easy to realize optimum design, rapid manufacturing process and high processing performance. Compared to conventional metal mirrors, additively manufacturing metal mirrors strengthen the stiffness of the mirror and achieve a higher degree of weight reduction simultaneously. Furthermore, additively manufacturing mirrors can meet the environmental adaptability and rapidity requirements of optical systems. This paper first discusses the evaluation indicators of metal mirrors. Second, the development status and technical parameters of metal mirrors based on additive manufacturing technology are reviewed. The design and preparation of metal mirrors for additive metal fabrication and the post-treatment of substrates are discussed. Then, through analysis, the preparation process and key technologies of additively manufacturing metal mirrors are summarized. Finally, prospects for additively manufacturing mirror applications are presented.

-

表 1 增材制造金属反射镜技术参数

Table 1. Technical parameters of additively manufacturing metal mirror

研制公司 基底材料 口径 改性镀层材料 面形精度 粗糙度 定向散射 美国康宁公司[9, 23] AlSi7Mg0.3 20 mm Al/Al-alloy 30.3 nm (PV)

1.5 nm(RMS)1~4 nm 消除 英国天文科技中心[19, 21, 26-27] AlSi10Mg 40 mm NiP 16 nm(RMS) 1.9 nm / 德国弗劳恩霍夫激光技术研究所[13] AlSi12 200 mm NiP 12.5 nm(RMS) 0.4 nm 未消除 德国弗劳恩霍夫激光技术研究所[16] AlSi40 200 mm NiP 7.3 nm(RMS) 0.4 nm / 坎普望远镜光学有限公司[28] AlSi40 210 mm NiP 300 nm(PV)

74 nm(RMS)/ / 通用电力公司[12] AlSi10Mg 150 mm / 43.2 nm(RMS) 7 nm / 亚利桑那大学[15, 24] AlSi10Mg 220 mm / 255 nm (PV) 22 nm / 表 2 铝合金反射镜改性参数

Table 2. Modification parameters of aluminum alloy mirror

-

[1] MATSON L E, CHEN M Y, ATAD-ETTEDGUI E, et al.Enabling materials and processes for large aerospace mirrors[J]. Proceedings of SPIE, 2008, 7018: 70180L. doi: 10.1117/12.790525 [2] 康健, 宣斌, 谢京江.表面改性碳化硅基底反射镜加工技术现状[J].中国光学, 2013, 6(6): 824-833. http://www.chineseoptics.net.cn/CN/abstract/abstract9042.shtmlKANG J, XUAN F, XIE J J. Manufacture technology status of surface modified silicon carbide mirrors[J]. Chinese Optics, 2013, 6(6): 824-833. (in Chinese) http://www.chineseoptics.net.cn/CN/abstract/abstract9042.shtml [3] 王富国, 乔兵, 张景旭. 2m SiC反射镜柔性被动支撑系统[J].光学 精密工程, 2017, 25(10): 2591-2598. http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201710008WANG F G, QIAO B, ZHANG J X. Flexible passive support system for 2m SiC reflective mirror[J]. Opt. Precision Eng., 2017, 25(10): 2591-2598. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201710008 [4] MILLER J L, FRIEDMAN E. Photonics Rules of Thumb[M]. New York: McGraw Hill, 2003. [5] 严丛林.反射镜支撑结构设计与分析[D].成都: 中国科学院研究生院(光电技术研究所), 2013.YAN C L. Design and analysis for the support structure of large aperture rectangular mirror[D]. Chengdu: Institute of Optics and Electronics, Chinese Academy of Sciences, 2013. (in Chinese) [6] HUANG Y T, FAN B, WAN Y J, et al.Improving the performance of single point diamond turning surface with ion beam figuring[J]. Optik, 2018, 172: 540-544. doi: 10.1016/j.ijleo.2018.07.039 [7] AIKENS D M, WOLFE C R, LAWSON J K. Use of power spectral density (PSD) functions in specifying optics for the National Ignition Facility[J]. Proceedings of SPIE, 1995, 2576: 281-292. doi: 10.1117/12.215604 [8] 谷抇昕.美媒展望塑造未来的18项航空航天技术[J].现代军事, 2016(12): 80-87. http://www.cnki.com.cn/Article/CJFDTotal-XDJI201612034.htmGU H X. The 18 media aerospace technologies that the US media look forward to shape the future[J]. Arms & Technology, 2016(12): 80-87. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-XDJI201612034.htm [9] WOODARD K S, MYRICK B H. Progress on high-performance rapid prototype aluminum mirrors[J]. Proceedings of SPIE, 2017, 10181: 101810T. http://cn.bing.com/academic/profile?id=e39bdec9f73668c3bafeb76f92f38ed7&encoded=0&v=paper_preview&mkt=zh-cn [10] WOODARD K S, COMSTOCK L E, WAMBOLDT L, et al.Optimum selection of high performance mirror substrates for diamond finishing[J]. Proceedings of SPIE, 2016, 9822: 98220C. http://cn.bing.com/academic/profile?id=10421dc55fcff27bb164b6a74ff56e2e&encoded=0&v=paper_preview&mkt=zh-cn [11] SCHEIDING S, GEBHARDT A, DAMM C, et al.Method for manufacturing a mirror comprising at least one cavity and optical mirror: USA, 20140247512[P]. 2014-09-04. [12] SWEENEY M, ACREMAN M, VETTESE T, et al.Application and testing of additive manufacturing for mirrors and precision structures[J]. Proceedings of SPIE, 2015, 9574: 957406. doi: 10.1117/12.2189202 [13] HILPERT E, HARTUNG J, RISSE S, et al.Precision manufacturing of a lightweight mirror body made by selective laser melting[J]. Precision Engineering, 2018, 53: 310-317. doi: 10.1016/j.precisioneng.2018.04.013 [14] BRUNELLE M, FERRALLI I, WHITSITT R, et al.Current use and potential of additive manufacturing for optical applications[J]. Proceedings of SPIE, 2017, 10448: 104480P. https://www.researchgate.net/publication/320435771_Current_use_and_potential_of_additive_manufacturing_for_optical_applications [15] MICI J, ROTHENBERG B, BRISSON E, et al.Optomechanical performance of 3D-printed mirrors with embedded cooling channels and substructures[J]. Proceedings of SPIE, 2015, 9573: 957306. doi: 10.1117/12.2188533 [16] HILPERT E, HARTUNG J, VON LUKOWICZ H, et al.Design, additive manufacturing, processing, and characterization of metal mirror made of aluminum silicon alloy for space applications[J]. Optical Engineering, 2019, 58(9): 092613. http://cn.bing.com/academic/profile?id=dc5a9ae9667c5d129b63370691638461&encoded=0&v=paper_preview&mkt=zh-cn [17] HARTUNG J, BEIER M, RISSE S. Novel applications based on freeform technologies[J]. Proceedings of SPIE, 2018, 10692: 106920K. http://cn.bing.com/academic/profile?id=9d05603193fdbc43e0a07f8ab6c38efb&encoded=0&v=paper_preview&mkt=zh-cn [18] HEIDLER N, HILPERT E, HARTUNG J, et al.Additive manufacturing of metal mirrors for TMA telescope[J]. Proceedings of SPIE, 2018, 10692: 106920C. http://cn.bing.com/academic/profile?id=3ab85a4f2ff00f97f9e59fc78e4986e2&encoded=0&v=paper_preview&mkt=zh-cn [19] ROULET M, ATKINS C, HUGOT E, et al.3D printing for astronomical mirrors[J]. Proceedings of SPIE, 2018, 10675: 1067504. http://cn.bing.com/academic/profile?id=416c88283bdb13bd34136daef6ed5ba8&encoded=0&v=paper_preview&mkt=zh-cn [20] STAMPFL J, HATZENBICHLER M. Additive Manufacturing Technologies[M]. LAPERRIÉRE L, REINHART G. The International Academy for Production Engineering. Berlin, Heidelberg: Springer, 2014: 20-27. [21] ATKINS C, FELDMAN C, BROOKS D, et al.Topological design of lightweight additively manufactured mirrors for space[J]. Proceedings of SPIE, 2018, 10706: 107060I. http://cn.bing.com/academic/profile?id=6446e0a09e136c8c7f728b9cc0e7e112&encoded=0&v=paper_preview&mkt=zh-cn [22] COMSTOCK Ⅱ L E, CRIFASI J C, ROY B P, et al.Mirror substrates with highly finishable corrosion-resistant coating: USA, 20160097885[P]. 2016-04-07. [23] National Aeronautics and Space Administration. Additive manufactured very light weight diamond turned aspheric mirror[R].Greenbelt, Maryland: SBIR/STTR, 2017. [24] HERZOG H, SEGAL J, SMITH J, et al.Optical fabrication of lightweighted 3D printed mirrors[J]. Proceedings of SPIE, 2015, 9573: 957308. doi: 10.1117/12.2188197 [25] LEUTERITZ G, LACHMAYER R. Additive manufacturing of reflective optics: evaluating finishing methods[J]. Proceedings of SPIE, 2018, 10523: 105230N. http://cn.bing.com/academic/profile?id=da130d753f75d35bc3b1e89e9ee155c6&encoded=0&v=paper_preview&mkt=zh-cn [26] ATKINS C, FELDMAN C, BROOKS D, et al.Additive manufactured X-ray optics for astronomy[J]. Proceedings of SPIE, 2017, 10399: 103991G. http://cn.bing.com/academic/profile?id=eb8eadcc24f8062436604af9e24e7d35&encoded=0&v=paper_preview&mkt=zh-cn [27] FELDMAN C, ATKINS C, BROOKS D, et al.Design and modeling of an additive manufactured thin shell for X-ray astronomy[J]. Proceedings of SPIE, 2017, 10399: 103991H. http://cn.bing.com/academic/profile?id=27d80bd4e329ecd165212eb810fb0977&encoded=0&v=paper_preview&mkt=zh-cn [28] EBERLE S, REUTLINGER A, CURZADD B, et al.Additive manufacturing of an AlSi40 mirror coated with electroless nickel for cryogenic space applications[J]. Proceedings of SPIE, 2019, 11180: 1118015. http://cn.bing.com/academic/profile?id=7d15af765536e3c9797933e0f51548fd&encoded=0&v=paper_preview&mkt=zh-cn [29] 唐鹏钧, 何晓磊, 杨斌, 等.激光选区熔化用AlSi10Mg粉末显微组织与性能[J].航空材料学报, 2018, 38(1): 47-53. http://d.old.wanfangdata.com.cn/Periodical/hkclxb201801006TANG P J, HE X L, YANG B, et al.Microstructure and properties of AlSi10Mg powder for selective laser melting[J]. Journal of Aeronautical Materials, 2018, 38(1): 47-53. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/hkclxb201801006 [30] 丁莹, 杨海欧, 白静, 等.激光立体成形AlSi10Mg合金的微观组织及力学性能[J].中国表面工程, 2018, 31(4): 46-54. http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&filename=BMGC201804006DING Y, YANG H O, BAI J, et al.Microstructure and mechanical property of AlSi10Mg alloy prepared by laser solid forming[J]. China Surface Engineering, 2018, 31(4): 46-54. (in Chinese) http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&filename=BMGC201804006 [31] 胡瑞.基于拓扑优化的空间反射镜与柔性支撑结构设计方法[D].大连: 大连理工大学, 2017.HU R. Topology optimization-based design method of space mirror and flexible support structure[D]. Dalian: Dalian University of Technology, 2017. (in Chinese) [32] 刘君欢.面向增材制造的拓扑优化结果精细化设计[D].大连: 大连理工大学, 2016.LIU J H. Refined design of topology optimization results for additive manufacturing[D]. Dalian: Dalian University of Technology, 2016. (in Chinese) [33] 叶虎勇, 陈桂林.地球同步轨道三轴稳定卫星的扫描镜设计及考虑[J].红外技术, 2003, 25(6): 1-5, 9. doi: 10.3969/j.issn.1001-8891.2003.06.001YE H Y, CHEN G L. Scanning mirror design considerations of 3-axis stability satellite[J]. Infrared Technology, 2003, 25(6): 1-5, 9. (in Chinese) doi: 10.3969/j.issn.1001-8891.2003.06.001 [34] 谢启明, 杨静, 徐放, 等.金属非球面反射镜的加工和检测技术[J].红外技术, 2015, 37(2): 119-123. http://d.old.wanfangdata.com.cn/Periodical/hwjs201502007XIE Q M, YANG J, XU F, et al.Manufacturing and test technology for metal aspherical reflector[J]. Infrared Technology, 2015, 37(2): 119-123. (in Chinese) http://d.old.wanfangdata.com.cn/Periodical/hwjs201502007 [35] SCHAEFER J P. High precision mirror, and a method of making it: USA, 20040165296[P]. 2004-08-26. [36] SCHAEFER J P. Advanced metal mirror processing for tactical ISR systems[J]. Proceedings of SPIE, 2013, 8713: 871306. doi: 10.1117/12.2015496 [37] HARRIS G G, MITCHELL D B, BROWN D J, et al.Method and apparatus for fabricating a precision optical surface: USA, 8398251[P]. 2013-03-19. [38] RISSE S, GEBHARDT A, PESCHEL T, et al.Substrate made of an aluminum-silicon alloy or crystalline silicon, metal mirror, method for the production thereof, and use thereof: USA, 20130057952[P]. 2013-03-07. [39] HOULLIER T, ROUSSELET N, SURREL Y, et al.Advanced optical freeform substrates fabricated by ceramic 3D printing and controlled by deflectometry[J]. Proceedings of SPIE, 2018, 10692: 106920P. http://cn.bing.com/academic/profile?id=49f1f275160b7c31dcf524410fb442a6&encoded=0&v=paper_preview&mkt=zh-cn [40] ROULET M, HUGOT E, ATKINS C, et al.Superpolished OAPs for WFIRST CGI[J]. Proceedings of SPIE, 2018, 10698: 106982Q. [41] HEINRICH A, BÖRRET R, MERKEL M, et al.Additive manufacturing of reflective and transmissive optics: potential and new solutions for optical systems[J]. Proceedings of SPIE, 2018, 10523: 1052302. http://cn.bing.com/academic/profile?id=849c7d71a65cb862b18f39e87873af3a&encoded=0&v=paper_preview&mkt=zh-cn -

下载:

下载: